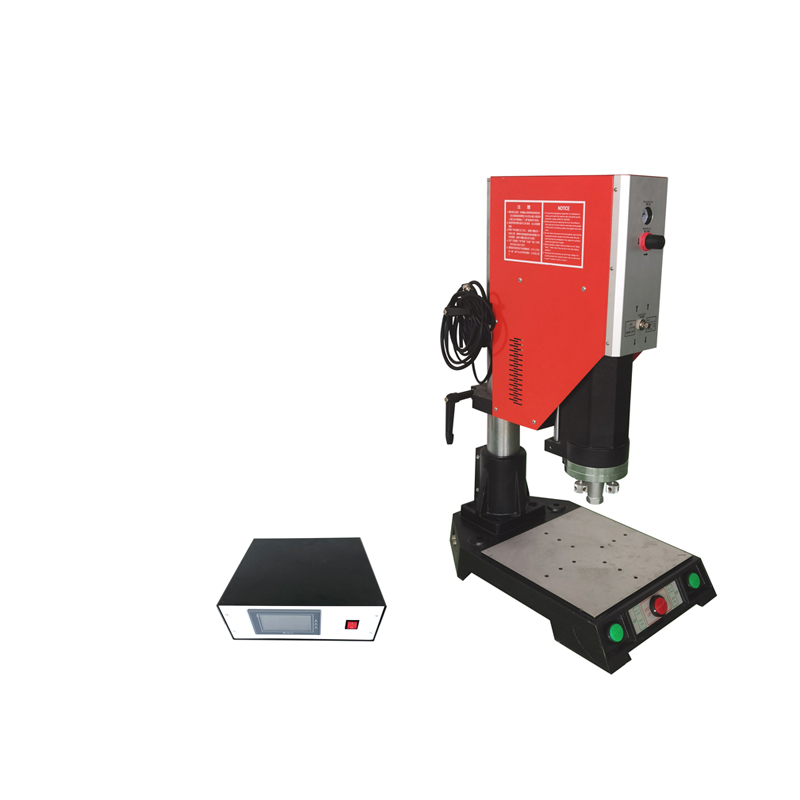

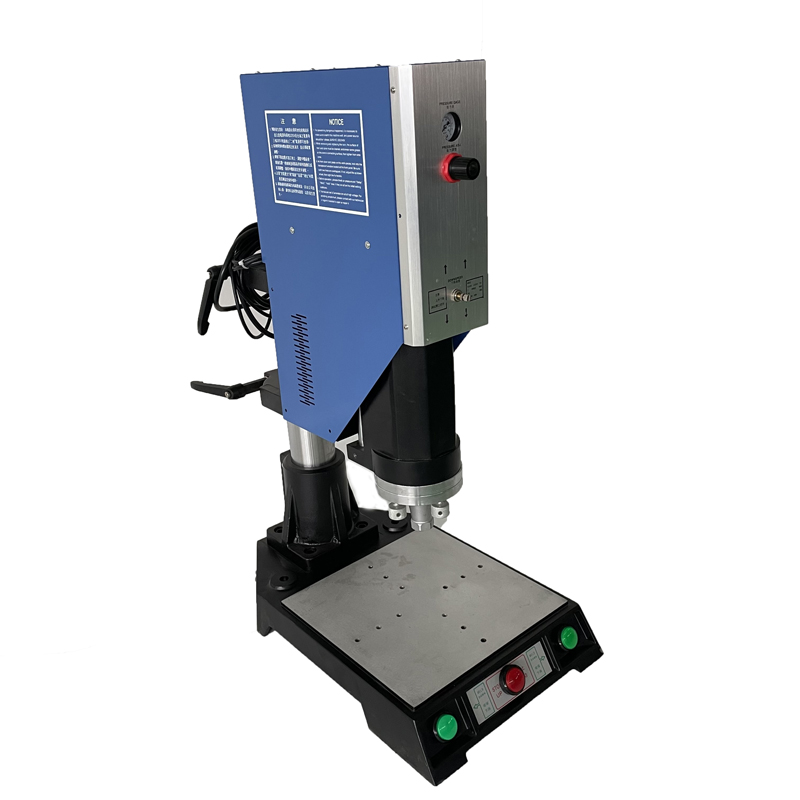

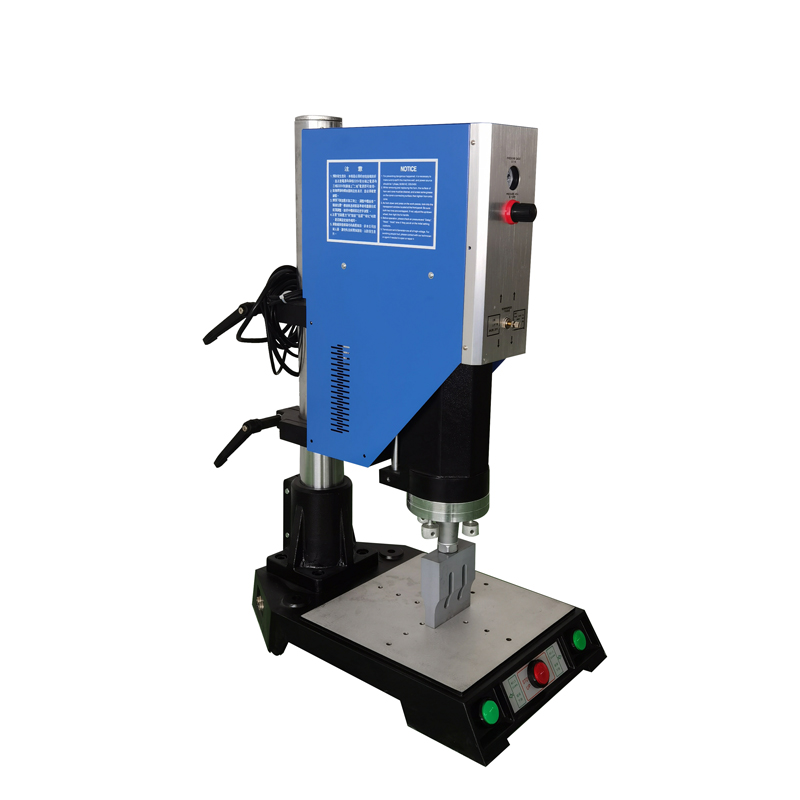

SD Card U Disk Communication Products Earphone Plastic Welder Ultrasonic Plastic Welder Machine

When our product undergoes deformation due to ultrasonic operation, it appears from the surface that it is the cause of ultrasonic fusion, but this is only a result. Any factor before the fusion of plastic products, what kind of result is formed after the fusion. If the main cause is not explored, it will consume a l…

SD Card U Disk Communication Products Earphone Plastic Welder Ultrasonic Plastic Welder Machine

When our product undergoes deformation due to ultrasonic operation, it appears from the surface that it is the cause of ultrasonic fusion, but this is only a result. Any factor before the fusion of plastic products, what kind of result is formed after the fusion. If the main cause is not explored, it will consume a lot of time in dealing with the problem of inappropriate treatment, and in ultrasonic indirect conduction fusion operations (non direct fusion), a pressure of less than 6kg cannot change the toughness and inertia of the plastic. So don’t try to use strong pressure to change the deformation before welding (the high pressure of the welding machine Z is 6kg), including forced extrusion using a mold fixture. Perhaps we will also fall into a blind spot, which is to explore the cause of deformation from the surface, that is, it cannot be seen with the naked eye before fusion, but after ultrasonic fusion is completed, it is obvious that deformation is found. The reason is that before the fusion of the product, it is difficult to detect the accumulated errors of various angles, radians, and residual materials due to the presence of the fuse wire. However, after the ultrasonic fusion is completed, it shows visible deformation to the naked eye.

