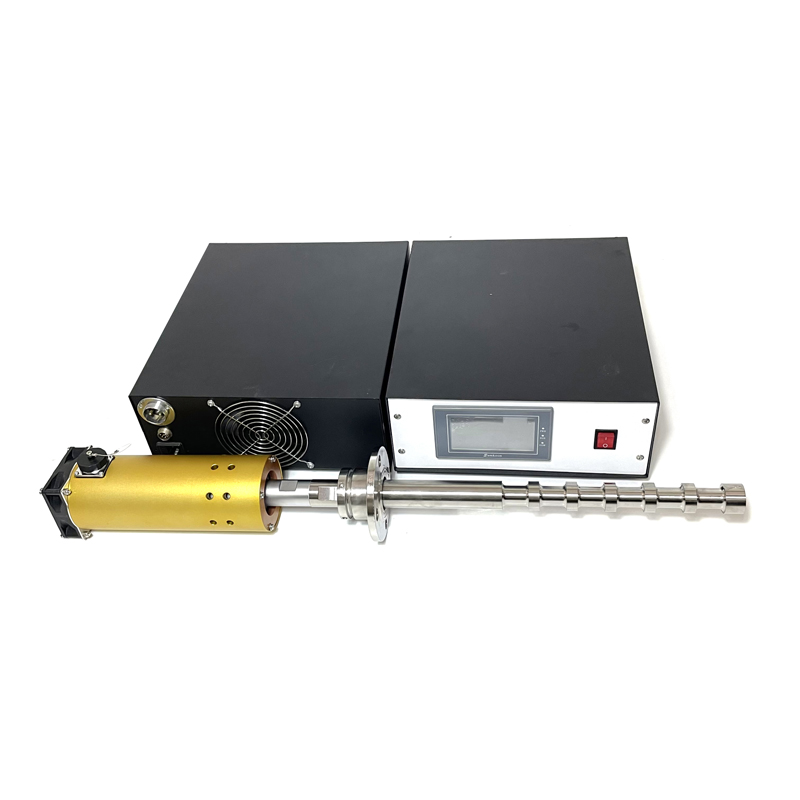

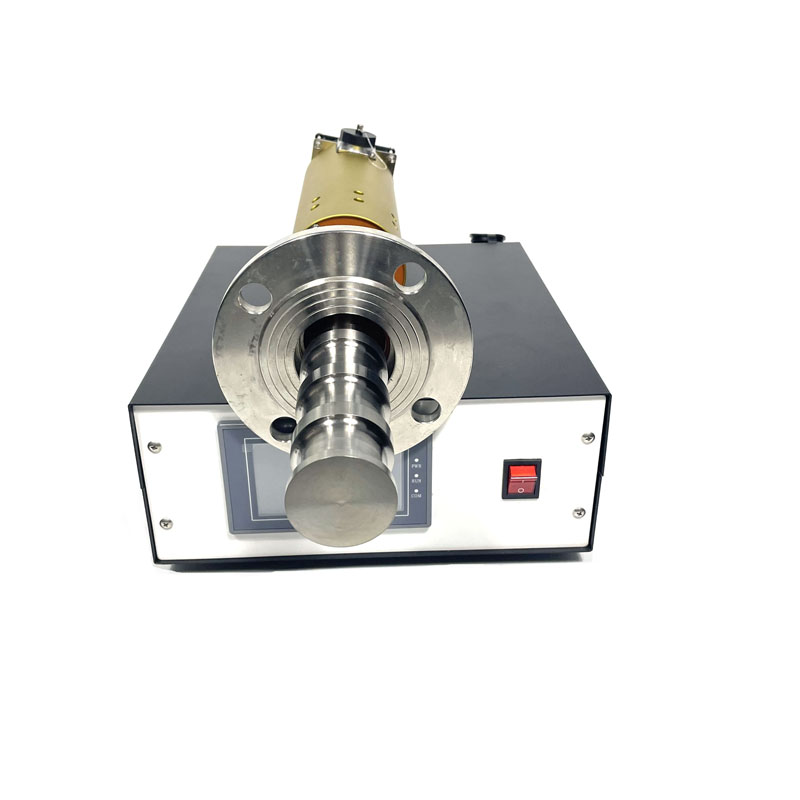

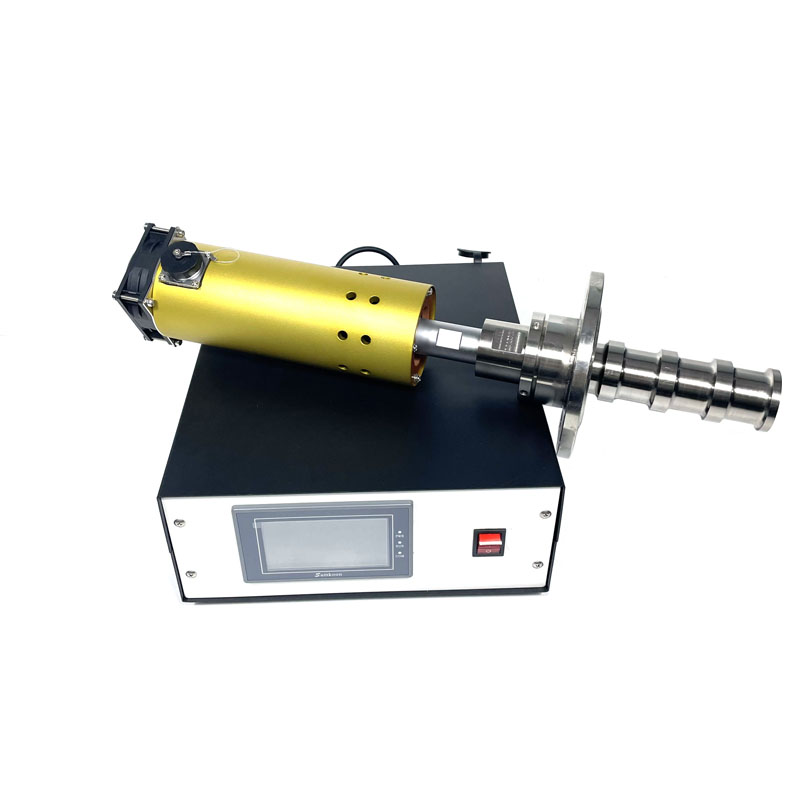

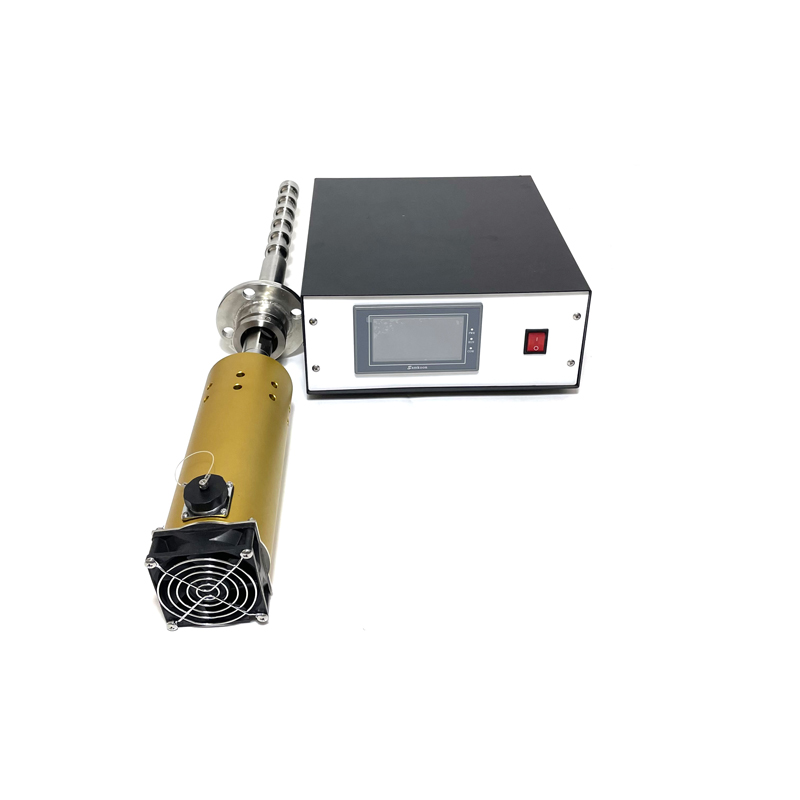

Ultrasonic Sonochemistry Tube Flow-Through Reactor Ultrasonic Crystallization And Sound Generator

The concentrated energy ultrasonic material emulsification disperser is a device that directly immerses the amplitude changing rod of a high-power ultrasonic transducer into the reaction liquid, allowing sound energy to enter the reaction system directly, without the need for transmission through the reactor wall of …

Ultrasonic Sonochemistry Tube Flow-Through Reactor Ultrasonic Crystallization And Sound Generator

The concentrated energy ultrasonic material emulsification disperser is a device that directly immerses the amplitude changing rod of a high-power ultrasonic transducer into the reaction liquid, allowing sound energy to enter the reaction system directly, without the need for transmission through the reactor wall of the cleaning tank. Its advantage is that it can directly transport a large amount of energy to the reaction medium, effectively converting electrical energy into mechanical energy, and controlling the magnitude of ultrasonic energy by changing the amplitude of transmission to the transducer.

This product has strong scalability

(1) Optional cooling water circulation device, consisting of a cooling water circulation device and a specially designed double-layer glass reactor, can achieve precise temperature control at any temperature point within the range of -5-100 ℃, effectively avoiding sample tissue damage caused by excessive temperature. Compared with traditional ice bath cooling, it is more convenient and accurate.

