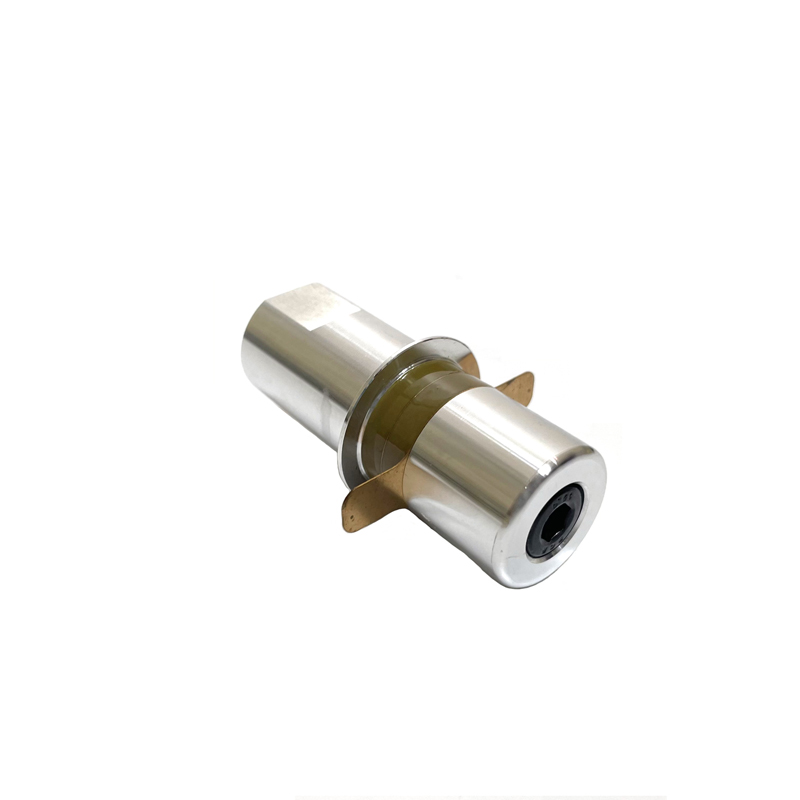

Ultrasonic Welding Transducer 100W 35KHZ Ultrasonic Earloop Welding Spot Welding Transducer

Due to the wide variety of transducers, this manual only publishes some transducer parameters. As the largest supplier of core components in China, our company has stock for the vast majority of types of transducers. Of course, products with special requirements can also be customized for customers. Due to differe…

Ultrasonic Welding Transducer 100W 35KHZ Ultrasonic Earloop Welding Spot Welding Transducer

Due to the wide variety of transducers, this manual only publishes some transducer parameters. As the largest supplier of core components in China, our company has stock for the vast majority of types of transducers. Of course, products with special requirements can also be customized for customers.

Due to different processing methods and requirements, the working mode of transducers can be roughly divided into continuous operation (lace machine, CD cover machine, zipper machine, metal welding machine, etc.) and pulse operation (such as plastic welding machine). Different working modes have different requirements for transducers. Generally speaking, continuous work has almost no pause time, but the working current is not very high. Pulse work is intermittent and has pauses, but the instantaneous current is very high. On average, the power of both states is high.

There are different regulations for the nominal power of machines with different purposes and purposes, in other words, the same transducer may have different nominal power when used on different machines. To avoid ambiguity, the customer should provide a detailed explanation of the structural type of the transducer, such as column type, inverted horn type, etc., as well as the diameter and number of piezoelectric ceramic chips.

