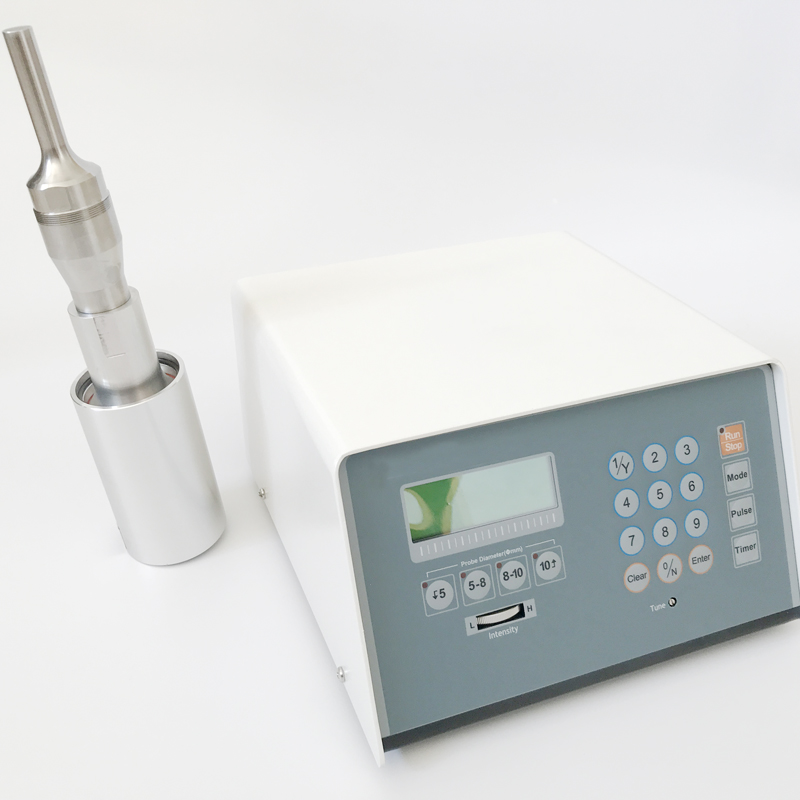

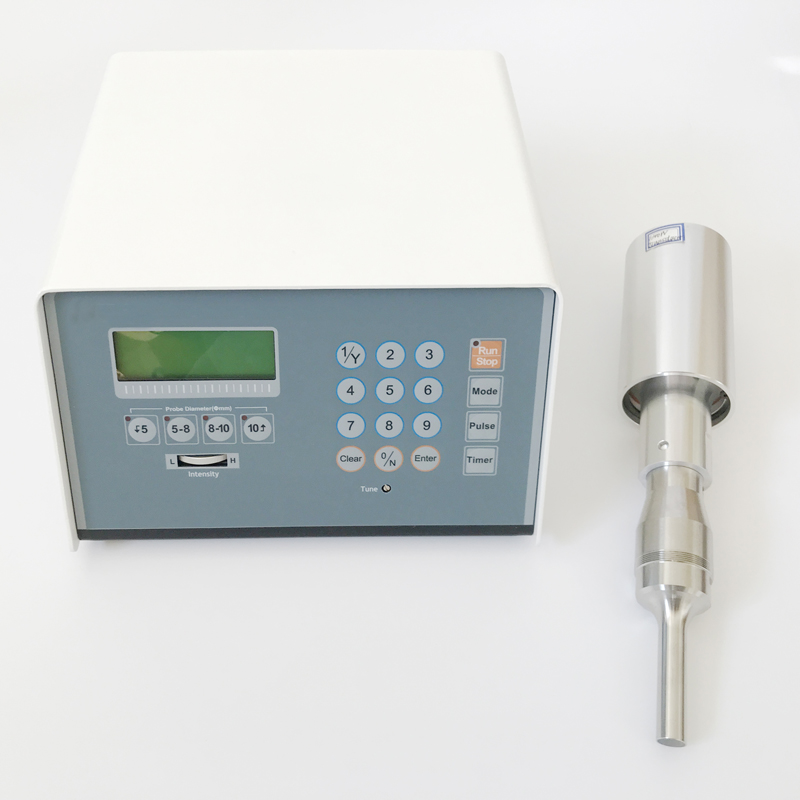

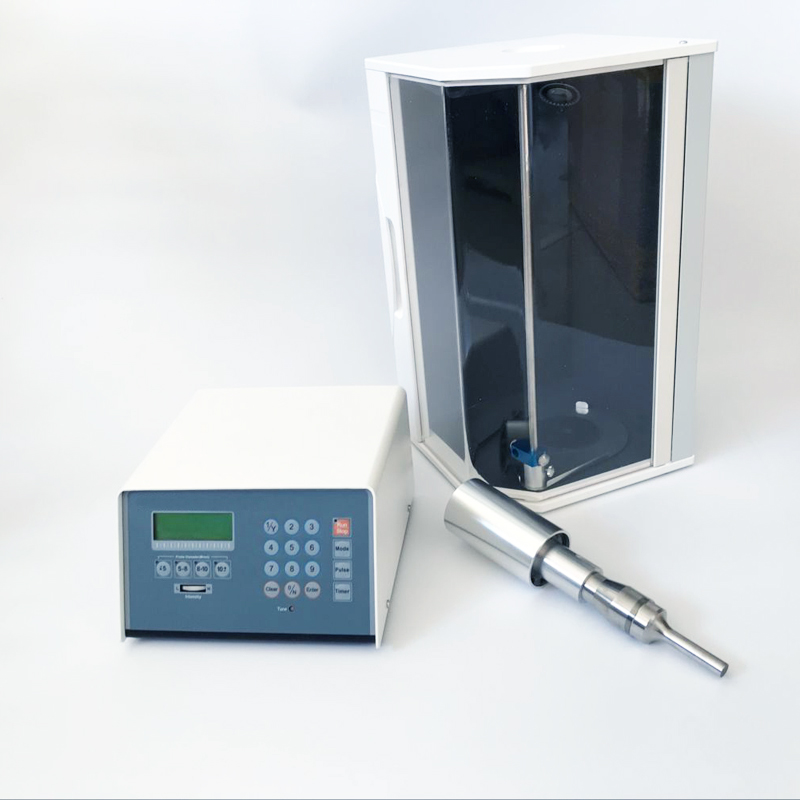

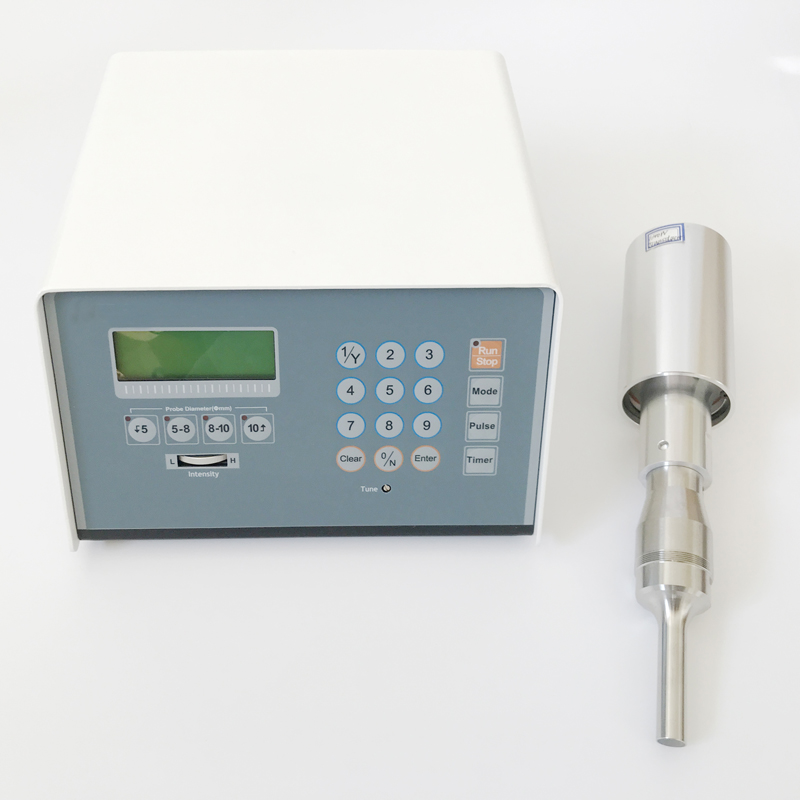

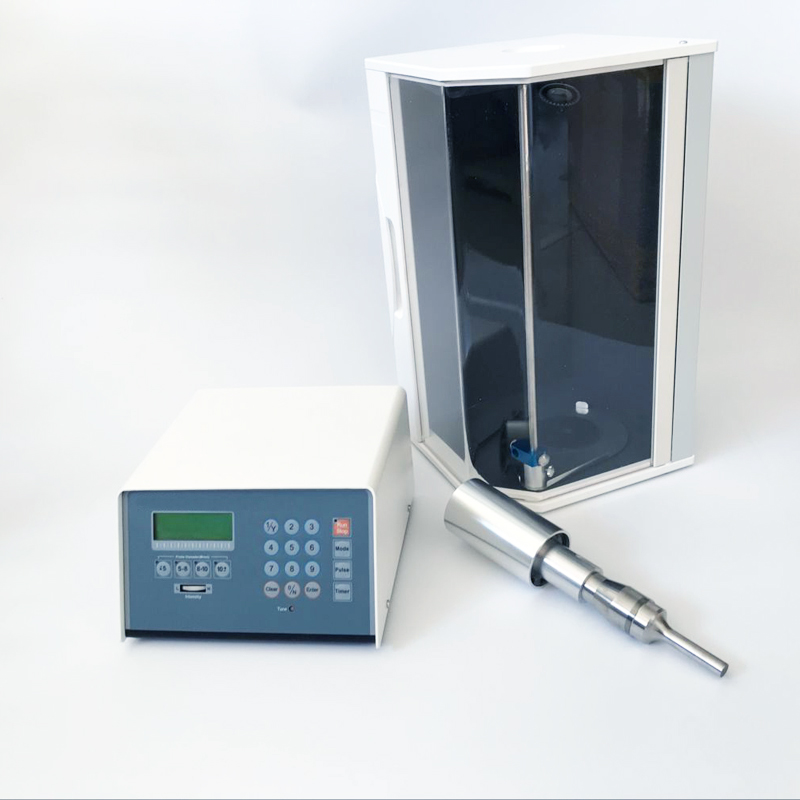

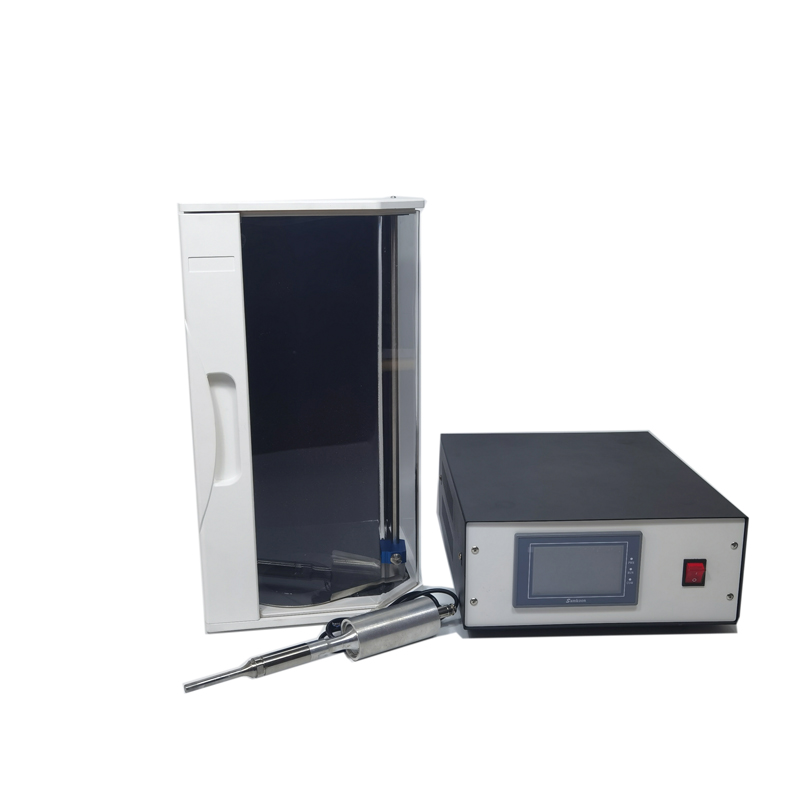

Ultrasonic Cell Disruptor Laboratory Homogenizer Disruptor Crusher Mixer Machine

Ultrasonic cell pulverizers have a wide range of applications, such as: Ultrasonic Extraction of Biological Nanoparticles (Ultrasonic Chemical Synthesis Method)In ultrasonic chemical reactions, the cavitation effect of sound waves plays a crucial role. During the irradiation process of ultrasound, the formation, g…

Ultrasonic Cell Disruptor Laboratory Homogenizer Disruptor Crusher Mixer Machine

Ultrasonic cell pulverizers have a wide range of applications, such as:

