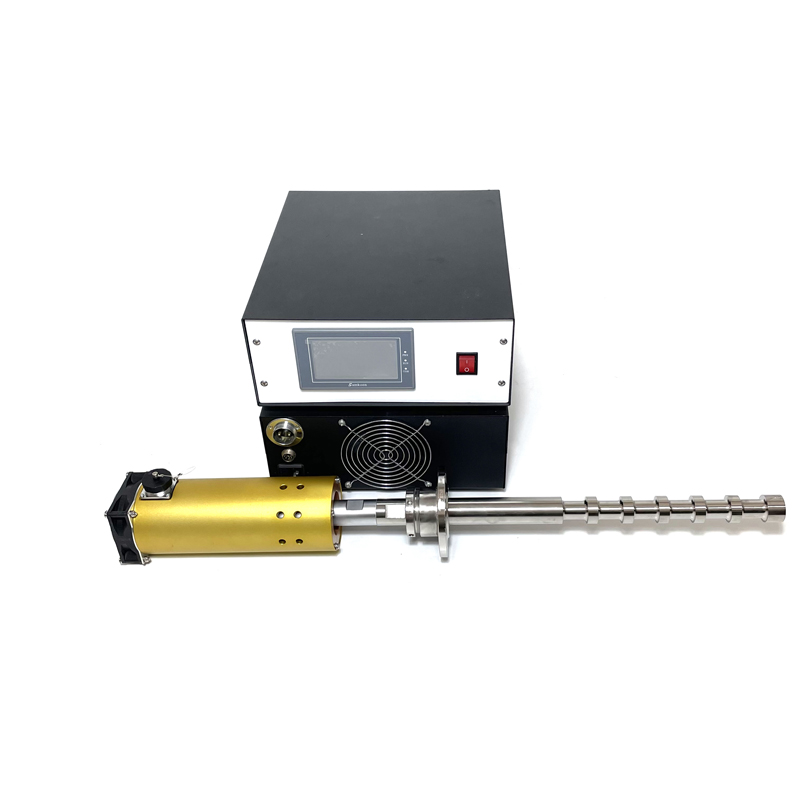

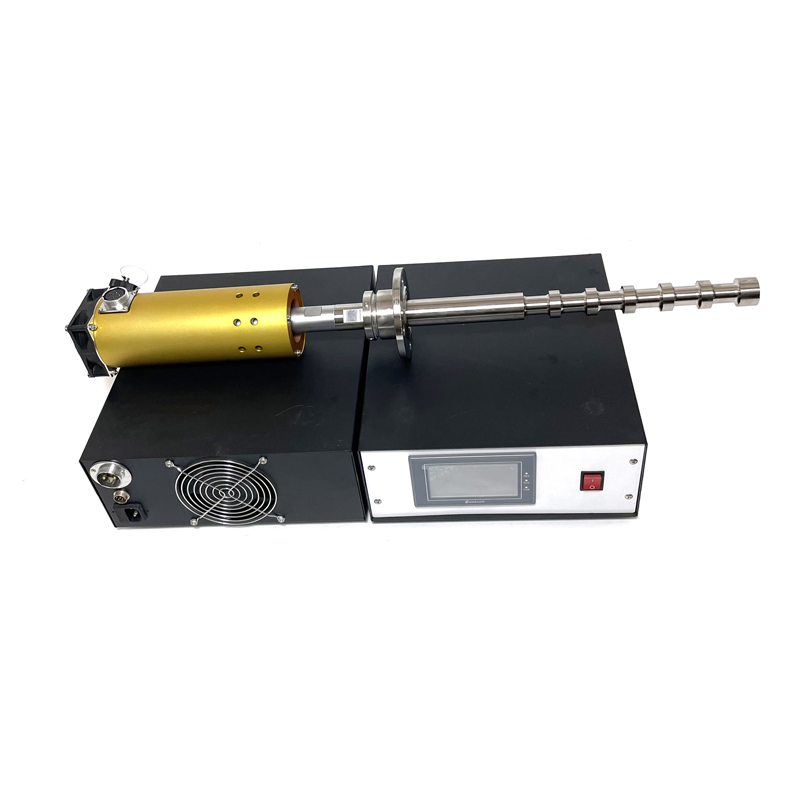

Small Herb Extraction Equipment/Ultrasonic Solvent Extraction and Concentrate Machine

Ultrasonic vibration rods, also known as ultrasonic vibration rods, have a wider range of applications and longer service life compared to traditional ultrasonic vibration plates. In industrial applications, the use of ultrasonic vibration rods for cleaning, extraction, chemical reactions, scale prevention, water tre…

Small Herb Extraction Equipment/Ultrasonic Solvent Extraction and Concentrate Machine

Ultrasonic vibration rods, also known as ultrasonic vibration rods, have a wider range of applications and longer service life compared to traditional ultrasonic vibration plates. In industrial applications, the use of ultrasonic vibration rods for cleaning, extraction, chemical reactions, scale prevention, water treatment, etc. is a very mature and widely used technology.

