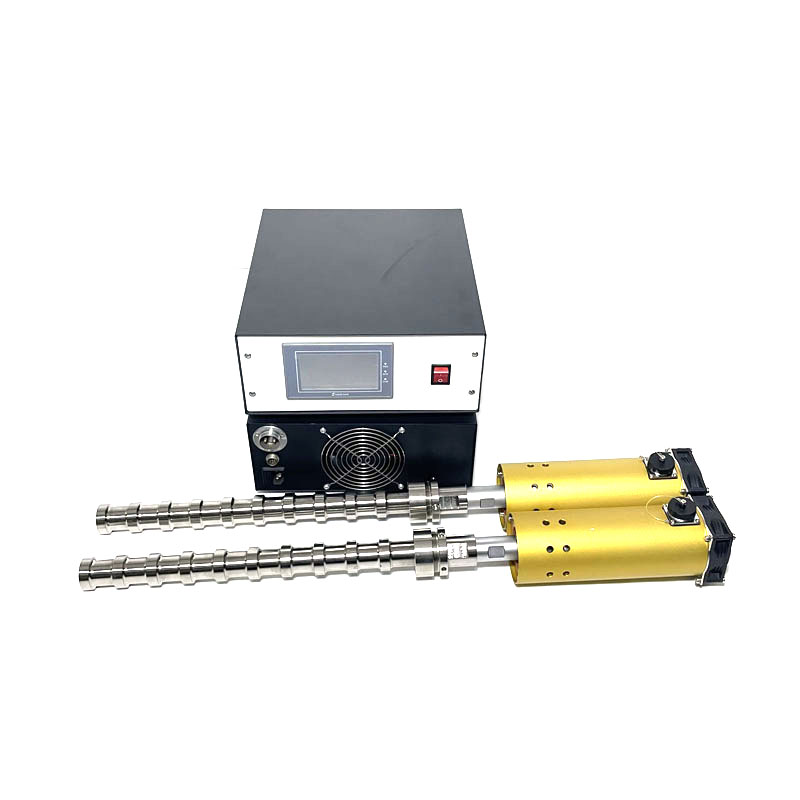

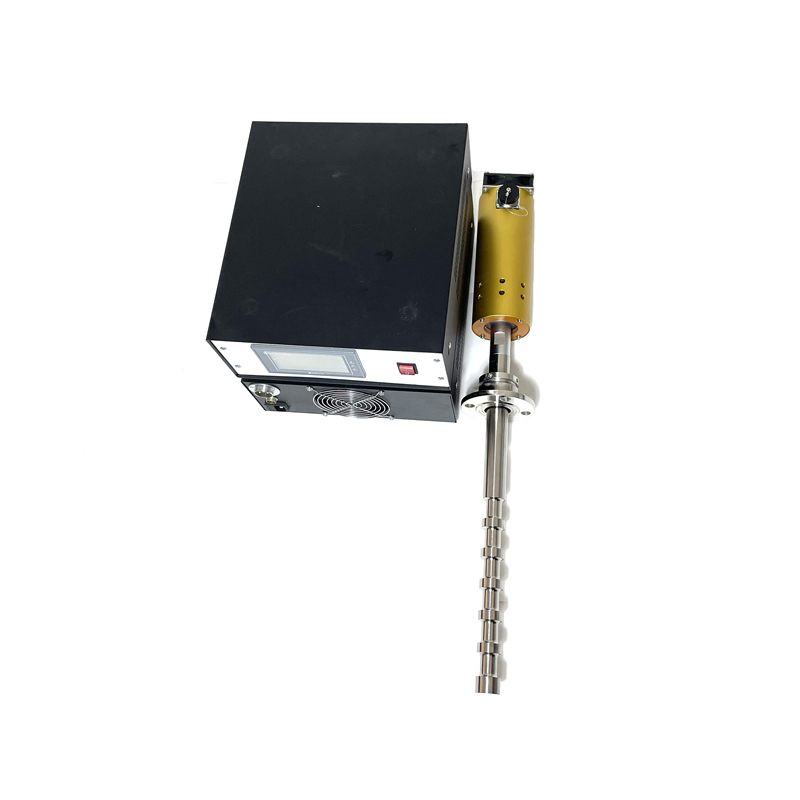

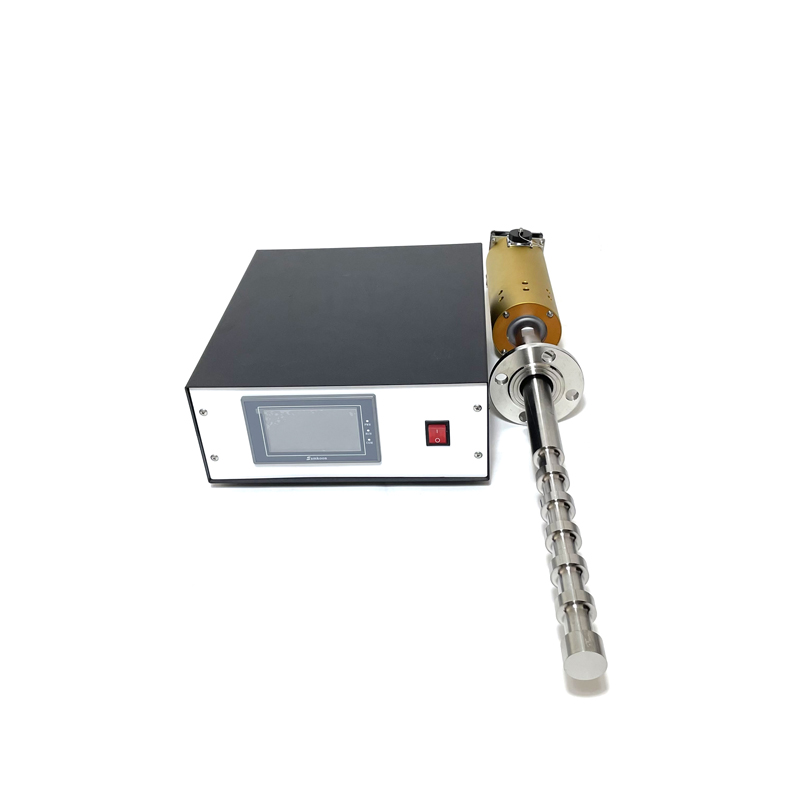

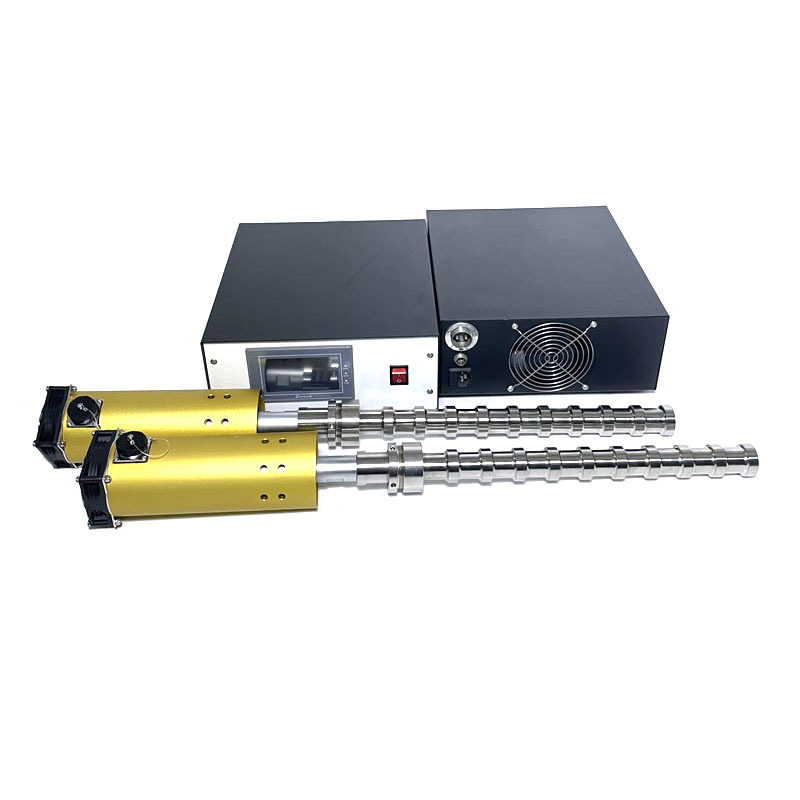

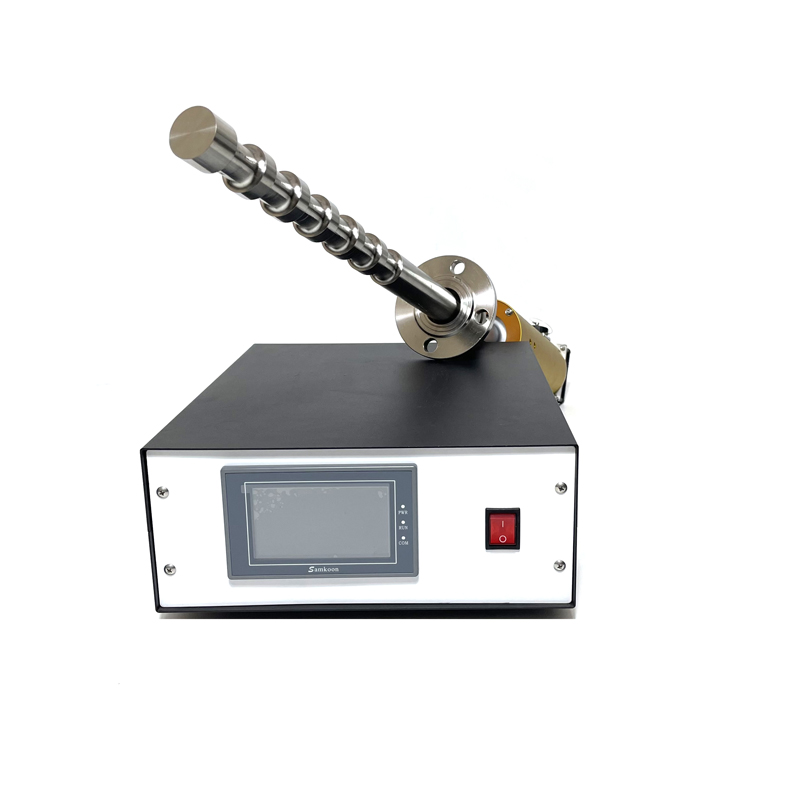

Ultrasonic Sonochemistry System With 600-3000w Generator Biodiesel Reactor

Ultrasonic dispersion is a microscopic consequence caused by pressure fluctuations and dental caries. Research on different materials (such as aqueous solution of nano silica powder and spray frozen mixture with variable solids) shows that ultrasonic has significant advantages over other materials and technologies (s…

Ultrasonic Sonochemistry System With 600-3000w Generator Biodiesel Reactor

Ultrasonic dispersion is a microscopic consequence caused by pressure fluctuations and dental caries. Research on different materials (such as aqueous solution of nano silica powder and spray frozen mixture with variable solids) shows that ultrasonic has significant advantages over other materials and technologies (such as rotor stator mixer (such as turax) or rubber mill). Especially for substances as small as a few nanometers to a few micrometers, ultrasonic cavitation is very effective in decomposing aggregates, aggregates, and even particles. When ultrasonic waves are used to grind high concentration batches, liquid jets are the result of ultrasonic worms, causing particles to collide with each other at speeds of up to 1000 kilometers per hour. This breaks the van der Waals force in aggregates and even elementary particles.

Ultrasonic liquid treatment is described by several parameters. The important factors are amplitude, pressure, temperature, viscosity, and concentration. The process output of a given parameter configuration, such as granularity, is used as a function of the volume of energy for each process. The function varies with changes in various parameters. In addition, the actual power output per unit surface area of the welding head of the ultrasonic unit depends on the parameters. Therefore, we will collect a large amount of information before you place your order. Alternatively, we suggest purchasing a set for testing, identifying working parameters, and then conducting large-scale production.

Application:

The typical applications of chemical ultrasound include ultrasonic homogenization, ultrasonic emulsification, ultrasonic dispersion, sterilization and wet grinding (particle size reduction), cell fragmentation and disintegration, extraction, degassing, and ultrasonic processes;

Ultrasonic dispersion does not require the use of emulsifiers. In many cases, the diameter of dispersed particles can reach 1 μ M or smaller. It can be carried out between the solid, liquid, and gas phases of the same substance, as well as between different solids, liquids, and gases. It has been widely used in food sample detection and analysis, nanomaterial preparation, and other fields.

As:

Paint, titanium oxide, iron oxide, carbon, etc. are dispersed in water or solvents.

