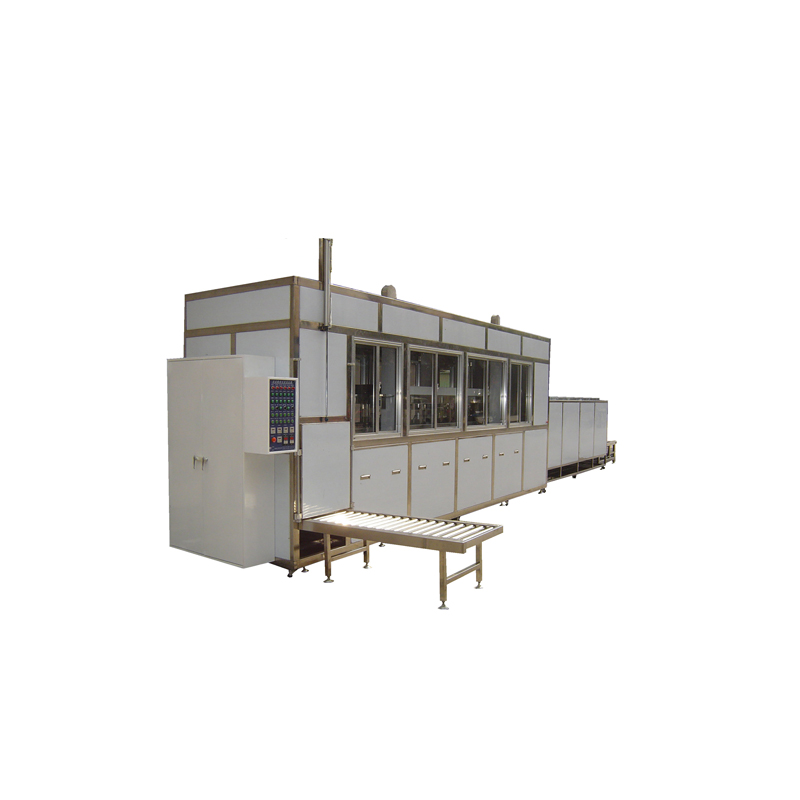

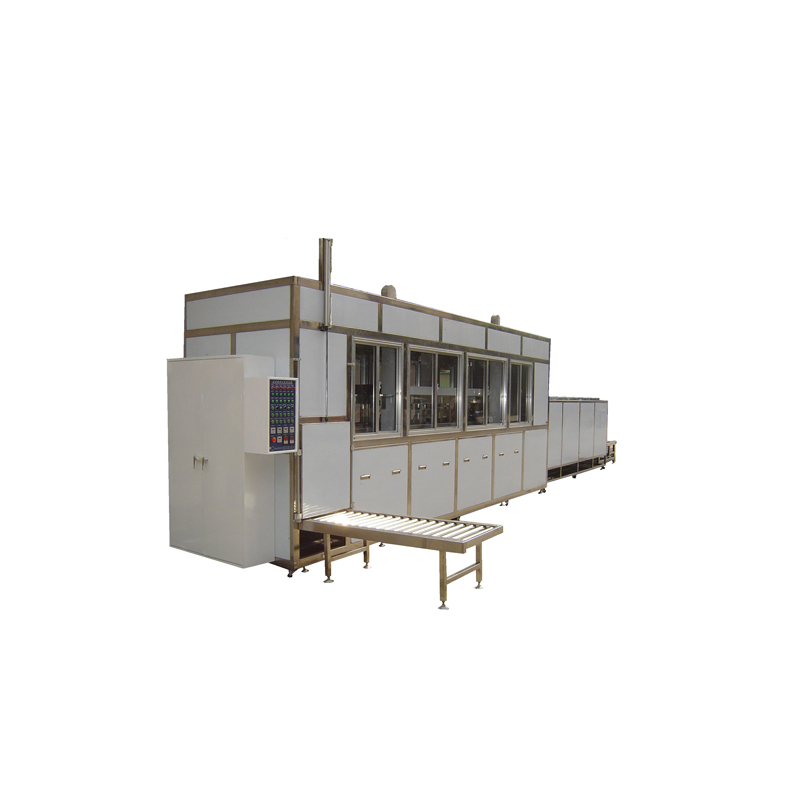

Customized Aluminum Casting Hanging Metal Parts Full Automatic Ultrasonic Cleaning Machine

