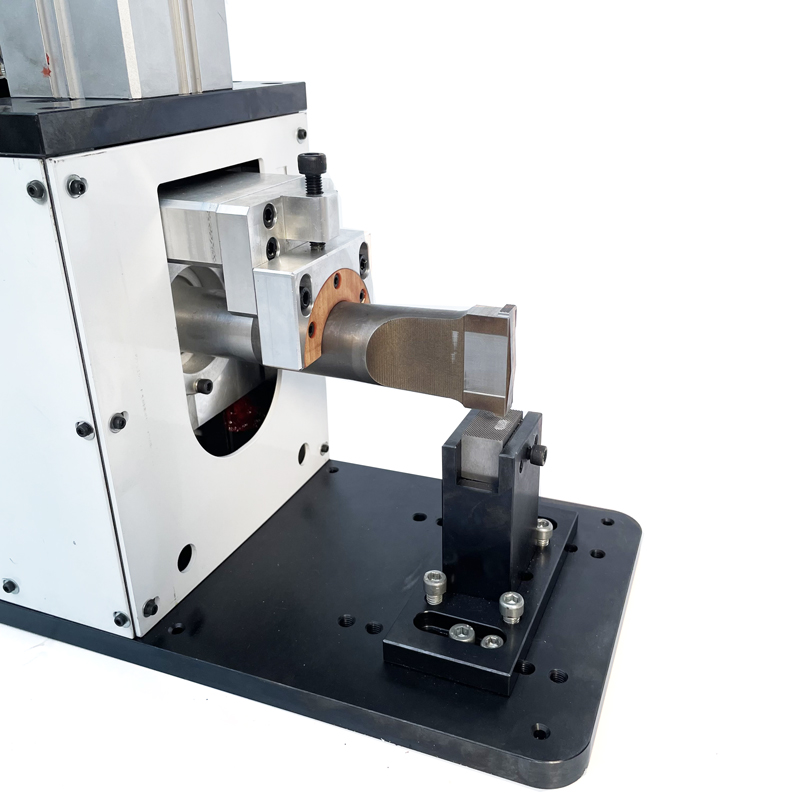

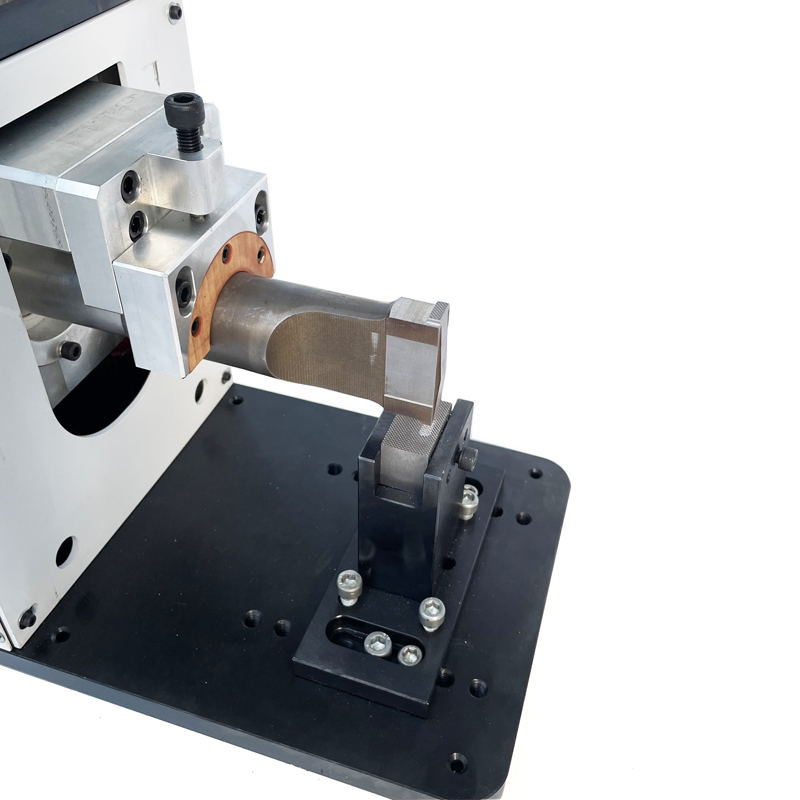

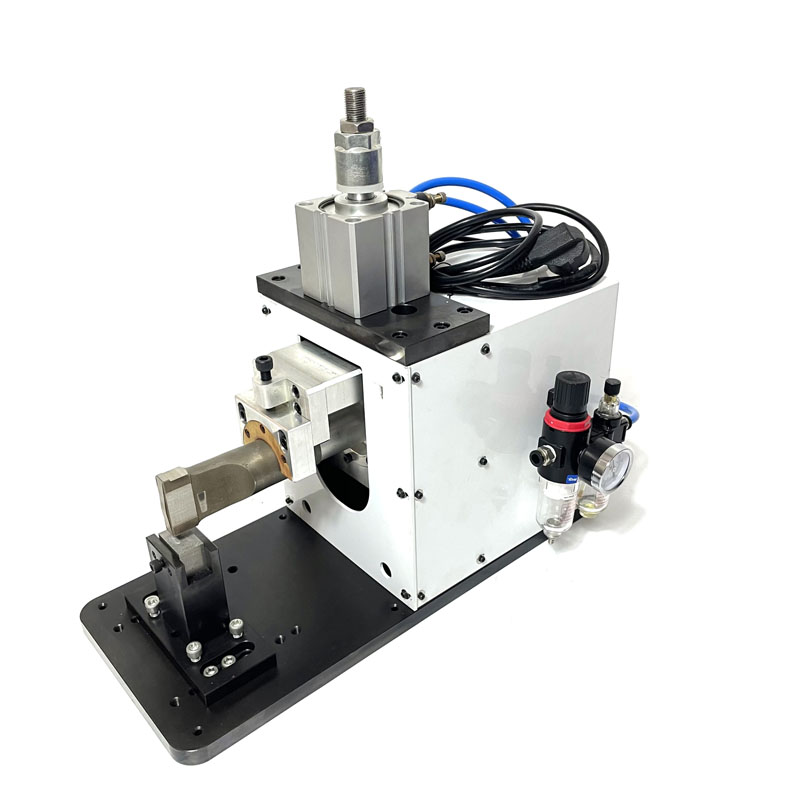

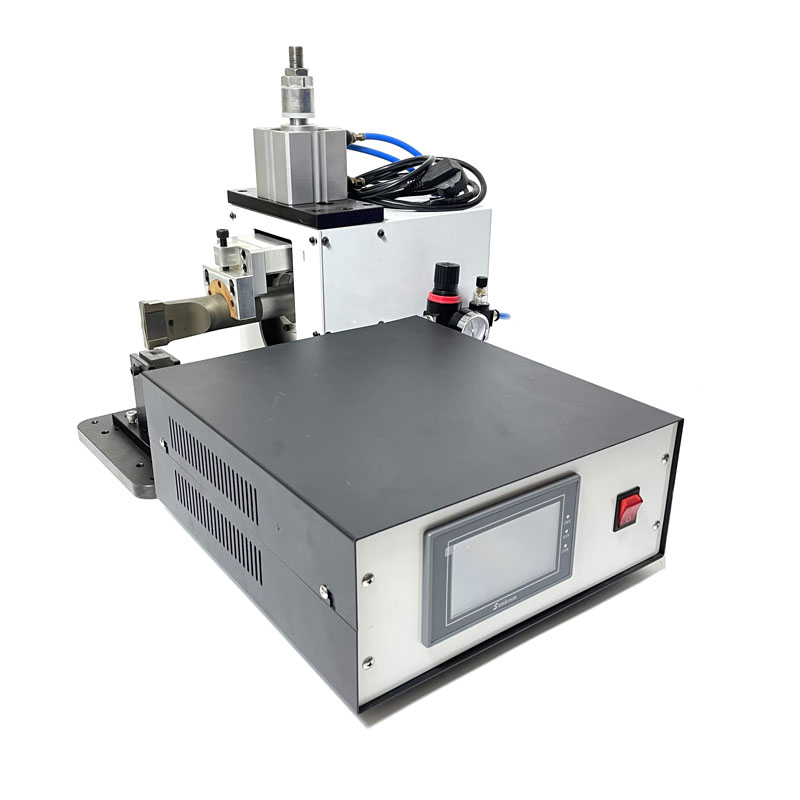

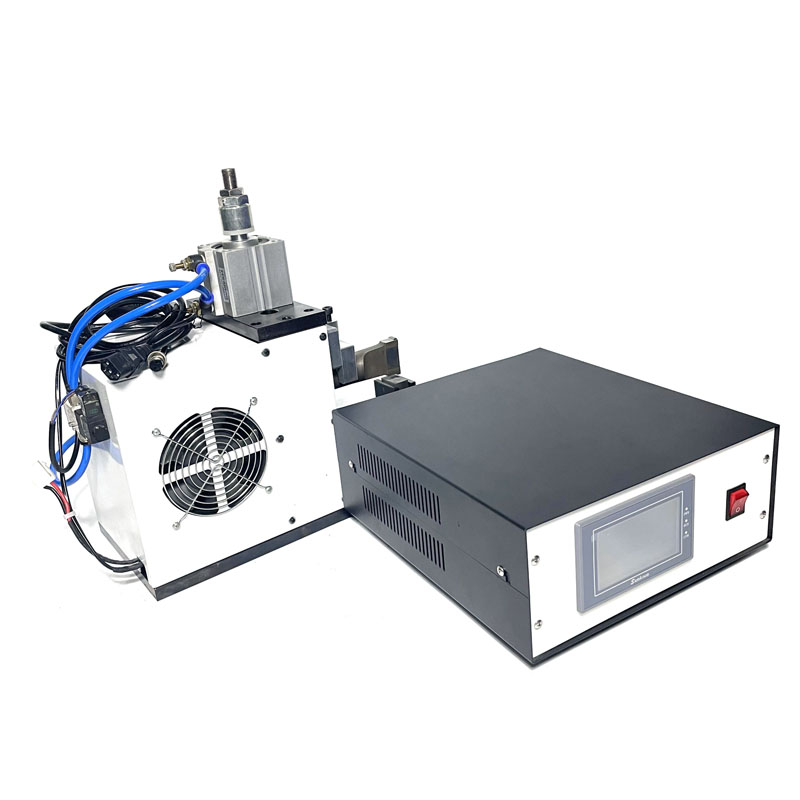

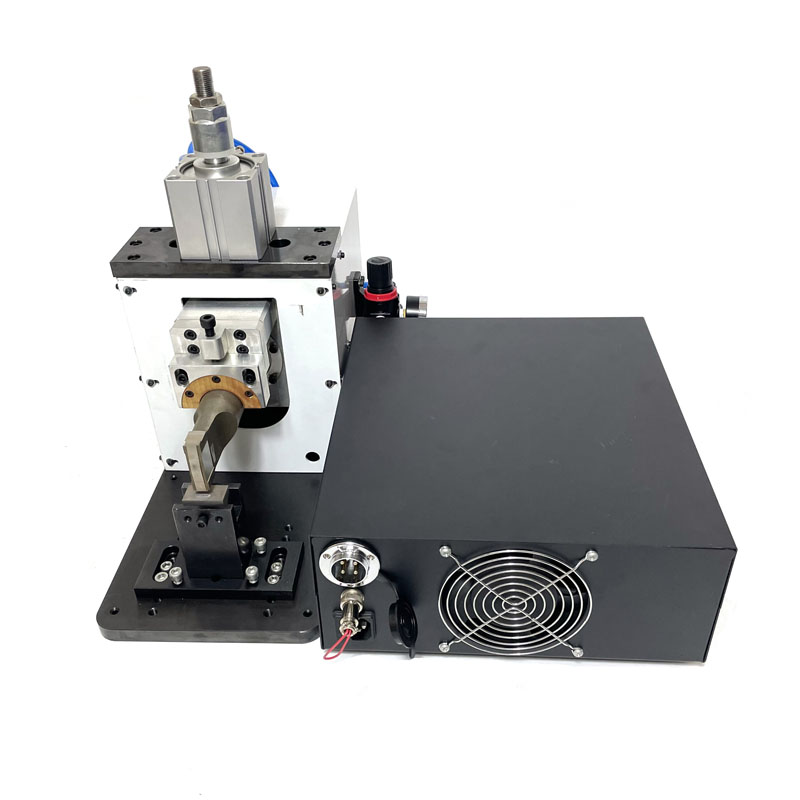