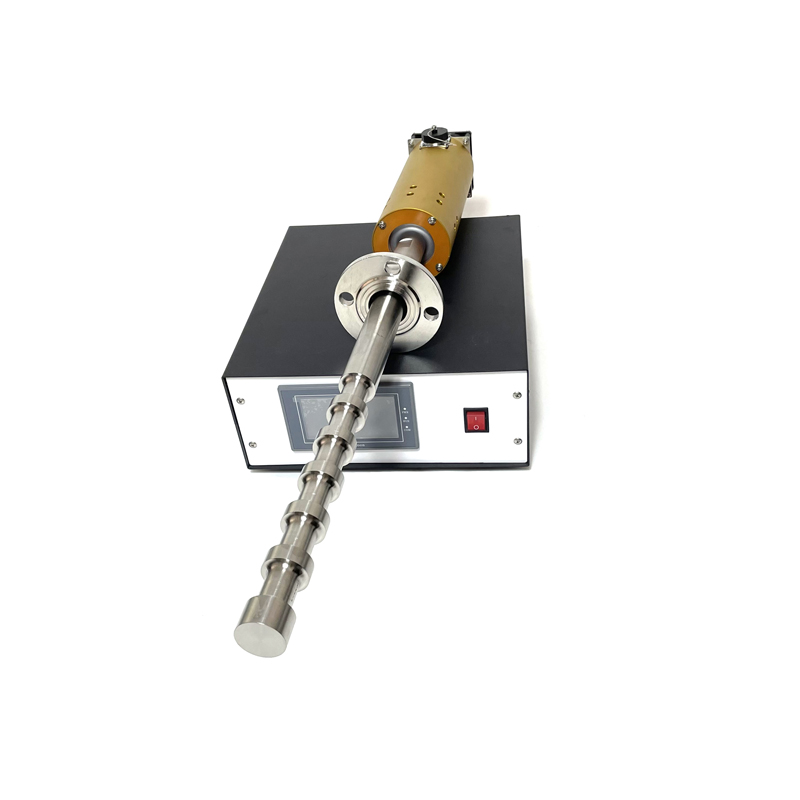

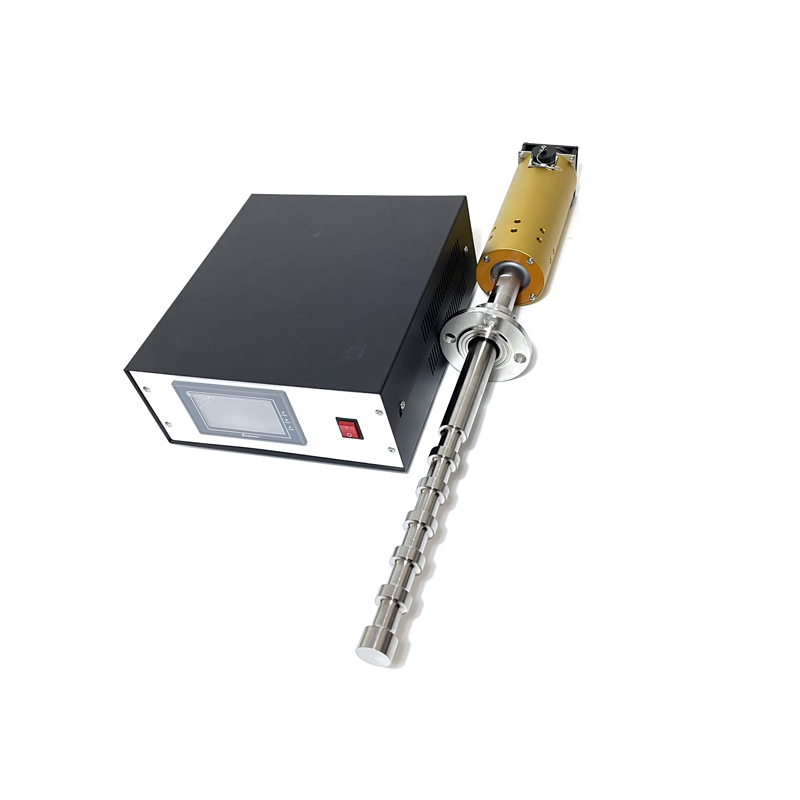

The ultrasonic vibrating rod utilizes the alternating period of positive and negative pressure during the transmission process of ultrasound, which compresses the medium molecules during the positive phase, increasing the original density of the medium; When the phase is negative, the molecules in the medium are sparse and discrete, resulting in a decrease in the density of the medium. The ultrasonic vibrating rod can uniformly generate ultrasonic waves around 360 °, and the energy output is not affected by load changes such as liquid level and temperature difference. The ultrasonic vibrating rod generally includes high-power ultrasonic transducer, amplitude transformer, tool head (transmitter), which is used to generate ultrasonic vibration and emit this vibration energy into the liquid. The transducer converts the input electrical energy into mechanical energy, which is ultrasound. Its manifestation is that the transducer moves back and forth in the longitudinal direction, with an amplitude typically of a few micrometers. This amplitude power density is not sufficient and cannot be directly used. The amplitude transformer amplifies the amplitude according to the design requirements, isolates the reaction solution and transducer, and also serves to fix the entire ultrasonic vibration system. The tool head is connected to the amplitude converter, which transmits ultrasonic energy vibration to the tool head, which then emits the ultrasonic energy into the chemical reaction liquid

The circuit adopts advanced energy-saving and environmental protection technology from Germany, and operates in full wave mode. Radial vibration generates ultrasonic waves 360 ° uniformly near the vibrating rod, and its amplitude is between the ultrasonic cleaning machine and the processor, so the direction of use is relatively flexible. Ultrasonic vibration rods can be used in any position, and occupy a small volume space, making them very flexible to use. Ultrasonic vibration rods are widely used in traditional ultrasonic pre-treatment, biochemistry, food, chemical, pharmaceutical and other industries.