Ultrasonic vibrator, also known as ultrasonic vibrator, refers to the overall structure of the transducer connected to the amplitude converter in the industry. The ultrasonic vibrator is a device that realizes the mutual conversion of electrical energy and mechanical energy (acoustic vibration) by the Piezoelectricity of piezoelectric ceramics, and amplifies through the front and rear irradiation cover blocks matched with acoustic impedance.

| Type | Full-length(mm) | Joint Bolt(mm) | Frequency(KHz) | Resonance Impedance(Ω) | Capacity(pF) | Input Power (W) |

| PU-UWT30500 P8 | 77 | M10×1.5 | 30 | 5 | 5500 | 500 |

| PU-UWT28200 P4 | 92.1 | M10×1 | 28 | 20 | 3000 | 200 |

| PU-UWT28100 P8 | 91 | M8×1 | 28 | 25 | 2200 | 100 |

| PU-UWT28250 P8 | 94 | 1/2-20 UNF | 28 | 20 | 4000 | 250 |

| PU-UWT35100 P8 | 71 | M8×1 | 35 | 25 | 2200 | 100 |

| PU-UWT38100 P8 | 66 | M8×1.25 | 38 | 40 | 1200 | 100 |

| PU-UWT38200 P4 | 65 | M8×1 | 38 | 14 | 3300 | 200 |

Ultrasonic Welding Transducer 100W 35KHZ Ultrasonic Earloop Welding Spot Welding Transducer

标签:Ultrasonic Earloop Welding Spot Welding Transducer, Ultrasonic Welding Transducer 100W 35KHZ

Send Inquiry

28KHz Ultrasonic Oscillator System With Transducer and Booster Applied for Spot Welding Machinary

28KHz Ultrasonic Oscillator System With Transducer and Booster Applied for Spot Welding Machinary 30kHz 800W High Quality Ultrasonic Plastic Welding Transducer Piezoelectric Ceramic Transducer

30kHz 800W High Quality Ultrasonic Plastic Welding Transducer Piezoelectric Ceramic Transducer 28KHZ 1000W Industrial Ultrasonic Spot Welding Machine Transducer Cutting Skin Scrubber Cavitation Pressure Transducer

28KHZ 1000W Industrial Ultrasonic Spot Welding Machine Transducer Cutting Skin Scrubber Cavitation Pressure Transducer 28KHZ 35KHZ Customized Ultrasonic Spot Welder Machine Transducer and Horn Ultrasonic Transducer Spot Welders

28KHZ 35KHZ Customized Ultrasonic Spot Welder Machine Transducer and Horn Ultrasonic Transducer Spot Welders 35KHZ 500W Ultrasonic Spot Welder Transducer For Handheld Ultrasonic Point Welding Machine

35KHZ 500W Ultrasonic Spot Welder Transducer For Handheld Ultrasonic Point Welding Machine Ultrasonic Welding Transducer 100W 35KHZ Ultrasonic Earloop Welding Spot Welding Transducer

Ultrasonic Welding Transducer 100W 35KHZ Ultrasonic Earloop Welding Spot Welding Transducer 28KHz Ultrasonic Oscillator System With Transducer and Booster Applied for Spot Welding Machinary

28KHz Ultrasonic Oscillator System With Transducer and Booster Applied for Spot Welding Machinary Plastic Ultrasonic Spot Welding Machine Transducer For Vibrator Ultrasonic Welding System

Plastic Ultrasonic Spot Welding Machine Transducer For Vibrator Ultrasonic Welding System 28KHZ 300W Ultrasonic Spot Welder Transducer For Portable Ultrasonic Plastic Welding Machine

28KHZ 300W Ultrasonic Spot Welder Transducer For Portable Ultrasonic Plastic Welding Machine 35KHZ 300W Ultrasonic Welder Transducers 25mm 35k Welding 300 Watt Ultrasonic Transducer 35khz For Mask Machine

35KHZ 300W Ultrasonic Welder Transducers 25mm 35k Welding 300 Watt Ultrasonic Transducer 35khz For Mask Machine 28KHZ 500W Ultrasonic Welding Machine Spot Welder Plastic Transducer Customize Converter replacement

28KHZ 500W Ultrasonic Welding Machine Spot Welder Plastic Transducer Customize Converter replacement 35KHZ 300W Ultrasonic Spot Welder Transducer For Hand Gun Handheld Welder Spot Welding Machine

35KHZ 300W Ultrasonic Spot Welder Transducer For Hand Gun Handheld Welder Spot Welding Machine