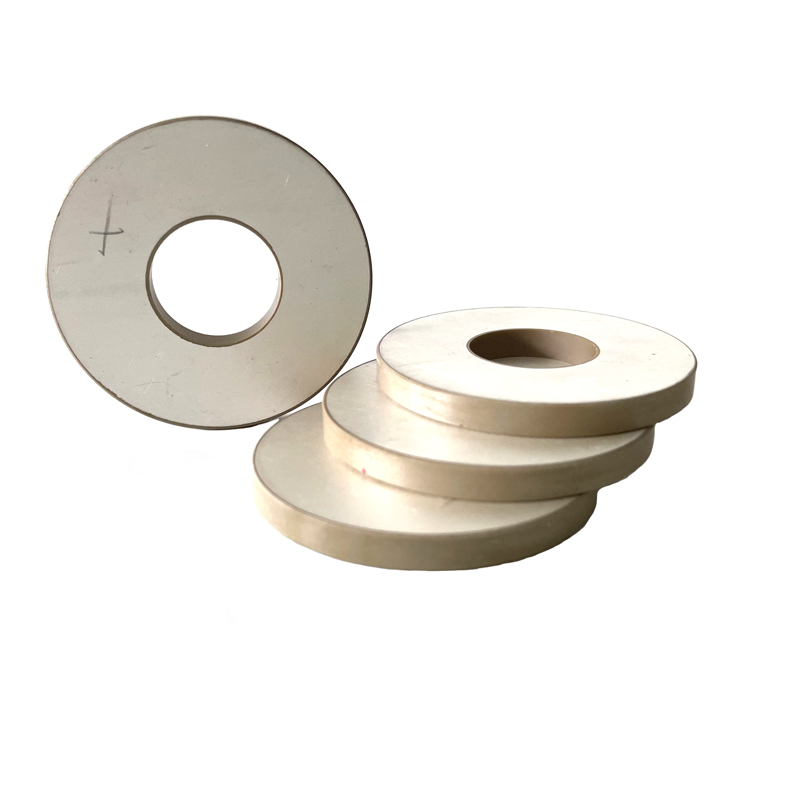

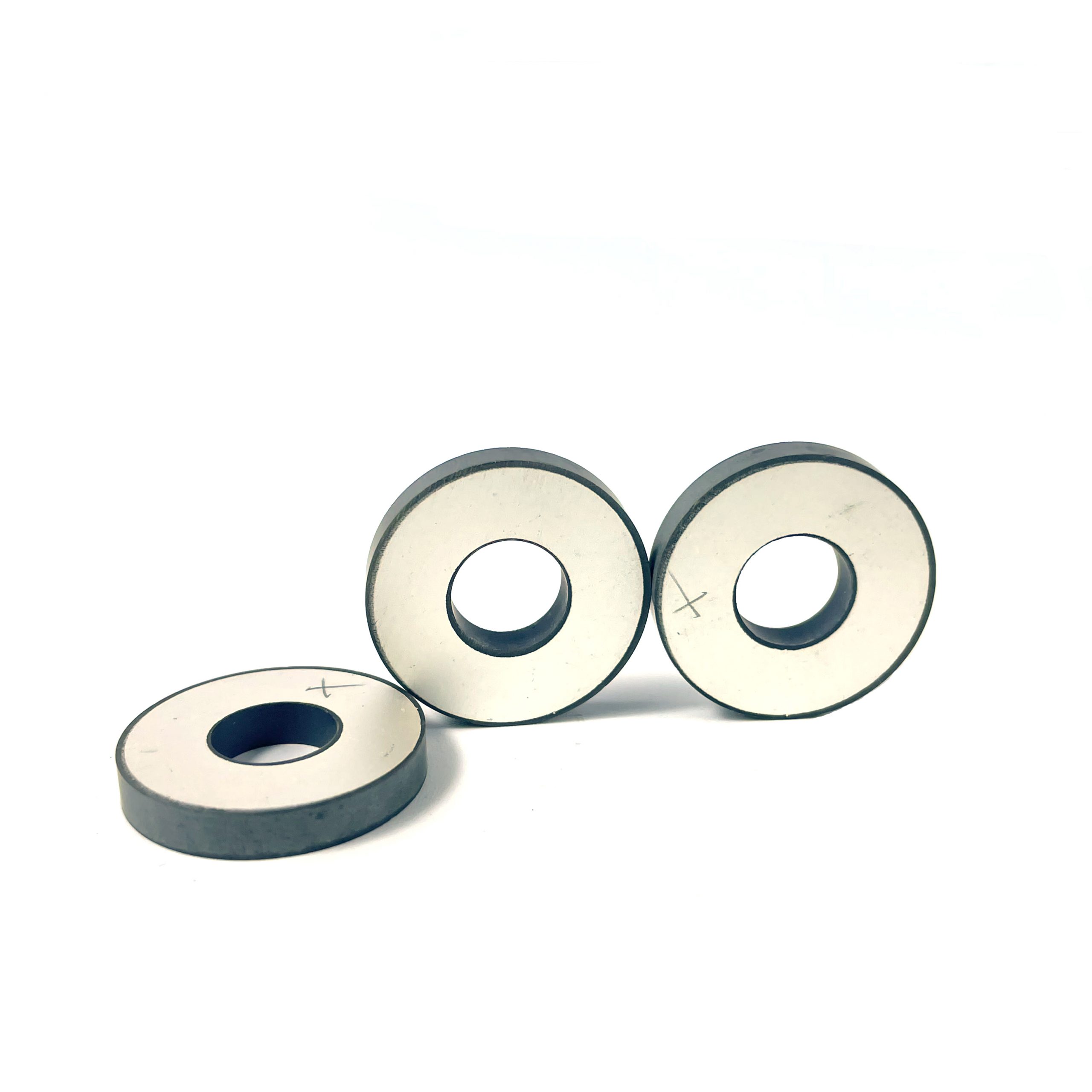

Piezoelectric Ceramic Element Ultrasonic Piezoelectric Ring Pzt Piezo Ceramic Disc Piezo Ceramic For Cleaning Ring And Welding Ring

The mechanism of ultrasonic cleaning is to use physical effects such as cavitation, radiation pressure, sound flow, etc. when ultrasonic waves propagate in the cleaning solution, to mechanically peel off the dirt on the cleaning piece. At the same time, it can promote chemical reactions between the cleaning solution …

The mechanism of ultrasonic cleaning is to use physical effects such as cavitation, radiation pressure, sound flow, etc. when ultrasonic waves propagate in the cleaning solution, to mechanically peel off the dirt on the cleaning piece. At the same time, it can promote chemical reactions between the cleaning solution and the dirt, achieving the purpose of cleaning the object. The frequency used for ultrasonic cleaning machines can be selected from 10 to 500 kHz based on the size and purpose of the cleaning material, usually ranging from 20 to 50 kHz. As the frequency of ultrasonic transducers increases, Langevin oscillators, longitudinal oscillators, thickness oscillators, etc. can be used. In terms of miniaturization, there are also radial and bending vibrations using circular oscillators. Ultrasonic cleaning has been increasingly widely used in various industries such as industry, agriculture, household equipment, electronics, automobiles, rubber, printing, aircraft, food, hospitals, and medical research.

| spec | Dimension (mm) | Radial frequency (KHz) | Capacitance (pf) | Dielectric dissipation factor tanδ(%) | Electromechanical coupling coefficient (Kr) | Impedance Zr(Ω) | Thickness frequency (KHz) |

