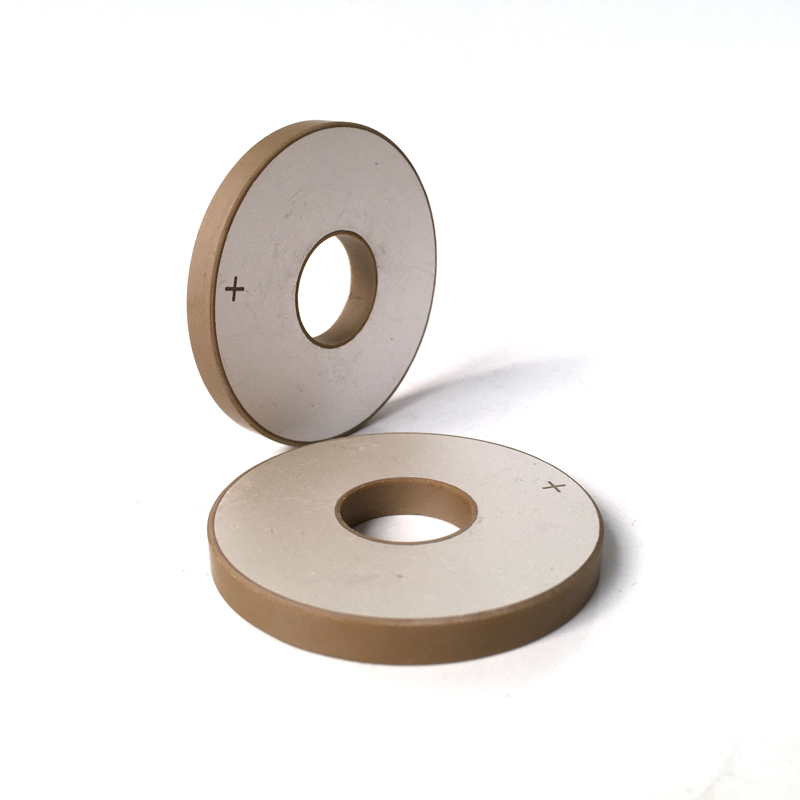

PZT8 Piezo Disk Element Discs Cleaning Welding Piezoelectric Ceramic Chip Ring

Piezoelectric ceramic transformers utilize the piezoelectric effect of polarized piezoelectric materials to achieve voltage output. The input part is driven by a sinusoidal voltage signal, which generates vibration through the inverse piezoelectric effect. The vibration wave is mechanically coupled to the output part…

PZT8 Piezo Disk Element Discs Cleaning Welding Piezoelectric Ceramic Chip Ring

Piezoelectric ceramic transformers utilize the piezoelectric effect of polarized piezoelectric materials to achieve voltage output. The input part is driven by a sinusoidal voltage signal, which generates vibration through the inverse piezoelectric effect. The vibration wave is mechanically coupled to the output part through the input and output parts, and the output part generates charges through the positive piezoelectric effect, achieving two transformations of the piezoelectric body’s electrical energy mechanical energy electrical energy, and obtaining the highest output voltage at the resonant frequency of the piezoelectric transformer. Compared with electromagnetic transformers, this has the advantages of small size, light weight, high power density, high efficiency, resistance to breakdown, high temperature, no fear of combustion, no electromagnetic interference and noise, simple structure, easy production, and mass production. In some fields, it has become an ideal replacement component for electromagnetic transformers. This type of transformer is used for switch converters, laptops, neon light drivers, etc.

| spec | Dimension (mm) | Radial frequency (KHz) | Capacitance (pf) | Dielectric dissipation factor tanδ(%) | Electromechanical coupling coefficient (Kr) | Impedance Zr(Ω) | Thickness frequency (KHz) |