- Ultrasonic Extraction of Biological Nanoparticles (Ultrasonic Chemical Synthesis Method)

In ultrasonic chemical reactions, the cavitation effect of sound waves plays a crucial role. During the irradiation process of ultrasound, the formation, growth, and collapse of cavitation bubbles will occur in the liquid. When the cavitation bubbles collapse, a strong pressure pulse covering them will be generated, generating many unique properties, such as generating high temperatures of up to 5000K and pressures greater than 200Mpa. This is the energy source of ultrasonic chemical synthesis, These energies can be utilized to synthesize nanoparticles on the surface of some special powders.

- Ultrasonic pharmaceutical

(1) Dispersion of injectable pharmaceutical substances – By mixing phospholipids and cholesterol in an appropriate method with the drug in an aqueous solution and dispersing them through ultrasound, smaller particles can be obtained for intravenous injection.

(2) Herb extraction – using ultrasound to disperse and destroy plant tissues, accelerating the penetration of solvents through tissues, and improving the extraction rate of effective ingredients in Chinese herbal medicine. If all alkaloids in the bark of Cinchona tree are extracted using general methods, it takes more than 5 hours, and ultrasonic dispersion can be completed in only half an hour.

(3) Preparation of suspension – Under ultrasonic cavitation and strong stirring, a solid drug is dispersed in an aqueous solution containing a surfactant to form an oral or intravenous suspension of about 1 μ m. Examples include “intravenous camptothecin suspension”, “liver contrast agent”, and “barium sulfate suspension”.

(4) Preparation of vaccines – cells or bacteria are dispersed using ultrasound to kill them, and then vaccines are made using appropriate methods.

- Dispersion of Cosmetics by Ultrasound

In order to further extract the essence of drugs and refine the particles, save production costs, achieve dispersion and emulsification effects, make cosmetics penetrate deeper into the inner layer of the skin, allow the skin to absorb well, and play the efficacy and role of drugs, ultrasonic emulsification can achieve extraordinary results. By using ultrasonic dispersion, wax and paraffin emulsions, makeup water, and other oil particles can be dispersed without the use of emulsifiers. The particle diameter of paraffin dispersed in water can reach below 1um.

