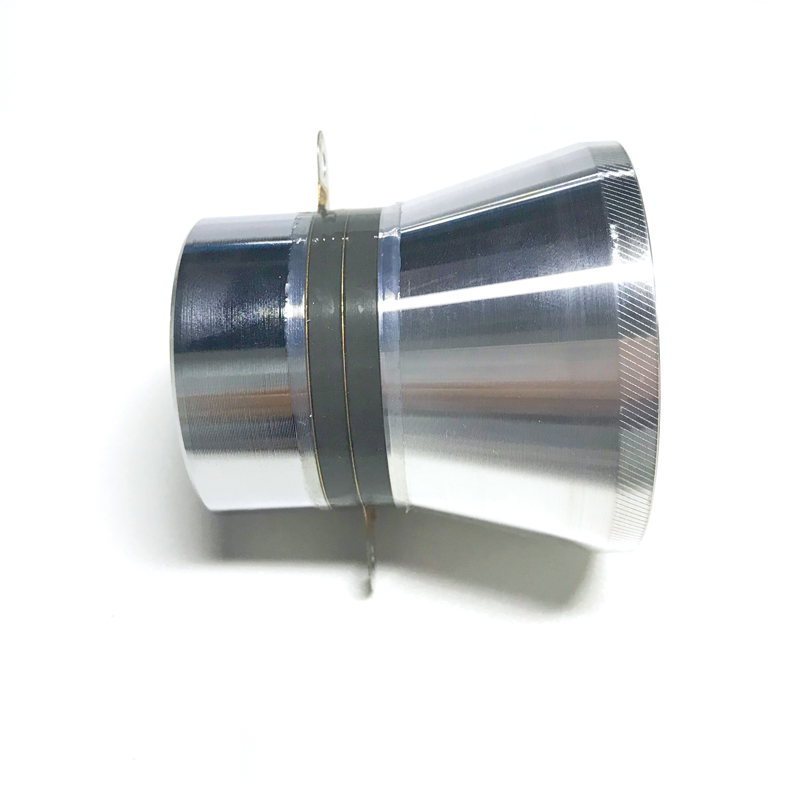

Ultrasonic Vibration Transducer Manufacturers 40K 60W Piezoelectric Ultrasonic Cleaning Transducer

Ultrasonic oscillator installation process: 1、 Preparation tools: argon arc welding, 10 # Hex key, chrome iron tin wire, 2.5 square high temperature wire, 2 * 2.5 cable wire, vibrator glue, (Wire stripper, sleeve, tie, sandblasting machine, pipe fittings, etc.). 2、 Welding screws: Calculate the ar…

Ultrasonic Vibration Transducer Manufacturers 40K 60W Piezoelectric Ultrasonic Cleaning Transducer

Ultrasonic oscillator installation process:

1、 Preparation tools: argon arc welding, 10 # Hex key, chrome iron tin wire, 2.5 square high temperature wire, 2 * 2.5 cable wire, vibrator glue, (Wire stripper, sleeve, tie, sandblasting machine, pipe fittings, etc.).

2、 Welding screws: Calculate the arrangement position of the vibrator, weld the screws on the cleaned position, and then clean the surrounding area of the screws, making sure they are flat to avoid affecting the installation of the vibrator.

3、 Glue configuration: Squeeze A glue around the screw, then squeeze B glue next to A glue, and quickly mix AB glue with a small iron rod to make it fully and evenly mixed.

4、 Installation of vibration head: Gently tighten the transducer to squeeze out the air and excess glue between the bottom and cylinder bottom contact surfaces, making the oscillator more tightly integrated with stainless steel.

5、 Curing and condensation: Place it in a relatively high room temperature for curing, and it can be connected within 4-8 hours. After 24 hours, it can be powered on for testing.

Note: 1. Metal nail machines can also replace argon arc welding.

- Welding screws must be fully welded, otherwise they may fall off easily.

- Regarding curing, the length of time should consider the temperature. If the temperature is low, the time will be longer. If the temperature is high, it will be faster. It is recommended to operate at room temperature, and even if heated, do not overheat. It is best to do so appropriately.

| Type | Length(mm) | Weight(g) | Frequency(KHz) | Resonance Impedance (Ω) | Static Capacity (pF)±10% | Input Power(W) |

