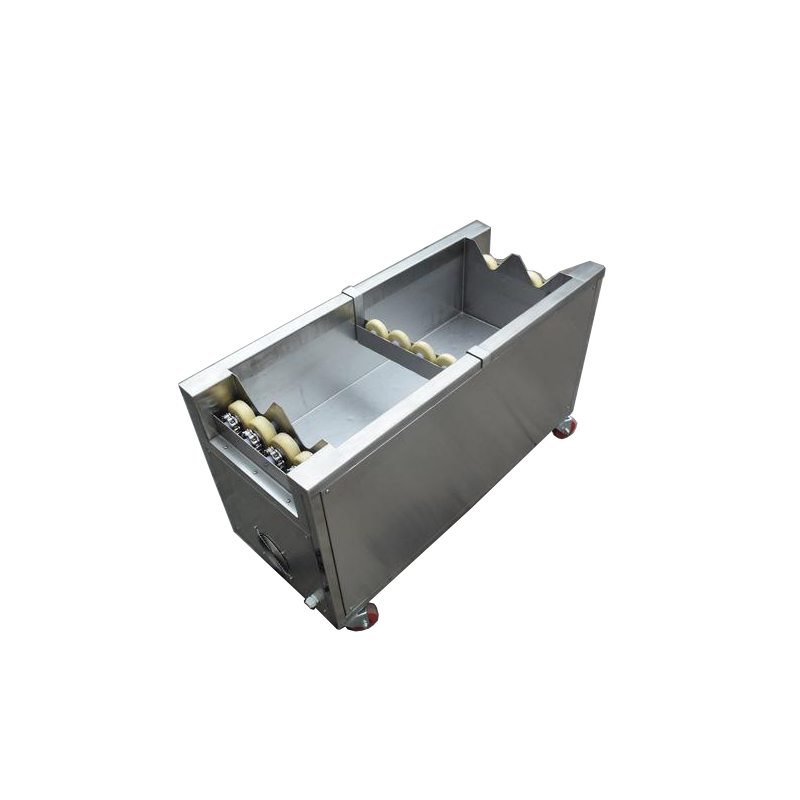

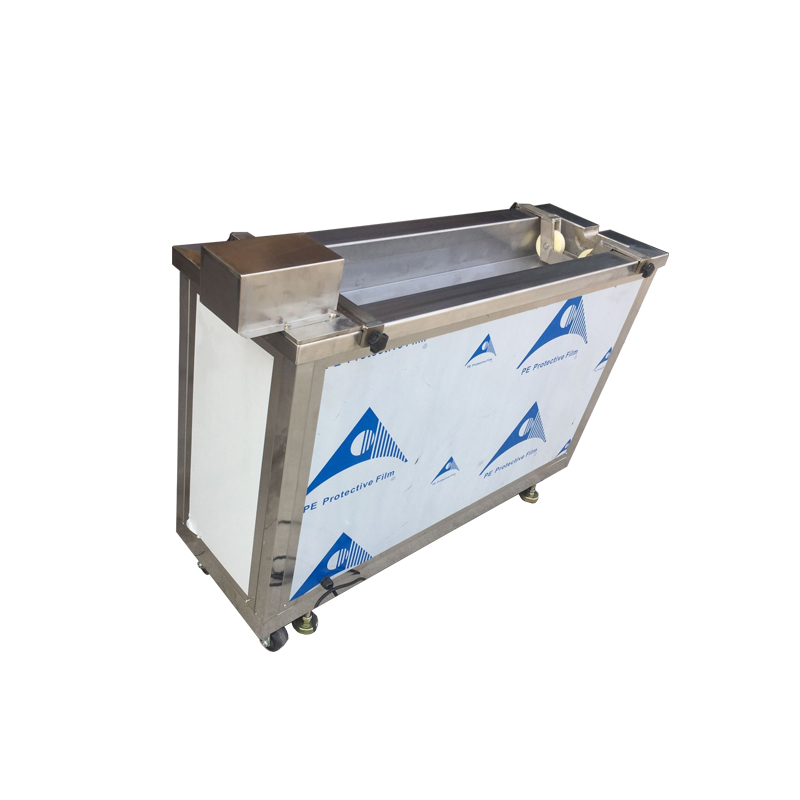

Ultrasonic Anilox Roller Cleaning Machine for Printing Industry With 40khz Frequency Ultrasonic Generator

