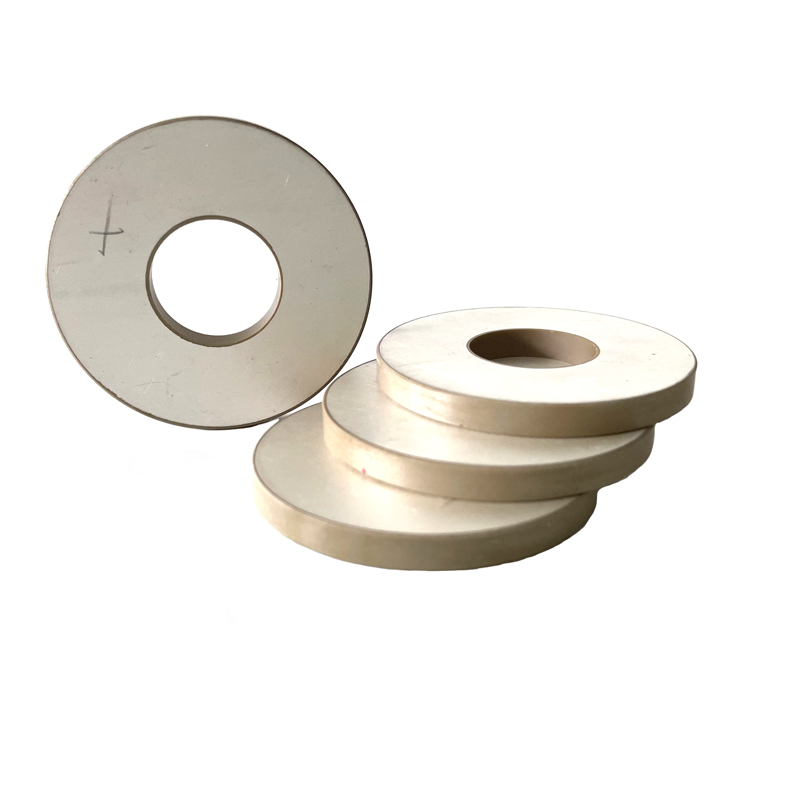

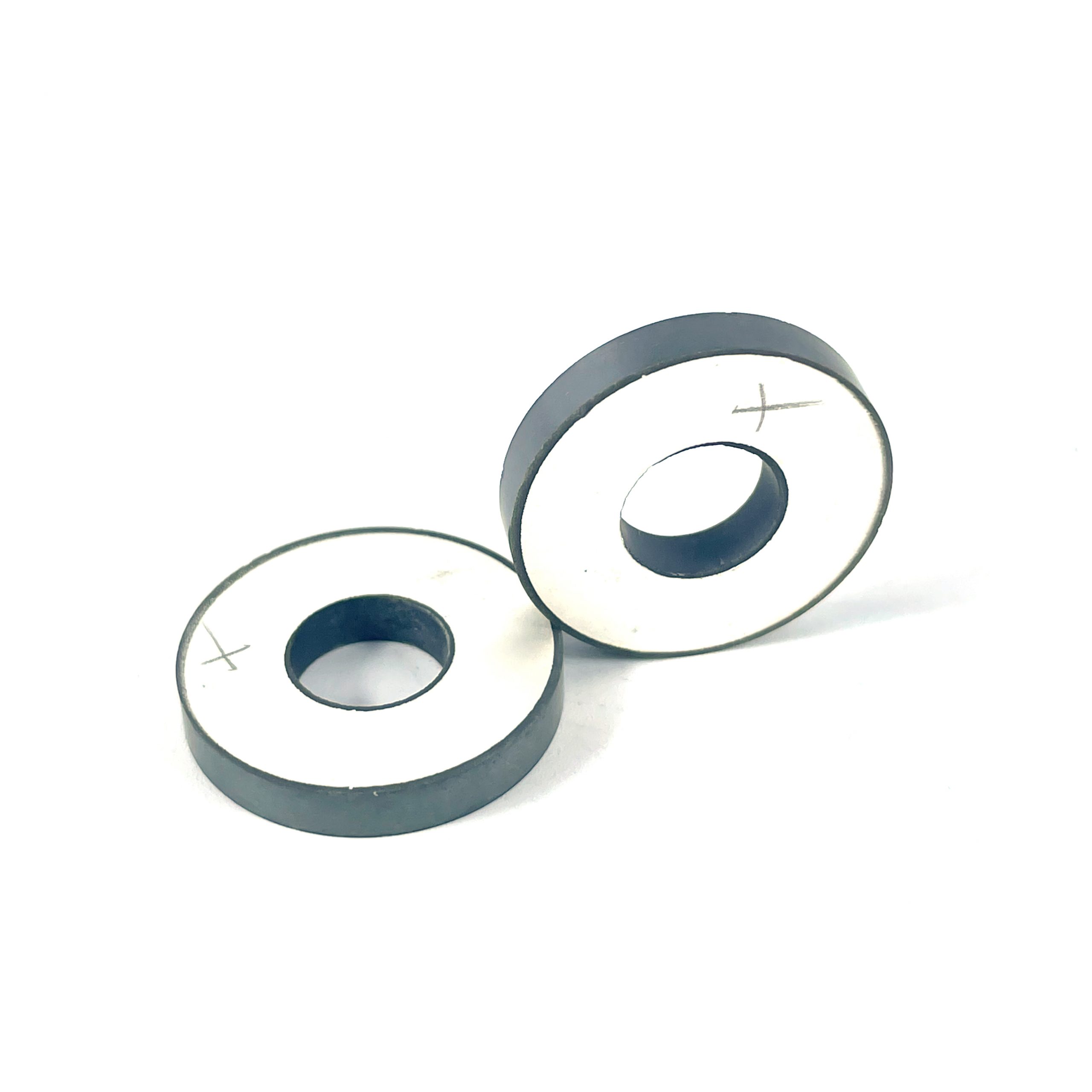

Ring Piezoelectric Ceramic Piezo Piezoelectric Ceramic Pzt Element Pzt8 Piezo Ceramic Ring Piezoelectric Transducer Piezo Sensor

Barium titanate is a ceramic material with excellent piezoelectric properties, and its crystal structure is perovskite type. In barium titanate ceramics, barium ions and titanium ions occupy the vertex and face center positions of the cube, forming a special crystal structure. This structure endows barium titanate ce…

Barium titanate is a ceramic material with excellent piezoelectric properties, and its crystal structure is perovskite type. In barium titanate ceramics, barium ions and titanium ions occupy the vertex and face center positions of the cube, forming a special crystal structure. This structure endows barium titanate ceramics with excellent piezoelectric properties, that is, they can undergo deformation and generate voltage under the action of an external electric field, and vice versa.

The preparation methods of barium titanate piezoelectric ceramic chips mainly include sol-gel method, chemical coprecipitation method, solid phase method, etc. Among them, the sol-gel method is one of the most commonly used preparation methods. The method is to dissolve barium titanate in organic solvent, and then prepare piezoelectric ceramic chips through gel, drying, sintering and other steps. The chemical co precipitation rule is to mix barium titanate precursor solution with barium salt solution, generate barium titanate precipitate through precipitation reaction, and then prepare piezoelectric ceramic sheets through drying, sintering and other steps. The solid-state method involves mixing barium titanate powder with an appropriate amount of sintering aids, and then preparing piezoelectric ceramic sheets through steps such as pressing and sintering.

| spec | Dimension (mm) | Radial frequency (KHz) | Capacitance (pf) | Dielectric dissipation factor tanδ(%) | Electromechanical coupling coefficient (Kr) | Impedance Zr(Ω) | Thickness frequency (KHz) |

