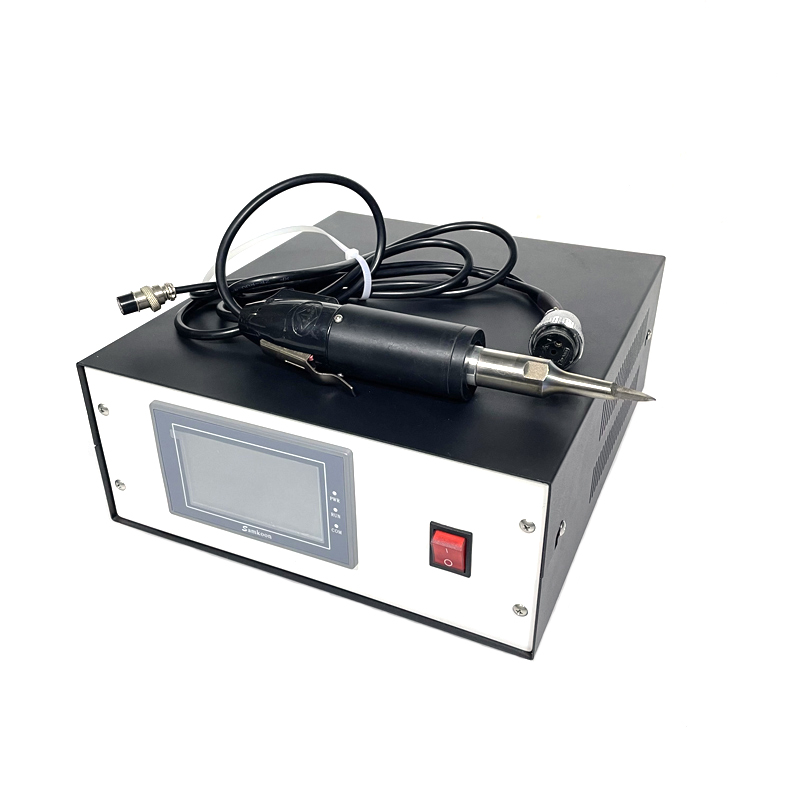

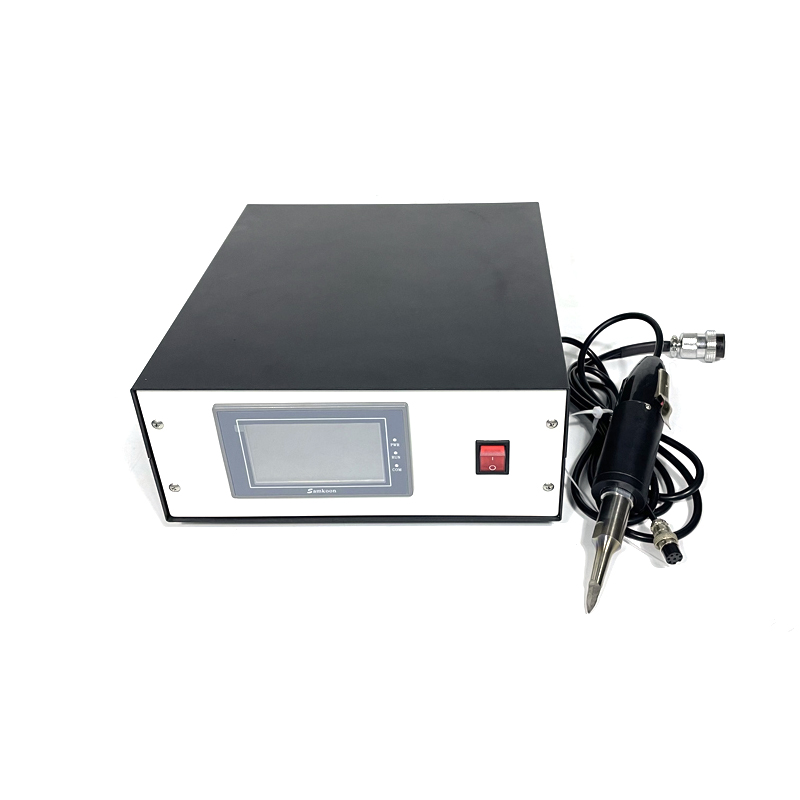

Hand held Knife 35kHz Ultrasonic Cutter Machine For Cutting Nonwoven With Glass Fibre

Advantages of ultrasonic cutting knives: Wide range: Various textile materials can be cut by ultrasound. For example, woven fabrics, non-woven fabrics and knitted fabrics of natural fiber and synthetic fibers, including aramid fiber, carbon fiber and glass fiber, can be cut by ultrasonic;Non pollution: When ultras…

Hand held Knife 35kHz Ultrasonic Cutter Machine For Cutting Nonwoven With Glass Fibre

Advantages of ultrasonic cutting knives:

- Wide range: Various textile materials can be cut by ultrasound. For example, woven fabrics, non-woven fabrics and knitted fabrics of natural fiber and synthetic fibers, including aramid fiber, carbon fiber and glass fiber, can be cut by ultrasonic;

