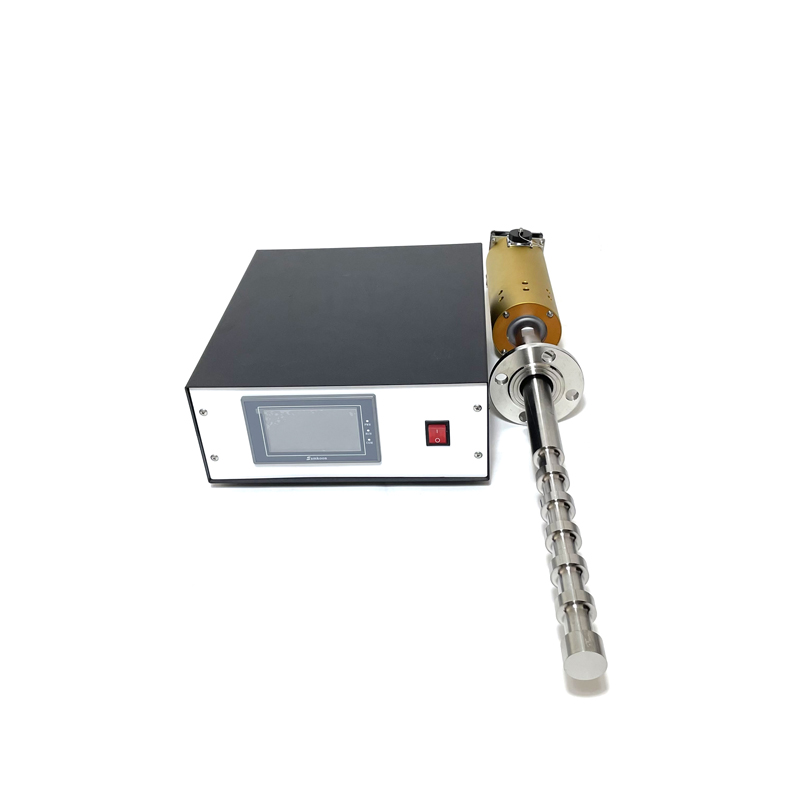

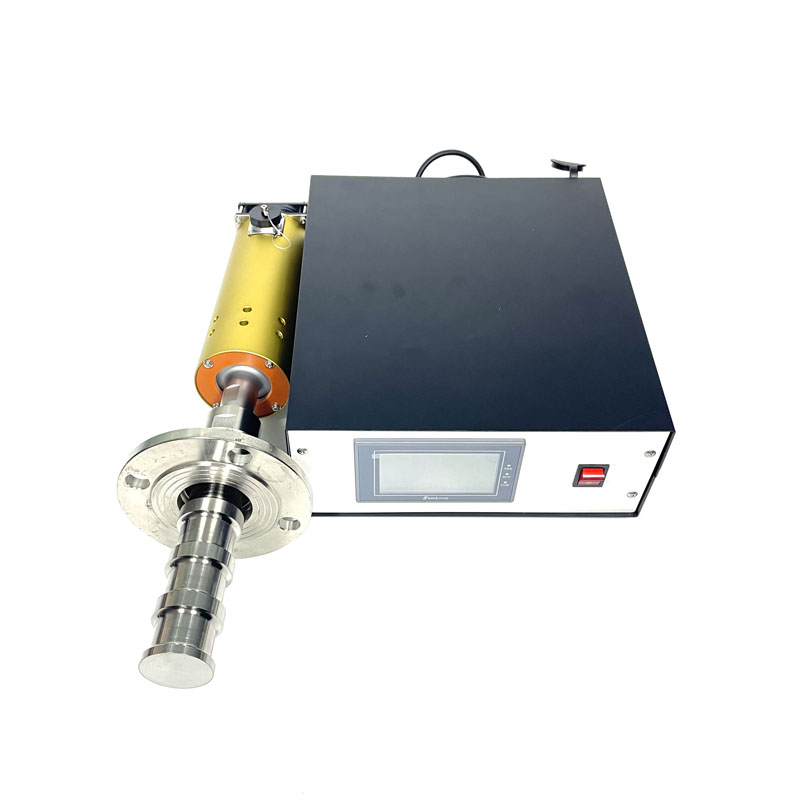

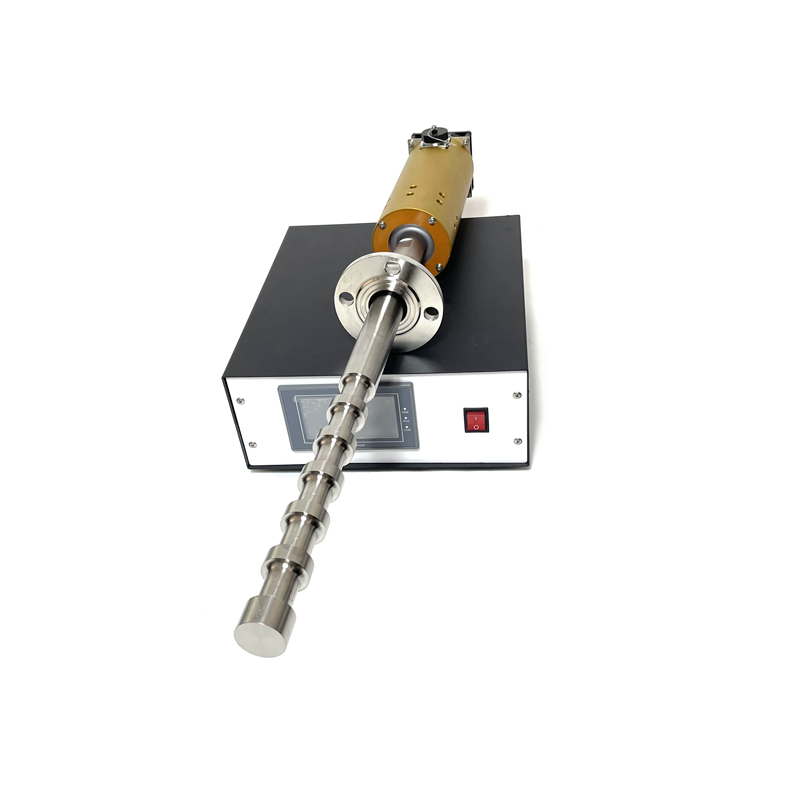

Ultrasonic Biodiesel Reactor Lab Emulsifying Machine Small Lab Mixing Equipment For Nanoemulsion

Using the ultrasonic stripping method, when the ultrasonic extraction of graphene dispersion stripping vibration rod equipment propagates in the liquid, high-frequency oscillation occurs in the graphite slurry, and cavitation bubbles form in the liquid phase. Due to the much larger size of graphite compared to cavita…

Ultrasonic Biodiesel Reactor Lab Emulsifying Machine Small Lab Mixing Equipment For Nanoemulsion

Using the ultrasonic stripping method, when the ultrasonic extraction of graphene dispersion stripping vibration rod equipment propagates in the liquid, high-frequency oscillation occurs in the graphite slurry, and cavitation bubbles form in the liquid phase. Due to the much larger size of graphite compared to cavitation bubbles, the collapse of cavitation bubbles near graphite is asymmetric, resulting in high-speed micro jets directed towards the surface of graphite, causing local damage to its surface. High frequency ultrasound causes high-frequency oscillation of the graphite slurry, and due to the difference in oscillation frequency, multiple layers are formed in the container, continuously peeling the graphite into graphene.

When graphene is matched with the surface of organic solvents, their interaction can balance the energy required to peel off graphene sheets. Then, through ultrasonic treatment, the ultrasonic extraction of graphene disperses and peels off the vibrating rod equipment to provide peeling force, achieving peeling effect. Increasing ultrasonic time can effectively improve graphene yield. Adjusting the ultrasonic power of the ultrasonic power supply also has a significant impact on the peeling effect of graphene. The peeling effect of graphene depends on the matching degree between the ultrasonic power and the van der Waals force between graphene layers. When the ultrasonic power is appropriately increased, the tensile stress generated on the surface of graphene is greater than the van der Waals force between graphene layers, and the peeling effect will also significantly increase.