| PU-PC25103 | Φ25×Φ10×3 | 66.4 | 1240±12.5% | ≤0.3 | ≥0.46 | ≤15 | 683±5% |

| PU-PC225104 | Φ25×Φ10×4 | 66.4 | 930±12.5% | ≤0.3 | ≥0.46 | ≤15 | 512±5% |

| PU-PC40155 | Φ40×Φ12×5 | 45.9 | 2070±12.5% | ≤0.3 | ≥0.46 | ≤15 | 410±5% |

| PU-PC40155 | Φ40×Φ15×5 | 42.2 | 1960±12.5% | ≤0.3 | ≥0.46 | ≤15 | 323±5% |

| PU-PC40176 | Φ40×Φ17×6 | 40.5 | 1555±12.5% | ≤0.3 | ≥0.46 | ≤15 | 341±5% |

| PU-PC40205 | Φ40×Φ20×5 | 37.9 | 1700±12.5% | ≤0.3 | ≥0.47 | ≤15 | 410±5% |

| PU-PC50206 | Φ50×Φ20×6 | 33.2 | 2490±12.5% | ≤0.3 | ≥0.46 | ≤15 | 341±5% |

| PU-PC501765 | Φ50×Φ17×6.5 | 34.8 | 2430±12.5% | ≤0.3 | ≥0.46 | ≤15 | 315±5% |

| PU-PC50236 | Φ50×Φ23×6 | 31.2 | 2340±12.5% | ≤0.3 | ≥0.47 | ≤15 | 341±5% |

| PU-PC50276 | Φ50×Φ27×6 | 29.3 | 2100±12.5% | ≤0.3 | ≥0.47 | ≤15 | 341±5% |

| PU-PC603010 | Φ60×Φ30×10 | 25.3 | 1922±12.5% | ≤0.3 | ≥0.47 | ≤18 | 205±5% |

Send Inquiry

Pzt4 Pzt8 Piezo Element Piezo Ceramic Ring 40*20*5mm PZT8 Material Ceramic Element Piezo Cylinder

Pzt4 Pzt8 Piezo Element Piezo Ceramic Ring 40*20*5mm PZT8 Material Ceramic Element Piezo Cylinder 70*30*10mm Pzt8 Ring Piezoceramic Cylinder Piezoelectric Ceramic Ring Elements

70*30*10mm Pzt8 Ring Piezoceramic Cylinder Piezoelectric Ceramic Ring Elements PZT 4 Material Piezoelectric Sensor Ultrasonic Ceramic Ring Hemisphere Element Piezo Ceramic Material Disc

PZT 4 Material Piezoelectric Sensor Ultrasonic Ceramic Ring Hemisphere Element Piezo Ceramic Material Disc 50x17x6.5mm Piezoceramic Rings Piezoelectric Elements PZT82 Material For Ultrasonic Welding Transducer

50x17x6.5mm Piezoceramic Rings Piezoelectric Elements PZT82 Material For Ultrasonic Welding Transducer 35*15*5mm PZT-8/PZT-4 Piezoelectric Ceramic Ring For 50W 28khz/40khz Ultrasonic Cleaning Machine Transducer

35*15*5mm PZT-8/PZT-4 Piezoelectric Ceramic Ring For 50W 28khz/40khz Ultrasonic Cleaning Machine Transducer 50*20*6mm Piezo Ceramic Ring PZT Electronic Ceramic Ring Piezoelectric Ceramic

50*20*6mm Piezo Ceramic Ring PZT Electronic Ceramic Ring Piezoelectric Ceramic Piezo Ring PZT8 60*30*10mm Piezo Ultrasonic Transducer For Welding Ultrasonic Welding For Mask Machine

Piezo Ring PZT8 60*30*10mm Piezo Ultrasonic Transducer For Welding Ultrasonic Welding For Mask Machine Piezoelectric Ceramic Element 60*30*10 Customized Ultrasonic Welding Ring Piezoelectric Ceramic

Piezoelectric Ceramic Element 60*30*10 Customized Ultrasonic Welding Ring Piezoelectric Ceramic PZT4 PZT5 PZT8 Ultrasonic Piezoelectric Ceramic Disc piezo ceramic plate piezoceramics

PZT4 PZT5 PZT8 Ultrasonic Piezoelectric Ceramic Disc piezo ceramic plate piezoceramics 50*20*5mm PZT-8 Piezoelectric Ceramic Ring For 2000W 20khz/15khz High Power Ultrasonic Transducer

50*20*5mm PZT-8 Piezoelectric Ceramic Ring For 2000W 20khz/15khz High Power Ultrasonic Transducer Ring Piezo Ceramic Crystal 16mm*7.8mm Piezo PZT Ceramic Piezoelectric Ceramic Element

Ring Piezo Ceramic Crystal 16mm*7.8mm Piezo PZT Ceramic Piezoelectric Ceramic Element 15x6x3mm P4 PZT High Power Vibrating Transducer Ultrasonic Piezoelectric Ceramics Ring Piezoelectric Ceramic Element

15x6x3mm P4 PZT High Power Vibrating Transducer Ultrasonic Piezoelectric Ceramics Ring Piezoelectric Ceramic Element