| PU-UT-20100 PZT-8 | 94 | 900 | 20 | 10-20 | 5200 | 100 |

| PU-UT-25100 PZT-4 | 77 | 710 | 25 | 10-20 | 6600 | 100 |

| PU-UT-28120 PZT-4 | 66 | 720 | 28 | 10-20 | 7800 | 120 |

| PU-UT-28100 PZT-8 | 66 | 625 | 28 | 10-20 | 5200 | 100 |

| PU-UT-28100 PZT-4 | 66 | 624 | 28 | 10-20 | 6600 | 100 |

| PU-UT-30100 PZT-8 | 61 | 555 | 30 | 10-20 | 5200 | 100 |

| PU-UT-2560 PZT-4 | 77 | 530 | 25 | 10-20 | 5400 | 60 |

| PU-UT-2860 PZT-8 | 68 | 470 | 28 | 10-20 | 3800 | 60 |

| PU-UT-2850 PZT-4 | 82 | 425 | 28 | 10-20 | 4100 | 50 |

| PU-UT-3360 PZT-8 | 58 | 420 | 33 | 10-20 | 3800 | 60 |

| PU-UT-4060 PZT-8 | 55 | 300 | 40 | 10-20 | 3800 | 60 |

| PU-UT-4060 PZT-4 | 56 | 310 | 40 | 10-20 | 5400 | 60 |

| PU-UT-4050 PZT-4 | 54 | 260 | 40 | 10-20 | 4100 | 50 |

| PU-UT-4050-1 PZT-4 | 57 | 300 | 40 | 10-20 | 4100 | 50 |

| PU-UT-5435 PZT-4 | 36 | 135 | 54 | 10-20 | 3200 | 35 |

| PU-UT-6860 PZT-8 | 80 | 460 | 68 | 10-20 | 3800 | 60 |

| PU-UT-68120 PZT-4 | 67 | 588 | 68 | 10-20 | 7800 | 120 |

| PU-UT-8060 PZT-4 | 60 | 325 | 80 | 10-20 | 5400 | 60 |

| PU-UT-12060 PZT-4 | 56 | 260 | 120 | 10-20 | 5400 | 60 |

| PU-UT-13550 PZT-4 | 54 | 215 | 135 | 10-20 | 4200 | 50 |

Ultrasonic Vibration Transducer Manufacturers 40K 60W Piezoelectric Ultrasonic Cleaning Transducer

标签:40K 60W Piezoelectric Ultrasonic Cleaning Transducer, Ultrasonic Vibration Transducer Manufacturers

Send Inquiry

28KHZ 50W Piezoelectric Ultrasonic Cleaning Transducer Piezoelectric Ultrasonic Transducer For Industrial Ultrasonic Cleaners

28KHZ 50W Piezoelectric Ultrasonic Cleaning Transducer Piezoelectric Ultrasonic Transducer For Industrial Ultrasonic Cleaners 40KHz 50W Ultrasonic Transducer For Industrial Ultrasonic Cleaning Machine

40KHz 50W Ultrasonic Transducer For Industrial Ultrasonic Cleaning Machine 28KHz 100W Ultrasonic Cleaning Transducer Oscillator For Engine Parts Degreasing Oil Washing Machine

28KHz 100W Ultrasonic Cleaning Transducer Oscillator For Engine Parts Degreasing Oil Washing Machine 17KHZ 50W Ultrasonic Cleaner Transducer For High Power Digital Ultrasonic Cleaner

17KHZ 50W Ultrasonic Cleaner Transducer For High Power Digital Ultrasonic Cleaner Pzt-8 25khz 60W Langevin Ultrasonic Piezoelectric Cleaning Transducer For Submersible Ultrasonic Cleaner

Pzt-8 25khz 60W Langevin Ultrasonic Piezoelectric Cleaning Transducer For Submersible Ultrasonic Cleaner 100W 28KHZ Ultrasonic Dishwasher Machine Transducer For Ultrasonic Cleaner

100W 28KHZ Ultrasonic Dishwasher Machine Transducer For Ultrasonic Cleaner 40KHz 50W Ultrasonic Cleaning Transducer For Ultrasound Cleaner Industrial Cleaning Machine

40KHz 50W Ultrasonic Cleaning Transducer For Ultrasound Cleaner Industrial Cleaning Machine 28khz 100W Oscillator Ultrasound Immersion Sensor Ultrasonic Cleaning Transducer For Ultrasonic Cleaner

28khz 100W Oscillator Ultrasound Immersion Sensor Ultrasonic Cleaning Transducer For Ultrasonic Cleaner 40KHZ Industrial Ultrasonic Cleaning Transducer For Large Industrial Ultrasonic Cleaning Machine

40KHZ Industrial Ultrasonic Cleaning Transducer For Large Industrial Ultrasonic Cleaning Machine 25KHz 60W Ultrasonic Cleaning Transducer For Ultrasound Cleaner Industrial Cleaning Machine

25KHz 60W Ultrasonic Cleaning Transducer For Ultrasound Cleaner Industrial Cleaning Machine Langevin Ultrasonic Piezoelectric Cleaning Transducer With 40KHz 28KHz Ultrasonic Transducer

Langevin Ultrasonic Piezoelectric Cleaning Transducer With 40KHz 28KHz Ultrasonic Transducer 28KHZ 100W Industrial Ultrasonic Frequency Transducer Ultrasonic Cleaner Transducer For Auto Parts Ultrasonic Cleaner

28KHZ 100W Industrial Ultrasonic Frequency Transducer Ultrasonic Cleaner Transducer For Auto Parts Ultrasonic Cleaner