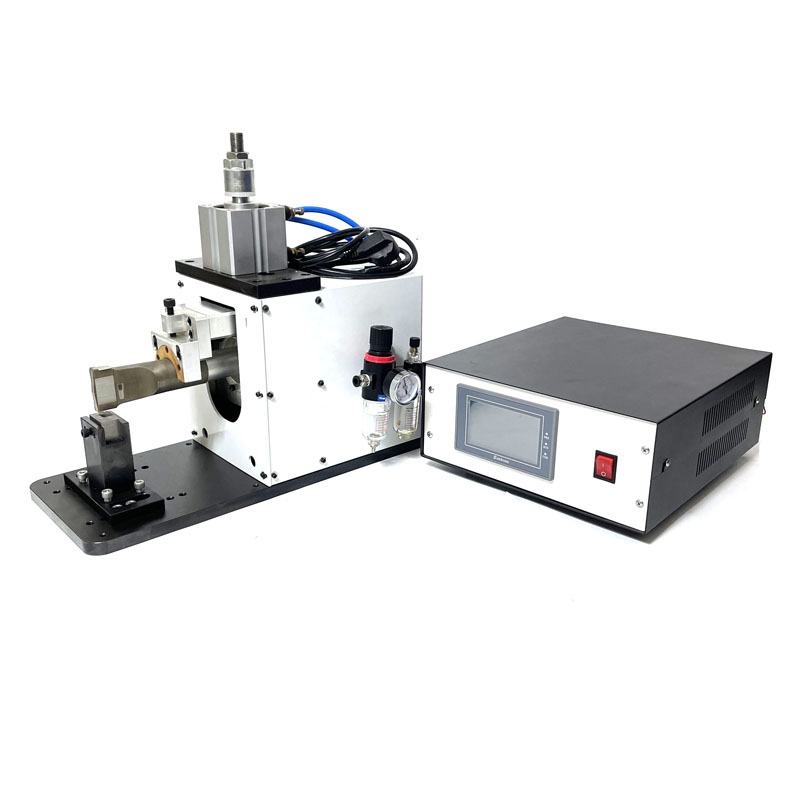

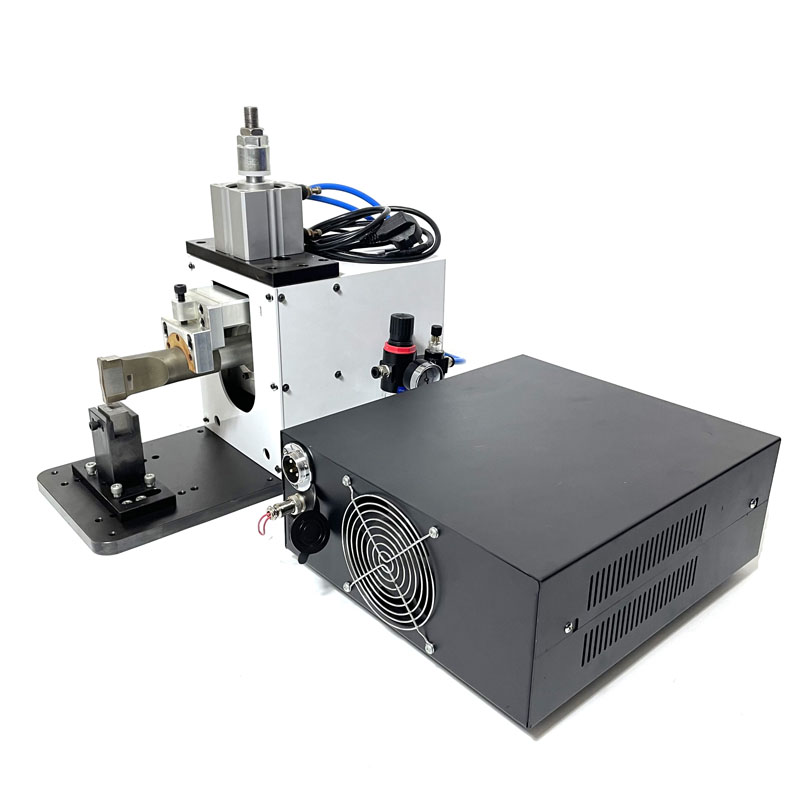

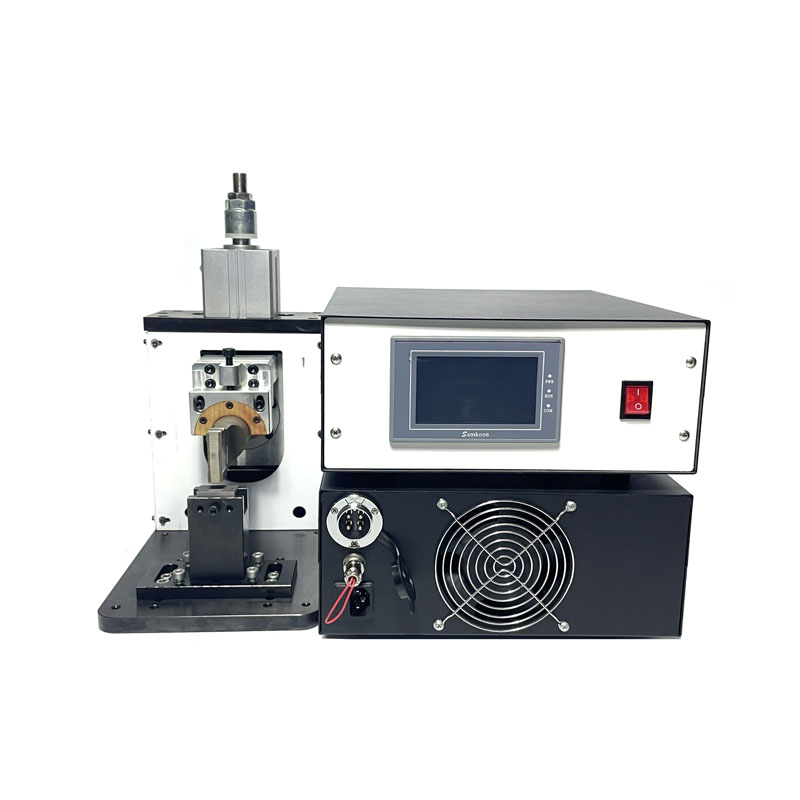

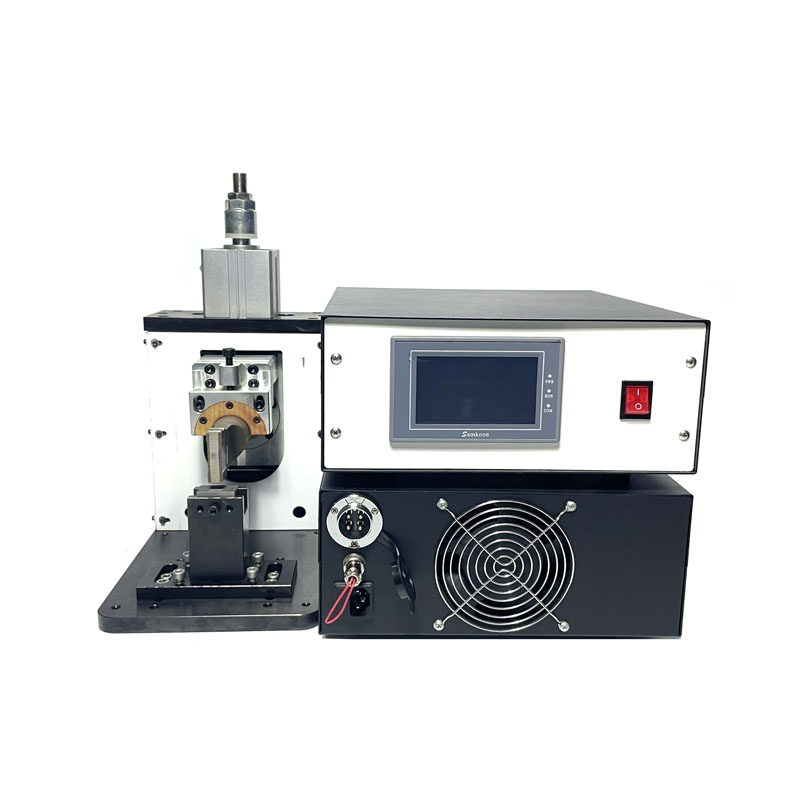

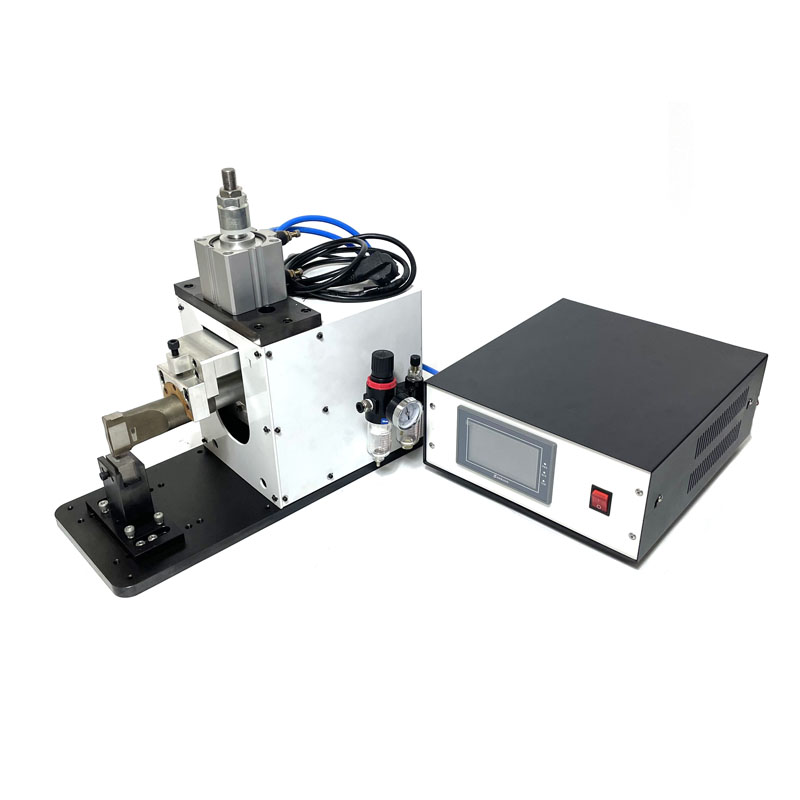

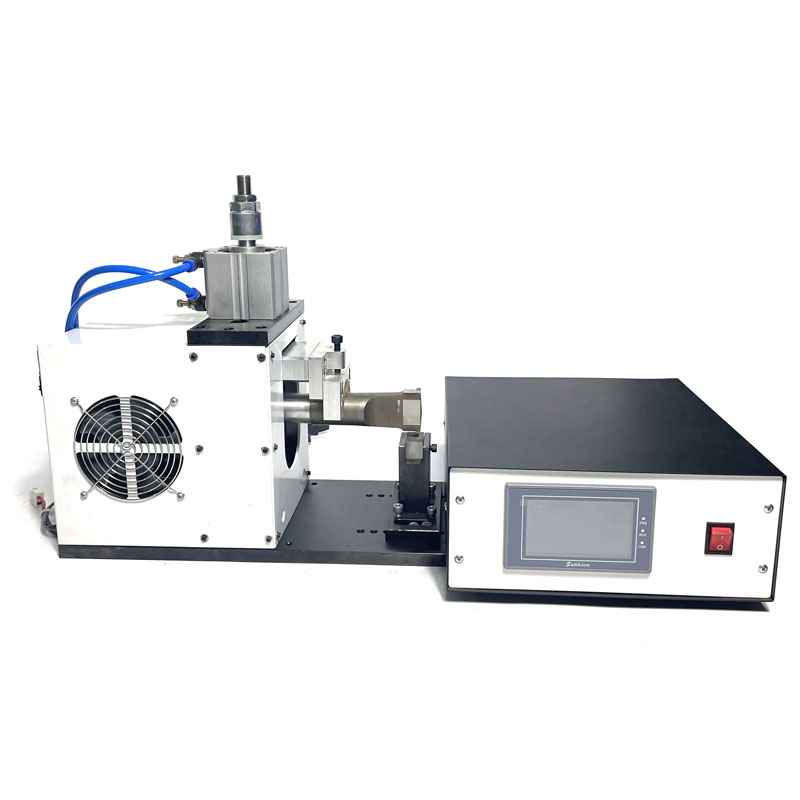

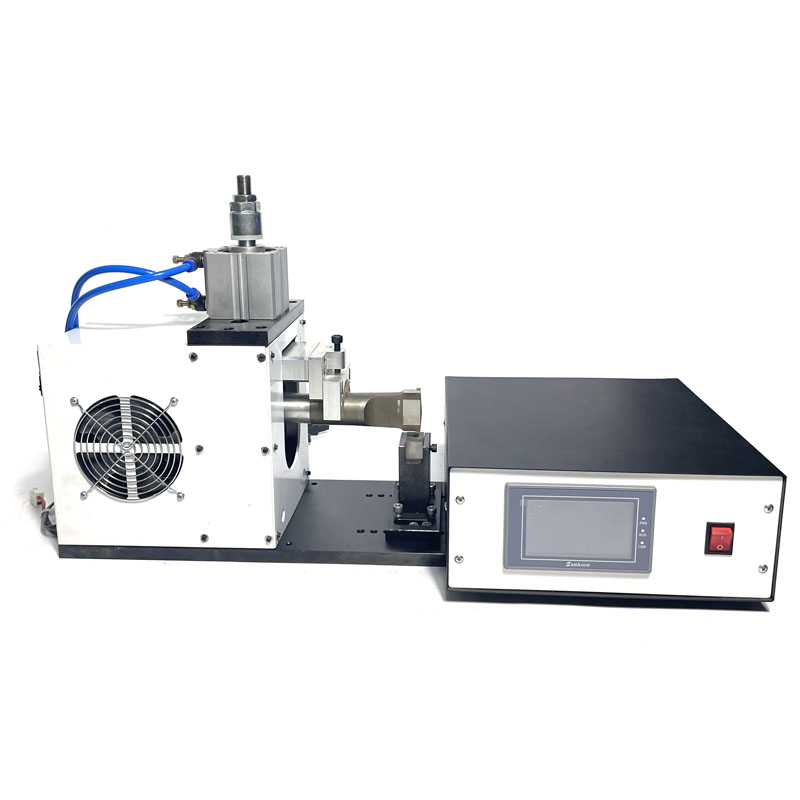