Application field of ultrasonic extraction of graphene dispersion peeling vibration rod equipment

Dispersion, homogenization of materials such as graphene and carbon nanotubes, disintegration, emulsification, homogenization, and fragmentation of particles such as soil, rock samples, non-ferrous metals, and rare earths.

| Tubular EquipmentType | Tubular TransducerType | Frequency(KHz) | UltrasoundOutput(W) | Total Length(mm) | Diameter(mm) | Static Capacity(pF±10%) |

| PU-UE1 | US-61 | 15-28 | 1000 | 500 | Φ50-55 | 68000 |

| PU-UE5 | US-25 | 15-28 | 1500 | 850 | Φ50-55 | 68000 |

| PU-UE6 | US-16 | 15-28 | 2000 | 1100 | Φ50-55 | 132000 |

Ultrasonic Biodiesel Reactor Lab Emulsifying Machine Small Lab Mixing Equipment For Nanoemulsion

标签:Small Lab Mixing Equipment For Nanoemulsion, Ultrasonic Biodiesel Reactor Lab Emulsifying Machine

Send Inquiry

Titanium Alloy 1000watt Ultrasonic Extraction Equipment For Plant Essential Oil Sonochemistry Biodiesel Reactor Disperser

Titanium Alloy 1000watt Ultrasonic Extraction Equipment For Plant Essential Oil Sonochemistry Biodiesel Reactor Disperser Ultrasonic Liquid Processor Ultrasonic Emulsifier Machine Homogenizer Chemicals With Signal Generator

Ultrasonic Liquid Processor Ultrasonic Emulsifier Machine Homogenizer Chemicals With Signal Generator 2000W 3000W 50L Vacuum Jacketed Glass Emulsifier Mixing Stirred Ultrasonic Homogenizer Reactor With Lcd Display Generator

2000W 3000W 50L Vacuum Jacketed Glass Emulsifier Mixing Stirred Ultrasonic Homogenizer Reactor With Lcd Display Generator Industrial Extractor Extraction Equipment Laboratory Ultrasonic Liquid Sonochemistry Processor Reactor

Industrial Extractor Extraction Equipment Laboratory Ultrasonic Liquid Sonochemistry Processor Reactor 3000W Ultrasonic Tubular Transducer Submersible Cleaner Vibration Rods For Biodiesel Refining Mixed Emulsification

3000W Ultrasonic Tubular Transducer Submersible Cleaner Vibration Rods For Biodiesel Refining Mixed Emulsification Ultrasonic Lab Homogenizer Herbal Extraction Machine Liquid Sonochemistry Processor Ultrasound Cell Disruption Equipment

Ultrasonic Lab Homogenizer Herbal Extraction Machine Liquid Sonochemistry Processor Ultrasound Cell Disruption Equipment Small Herb Extraction Equipment Ultrasonic Solvent Extraction And Concentrate Machine

Small Herb Extraction Equipment Ultrasonic Solvent Extraction And Concentrate Machine Lab Ultrasonic Sonochemistry Ultrasonic Crystallization Jacketed Double Layer Glass Reactor

Lab Ultrasonic Sonochemistry Ultrasonic Crystallization Jacketed Double Layer Glass Reactor Industrial Ultrasonic Nano Dispersing Machine Ultrasonic Homogenize Emulsify System With Signal Generator

Industrial Ultrasonic Nano Dispersing Machine Ultrasonic Homogenize Emulsify System With Signal Generator Ultrasonic Liquid Machine Mixer Biodiesel Mixer Reactor Nano Shampoo Mixing Machine Mixer

Ultrasonic Liquid Machine Mixer Biodiesel Mixer Reactor Nano Shampoo Mixing Machine Mixer 1000W 20KHZ Industrial Ultrasonic Emulsifier Biodiesel Processor Reactor

1000W 20KHZ Industrial Ultrasonic Emulsifier Biodiesel Processor Reactor Industrial Sonochemistry Extraction Equipment Ultrasonic Extractor Industrial Ultrasonic Liquid Sonochemistry Processor

Industrial Sonochemistry Extraction Equipment Ultrasonic Extractor Industrial Ultrasonic Liquid Sonochemistry Processor