- Ultrasound technology for alcoholization and aging of wine

A bottle of fine wine is favored for its mellow taste, soft texture, and rich aroma. People often use aged wine to describe the preciousness of wine. A bottle of aged wine from the last century is priced at tens of thousands of yuan, and the meaning of its price lies in the storage of time. The main controlling factor of alcohol is chemical changes, namely the formation of acids and further esterification, where esters participate in the association of ethanol and water. Freshly produced wine contains a strong and spicy taste, which takes a long time to resolve. This slow change is called alcohol aging. Ultrasonic treatment with a power of 1.6KW and a frequency of 17.5-22KHZ for 5-10 minutes can shorten the aging time of wine by 1/3 to 1/2.

- Ultrasonic treatment of silicon scale

Therefore, ultrasonic cell pulverizers can and have been widely used in teaching, research, and production in fields such as biochemistry, microbiology, pharmacology, physics, zoology, agriculture, medicine, and pharmaceuticals.

In the production of waste paper deinked pulp, in order to ensure the final quality of the pulp and finished paper, as well as the papermaking requirements of the paper machine, there are strict requirements for the removal rate of adhesive and the residual rate of ink particles. Therefore, most deinked production lines use thermal dispersion equipment to decompose larger adhesive into small particles that cannot be seen by the naked eye and completely remove ink particles that have not completely separated from the fibers to ensure the quality of the pulp. In order to better improve the quality of pulp, especially the whiteness, most waste paper production lines add chemicals such as hydrogen peroxide (bleach), sodium hydroxide, sodium silicate (stabilizer), EDTA, etc. before thermal dispersion, in order to achieve the goal of high-temperature and high concentration bleaching through the mixing effect of thermal dispersion.