| PU-PC25103 | Φ25×Φ10×3 | 66.4 | 1240±12.5% | ≤0.3 | ≥0.46 | ≤15 | 683±5% |

| PU-PC225104 | Φ25×Φ10×4 | 66.4 | 930±12.5% | ≤0.3 | ≥0.46 | ≤15 | 512±5% |

| PU-PC40155 | Φ40×Φ12×5 | 45.9 | 2070±12.5% | ≤0.3 | ≥0.46 | ≤15 | 410±5% |

| PU-PC40155 | Φ40×Φ15×5 | 42.2 | 1960±12.5% | ≤0.3 | ≥0.46 | ≤15 | 323±5% |

| PU-PC40176 | Φ40×Φ17×6 | 40.5 | 1555±12.5% | ≤0.3 | ≥0.46 | ≤15 | 341±5% |

| PU-PC40205 | Φ40×Φ20×5 | 37.9 | 1700±12.5% | ≤0.3 | ≥0.47 | ≤15 | 410±5% |

| PU-PC50206 | Φ50×Φ20×6 | 33.2 | 2490±12.5% | ≤0.3 | ≥0.46 | ≤15 | 341±5% |

| PU-PC501765 | Φ50×Φ17×6.5 | 34.8 | 2430±12.5% | ≤0.3 | ≥0.46 | ≤15 | 315±5% |

| PU-PC50236 | Φ50×Φ23×6 | 31.2 | 2340±12.5% | ≤0.3 | ≥0.47 | ≤15 | 341±5% |

| PU-PC50276 | Φ50×Φ27×6 | 29.3 | 2100±12.5% | ≤0.3 | ≥0.47 | ≤15 | 341±5% |

| PU-PC603010 | Φ60×Φ30×10 | 25.3 | 1922±12.5% | ≤0.3 | ≥0.47 | ≤18 | 205±5% |

PZT8 Piezo Disk Element Discs Cleaning Welding Piezoelectric Ceramic Chip Ring

标签:Cleaning Welding Piezoelectric Ceramic Chip Ring, PZT8 Piezo Disk Element Discs

Send Inquiry

Piezoelectric Crystal Ring Element UltrasonicPiezo Ceramic PZT 4 Material Piezoelectric Sensor Ultrasonic Ceramic Ring

Piezoelectric Crystal Ring Element UltrasonicPiezo Ceramic PZT 4 Material Piezoelectric Sensor Ultrasonic Ceramic Ring 40*20*5mm PZT-8 Piezoelectric Ceramic Ring For 800W 28khz Piezo Ultrasonic Vibrator Transducer

40*20*5mm PZT-8 Piezoelectric Ceramic Ring For 800W 28khz Piezo Ultrasonic Vibrator Transducer 50*20*6mm Ring Piezoelectric Ceramic Ring Piezo Ceramic Element PZT4 PZT8 Piezoelectric Element

50*20*6mm Ring Piezoelectric Ceramic Ring Piezo Ceramic Element PZT4 PZT8 Piezoelectric Element 70*30*10mm Pzt8 Ring Piezoceramic Cylinder Piezoelectric Ceramic Ring Elements

70*30*10mm Pzt8 Ring Piezoceramic Cylinder Piezoelectric Ceramic Ring Elements 38*15*5 Piezoelectric Ceramic Element Ring Piezoelectric Ceramic For Ultrasonic Vibration Trasnducer

38*15*5 Piezoelectric Ceramic Element Ring Piezoelectric Ceramic For Ultrasonic Vibration Trasnducer 45*15*5mm PZT-8/PZT-4 Piezoelectric Ceramic Ring 28khz/35khz 800W Ultrasonic Welding Transducer With Booster

45*15*5mm PZT-8/PZT-4 Piezoelectric Ceramic Ring 28khz/35khz 800W Ultrasonic Welding Transducer With Booster 50*17*6.5 15khz pzt-4 pzt-8 disc piezo ultrasonic transducer sensors piezoelectric ceramic components piezo crystal

50*17*6.5 15khz pzt-4 pzt-8 disc piezo ultrasonic transducer sensors piezoelectric ceramic components piezo crystal 38*15*5 Ring Piezoelectric Ceramic Element Ring For Ultrasonic Cleaning Trasnducer Machine

38*15*5 Ring Piezoelectric Ceramic Element Ring For Ultrasonic Cleaning Trasnducer Machine PZT4 PZT5 PZT8 High Efficiency Piezoelectric Ceramic Materials for Ultrasonic Cleaning 38X15X5mm

PZT4 PZT5 PZT8 High Efficiency Piezoelectric Ceramic Materials for Ultrasonic Cleaning 38X15X5mm 50x17x6.5mm PZT-8 Piezoelectric Ceramic Ring For 20khz 15khz 2600W Ultrasonic Welder Transducer

50x17x6.5mm PZT-8 Piezoelectric Ceramic Ring For 20khz 15khz 2600W Ultrasonic Welder Transducer 60*30*10mm Piezoelectric Ceramic Ring Pzt-4/Pzt-8 Piezo Ceramic Element Ultrasonic Piezo Element Piezoelectric Ceramic Ring

60*30*10mm Piezoelectric Ceramic Ring Pzt-4/Pzt-8 Piezo Ceramic Element Ultrasonic Piezo Element Piezoelectric Ceramic Ring 35*15*5mm PZT-8/PZT-4 Piezoelectric Ceramic Ring For 50W 28khz/40khz Ultrasonic Cleaning Machine Transducer

35*15*5mm PZT-8/PZT-4 Piezoelectric Ceramic Ring For 50W 28khz/40khz Ultrasonic Cleaning Machine Transducer