Although there are many other cleaning methods for the anilox roller, such as using caustic soda or strong alkali for heating cleaning, high-pressure air sandblasting, or direct spray cleaning with baking soda powder, currently using ultrasonic cleaning machines is relatively safe and effective. The three cleaning me…

Although there are many other cleaning methods for the anilox roller, such as using caustic soda or strong alkali for heating cleaning, high-pressure air sandblasting, or direct spray cleaning with baking soda powder, currently using ultrasonic cleaning machines is relatively safe and effective. The three cleaning methods are compared as follows:

1) Caustic soda or heating cleaning, which belongs to pure chemical action, has the advantage of low cost, but is not suitable for metal anilox roller corrosion; Although ceramics have a certain degree of corrosion resistance to strong alkali, during the heating process, the metal base rod of the anilox roller expands due to heat, which can easily cause cracks in the outer layer of the ceramic. Long term use of strong alkali can also damage the ceramic.

2) High pressure air sandblasting or baking soda dry powder direct spray cleaning belongs to pure physical impact on the surface of the anilox roller. There are uneven particles of sand or powder that cannot enter the depth of the mesh hole, and it is difficult to thoroughly clean the anilox roller with high wire count; Moreover, the direct high-pressure spray can easily collapse the mesh wall of the anilox roller after long-term use.

3) Using an ultrasonic cleaning machine is a combination of chemistry and physics. Fine bubbles can directly enter the mesh cavity, which can clean high wire count anilox rollers; The cleaning fluid is neutral or slightly weak alkali, and the impact force of water bubbles generated by ultrasound is very small, making it relatively unlikely to damage the anilox roller.

Send Inquiry

Printing Ultrasonic Anilox Roller Cleaning Machine And Digital Ultrasonic Generator

Printing Ultrasonic Anilox Roller Cleaning Machine And Digital Ultrasonic Generator 3000W Ultrasonic Metal Ceramic Anilox Roller Roll Surface Cleaner Machine

3000W Ultrasonic Metal Ceramic Anilox Roller Roll Surface Cleaner Machine Automatic Anilox Roll Ultrasonic Cleaning Machine Customized Single Tank Industrial Ultrasonic Cleaner

Automatic Anilox Roll Ultrasonic Cleaning Machine Customized Single Tank Industrial Ultrasonic Cleaner Customized Wholesale Auto Save Setting Parameters Anilox Roller Washing Machine Ultrasonic Cleaning Equipment

Customized Wholesale Auto Save Setting Parameters Anilox Roller Washing Machine Ultrasonic Cleaning Equipment Ceramic Anilox Roller Laser Engraved Flexography Ceramic Anilox Roller Ultrasonic Cleaning Machine

Ceramic Anilox Roller Laser Engraved Flexography Ceramic Anilox Roller Ultrasonic Cleaning Machine Rotation Clean Ink Glue Oil Anilox Roller Industrial Ultrasonic Cleaning Machine Ultrasonic Cleaner

Rotation Clean Ink Glue Oil Anilox Roller Industrial Ultrasonic Cleaning Machine Ultrasonic Cleaner 1500W 40KHZ Anilox Roller Ultrasonic Washing Cleaning Machine With Transducer Generator

1500W 40KHZ Anilox Roller Ultrasonic Washing Cleaning Machine With Transducer Generator Anilox Rolls and Sleeves Flexo Printing Ultrasonic Cleaner And Ultrasonic Generator

Anilox Rolls and Sleeves Flexo Printing Ultrasonic Cleaner And Ultrasonic Generator Sonic Solutions Ultrasonic Anilox Roll Cleaners And Digital Ultrasonic Generator

Sonic Solutions Ultrasonic Anilox Roll Cleaners And Digital Ultrasonic Generator Ultrasonic Anilox Roll and Sleeve Cleaning Flexo Printing Ultrasonic Cleaning Machine

Ultrasonic Anilox Roll and Sleeve Cleaning Flexo Printing Ultrasonic Cleaning Machine Printing Rollers And Anilox Ultrasonic Cleaning Nachine And Digital Ultrasonic Generator

Printing Rollers And Anilox Ultrasonic Cleaning Nachine And Digital Ultrasonic Generator Multi Four Roll Ultrasonic Cleaner Ceramic Anilox Roll Cleaning Systems With Ultrasonic Power Generator

Multi Four Roll Ultrasonic Cleaner Ceramic Anilox Roll Cleaning Systems With Ultrasonic Power Generator