| Type | Power(W) | Frequency (KHz) |

| PU-UWM600W | 600W | 15KHZ/20KHZ/28KHZ/40KHZ |

| PU-UWM900W | 900W | 15KHZ/20KHZ/28KHZ/40KHZ |

| PU-UWM1000W | 1000W | 15KHZ/20KHZ/28KHZ/30KHZ |

| PU-UWM1500W | 1500W | 15KHZ/20KHZ |

| PU-UWM1800W | 1800W | 15KHZ/20KHZ |

| PU-UWM2000W | 2000W | 15KHZ/20KHZ |

| PU-UWM2600W | 2600W | 15KHZ |

| PU-UWM3200W | 3200W | 15KHZ |

| PU-UWM4200W | 4200W | 15KHZ |

SD Card U Disk Communication Products Earphone Plastic Welder Ultrasonic Plastic Welder Machine

标签:Earphone Plastic Welder Ultrasonic Plastic Welder Machine

Send Inquiry

3200W 15KHZ Ultrasonic Sealing Welding Cutting Sponge Scouring Pad Making Machine Machine Plastic Welding

3200W 15KHZ Ultrasonic Sealing Welding Cutting Sponge Scouring Pad Making Machine Machine Plastic Welding 15K 2600W PSA Rigid Plastic Sealing Ultrasonic Grading Playing Card Slab Cases Welding Machine

15K 2600W PSA Rigid Plastic Sealing Ultrasonic Grading Playing Card Slab Cases Welding Machine PSA Clear Graded Card Slab Ultrasonic Plastic Welding Machine for Sports Grading Card Acrylic Case Sealing DNA Sonic Welder

PSA Clear Graded Card Slab Ultrasonic Plastic Welding Machine for Sports Grading Card Acrylic Case Sealing DNA Sonic Welder Plastic Cards Case Ultrasonic Welder Sealer Ultrasonic Welding Machine for PSA / DNA Sports Grading Card Slabs

Plastic Cards Case Ultrasonic Welder Sealer Ultrasonic Welding Machine for PSA / DNA Sports Grading Card Slabs 4200W Ultrasonic Plastic Welding Machine For Electronic Parts Ultrasonic Welding Equipment Big Power Ultrasonic Machine

4200W Ultrasonic Plastic Welding Machine For Electronic Parts Ultrasonic Welding Equipment Big Power Ultrasonic Machine 15khz 4200W 6000W Comic Books Transparent Plastic Welding Machine Ultrasonic Sealing Machine

15khz 4200W 6000W Comic Books Transparent Plastic Welding Machine Ultrasonic Sealing Machine NBA card Slabs PSA Card Slab Graded Trading Cards Slab 15khz Ultrasonic Welder Machine With Power Generator

NBA card Slabs PSA Card Slab Graded Trading Cards Slab 15khz Ultrasonic Welder Machine With Power Generator Ultrasonic Welding Plastic Parts ABS PVC Manufacturer Ultrasonic Welding Machine And Sound Generator

Ultrasonic Welding Plastic Parts ABS PVC Manufacturer Ultrasonic Welding Machine And Sound Generator Automatic Frequency Tracking 15K 2600W Ultrasonic Welding Machine for Plastic PSA Slabs Case ABS PP Welding Machine

Automatic Frequency Tracking 15K 2600W Ultrasonic Welding Machine for Plastic PSA Slabs Case ABS PP Welding Machine Psa Grading Card Slab Cases Sealing Ultrasonic Welding Machine For Plastic Psa Grade Welding

Psa Grading Card Slab Cases Sealing Ultrasonic Welding Machine For Plastic Psa Grade Welding Universal Plastic Cards Case Ultrasonic Welder Sealer PSA / DNA Sports Grading Card Slabs Welding Machine

Universal Plastic Cards Case Ultrasonic Welder Sealer PSA / DNA Sports Grading Card Slabs Welding Machine 2600W Welding Machine Ultrasonic Plastic Acrylic Welding Machine For Grading Card Slabs With Transducer Generator

2600W Welding Machine Ultrasonic Plastic Acrylic Welding Machine For Grading Card Slabs With Transducer Generator