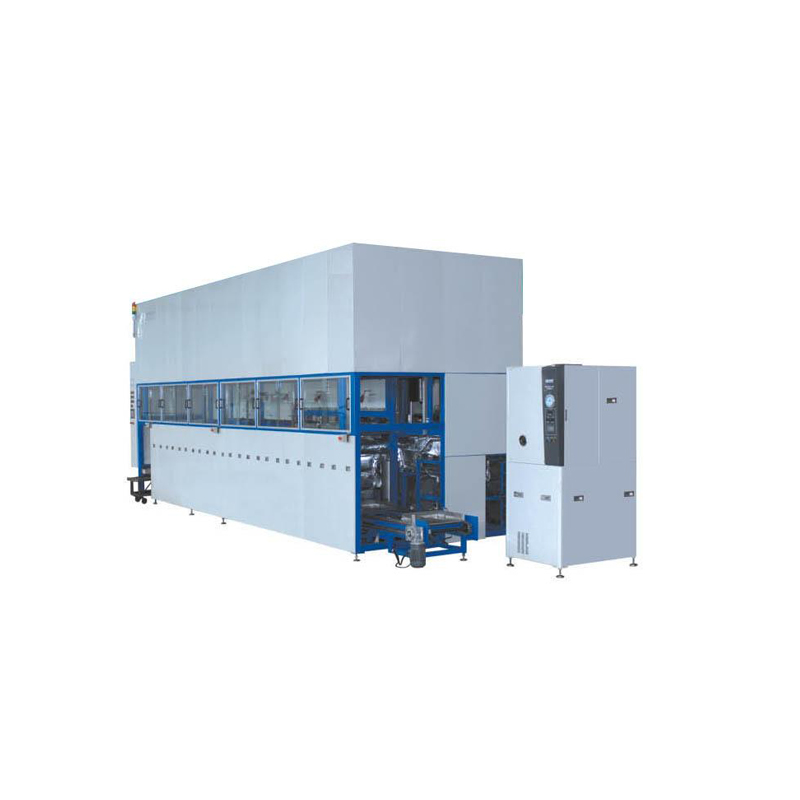

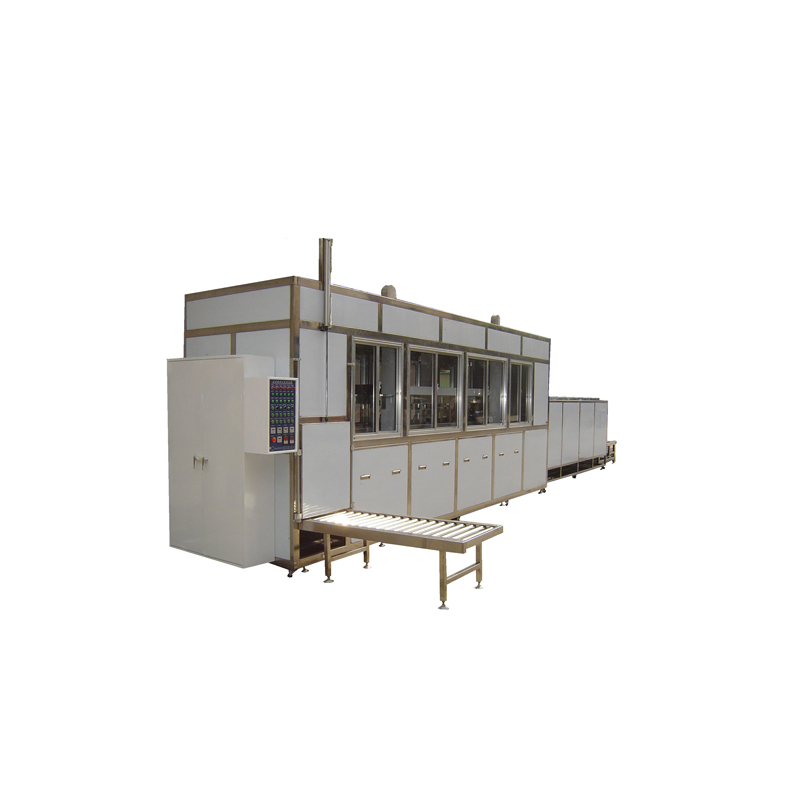

Customized Service Automatic Ultrasonic Electronic Component Cleaning Machine Equipment And Vibrating Generator

The fully automatic precision hardware ultrasonic cleaning machine is mainly applicable to large-scale aqueous cleaning, which can achieve large-scale automatic cleaning operations, thereby reducing labor intensity in the cleaning process, more ensuring the consistency of cleaning quality, and improving production ef…

The fully automatic precision hardware ultrasonic cleaning machine is mainly applicable to large-scale aqueous cleaning, which can achieve large-scale automatic cleaning operations, thereby reducing labor intensity in the cleaning process, more ensuring the consistency of cleaning quality, and improving production efficiency.

