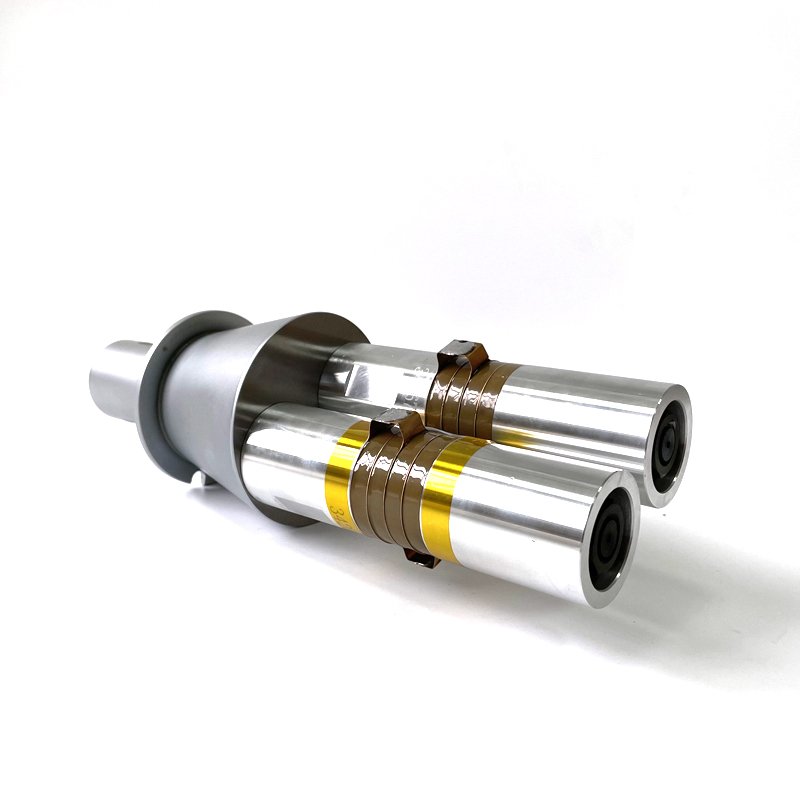

Industrial Ultrasonic Welding Transducer For Welding Abs Pp Non Woven Bags Fabric Sealing Machine

The function of an ultrasonic transducer is to convert electrical signals into mechanical vibration signals. There are two physical effects of converting electrical signals into mechanical vibration signals. A: Magnetostrictive effect. B: The inverse effect of piezoelectric effect. The magnetostrictive effect is comm…

Industrial Ultrasonic Welding Transducer For Welding Abs Pp Non Woven Bags Fabric Sealing Machine

The function of an ultrasonic transducer is to convert electrical signals into mechanical vibration signals. There are two physical effects of converting electrical signals into mechanical vibration signals. A: Magnetostrictive effect. B: The inverse effect of piezoelectric effect. The magnetostrictive effect is commonly used in early ultrasonic applications, with the advantages of high achievable power capacity and the disadvantages of low conversion efficiency, difficulty in production, and difficulty in large-scale industrial production. Since the invention of piezoelectric ceramic transducers, the application of the inverse effect of piezoelectric effect has been widely adopted. Piezoelectric ceramic transducers have the advantages of high conversion efficiency and mass production, but their disadvantage is small power capacity. Existing ultrasonic machines typically use piezoelectric ceramic transducers. A piezoelectric ceramic transducer is formed by clamping the piezoelectric ceramic between two metal front and rear load blocks and tightly connecting them with screws. The output amplitude of a typical sensor is approximately 10 μ M.

The ultrasonic transducer is the core component of a welding machine, mainly composed of a vibrator and an amplitude modulator. Its function is to convert electrical energy into mechanical energy through the simple harmonic vibration of the vibrator itself and drive the entire transducer to resonate under the excitation of electrical signals. The transducer oscillator adopts a sandwich structure, consisting of pre-stressed bolts that clamp the front and rear drive blocks, piezoelectric chips, and electrode plates. The front drive block and amplitude modulator are assembled through connecting screws.