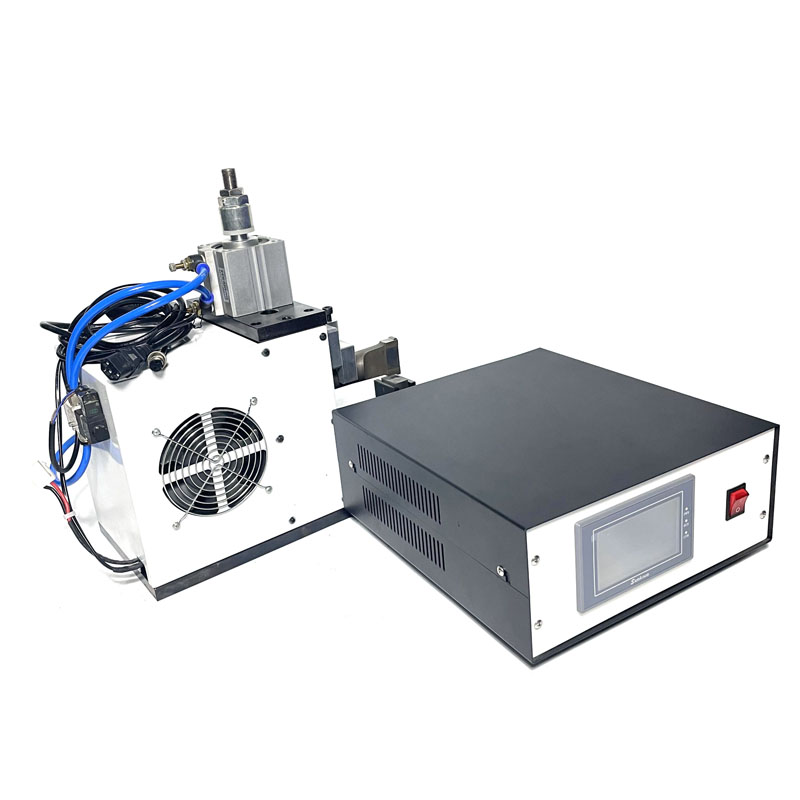

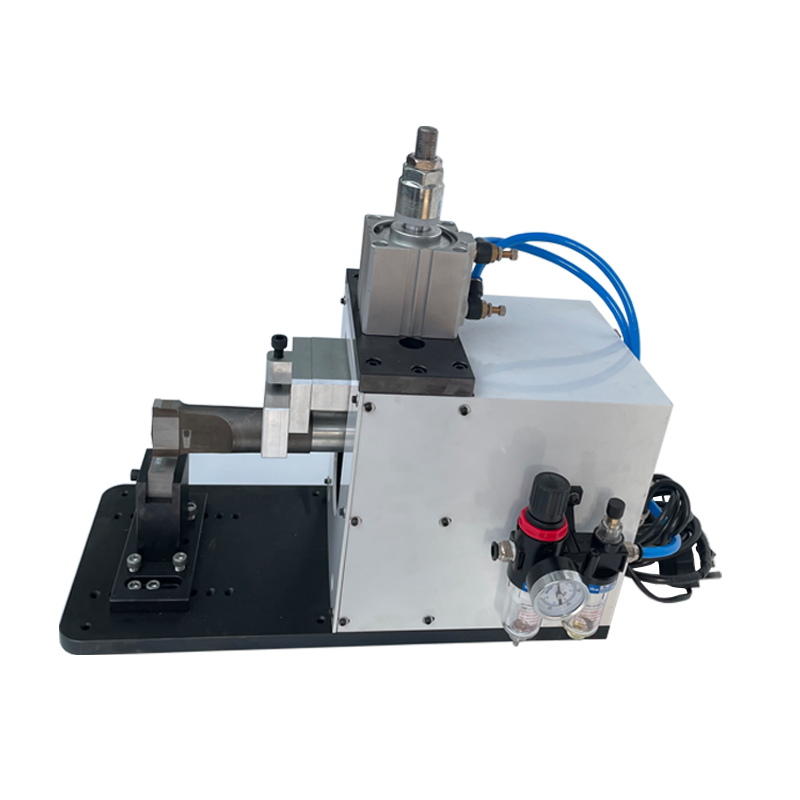

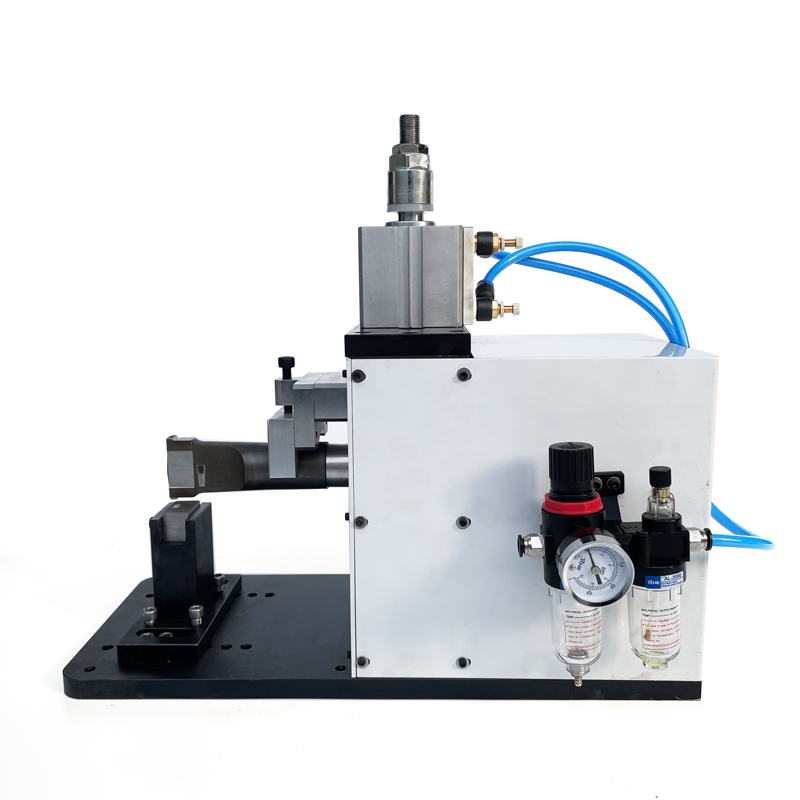

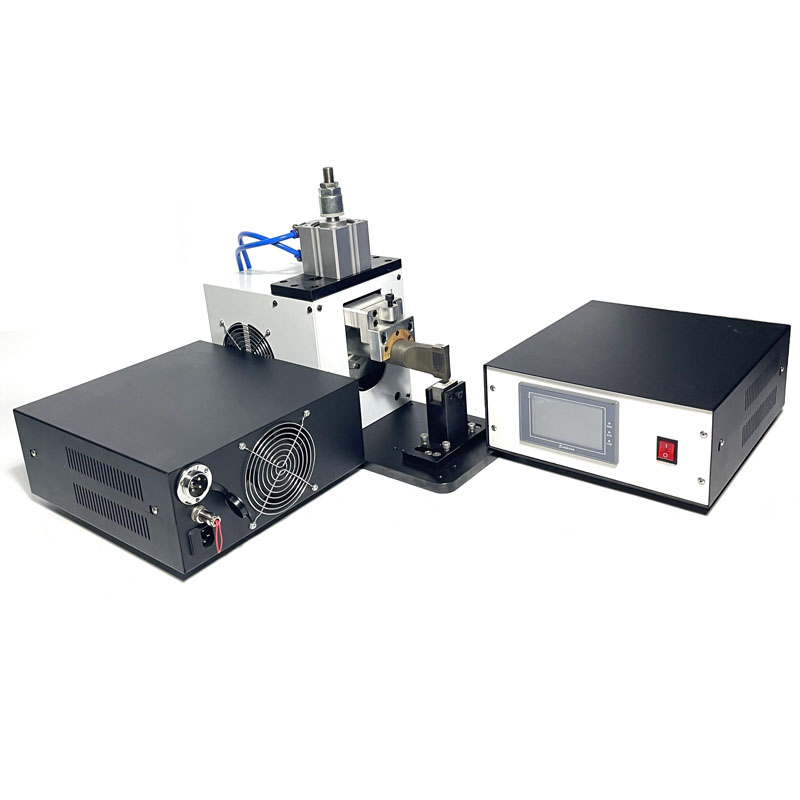

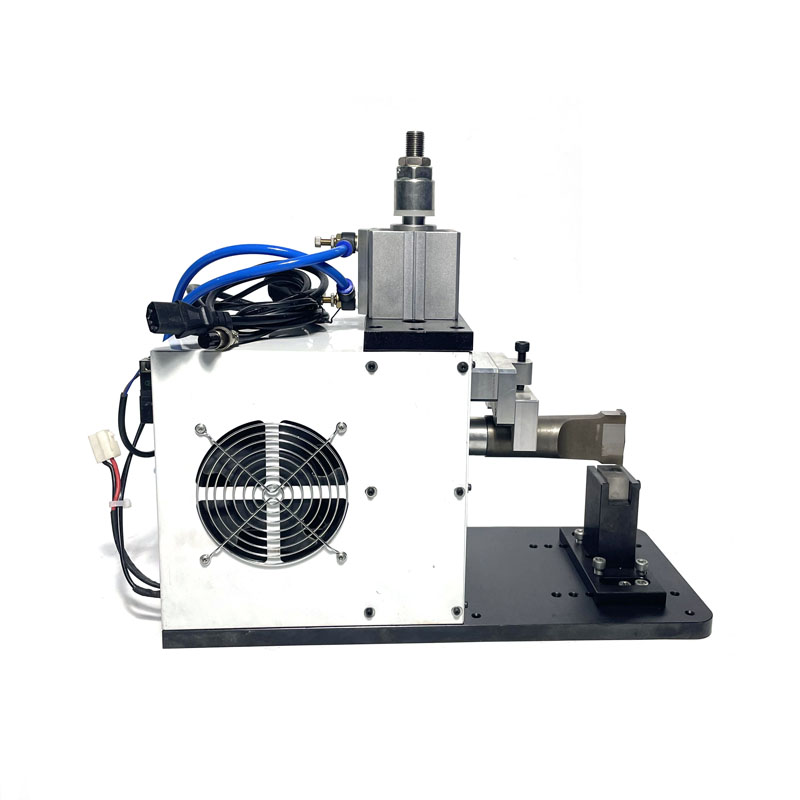

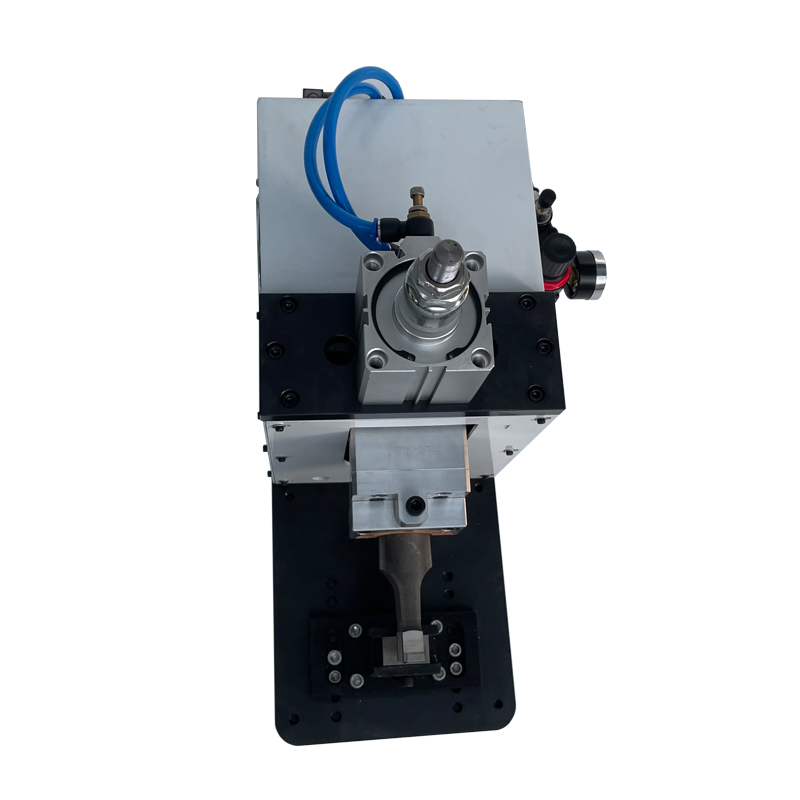

Battery Ultrasonic Spot Welder Machine For 18650 & Pouch Cell Al/Ni/Cu Metal Tab Foil Welding

At present, lithium-ion batteries have the advantages of high specific energy, more recycling times, and long storage time. They are not only widely used in portable electronic devices such as mobile phones, digital cameras, and laptops, but also widely used in electric vehicles, electric bicycles, and electric tools…

Battery Ultrasonic Spot Welder Machine For 18650 & Pouch Cell Al/Ni/Cu Metal Tab Foil Welding

At present, lithium-ion batteries have the advantages of high specific energy, more recycling times, and long storage time. They are not only widely used in portable electronic devices such as mobile phones, digital cameras, and laptops, but also widely used in electric vehicles, electric bicycles, and electric tools and other large and medium-sized electric equipment. Therefore, the performance requirements of lithium-ion batteries are increasingly high.

