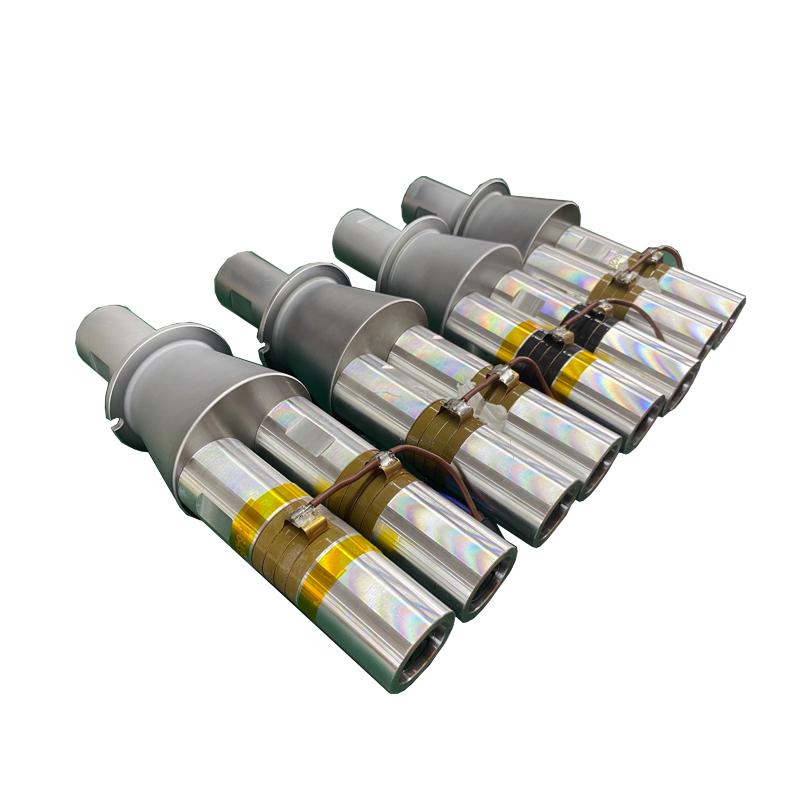

PZT-8 15KHZ 2000W Ultrasonic Welding Transducer For Ultrasonic Welding Plastic Parts Machine

Ultrasonic welding transducer is usually used for plastic welding, which completely replaces the traditional industry of adhesive bonding. In the ultrasonic welding process, there are no materials such as bolts, nails, buckles, welding materials or adhesives combined together. It has a faster speed than traditional a…

PZT-8 15KHZ 2000W Ultrasonic Welding Transducer For Ultrasonic Welding Plastic Parts Machine

Ultrasonic welding transducer is usually used for plastic welding, which completely replaces the traditional industry of adhesive bonding. In the ultrasonic welding process, there are no materials such as bolts, nails, buckles, welding materials or adhesives combined together. It has a faster speed than traditional adhesives or adhesive water, and the drying time is also very fast. The welding process can be easily automated and can be easily customized, To adapt to the specific specifications of each type of product being welded.

Ultrasonic plastic transducers vary in size and specifications due to different usage scenarios and welding materials. Its output power comes from manual welding.

Ultrasound has the following characteristics:

- Ultrasound can effectively propagate in media such as gas, liquid, solid, and solid melt.

- Ultrasound can transmit strong energy.

- Ultrasound can cause reflection, interference, superposition, and resonance phenomena.

- When ultrasonic waves propagate in liquid media, they can generate strong impacts and cavitation phenomena at the interface.

Ultrasonic spot welding is an assembly method that connects two thermoplastic workpieces without forming holes or energy conducting ribs at local locations. Ultrasonic spot welding produces strong structural welds, suitable for large parts, thermoplastic extruded or cast plates, thermoplastic corrugated plates, and workpieces with complex geometric shapes and difficult to access joint surfaces. This article discusses the principle and mechanism, adaptability, variants, process parameters, equipment requirements, characteristics, and applications of ultrasonic spot welding

| Type | Full-length(mm) | Joint Bolt(mm) | Frequency(KHz) | Resonance Impedance(Ω) | Capacity(pF) | Input Power (W) |