- Non pollution: When ultrasonic cutting, the equipment is only heated to around 50 ℃, without generating smoke and odor, and also eliminates the risk of injury and fire during cutting;

- High reliability: When the ultrasonic generator operates, it will generate electromagnetic vibrations of 20-40KHZ, which are transformed into mechanical vibrations through piezoelectric ceramics. This oscillation is transmitted to the ultrasonic cutting knife and the material to be cut, and generates heat from inside, which then mechanically divides the material. Contrary to high-temperature cutting, ultrasound mainly uses mechanical energy rather than thermal energy, resulting in less wear on the ultrasonic cutting blade;

- Cut neatly: The cut edges are very neat, and the warp and weft yarns of the fabric will not shift or detach. Cotton and viscose fabrics can be cut at a speed of up to 10 meters per minute on stretchers and cylindrical fabric slitters. When cutting non thermoplastic materials, the fibers are treated or enter the ultrasonic working area, resulting in fusion at their edges;

- Traditional comparison: Compared to cold cutting, when using ultrasonic cutting, the thermoplastic material is cut and the edge of the cut will fuse. Compared to thermal cutting, using ultrasonic cutting can make the edges of the cut fabric very soft, avoiding excessive edge thickening caused by melt shrinkage. Due to the fact that ultrasound is heating the fabric from the inside rather than from the outside, it will not cause the fabric to turn yellow.

| Type | power (W) | Frequency | Welding time | Contains |

| PU-QG100W | 100W | 30khz,35khz,40khz | 0.1-3sec | generator , transducer ,horn,head |

| PU-QG300W | 300W | 30khz,35khz,40khz | 0.1-3sec | generator , transducer ,horn,head |

| PU-QG500W | 500W | 30khz,35khz,40khz | 0.1-3sec | generator , transducer ,horn,head |

Hand held Knife 35kHz Ultrasonic Cutter Machine For Cutting Nonwoven With Glass Fibre

标签:35kHz Ultrasonic Cutter Machine, 35kHz Ultrasonic Cutter Machine For Cutting Nonwoven

Send Inquiry

You May Also Like

Portable Ultrasonic Cutter Knife 35khz Handheld Plastic Fabric Cutter Knife Hand Held For Nonwoven With Glass Fibre

Portable Ultrasonic Cutter Knife 35khz Handheld Plastic Fabric Cutter Knife Hand Held For Nonwoven With Glass Fibre Hand-Held Cutting Knife Ultrasonic Cutter for Raw Rubber/Bread 35kHz Ultrasonic Cutting Knife For Plastic

Hand-Held Cutting Knife Ultrasonic Cutter for Raw Rubber/Bread 35kHz Ultrasonic Cutting Knife For Plastic 35KHZ Handheld Ultrasonic Cutting Knife Raw Rubber Hand-Held Cutting Knife Ultrasonic Cutter Hand held

35KHZ Handheld Ultrasonic Cutting Knife Raw Rubber Hand-Held Cutting Knife Ultrasonic Cutter Hand held 35khz 300W Hand Held Ultrasonic Cutting knife For ABS PP PE PVC Plastic Material Ultrasonic Plastic Cutter

35khz 300W Hand Held Ultrasonic Cutting knife For ABS PP PE PVC Plastic Material Ultrasonic Plastic Cutter Seal Hand Held Ultrasonic Fabric Cutter 40KHZ Rack-Mounted Frequency Tuning Method

Seal Hand Held Ultrasonic Fabric Cutter 40KHZ Rack-Mounted Frequency Tuning Method 30kHz Hand Held Ultrasonic Cutter Knife For Cutting Composite Materials

30kHz Hand Held Ultrasonic Cutter Knife For Cutting Composite Materials 800W Ultrasonic Plastic Cutting Blade Machine With Ultrasonic Vibration Generator

800W Ultrasonic Plastic Cutting Blade Machine With Ultrasonic Vibration Generator Cutter Knife Hand Held For Nonwoven With Glass Fibre Portable Sealing Ultrasonic Label Cutting Machine

Cutter Knife Hand Held For Nonwoven With Glass Fibre Portable Sealing Ultrasonic Label Cutting Machine 35Khz Ultrasonic Hand-Held Plastic Fabric Cutter Knife For Automata And Plotter And Generator Control Box

35Khz Ultrasonic Hand-Held Plastic Fabric Cutter Knife For Automata And Plotter And Generator Control Box 300W Ultrasonic Elliptical Vibration Cutting Device And Variable Frequency Ultrasonic Generator

300W Ultrasonic Elliptical Vibration Cutting Device And Variable Frequency Ultrasonic Generator Hand-Held Knife Ultrasonic Cutting Machine for Non-Woven Fabric Cloth Textile Paper and Plastic Cutting

Hand-Held Knife Ultrasonic Cutting Machine for Non-Woven Fabric Cloth Textile Paper and Plastic Cutting 35khz Ultrasonic Plastic Cutter Equipment Ultrasonic Cutting Knife With Blade Replaceable

35khz Ultrasonic Plastic Cutter Equipment Ultrasonic Cutting Knife With Blade Replaceable