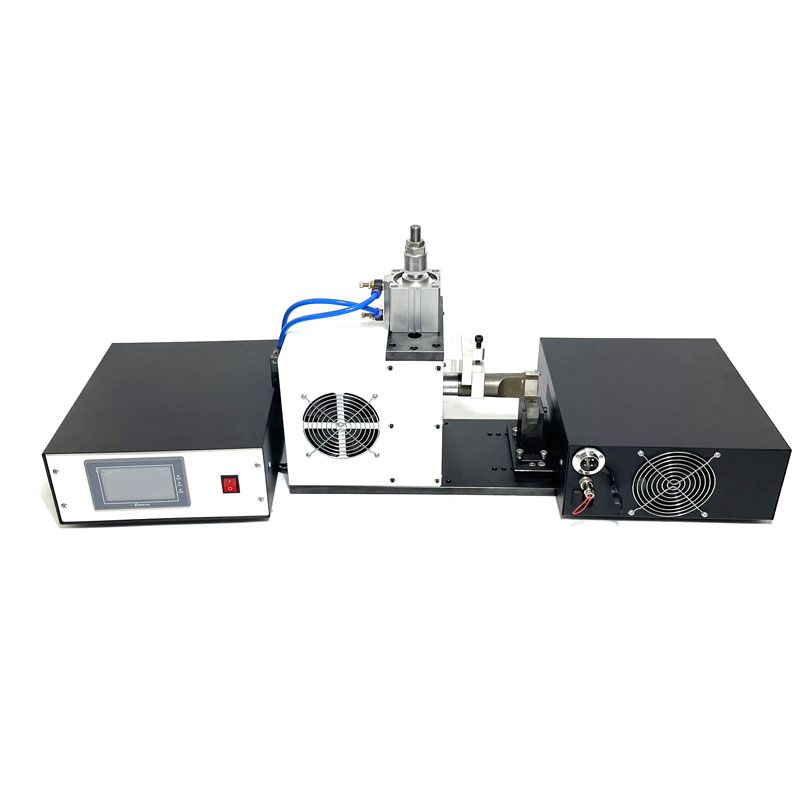

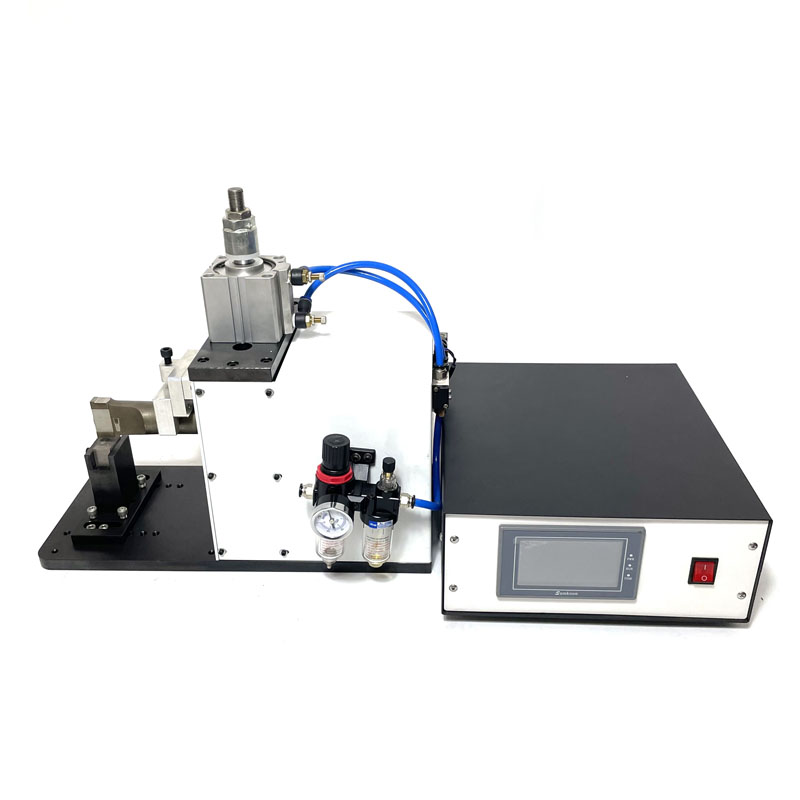

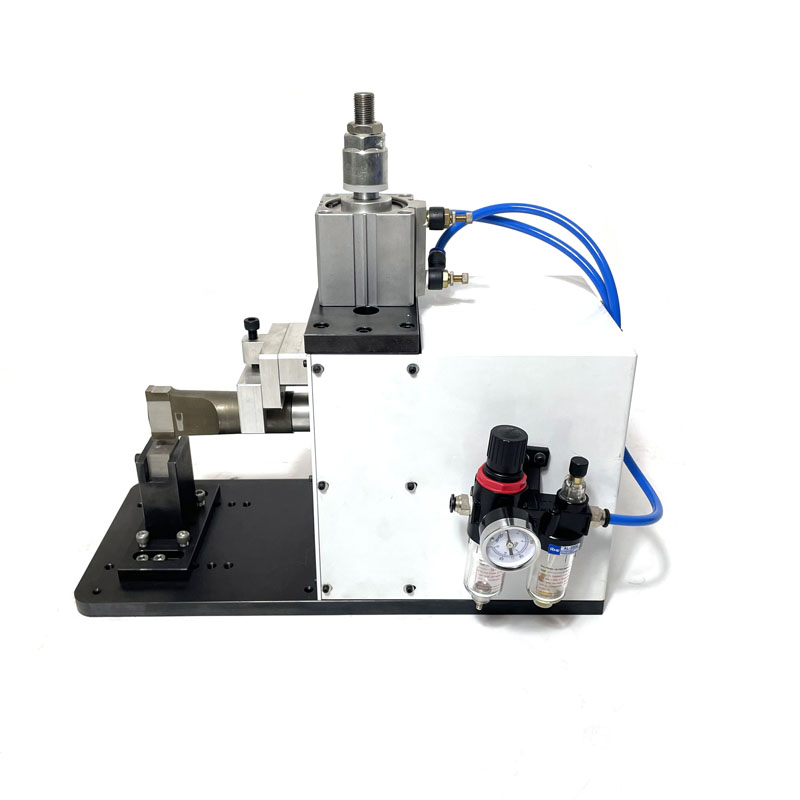

Ultrasonic Metal Spot Welder For Battery Cell Sealing And Cutting Copper Tube Ultrasonic Wire Welding Machine

Characteristics of ultrasonic battery metal spot welding equipment: The roller bearing slider ensures smooth operation and great accuracy of the system; Welding head and selecting low-cost replaceable welding nozzle or integrated high hardness tool steel welding head can quickly install and reduce costs; The…

Characteristics of ultrasonic battery metal spot welding equipment:

The roller bearing slider ensures smooth operation and great accuracy of the system;

Welding head and selecting low-cost replaceable welding nozzle or integrated high hardness tool steel welding head can quickly install and reduce costs;

The unique actuator of the special ultrasonic welding machine can effectively transmit the ultrasonic energy to the welding head, and the welding quality is guaranteed;

Easy to operate, built-in electronic protection circuit, safe to use, suitable for welding of similar metals, capable of single or multiple point welding of non-ferrous metals;