In biochemistry, ultrasonic vibration rods are widely used in emulsification, separation, homogenization, extraction, catalytic reactions, and other fields to improve production capacity;

In the food industry, ultrasonic vibration rods are used for uniform mixing and play an undeniable role in homogenization;

In the chemical industry, ultrasonic vibration rods are suitable for cleaning pipelines, tanks, and kettles;

In the process of extracting biodiesel from waste oils and palm oil, the catalytic effect of ultrasound is astonishing, with an efficiency increase of more than ten times. It will have broad development prospects in the petrochemical industry, and there are currently more than 40 application cases.

| Tubular EquipmentType | Tubular TransducerType | Frequency(KHz) | UltrasoundOutput(W) | Total Length(mm) | Diameter(mm) | Static Capacity(pF±10%) |

| PU-UE1 | US-61 | 15-28 | 1000 | 500 | Φ50-55 | 68000 |

| PU-UE5 | US-25 | 15-28 | 1500 | 850 | Φ50-55 | 68000 |

| PU-UE6 | US-16 | 15-28 | 2000 | 1100 | Φ50-55 | 132000 |

Small Herb Extraction Equipment/Ultrasonic Solvent Extraction and Concentrate Machine

标签:Small Herb Extraction Equipment/Ultrasonic Solvent Extraction, Solvent Extraction and Concentrate Machine

Send Inquiry

20khz 1000W Industrial Ultrasonic Emulsifier Biodiesel Processor Reactor Sonochemistry Ultrasonic Biodiesel

20khz 1000W Industrial Ultrasonic Emulsifier Biodiesel Processor Reactor Sonochemistry Ultrasonic Biodiesel 20KHZ 500W/1000W Ultrasonic Laboratory Processors Ultrasonic Sonochemistry Homogenize Liquids

20KHZ 500W/1000W Ultrasonic Laboratory Processors Ultrasonic Sonochemistry Homogenize Liquids 2000W Ultrasonic Sonochemistry Reactor Ultrasonic Assisted Extraction Method

2000W Ultrasonic Sonochemistry Reactor Ultrasonic Assisted Extraction Method 300W 20KHZ Ultrasonic Cavitation Reactor Ultrasonic Sonochemistry Biodiesel And Sound Generator

300W 20KHZ Ultrasonic Cavitation Reactor Ultrasonic Sonochemistry Biodiesel And Sound Generator Ultrasonic Sonochemistry Cell Diffusion Emulsion Fusion Industrial Ultrasonic Sonochemical Equipment

Ultrasonic Sonochemistry Cell Diffusion Emulsion Fusion Industrial Ultrasonic Sonochemical Equipment 1000W Ultrasonic Liquid Sonochemistry Reactor And Power Generator For Ultrasonic Sonochemistry Machine

1000W Ultrasonic Liquid Sonochemistry Reactor And Power Generator For Ultrasonic Sonochemistry Machine 20KHZ 1000W Ultrasonic Tissue Extraction Machine Extractor Homogenizer Reactor

20KHZ 1000W Ultrasonic Tissue Extraction Machine Extractor Homogenizer Reactor Ultrasonic Disruption And Extraction Ultrasonic Processor Homogenizer Mixer Extraction Sonicator Dispersion

Ultrasonic Disruption And Extraction Ultrasonic Processor Homogenizer Mixer Extraction Sonicator Dispersion 20KHZ 2000W 220V Ultrasonic Sonochemistry Reactor Disperser Emulsifying Homogenizer For Hemp Oil Extraction

20KHZ 2000W 220V Ultrasonic Sonochemistry Reactor Disperser Emulsifying Homogenizer For Hemp Oil Extraction 20KHZ 2000W 220V Ultrasonic Chemical Sonochemistry Dispersed Reactor For Laboratory Industry

20KHZ 2000W 220V Ultrasonic Chemical Sonochemistry Dispersed Reactor For Laboratory Industry Ultrasonic Waterproof Coating Agent Emulsify Reactor And Ultrasonic Frequency Generator

Ultrasonic Waterproof Coating Agent Emulsify Reactor And Ultrasonic Frequency Generator Ultrasonic Extractor Homogenizer Industrial Ultrasonic Extractor Extraction Sonochemistry Reactor Liquid Sonochemistry Processor

Ultrasonic Extractor Homogenizer Industrial Ultrasonic Extractor Extraction Sonochemistry Reactor Liquid Sonochemistry Processor