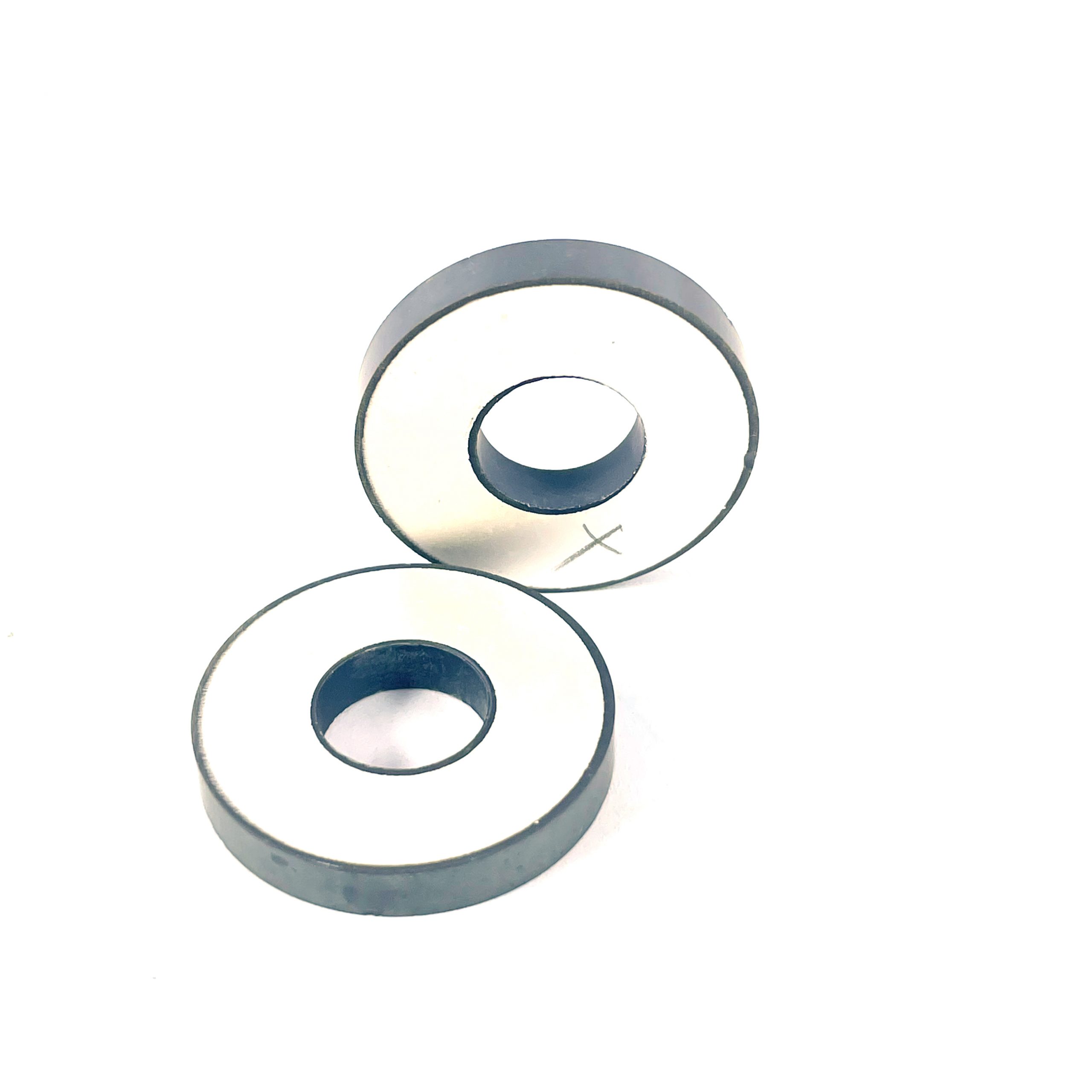

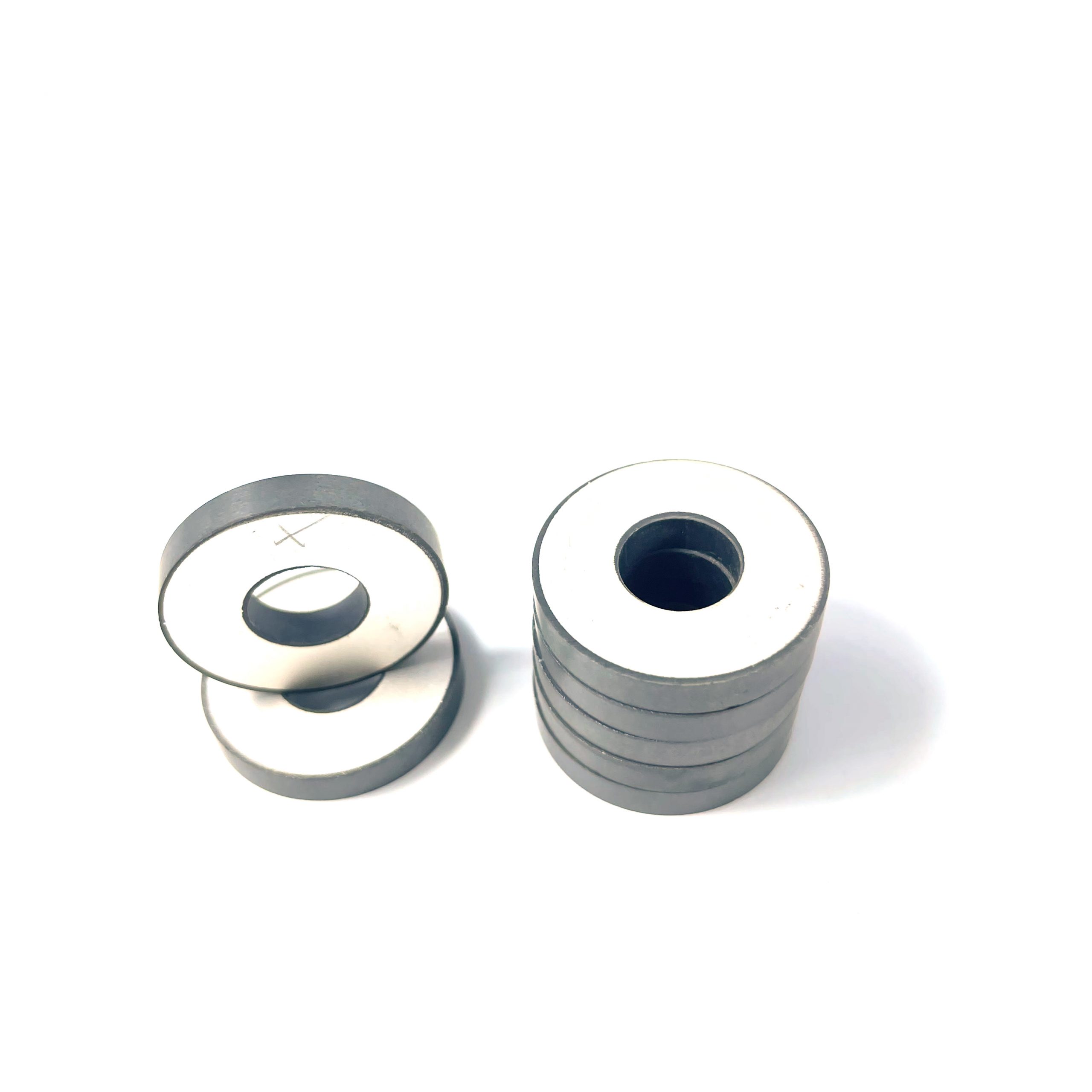

Piezo Disk 60*30*10mm Piezoelectric Ceramic Ring For Ultrasonic Welding Machine Piezo Transducer

The manufacturing process of circular piezoelectric ceramic sheets is relatively complex, but through continuous optimization and improvement, a mature process flow has been formed. Firstly, it is necessary to choose suitable raw materials, such as ceramic materials with piezoelectric effects such as barium titanate …

Piezo Disk 60*30*10mm Piezoelectric Ceramic Ring For Ultrasonic Welding Machine Piezo Transducer

The manufacturing process of circular piezoelectric ceramic sheets is relatively complex, but through continuous optimization and improvement, a mature process flow has been formed. Firstly, it is necessary to choose suitable raw materials, such as ceramic materials with piezoelectric effects such as barium titanate and lead zirconate. Then, circular piezoelectric ceramic sheets with specific shapes and sizes are prepared through steps such as mixed grinding, pre firing, secondary fine grinding, granulation, forming, shaping, and sintering into ceramics. In the manufacturing process, control of various links is crucial, such as the proportion of raw materials, pre firing temperature and time, molding pressure, etc., which will affect the performance and quality of the final product.

The application fields of circular piezoelectric ceramic sheets are very extensive. In the field of sensors, circular piezoelectric ceramic sheets can be used as force sensors, acceleration sensors, etc., for measuring various physical quantities. In the field of actuators, circular piezoelectric ceramic sheets can utilize the inverse piezoelectric effect to achieve mechanical displacement, and are widely used in precision positioning, vibration control, and other fields. In addition, in the field of transducers, circular piezoelectric ceramic sheets can convert mechanical energy into electrical energy, achieving energy recovery and utilization.

| spec | Dimension (mm) | Radial frequency (KHz) | Capacitance (pf) | Dielectric dissipation factor tanδ(%) | Electromechanical coupling coefficient (Kr) | Impedance Zr(Ω) | Thickness frequency (KHz) |