| Type | Power (w) | Output Amplitude | Available Converter |

| PU-100UP | 100 | 1/8″3/16″1/4″ | 100ul~80ml 1%~99% |

| PU-150UP | 150 | 1/8″3/16″1/4″ | 100ul~100ml 1%~99% |

| PU-250UP | 250 | 1/8″3/16″1/4″ | 100ul~200ml 1%~99% |

| PU-500UP | 500 | 1/8″3/16″1/4″1/2″ | 250ul~500ml 1%~99% |

| PU-800UP | 800 | 1/8″3/16″1/4″1/2″3/4″ | 250ul~800ml 1%~99% |

Ultrasonic Cell Disruptor Laboratory Homogenizer Disruptor Crusher Mixer Machine

标签:Ultrasonic Cell Disruptor Laboratory Homogenizer Disruptor

Send Inquiry

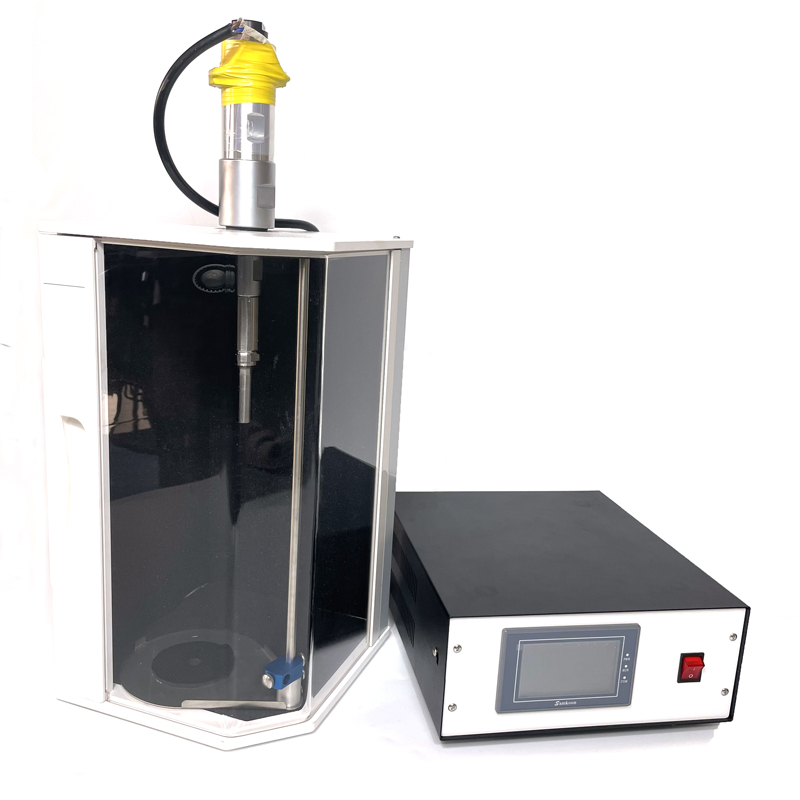

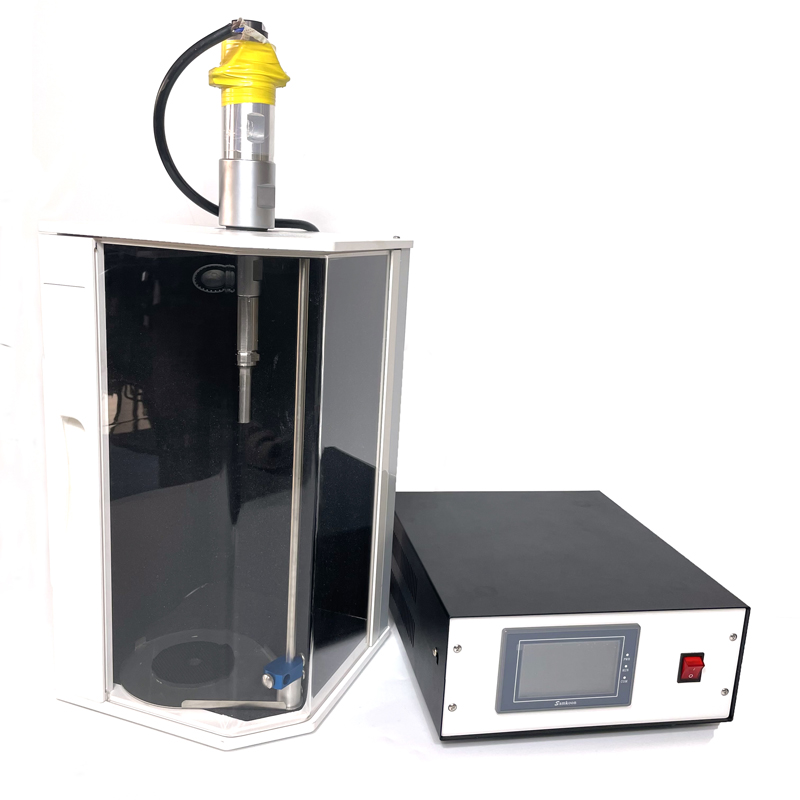

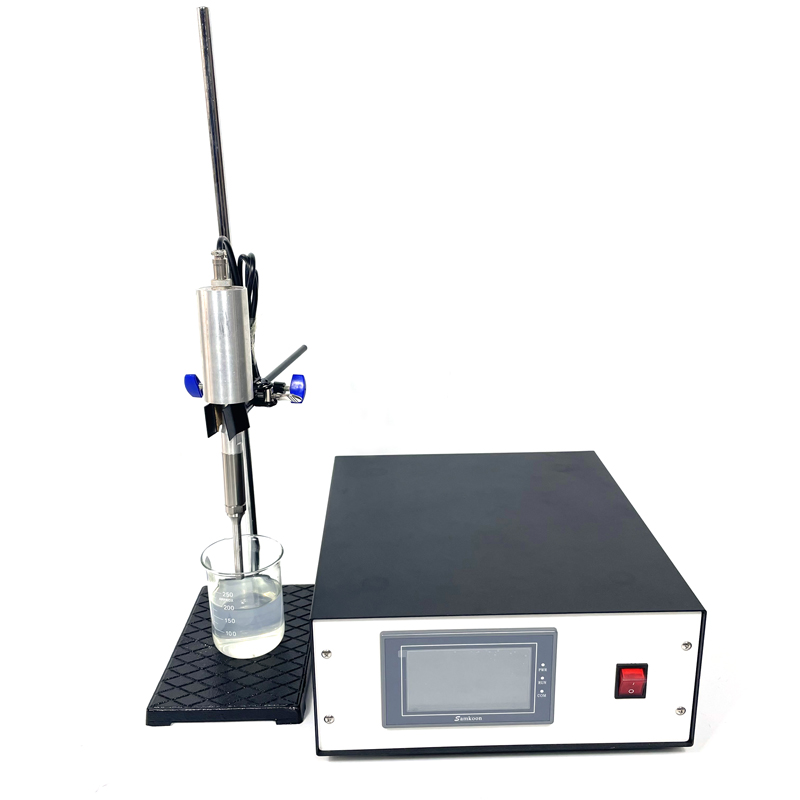

2000W Ultrasonic Cell Crusher Ultrasonic Homogenizers Nano Emulsifier Mixing Machine Cell Disruptor

2000W Ultrasonic Cell Crusher Ultrasonic Homogenizers Nano Emulsifier Mixing Machine Cell Disruptor Lab Ultrasonic Homogenizer Sonicator Industrial Liquid Mixer Mixing Powder Mixing Raw Material

Lab Ultrasonic Homogenizer Sonicator Industrial Liquid Mixer Mixing Powder Mixing Raw Material Digital Ultrasonic Liquid Processor Nanoparticle Probe Homogenizer Sonicator Cell Disruptor

Digital Ultrasonic Liquid Processor Nanoparticle Probe Homogenizer Sonicator Cell Disruptor Bench-Scale Ultrasonic Liquid Processor 3000W Ultrasonic Continuous Liquid Processor Sonochemistry

Bench-Scale Ultrasonic Liquid Processor 3000W Ultrasonic Continuous Liquid Processor Sonochemistry Ultrasonic Liquid Biodiesel Processor Cell Disruptor Homogenizer Rod Vibrator Homogenizer Sonicator