The principle of the fully automatic ultrasonic cleaning machine is to convert the acoustic energy of the power ultrasonic frequency source into mechanical vibration through the transducer, and make it radiate the cleaning liquid in the tank to the ultrasonic through the cleaning tank wall. Because of the radiated ul…

Customized Aluminum Casting Hanging Metal Parts Full Automatic Ultrasonic Cleaning Machine

The principle of the fully automatic ultrasonic cleaning machine is to convert the acoustic energy of the power ultrasonic frequency source into mechanical vibration through the transducer, and make it radiate the cleaning liquid in the tank to the ultrasonic through the cleaning tank wall. Because of the radiated ultrasonic wave, the microbubbles in the liquid in the groove can keep vibration under the action of acoustic wave. When the sound pressure or sound intensity reaches a certain level, the bubble will expand rapidly and then suddenly close. In this process, the shock wave will be generated at the moment of bubble closure, and 1012-1013pa pressure and local temperature will be generated around the bubble. The huge pressure generated by this ultrasonic cavitation can destroy the insoluble dirt and make them differentiate into solution. The direct and repeated impact of steam cavitation on the dirt. On the one hand, it can destroy the adsorption between the dirt and the surface of the cleaning part, and on the other hand, it can cause the fatigue damage of the dirt layer and be refuted. The vibration of gas-type bubbles can scrub the solid surface. Once the dirt layer has a seam, the bubbles immediately “drill in” and vibrate to make the dirt layer fall off. Because of the cavitation function, the two liquids disperse rapidly at the interface and emulsify. When the solid particles are wrapped in oil and adhere to the surface of the cleaning part, the oil is emulsified Solid particles fall off by themselves, and when ultrasonic wave propagates in the cleaning solution, it will generate positive and negative alternating sound pressure, form a jet, and impact the cleaning part. At the same time, due to nonlinear effects, it will generate sound flow and micro-acoustic flow, while ultrasonic cavitation will generate high-speed micro-jet at the interface of solid and liquid. All these effects can destroy the dirt, remove or weaken the boundary dirt layer, increase the mixing and diffusion effects, and accelerate the dissolution of soluble dirt, Strengthen the cleaning effect of chemical cleaning agent. It can be seen that any place where the liquid can be immersed and the sound field exists has the cleaning function, and its characteristics are applicable to the cleaning of parts with very complex surface shape. Especially after using this technology, the amount of chemical solvent can be reduced, thus greatly reducing environmental pollution.

Customized Aluminum Casting Hanging Metal Parts Full Automatic Ultrasonic Cleaning Machine

标签:fully automatic ultrasonic cleaning machine, Metal Parts Full Automatic Ultrasonic Cleaning Machine

