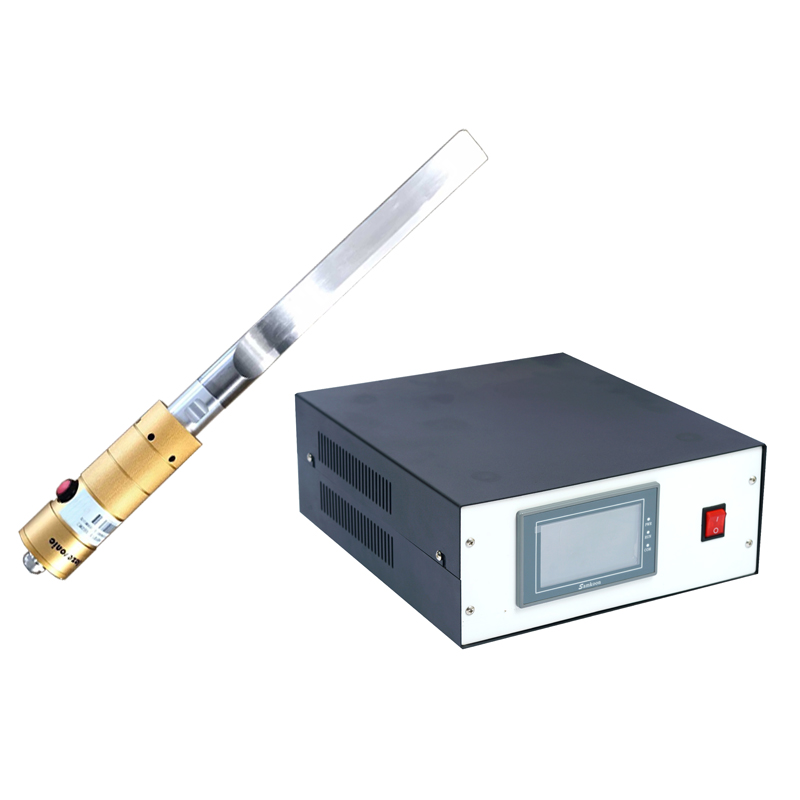

High Power Ultrasound 25khz Knife Rubber Plastic Manual Fabric Cutter Ultrasonic Cutting Machine

The main function of ultrasonic cutting technology is to separate connected parts. The pressure on the object to be cut can be reduced by large frequency vibration per second. This will result in a neat and clean cut surface. In practical application, it is divided into two processes, separate welding and cutting. …

High Power Ultrasound 25khz Knife Rubber Plastic Manual Fabric Cutter Ultrasonic Cutting Machine

The main function of ultrasonic cutting technology is to separate connected parts. The pressure on the object to be cut can be reduced by large frequency vibration per second. This will result in a neat and clean cut surface. In practical application, it is divided into two processes, separate welding and cutting.

Thermoplastic multilayer textiles, non-woven materials or films can be cut into arbitrary shapes with ultrasonic wave, and welded along the cutting contour at the same time. The thermoplastic fiber content shall be at least 20%. The cutting anvil with the corresponding cutting profile is cut by the vibration generated by the ultrasonic system. At the same time, vibration attenuation will generate heat in the cutting area, so as to weld along the cutting edge.

The blade vibrated by ultrasonic wave can quickly and accurately separate the articles to be cut under small resistance without residue. Ultrasonic has been applied to cutting finished products for many years. When cutting baked food, energy bar, cheese, pizza and other materials, vibrating (cold) cutting welding head can reduce the resistance in the cutting process and remove the adhered product residue. Result: A flat surface that can be re cut is formed without deformation or thermal damage to the product.

| Type | power (W) | Frequency | Welding time | Contains |

| PU-QG100W | 100W | 30khz,35khz,40khz | 0.1-3sec | generator , transducer ,horn,head |

| PU-QG300W | 300W | 30khz,35khz,40khz | 0.1-3sec | generator , transducer ,horn,head |

| PU-QG500W | 500W | 30khz,35khz,40khz | 0.1-3sec | generator , transducer ,horn,head |

High Power Ultrasound 25khz Knife Rubber Plastic Manual Fabric Cutter Ultrasonic Cutting Machine

Send Inquiry

Portable Manual Ultrasonic Cutter Machine 40kHz Plastic Ultrasonic Cutting Knife

Portable Manual Ultrasonic Cutter Machine 40kHz Plastic Ultrasonic Cutting Knife Frozen Meat Cake Ultrasonic Cutter Professional 28kHz Ultrasonic Food Cutting Machine

Frozen Meat Cake Ultrasonic Cutter Professional 28kHz Ultrasonic Food Cutting Machine Portable Ultrasound Ultrasonic Cutter Machine For Fabric Cutter Blade Knife Equipment

Portable Ultrasound Ultrasonic Cutter Machine For Fabric Cutter Blade Knife Equipment 35khz Ultrasonic Plastic Cutter Equipment Ultrasonic Cutting Knife With Blade Replaceable

35khz Ultrasonic Plastic Cutter Equipment Ultrasonic Cutting Knife With Blade Replaceable 35Khz Ultrasonic Hand-Held Plastic Fabric Cutter Knife For Automata And Plotter And Generator Control Box

35Khz Ultrasonic Hand-Held Plastic Fabric Cutter Knife For Automata And Plotter And Generator Control Box 35Khz Handheld Ultrasonic Knife Ultrasonic Cutting Machine Replacement Traditional Cutter

35Khz Handheld Ultrasonic Knife Ultrasonic Cutting Machine Replacement Traditional Cutter Ultrasonic Cake slicer Cutter Cheese Cutting Knife Hand Held Cutting Blade

Ultrasonic Cake slicer Cutter Cheese Cutting Knife Hand Held Cutting Blade Portable Ultrasonic Cutter Knife 35khz Handheld Plastic Fabric Cutter Knife Hand Held For Nonwoven With Glass Fibre

Portable Ultrasonic Cutter Knife 35khz Handheld Plastic Fabric Cutter Knife Hand Held For Nonwoven With Glass Fibre Ultrasonic Textile Cutter Cutting Machine Ultrasonic Cutter Knife Ultrasonic Multifunctional Hand-held Cutter

Ultrasonic Textile Cutter Cutting Machine Ultrasonic Cutter Knife Ultrasonic Multifunctional Hand-held Cutter 28khz 1000W Hand Held Ultrasonic Knife Ultrasonic Cutting Ultrasonic Cheese Cutter Machine

28khz 1000W Hand Held Ultrasonic Knife Ultrasonic Cutting Ultrasonic Cheese Cutter Machine Ultrasonic Fabric Cutting Ultrasonic Cutting Blade Ultrasonic Fabric Cutting Systems Of Industrial Fabrics And Textiles

Ultrasonic Fabric Cutting Ultrasonic Cutting Blade Ultrasonic Fabric Cutting Systems Of Industrial Fabrics And Textiles Ultrasound Titanium Alloy Knife Blade Accessory Ultrasonic Cake Cutting Knife Handheld Cutter Home Kitchen Appliance Table Top Slicer

Ultrasound Titanium Alloy Knife Blade Accessory Ultrasonic Cake Cutting Knife Handheld Cutter Home Kitchen Appliance Table Top Slicer