Ultrasonic Liquid Biodiesel Processor Cell Disruptor Homogenizer Rod Vibrator Homogenizer Sonicator Liquid Processor Ultrasonic Sonicator Cell Homogenizer Sonicator Sonochemistry Processor

Liquid Processor Ultrasonic Sonicator Cell Homogenizer Sonicator Sonochemistry Processor 500W 20KHZ Probe Ultrasonic Sonicator Cell Disruption Instruments Herbal Extract

500W 20KHZ Probe Ultrasonic Sonicator Cell Disruption Instruments Herbal Extract Sonicator 20K 2000W Laboratory Ultrasonic Cell Disruptor Homogenizer Rod Vibrator Medical Bioactive Compounds cell Disruption

Sonicator 20K 2000W Laboratory Ultrasonic Cell Disruptor Homogenizer Rod Vibrator Medical Bioactive Compounds cell Disruption Ultrasound Nano Material Dispersion Instrument Ultrasonic Homogenizer And Ultrasonic Emulsification Device Probe Sonicator

Ultrasound Nano Material Dispersion Instrument Ultrasonic Homogenizer And Ultrasonic Emulsification Device Probe Sonicator 20k 1000w Industrial Ultrasonic Homogenizer Dispersion Ultrasonic Liquid Processor

20k 1000w Industrial Ultrasonic Homogenizer Dispersion Ultrasonic Liquid Processor Lab Ultrasonic Cell Homogenizer Disruptor Crusher Lab Bench Top Ultrasonic Material Mixer Machine Cell Crusher

Lab Ultrasonic Cell Homogenizer Disruptor Crusher Lab Bench Top Ultrasonic Material Mixer Machine Cell Crusher LCD Display Ultrasonic Cell Disruptor Ultrasound Homogenizer Sonicator Laboratory Homogenizer Disruptor Crusher Mixer Machine

LCD Display Ultrasonic Cell Disruptor Ultrasound Homogenizer Sonicator Laboratory Homogenizer Disruptor Crusher Mixer Machine