| PLS-HJHNQ152600 | 153 | M20×1.5 | 15 | 15 | 13000 | 2600 |

| PLS-HJHNQ152000 | 167 | M20×1.5 | 15 | 10 | 9500 | 2000 |

| PLS-HJHNQ202000 | 128 | M18×1 | 20 | 10 | 11000 | 2000 |

| PLS-HJHNQ30500 | 77 | M10×1.5 | 30 | 5 | 5500 | 500 |

| PLS-HJHNQ28200 | 92.1 | M10×1 | 28 | 20 | 3000 | 200 |

| PLS-HJHNQ28100 | 91 | M8×1 | 28 | 25 | 2200 | 100 |

| PLS-HJHNQ28250 | 94 | 1/2-20 UNF | 28 | 20 | 4000 | 250 |

| PLS-HJHNQ202000 | 128 | 1/2-20 UNF | 20 | 10 | 20000 | 2000 |

| PLS-HJHNQ201500 | 124 | 1/2-20 UNF | 20 | 10 | 16000 | 1500 |

| PLS-HJHNQ38100 | 66 | M8×1.25 | 38 | 40 | 1200 | 100 |

| PLS-HJHNQ38200 | 65 | M8×1 | 38 | 14 | 3300 | 200 |

PZT-8 15KHZ 2000W Ultrasonic Welding Transducer For Ultrasonic Welding Plastic Parts Machine

标签:PZT-8 15KHZ 2000W Ultrasonic Welding Transducer, Ultrasonic Welding Transducer For Ultrasonic Welding

Send Inquiry

2600W 20KHZ High Power Piezo Ceramic Ultrasonic Welding Transducer For Plastic Welding Machine

2600W 20KHZ High Power Piezo Ceramic Ultrasonic Welding Transducer For Plastic Welding Machine 20khz 2000W Ultrasonic Plastic Welding Transducer For Ultrasonic Welding Machine

20khz 2000W Ultrasonic Plastic Welding Transducer For Ultrasonic Welding Machine 15khz 2600W Ultrasonic Welding Transducer Use For Ultrasonic Plastic Pvc Fabric Welding Machine

15khz 2600W Ultrasonic Welding Transducer Use For Ultrasonic Plastic Pvc Fabric Welding Machine 20KHZ 3000W High Power Ultrasonic Welding Piezoelectric Transducer For Ultrasonic Plastic Welding Machine

20KHZ 3000W High Power Ultrasonic Welding Piezoelectric Transducer For Ultrasonic Plastic Welding Machine Auto 20khz Earloop Ultrasonic Welding Transducer For PE PVC PP HDPE LDPE EPDM Plastic Welding Machine

Auto 20khz Earloop Ultrasonic Welding Transducer For PE PVC PP HDPE LDPE EPDM Plastic Welding Machine 20kHz 2000W Ultrasonic Plastic Welding Transducer Piezoelectric Ceramic Transducer for Bag Making Machinery

20kHz 2000W Ultrasonic Plastic Welding Transducer Piezoelectric Ceramic Transducer for Bag Making Machinery 20kHz 15K 2000W Piezoelectric Ceramic Ultrasonic Welding Transducer and Booster For Plastic Welding Machine

20kHz 15K 2000W Piezoelectric Ceramic Ultrasonic Welding Transducer and Booster For Plastic Welding Machine Ultrasonic PVC Welding Machine Transducer Mold Other Welding Equipment High Power Transducer Ultrasonic

Ultrasonic PVC Welding Machine Transducer Mold Other Welding Equipment High Power Transducer Ultrasonic Ultrasonic Welding Machine Spot Welder Plastic Customize Transducer 20kHz Converter replacement for Herrmann type

Ultrasonic Welding Machine Spot Welder Plastic Customize Transducer 20kHz Converter replacement for Herrmann type 28KHz 20khz 18khz 15khz Ultrasonic Welding Transducer With Booster For Ultrasonic Mask Machine

28KHz 20khz 18khz 15khz Ultrasonic Welding Transducer With Booster For Ultrasonic Mask Machine 15KHZ 4200W High Power Ultrasonic Welding Transducer / Double Welding Vibrators for Welding Machine

15KHZ 4200W High Power Ultrasonic Welding Transducer / Double Welding Vibrators for Welding Machine 20kHz 2000W Ultrasonic Plastic Welding Transducer Piezoelectric Ceramic Transducer for Bag Making Machinery

20kHz 2000W Ultrasonic Plastic Welding Transducer Piezoelectric Ceramic Transducer for Bag Making Machinery