Micropulverization of graphene

● Disperse fluorescent materials

● Dispersion of photosensitive materials

Dispersion of dyes in molten paraffin

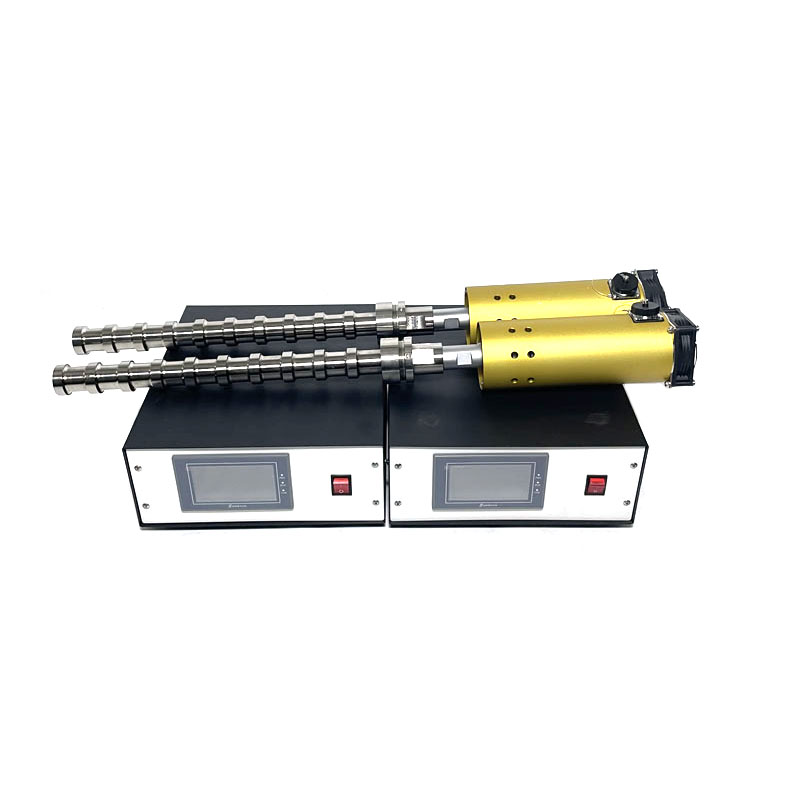

| Tubular EquipmentType | Tubular TransducerType | Frequency(KHz) | UltrasoundOutput(W) | Total Length(mm) | Diameter(mm) | Static Capacity(pF±10%) |

| PU-UE1 | US-61 | 15-28 | 1000 | 500 | Φ50-55 | 68000 |

| PU-UE5 | US-25 | 15-28 | 1500 | 850 | Φ50-55 | 68000 |

| PU-UE6 | US-16 | 15-28 | 2000 | 1100 | Φ50-55 | 132000 |

Ultrasonic Sonochemistry System With 600-3000w Generator Biodiesel Reactor

Send Inquiry

20KHZ Ultrasonic Biodiesel Reactor With Ultrasonic Generator For Industrial Extractor Reactor

20KHZ Ultrasonic Biodiesel Reactor With Ultrasonic Generator For Industrial Extractor Reactor Industrial Extractor Extraction Equipment Laboratory Ultrasonic Liquid Sonochemistry Processor Reactor

Industrial Extractor Extraction Equipment Laboratory Ultrasonic Liquid Sonochemistry Processor Reactor 20KHZ Ultrasonic Emulsifier Liquid Processor Reactor Emulsifying Homogenizer Mixing Equipment

20KHZ Ultrasonic Emulsifier Liquid Processor Reactor Emulsifying Homogenizer Mixing Equipment Lab Ultrasonic Probe Homogenizer Sonicator Ultrasonic Biodiesel Reactor And Generator Control Box

Lab Ultrasonic Probe Homogenizer Sonicator Ultrasonic Biodiesel Reactor And Generator Control Box 1000W Industry Ultrasonic Biodiesel Oil Ultrasonic Sonochemistry Reactor And Power Supply Generator

1000W Industry Ultrasonic Biodiesel Oil Ultrasonic Sonochemistry Reactor And Power Supply Generator 20KHZ 3000W Industrial Ultrasonic Sonochemistry System Ultrasonic Disperser Machine

20KHZ 3000W Industrial Ultrasonic Sonochemistry System Ultrasonic Disperser Machine Ultrasonic Assisted Extraction Machine Ultrasonic Biodiesel Reactor Extraction Dispersion Cell Crusher Homogenizer

Ultrasonic Assisted Extraction Machine Ultrasonic Biodiesel Reactor Extraction Dispersion Cell Crusher Homogenizer Ultrasonic Cavitation Reactor Biodiesel 2000 Watt Underwater Acoustic Ultrasonic Tubular Transducer

Ultrasonic Cavitation Reactor Biodiesel 2000 Watt Underwater Acoustic Ultrasonic Tubular Transducer 20KHZ 2000W 220V Ultrasound Nano Emulsification Disperser Laboratory Ultrasonic Emulsifier Equipment

20KHZ 2000W 220V Ultrasound Nano Emulsification Disperser Laboratory Ultrasonic Emulsifier Equipment Ultrasonic Homogenizer Sonicator Processor Cell Peraffin Wax Dispersion Oil In Water Emulsifier

Ultrasonic Homogenizer Sonicator Processor Cell Peraffin Wax Dispersion Oil In Water Emulsifier 1200W 20KHZ Industrial Ultrasonic Emulsifier Biodiesel Processor Reactor With Signal Generator

1200W 20KHZ Industrial Ultrasonic Emulsifier Biodiesel Processor Reactor With Signal Generator Batch and Continuous Ultrasonic Reactors Emulsify Homogenizer Disrupter And Ultrasonic Frequency Generator

Batch and Continuous Ultrasonic Reactors Emulsify Homogenizer Disrupter And Ultrasonic Frequency Generator