- Adopt PLC automatic control, multi-level password permissions, randomly adjustable process parameters, and visible working status;

- Full automatic and manual operation mode selection;

- Unique gantry and other position manipulators operate stably, position accurately, effectively separate lifting and lateral movement, work without interference with each other, and are easy to diagnose and eliminate faults.

- Adopt stainless steel gantry, with high strength and corrosion resistance;

- The cleaning tank can be equipped with a workpiece turnover mechanism and a fixed station high-pressure spray, which can achieve all-round cleaning of the workpiece, especially suitable for cleaning workpieces with blind holes;

- The plastic steel window package is convenient for observing the operation status of the machine body.

- Fully enclosed structure, with moisture and waste discharge functions, low noise, and no pollution to the workshop.

- The combined design of cleaning, drying, and cooling facilitates timely handling and taking.

- Optional: oil water separation system, magnetic separation system, automatic slag scraping system, automatic dosing, vacuum cleaning, vacuum drying, and other systems

标签:Automatic Ultrasonic Electronic Component Cleaning Machine, Automatic Ultrasonic Electronic Component Cleaning Machine Equipment And Vibrating Generator, fully automatic precision hardware ultrasonic cleaning machine

Send Inquiry

Customized Service Automatic Ultrasonic Electronic Component Cleaning Machine Equipment And Vibrating Generator

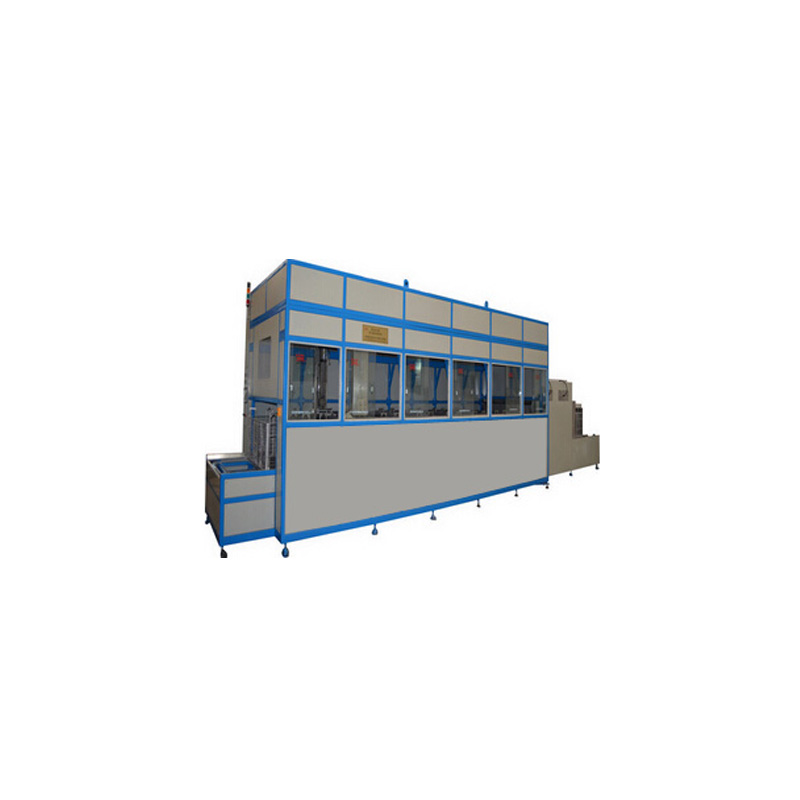

Customized Service Automatic Ultrasonic Electronic Component Cleaning Machine Equipment And Vibrating Generator Customized Aluminum Casting Hanging Metal Parts Full Automatic Ultrasonic Cleaning Machine