| Type | Full-length(mm) | Joint Bolt(mm) | Frequency(KHz) | Resonance Impedance(Ω) | Capacity(pF) | Input Power (W) |

| PLS-HJHNQ152600 | 153 | M20×1.5 | 15 | 15 | 13000 | 2600 |

| PLS-HJHNQ152000 | 167 | M20×1.5 | 15 | 10 | 9500 | 2000 |

| PLS-HJHNQ202000 | 128 | M18×1 | 20 | 10 | 11000 | 2000 |

| PLS-HJHNQ30500 | 77 | M10×1.5 | 30 | 5 | 5500 | 500 |

| PLS-HJHNQ28200 | 92.1 | M10×1 | 28 | 20 | 3000 | 200 |

| PLS-HJHNQ28100 | 91 | M8×1 | 28 | 25 | 2200 | 100 |

| PLS-HJHNQ28250 | 94 | 1/2-20 UNF | 28 | 20 | 4000 | 250 |

| PLS-HJHNQ202000 | 128 | 1/2-20 UNF | 20 | 10 | 20000 | 2000 |

| PLS-HJHNQ201500 | 124 | 1/2-20 UNF | 20 | 10 | 16000 | 1500 |

| PLS-HJHNQ38100 | 66 | M8×1.25 | 38 | 40 | 1200 | 100 |

| PLS-HJHNQ38200 | 65 | M8×1 | 38 | 14 | 3300 | 200 |

Industrial Ultrasonic Welding Transducer For Welding Abs Pp Non Woven Bags Fabric Sealing Machine

标签:industrial ultrasonic welding transducer, Ultrasonic Welding Transducer For Welding Abs Pp Non Woven Bags Fabric

Send Inquiry

28KHz 20khz 18khz 15khz Ultrasonic Welding Transducer With Booster For Ultrasonic Mask Machine

28KHz 20khz 18khz 15khz Ultrasonic Welding Transducer With Booster For Ultrasonic Mask Machine Ultrasonic Plastic Welder Transducer For Kn95 Face Welding Equipment With Generator Transducer Horn

Ultrasonic Plastic Welder Transducer For Kn95 Face Welding Equipment With Generator Transducer Horn PZT-4 PZT-8 Ultrasonic Welding Transducer For Ultrasonic Acrylic Plastic Welding Machine

PZT-4 PZT-8 Ultrasonic Welding Transducer For Ultrasonic Acrylic Plastic Welding Machine 15KHZ 2000W Ultrasonic Welding Sensor Transducer With Booster For Plastic Welding Machine And Cutting Machine

15KHZ 2000W Ultrasonic Welding Sensor Transducer With Booster For Plastic Welding Machine And Cutting Machine 20KHZ Branson Type Converter Ultrasonic Welding Transducer For Ultrasonic Plastic Welding Machine

20KHZ Branson Type Converter Ultrasonic Welding Transducer For Ultrasonic Plastic Welding Machine Ultrasonic Welding Machine Spot Welder Plastic Transducer 20khz Ultrasonic Converter

Ultrasonic Welding Machine Spot Welder Plastic Transducer 20khz Ultrasonic Converter 20kHz 15K 2000W Piezoelectric Ceramic Ultrasonic Welding Transducer and Booster For Plastic Welding Machine

20kHz 15K 2000W Piezoelectric Ceramic Ultrasonic Welding Transducer and Booster For Plastic Welding Machine 20khz 2000w Ultrasonic Piezoelectric Welding Transducer With Titanium Booster for Zipper Plastic Bag Machine

20khz 2000w Ultrasonic Piezoelectric Welding Transducer With Titanium Booster for Zipper Plastic Bag Machine Welder Transducer Ultrasonic PZT8 High Power Ultrasonic Welding Piezoelectric Oscillator Transducer

Welder Transducer Ultrasonic PZT8 High Power Ultrasonic Welding Piezoelectric Oscillator Transducer 15KHZ 3200W High Power Piezoelectric Ultrasonic Welding Machine Transducer For Plastic Welding Machine

15KHZ 3200W High Power Piezoelectric Ultrasonic Welding Machine Transducer For Plastic Welding Machine 20KHZ 3000W High Power Ultrasonic Welding Piezoelectric Transducer For Ultrasonic Plastic Welding Machine

20KHZ 3000W High Power Ultrasonic Welding Piezoelectric Transducer For Ultrasonic Plastic Welding Machine PZT-4 15KHZ 3000W Ultrasonic Welding Transducer For Ultrasonic Seamless Sealing Welding Machine

PZT-4 15KHZ 3000W Ultrasonic Welding Transducer For Ultrasonic Seamless Sealing Welding Machine