Ultrasonic Battery Metal Spot Welding Equipment Process

- Manually place workpieces (aluminum, nickel, copper, and metal sheets) into the lower fixture on the equipment workbench;

- Press the device start switch, the device will automatically compress the workpiece and start spot welding;

- After a welding is completed, the equipment automatically opens the clamping device and moves the welding workpiece to a position (the moving distance can be adjusted according to the spacing of the metal sheets), and the next welding begins. By analogy, the required number of welding strips will be gradually completed;

- After the entire welding is completed, the equipment automatically opens all clamping devices and restores the lower tooling to its original position;

- The operator takes out the welded workpiece and completes the welding.

Advantages and Applications of Ultrasonic Battery Metal Spot Welding Equipment

| Type | Power(W) | Frequency (KHz) |

| PU-MSW2000W | 2000W | 20KHZ |

| PU-MSW2600W | 2600W | 20KHZ |

| PU-MSW3200W | 3200W | 20KHZ |

| PU-MSW4000W | 4000W | 20KHZ |

| PU-MSW800W | 800W | 40khz |

标签:Copper Tube Ultrasonic Wire Welding Machine, ultrasonic metal spot welder, Ultrasonic Metal Spot Welder For Battery Cell Sealing And Cutting

Send Inquiry

Ultrasonic Lithium Battery Spot Welding Machine for Aluminum Foil Copper Foil Welding of Li-ion Battery Spot Welding System

Ultrasonic Lithium Battery Spot Welding Machine for Aluminum Foil Copper Foil Welding of Li-ion Battery Spot Welding System 20kHz Ultrasonic Metal Spot Welding Lithium Battery Welder For Stacked Electrode Sheets Tabs

20kHz Ultrasonic Metal Spot Welding Lithium Battery Welder For Stacked Electrode Sheets Tabs Au Fe Ni Ag Tab Ultrasonic Metal Spot Welder Welding Machine for Pouch Cell Preparation

Au Fe Ni Ag Tab Ultrasonic Metal Spot Welder Welding Machine for Pouch Cell Preparation Pouch Cell Ultrasonic Spot Welder Welding Machine For Al Tab Or Aluminum Foil Welding Machines

Pouch Cell Ultrasonic Spot Welder Welding Machine For Al Tab Or Aluminum Foil Welding Machines 4200W 20khz High Power Ultrasonic Metal Welding Machine With Ultrasonic Generator

4200W 20khz High Power Ultrasonic Metal Welding Machine With Ultrasonic Generator Ultrasonic Metal Welding Machine For Aluminum Wire Copper Wire Lithium Battery Pack Welding Electronic Cars

Ultrasonic Metal Welding Machine For Aluminum Wire Copper Wire Lithium Battery Pack Welding Electronic Cars 20khz Ultrasonic Metal Battery Spot Welder Machine For Pouch Cell And Supercapacitor

20khz Ultrasonic Metal Battery Spot Welder Machine For Pouch Cell And Supercapacitor Ultrasonic Wire Harness Welding Machine for Copper and Aluminum Metal Braid Wire Welding Machine

Ultrasonic Wire Harness Welding Machine for Copper and Aluminum Metal Braid Wire Welding Machine 0.5-20mm2 Ultrasonic Wire Cable Welding Machine Wire Connect Splicing Machine Ultrasonic Cable Wire Harness Welding Machine

0.5-20mm2 Ultrasonic Wire Cable Welding Machine Wire Connect Splicing Machine Ultrasonic Cable Wire Harness Welding Machine 3000W 20Khz Ultrasonic Metal Spot Welder Al Tab Ni Tag Ultrasonic Welding Machine For 18650 Lithium Battery

3000W 20Khz Ultrasonic Metal Spot Welder Al Tab Ni Tag Ultrasonic Welding Machine For 18650 Lithium Battery Ultrasonic Metal Welding Machine For Pouch Cell Electrode Tab/foil Aluminum Copper Foil With Digital Generator

Ultrasonic Metal Welding Machine For Pouch Cell Electrode Tab/foil Aluminum Copper Foil With Digital Generator 2000W Ultrasonic Spot Welder for Copper Foil / Ultrasonic Metal Welder /Ultrasonic Metal Welding Machine

2000W Ultrasonic Spot Welder for Copper Foil / Ultrasonic Metal Welder /Ultrasonic Metal Welding Machine