(2) Optional magnetic stirrer. Mixing can improve the emulsification rate of the treated sample and achieve better treatment effect.

In order to stabilize the newly formed dispersed phase droplets to prevent coalescence, emulsifiers (surfactants, surfactants) and stabilizers are added to the lotion. Maintain the final droplet size distribution at the same level as the distribution after droplet rupture in the ultrasonic dispersion zone.

Unstable emulsion causing coalescence

The cavitation process is influenced by the frequency and intensity of ultrasound, and the occurrence of cavitation in the body largely depends on the presence of undissolved gas suspended in the liquid. The presence of gas seems to play a catalytic role. Under a certain pressure, the formation of a cavity depends to a certain extent on the development time and ultrasound frequency. The phacoemulsification process represents competition between opposing processes. Therefore, it is necessary to choose appropriate working conditions and frequencies in order for destructive effects to dominate.

To prepare oil in water lotion, its limit sound intensity is much lower than that of water in oil lotion. The type of sound field affects the emulsification process by applying a certain amount of traveling wave. Compared to applying some stationary waves, the process efficiency is improved. This can be explained by the fact that in a stationary wave field, condensation dominates the opposite process of dispersion.

| Tubular EquipmentType | Tubular TransducerType | Frequency(KHz) | UltrasoundOutput(W) | Total Length(mm) | Diameter(mm) | Static Capacity(pF±10%) |

| PU-UE1 | US-61 | 15-28 | 1000 | 500 | Φ50-55 | 68000 |

| PU-UE5 | US-25 | 15-28 | 1500 | 850 | Φ50-55 | 68000 |

| PU-UE6 | US-16 | 15-28 | 2000 | 1100 | Φ50-55 | 132000 |

Ultrasonic Sonochemistry Tube Flow-Through Reactor Ultrasonic Crystallization And Sound Generator

标签:Ultrasonic Crystallization And Sound Generator, Ultrasonic Sonochemistry Tube Flow-Through Reactor

Send Inquiry

1800W Ultrasonic Cavitation Reactor Ultrasonic Sonochemistry Biodiesel Extraction With Signal Generator

1800W Ultrasonic Cavitation Reactor Ultrasonic Sonochemistry Biodiesel Extraction With Signal Generator 2000W 20KHZ Ultrasonic Sonochemical Biodiesel Reactors Dispersion Homogenizer Mixing Processor

2000W 20KHZ Ultrasonic Sonochemical Biodiesel Reactors Dispersion Homogenizer Mixing Processor Ultrasonic Vibration Reactor Cream Emulsify Homogenizer Mixing Machine And Ultrasonic Power Generator

Ultrasonic Vibration Reactor Cream Emulsify Homogenizer Mixing Machine And Ultrasonic Power Generator 1000W 20KHZ Ultrasonic Emulsifier Mixer Homogenizer Ultrasonic Extraction Reactor

1000W 20KHZ Ultrasonic Emulsifier Mixer Homogenizer Ultrasonic Extraction Reactor Industrial Ultrasonic Liquid Sonochemistry Processor For Emulsifier Extraction Disruption Sonicator Ultrasonic Homogeniz

Industrial Ultrasonic Liquid Sonochemistry Processor For Emulsifier Extraction Disruption Sonicator Ultrasonic Homogeniz 5000W 20KHZ Ultrasonic Emulsifier Mixer Homogenizer For Ultrasonic Biodiesel Production

5000W 20KHZ Ultrasonic Emulsifier Mixer Homogenizer For Ultrasonic Biodiesel Production Ultrasonic Extraction Equipment Ultrasonic Homogenizer for Pharmaceutical Extraction

Ultrasonic Extraction Equipment Ultrasonic Homogenizer for Pharmaceutical Extraction Ultrasonic Plant Oil Extraction Machine Ultrasonic Sonochemistry Essential Oil Extraction Equipment

Ultrasonic Plant Oil Extraction Machine Ultrasonic Sonochemistry Essential Oil Extraction Equipment 2000W Ultrasonic Cavitation Reactor Biodiesel Underwater Acoustic Ultrasonic Tubular Transducer

2000W Ultrasonic Cavitation Reactor Biodiesel Underwater Acoustic Ultrasonic Tubular Transducer 20khz 2000W Ultrasonic Emulsifier Mixer Homogenizer For Nanoparticle Dispersion

20khz 2000W Ultrasonic Emulsifier Mixer Homogenizer For Nanoparticle Dispersion Laboratory Ultrasonic Liquid Processor Homogenizer Ultrasonic Homogenizer Machine Emulsifier

Laboratory Ultrasonic Liquid Processor Homogenizer Ultrasonic Homogenizer Machine Emulsifier Ultrasonic Sonochemistry Reactor Disperser Emulsifying Homogenizer For Hemp Oil Extraction

Ultrasonic Sonochemistry Reactor Disperser Emulsifying Homogenizer For Hemp Oil Extraction