In the field of electric tools using lithium ion batteries, with the increasing requirements of customers, the capacity of the battery cell and the discharge current of the battery pack are gradually increasing, so the thickness of the nickel strip is also gradually increasing. The existing nickel strip includes a positive nickel strip 1, a negative nickel strip 2 and a nickel strip connection part 6. The positive nickel strip 1 and negative nickel strip 2 are respectively located at the left and right ends of the nickel strip connection part 6.

For the existing ultrasonic metal welding machine, in order to weld thick nickel strips (such as 0.3 mm thick nickel strips), it is necessary to increase the power during welding and use higher power for welding, which will greatly reduce the service life of the spot welding machine, and is prone to dangerous situations, causing the spot welding machine to burn out due to high power operation. Therefore, there is an urgent need to develop a nickel strip at present. While increasing the thickness, the spot welder does not need to increase the working power. The spot welder can complete welding under the normal use power.

| Type | Power(W) | Frequency (KHz) |

| PU-MSW2000W | 2000W | 20KHZ |

| PU-MSW2600W | 2600W | 20KHZ |

| PU-MSW3200W | 3200W | 20KHZ |

| PU-MSW4000W | 4000W | 20KHZ |

| PU-MSW800W | 800W | 40khz |

Battery Ultrasonic Spot Welder Machine For 18650 & Pouch Cell Al/Ni/Cu Metal Tab Foil Welding

标签:ultrasonic metal welding machine, Ultrasonic Spot Welder Machine

Send Inquiry

Full Automatic Aluminum Sheet copper wire Ultrasonic Wire Harness Welding Machine And Power Supply Generator

Full Automatic Aluminum Sheet copper wire Ultrasonic Wire Harness Welding Machine And Power Supply Generator 4000W High Power Ultrasonic Metal Welding Machine Of Copper Wire Soldering Metal Wire Splicing

4000W High Power Ultrasonic Metal Welding Machine Of Copper Wire Soldering Metal Wire Splicing Ultrasonic Copper Wire Spot Welding Machine For Aluminum Wire For Battery Wire Welding Machine

Ultrasonic Copper Wire Spot Welding Machine For Aluminum Wire For Battery Wire Welding Machine Prismatic And Pouch Battery Ultrasonic Spot Welding Machine Ultrasonic Battery Welding Machine For Battery Cathode

Prismatic And Pouch Battery Ultrasonic Spot Welding Machine Ultrasonic Battery Welding Machine For Battery Cathode 20khz 2000W Ultrasonic Spot Metal Welder for Multi Copper Wires With Copper Plate

20khz 2000W Ultrasonic Spot Metal Welder for Multi Copper Wires With Copper Plate 1800W 20KHZ Ultrasonic Welder Fast Lithium Battery Welding Copper With Drivers Generator

1800W 20KHZ Ultrasonic Welder Fast Lithium Battery Welding Copper With Drivers Generator Ultrasonic Wire Harness Welding Machine for Copper and Aluminum Metal Braid Wire Welding Machine

Ultrasonic Wire Harness Welding Machine for Copper and Aluminum Metal Braid Wire Welding Machine 20khz Ultrasonic Metal Battery Spot Welder Machine for Pouch Cell and Supercapacitor

20khz Ultrasonic Metal Battery Spot Welder Machine for Pouch Cell and Supercapacitor Pouch Cell Ultrasonic Spot Welder Welding Machine For Al Tab Or Aluminum Foil Welding Machines

Pouch Cell Ultrasonic Spot Welder Welding Machine For Al Tab Or Aluminum Foil Welding Machines Wire Bonding Ultrasonic Metal Welding Machine of Nickel Aluminum Copper Wire Soldering Metal Wire Splicing Ultrasonic Welder

Wire Bonding Ultrasonic Metal Welding Machine of Nickel Aluminum Copper Wire Soldering Metal Wire Splicing Ultrasonic Welder Lithium Battery Cap Pneumatic Ultrasonic Metal Spot Welder Welding Machine For Pouch Cell Electrode Tab/Foil

Lithium Battery Cap Pneumatic Ultrasonic Metal Spot Welder Welding Machine For Pouch Cell Electrode Tab/Foil 3KW Ultrasonic Wiring Harness Metal Welding Machine And Frequency Generator

3KW Ultrasonic Wiring Harness Metal Welding Machine And Frequency Generator