| PU-PC25103 | Φ25×Φ10×3 | 66.4 | 1240±12.5% | ≤0.3 | ≥0.46 | ≤15 | 683±5% |

| PU-PC225104 | Φ25×Φ10×4 | 66.4 | 930±12.5% | ≤0.3 | ≥0.46 | ≤15 | 512±5% |

| PU-PC40155 | Φ40×Φ12×5 | 45.9 | 2070±12.5% | ≤0.3 | ≥0.46 | ≤15 | 410±5% |

| PU-PC40155 | Φ40×Φ15×5 | 42.2 | 1960±12.5% | ≤0.3 | ≥0.46 | ≤15 | 323±5% |

| PU-PC40176 | Φ40×Φ17×6 | 40.5 | 1555±12.5% | ≤0.3 | ≥0.46 | ≤15 | 341±5% |

| PU-PC40205 | Φ40×Φ20×5 | 37.9 | 1700±12.5% | ≤0.3 | ≥0.47 | ≤15 | 410±5% |

| PU-PC50206 | Φ50×Φ20×6 | 33.2 | 2490±12.5% | ≤0.3 | ≥0.46 | ≤15 | 341±5% |

| PU-PC501765 | Φ50×Φ17×6.5 | 34.8 | 2430±12.5% | ≤0.3 | ≥0.46 | ≤15 | 315±5% |

| PU-PC50236 | Φ50×Φ23×6 | 31.2 | 2340±12.5% | ≤0.3 | ≥0.47 | ≤15 | 341±5% |

| PU-PC50276 | Φ50×Φ27×6 | 29.3 | 2100±12.5% | ≤0.3 | ≥0.47 | ≤15 | 341±5% |

| PU-PC603010 | Φ60×Φ30×10 | 25.3 | 1922±12.5% | ≤0.3 | ≥0.47 | ≤18 | 205±5% |

标签:Piezo Ceramic Disc Piezo Ceramic, Piezo Ceramic For Cleaning Ring And Welding Ring, Piezoelectric Ceramic Element Ultrasonic Piezoelectric Ring

Send Inquiry

38*15*5 Piezoelectric Ceramic Element Ring Piezoelectric Ceramic For Ultrasonic Vibration Trasnducer

38*15*5 Piezoelectric Ceramic Element Ring Piezoelectric Ceramic For Ultrasonic Vibration Trasnducer Vibration 45*15*5 Piezo Sensors PZT Rings Piezoelectric Ceramics Piezo Ceramic Ring Transducer 44 KHz

Vibration 45*15*5 Piezo Sensors PZT Rings Piezoelectric Ceramics Piezo Ceramic Ring Transducer 44 KHz Ring Piezo Ceramic Crystal 16mm*7.8mm Piezo PZT Ceramic Piezoelectric Ceramic Element

Ring Piezo Ceramic Crystal 16mm*7.8mm Piezo PZT Ceramic Piezoelectric Ceramic Element Piezoelectric ceramic Pzt8 Electric Piezo plate OD50mm rings for 20kHz 2000w Ultrasonic Welding Mask Machine

Piezoelectric ceramic Pzt8 Electric Piezo plate OD50mm rings for 20kHz 2000w Ultrasonic Welding Mask Machine 15kHz -40kHz piezoelectric ceramic ring Customize Ultrasonic Piezo Element Piezoelectric Ceramic Ring

15kHz -40kHz piezoelectric ceramic ring Customize Ultrasonic Piezo Element Piezoelectric Ceramic Ring Piezoelectric Ceramic Element Ultrasonic Piezo Electric Ceramics Ring Usd For Ultrasonic Welding Mask Machine

Piezoelectric Ceramic Element Ultrasonic Piezo Electric Ceramics Ring Usd For Ultrasonic Welding Mask Machine 10×5*x2mm PZT8 Piezo Ceramic for Tooth Cleaning Ultrasonic Beauty Transducer

10×5*x2mm PZT8 Piezo Ceramic for Tooth Cleaning Ultrasonic Beauty Transducer PZT8 Piezo Disk Element Discs Cleaning Welding Piezoelectric Ceramic Chip Ring

PZT8 Piezo Disk Element Discs Cleaning Welding Piezoelectric Ceramic Chip Ring Ultrasonic Welding Mask Machine Piezo Ceramic Ring 60*30*10mm Ultrasonic Transducer Piezoelectric Ceramic Ring

Ultrasonic Welding Mask Machine Piezo Ceramic Ring 60*30*10mm Ultrasonic Transducer Piezoelectric Ceramic Ring Piezoelectric Ceramic Element Ultrasonic Piezoelectric Ring Pzt Piezo Ceramic Disc Piezo Ceramic For Cleaning Ring And Welding Ring

Piezoelectric Ceramic Element Ultrasonic Piezoelectric Ring Pzt Piezo Ceramic Disc Piezo Ceramic For Cleaning Ring And Welding Ring PZT Customize Ultrasonic Piezo Element Piezoelectric Ceramic Ring Various Size Ultrasonic Element Pzt Piezoelectric Ceramic

PZT Customize Ultrasonic Piezo Element Piezoelectric Ceramic Ring Various Size Ultrasonic Element Pzt Piezoelectric Ceramic PZT-8 PZT-4 Material Piezoelectric Ceramic Ring/Disc/Sheet for Ultrasonic Transducer

PZT-8 PZT-4 Material Piezoelectric Ceramic Ring/Disc/Sheet for Ultrasonic Transducer