Send Inquiry

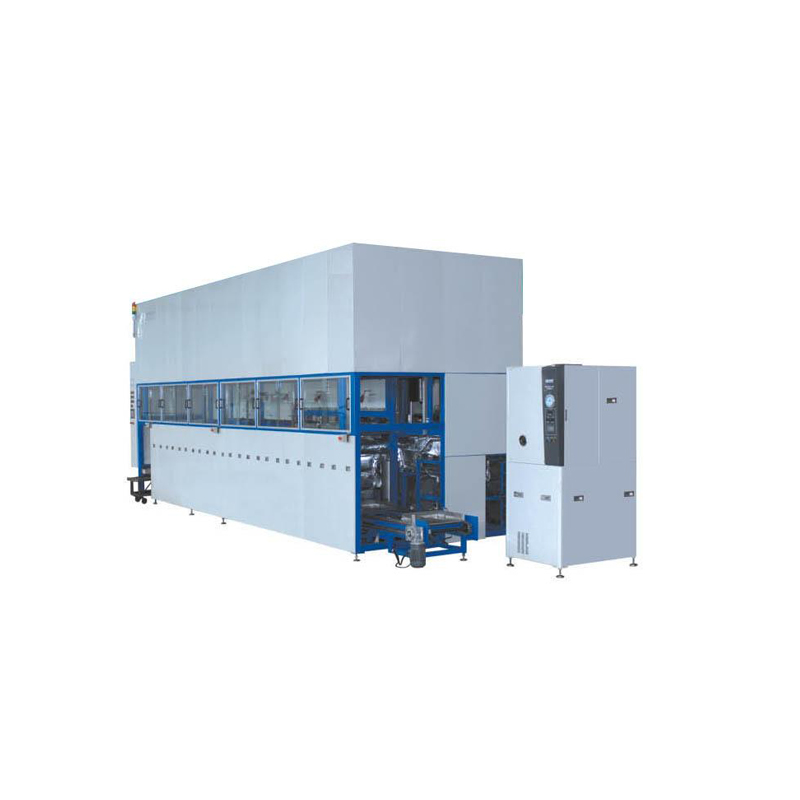

Automation Ultrasonic Cleaning Machine PLC Industrial Cleaning Equipment Removal Of Oil Cleaning And Rust Removal

Automation Ultrasonic Cleaning Machine PLC Industrial Cleaning Equipment Removal Of Oil Cleaning And Rust Removal 5000W Customized Industrial Ultrasonic Cleaner Automatic Parts Cleaning Machine With Filter System

5000W Customized Industrial Ultrasonic Cleaner Automatic Parts Cleaning Machine With Filter System Solar Silicon Ultrasonic Cleaning Equipment OEM Automatic Ultrasonic Cleaning System

Solar Silicon Ultrasonic Cleaning Equipment OEM Automatic Ultrasonic Cleaning System 1000L Repair Tools Parts Ultrasonic Ion Industrial Washing Machine Prices Ultrasonic Cleaning Line With Robot Arm

1000L Repair Tools Parts Ultrasonic Ion Industrial Washing Machine Prices Ultrasonic Cleaning Line With Robot Arm 25KHZ Automotive Parts Ultrasonic Cleaning Machine & Systems And Multi-Function Generator

25KHZ Automotive Parts Ultrasonic Cleaning Machine & Systems And Multi-Function Generator Automatic Ultrasonic Cleaning Machine Suitable Sor Cleaning And Drying Aluminum Alloy Die-Casting Parts Automotive Tools

Automatic Ultrasonic Cleaning Machine Suitable Sor Cleaning And Drying Aluminum Alloy Die-Casting Parts Automotive Tools Oil Stain Cleaning Of Hardware Auto Parts Fully Automatic Cleaning Ultrasonic Cleaning Equipment

Oil Stain Cleaning Of Hardware Auto Parts Fully Automatic Cleaning Ultrasonic Cleaning Equipment 40KHZ Automatic Systems Cleaning Machine Smt Ultrasonic Cleaner Vaccum Automatic Pcb Cleaner For Pcb

40KHZ Automatic Systems Cleaning Machine Smt Ultrasonic Cleaner Vaccum Automatic Pcb Cleaner For Pcb Automatic Ultrasonic Cleaning Machine Assembly Line Type Ultrasonic Cleaning Equipment

Automatic Ultrasonic Cleaning Machine Assembly Line Type Ultrasonic Cleaning Equipment Hydro Carbon Vacuum Cleaning line surface Cleaning Cell Phone manufacture Automatic Cleaning Process Ultrasonic Cleaner

Hydro Carbon Vacuum Cleaning line surface Cleaning Cell Phone manufacture Automatic Cleaning Process Ultrasonic Cleaner Customized Service Automatic Ultrasonic Electronic Component Cleaning Machine Equipment And Vibrating Generator

Customized Service Automatic Ultrasonic Electronic Component Cleaning Machine Equipment And Vibrating Generator Customized Automatic Car Engine Solar Panel Hydrocarbon Rust Metal Grease Removal Industrial Washing Filter Dry Cleaning Machine

Customized Automatic Car Engine Solar Panel Hydrocarbon Rust Metal Grease Removal Industrial Washing Filter Dry Cleaning Machine