| PU-PC25103 | Φ25×Φ10×3 | 66.4 | 1240±12.5% | ≤0.3 | ≥0.46 | ≤15 | 683±5% |

| PU-PC225104 | Φ25×Φ10×4 | 66.4 | 930±12.5% | ≤0.3 | ≥0.46 | ≤15 | 512±5% |

| PU-PC40155 | Φ40×Φ12×5 | 45.9 | 2070±12.5% | ≤0.3 | ≥0.46 | ≤15 | 410±5% |

| PU-PC40155 | Φ40×Φ15×5 | 42.2 | 1960±12.5% | ≤0.3 | ≥0.46 | ≤15 | 323±5% |

| PU-PC40176 | Φ40×Φ17×6 | 40.5 | 1555±12.5% | ≤0.3 | ≥0.46 | ≤15 | 341±5% |

| PU-PC40205 | Φ40×Φ20×5 | 37.9 | 1700±12.5% | ≤0.3 | ≥0.47 | ≤15 | 410±5% |

| PU-PC50206 | Φ50×Φ20×6 | 33.2 | 2490±12.5% | ≤0.3 | ≥0.46 | ≤15 | 341±5% |

| PU-PC501765 | Φ50×Φ17×6.5 | 34.8 | 2430±12.5% | ≤0.3 | ≥0.46 | ≤15 | 315±5% |

| PU-PC50236 | Φ50×Φ23×6 | 31.2 | 2340±12.5% | ≤0.3 | ≥0.47 | ≤15 | 341±5% |

| PU-PC50276 | Φ50×Φ27×6 | 29.3 | 2100±12.5% | ≤0.3 | ≥0.47 | ≤15 | 341±5% |

| PU-PC603010 | Φ60×Φ30×10 | 25.3 | 1922±12.5% | ≤0.3 | ≥0.47 | ≤18 | 205±5% |

Piezo Disk 60*30*10mm Piezoelectric Ceramic Ring For Ultrasonic Welding Machine Piezo Transducer

Send Inquiry

35*15*5mm PZT-4 Ultrasonic Transducer Pzt8 Ring Ultrasonic Piezo Element Pzt Ceramic Piezoelectric Crystal

35*15*5mm PZT-4 Ultrasonic Transducer Pzt8 Ring Ultrasonic Piezo Element Pzt Ceramic Piezoelectric Crystal 50*20*6 PZT8 Piezoelectric ceramic chip Ultrasonic Piezoelectric ceramic sheet Transducer chip Spot

50*20*6 PZT8 Piezoelectric ceramic chip Ultrasonic Piezoelectric ceramic sheet Transducer chip Spot 60*30*10mm PZT-8 Piezoelectric Ceramic Ring For 15khz 3200W And 4200W Ultrasonic Welding Machine Transducer

60*30*10mm PZT-8 Piezoelectric Ceramic Ring For 15khz 3200W And 4200W Ultrasonic Welding Machine Transducer 35*15*5mm PZT-8/PZT-4 Piezoelectric Ceramic Ring For 50W 28khz/40khz Ultrasonic Cleaning Machine Transducer

35*15*5mm PZT-8/PZT-4 Piezoelectric Ceramic Ring For 50W 28khz/40khz Ultrasonic Cleaning Machine Transducer 38*15*5mm Ring Ultrasonic Piezo Crystal Piezo Ceramic Ultrasonic Transducers Customization Ultrasonic Piezo Transducer

38*15*5mm Ring Ultrasonic Piezo Crystal Piezo Ceramic Ultrasonic Transducers Customization Ultrasonic Piezo Transducer 60*30*10 mm Pzt8 Piezoelectric Ceramic Ring Piezo Ceramic Ring Piezoceramic Cylinder

60*30*10 mm Pzt8 Piezoelectric Ceramic Ring Piezo Ceramic Ring Piezoceramic Cylinder 50*20*6mm Ring Piezoelectric Ceramic Ring Piezo Ceramic Element PZT4 PZT8 Piezoelectric Element

50*20*6mm Ring Piezoelectric Ceramic Ring Piezo Ceramic Element PZT4 PZT8 Piezoelectric Element Custom 15khz 18khz 20khz 40khz 35 khz Piezoelectric Crystal Ring Material for Ultrasonic Cleaner Welding PZT Piezo 60*30*10mm

Custom 15khz 18khz 20khz 40khz 35 khz Piezoelectric Crystal Ring Material for Ultrasonic Cleaner Welding PZT Piezo 60*30*10mm 60*30*10mm PZT-8 Piezoelectric Ceramic Ring For 15khz 3200W And 4200W Ultrasonic Welding Machine Transducer

60*30*10mm PZT-8 Piezoelectric Ceramic Ring For 15khz 3200W And 4200W Ultrasonic Welding Machine Transducer PZT8 Ceramic Piezo Ring 50*17*6.5mm Piezoelectric Ring Ceramic transducer for Ultrasonic transducer

PZT8 Ceramic Piezo Ring 50*17*6.5mm Piezoelectric Ring Ceramic transducer for Ultrasonic transducer 25*10*4mm PZT-8 Piezoelectric Ceramic Ring For 28khz/40khz 100W Ultrasonic Welder Converters Transducer

25*10*4mm PZT-8 Piezoelectric Ceramic Ring For 28khz/40khz 100W Ultrasonic Welder Converters Transducer Piezoelectric Ceramic Element 50x20x6mm Ring Pzt 8 Piezoelectric Ceramics Ultrasonic Piezoelectric Ceramic

Piezoelectric Ceramic Element 50x20x6mm Ring Pzt 8 Piezoelectric Ceramics Ultrasonic Piezoelectric Ceramic