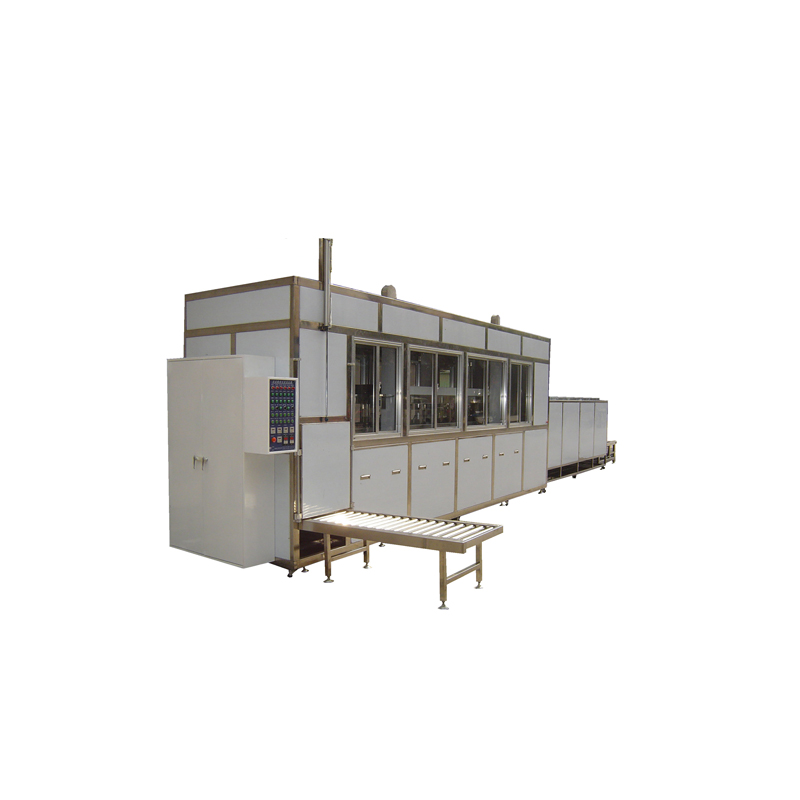

Customized Aluminum Casting Hanging Metal Parts Full Automatic Ultrasonic Cleaning Machine Industrial Ultrasonic Cleaning System Customized Automatic Cleaner Line Automatic production Line

Industrial Ultrasonic Cleaning System Customized Automatic Cleaner Line Automatic production Line Large Size Power Adjustable Ultrasonic Cleaning Automatic Car Wash Build A Big Ultrasonic Cleaner

Large Size Power Adjustable Ultrasonic Cleaning Automatic Car Wash Build A Big Ultrasonic Cleaner PLC Automatic Cleaning Machine Customizable Mechanical Arm Automated Ultrasonic Washing System

PLC Automatic Cleaning Machine Customizable Mechanical Arm Automated Ultrasonic Washing System 25KHZ Automotive Parts Ultrasonic Cleaning Machine & Systems And Multi-Function Generator

25KHZ Automotive Parts Ultrasonic Cleaning Machine & Systems And Multi-Function Generator Dpf Cleaning Machine Ultrasonic Cleaner Professional DPF Ultrasonic Cleaning Machine with Oil Filter System

Dpf Cleaning Machine Ultrasonic Cleaner Professional DPF Ultrasonic Cleaning Machine with Oil Filter System Automatic Multi-Stage Ultrasonic Precision Cleaning Machine for Optical Moulds

Automatic Multi-Stage Ultrasonic Precision Cleaning Machine for Optical Moulds Oil Stain Cleaning Of Hardware Auto Parts Fully Automatic Cleaning Ultrasonic Cleaning Equipment

Oil Stain Cleaning Of Hardware Auto Parts Fully Automatic Cleaning Ultrasonic Cleaning Equipment 40KHZ Automatic Systems Cleaning Machine Smt Ultrasonic Cleaner Vaccum Automatic Pcb Cleaner For Pcb

40KHZ Automatic Systems Cleaning Machine Smt Ultrasonic Cleaner Vaccum Automatic Pcb Cleaner For Pcb Hydro Carbon Vacuum Cleaning line surface Cleaning Cell Phone manufacture Automatic Cleaning Process Ultrasonic Cleaner

Hydro Carbon Vacuum Cleaning line surface Cleaning Cell Phone manufacture Automatic Cleaning Process Ultrasonic Cleaner 25khz Industrial Ultrasonic Cleaner System for Auto Parts DPF Engine Block Carbon Cleaning Machine

25khz Industrial Ultrasonic Cleaner System for Auto Parts DPF Engine Block Carbon Cleaning Machine