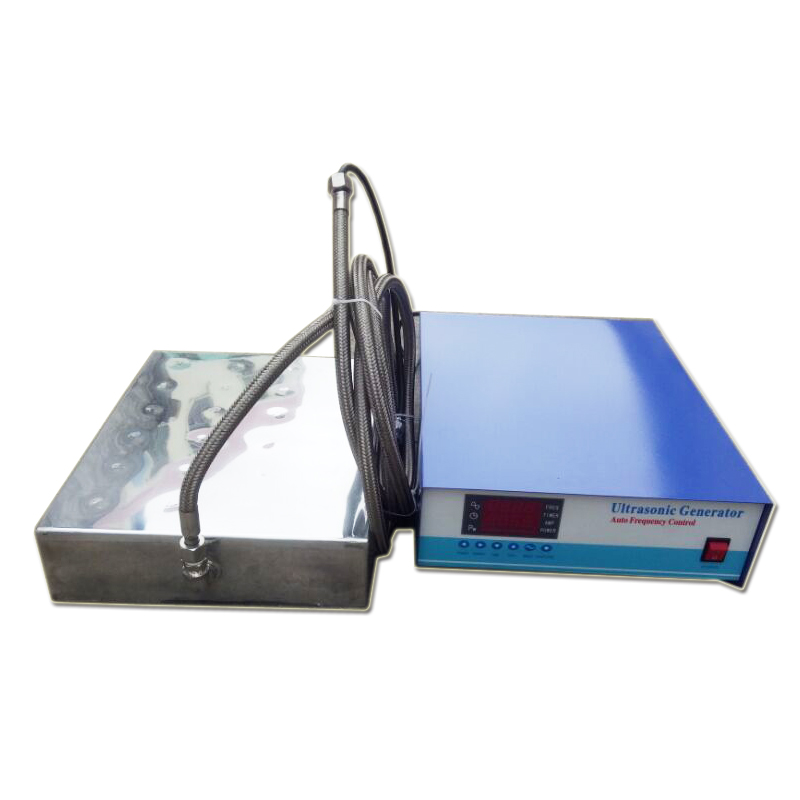

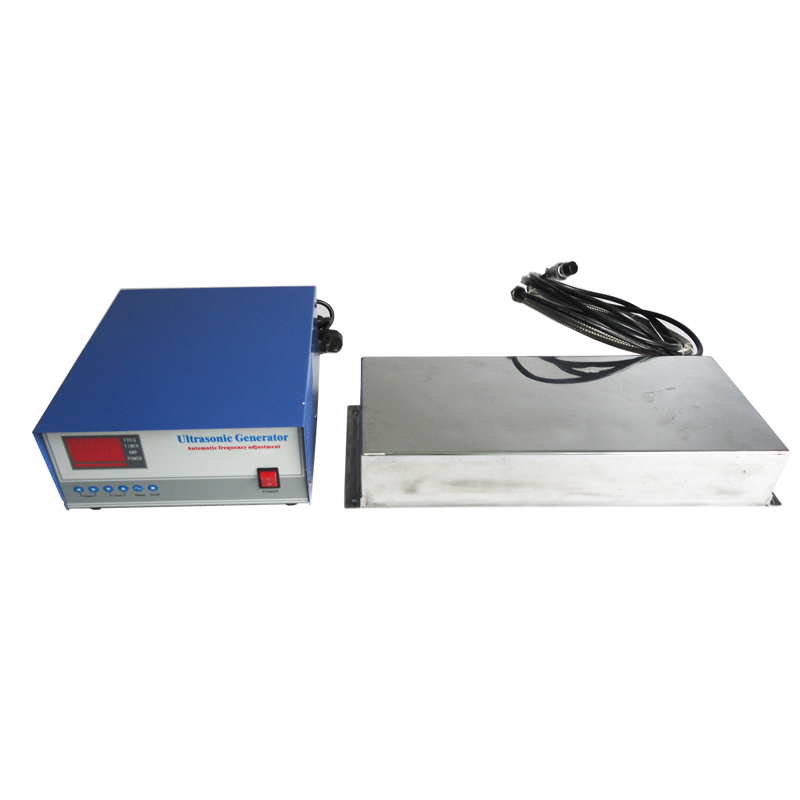

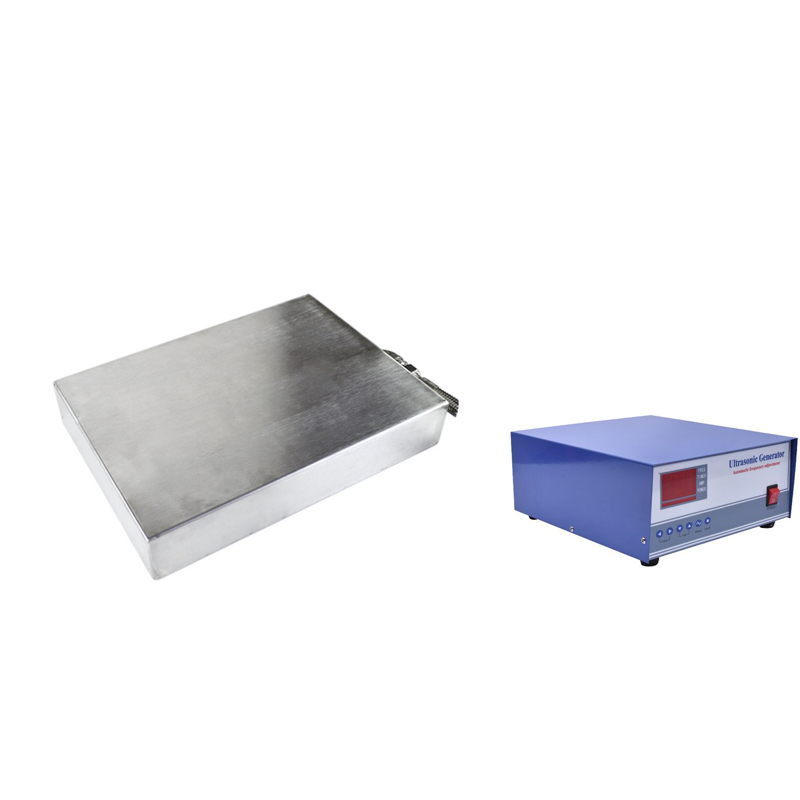

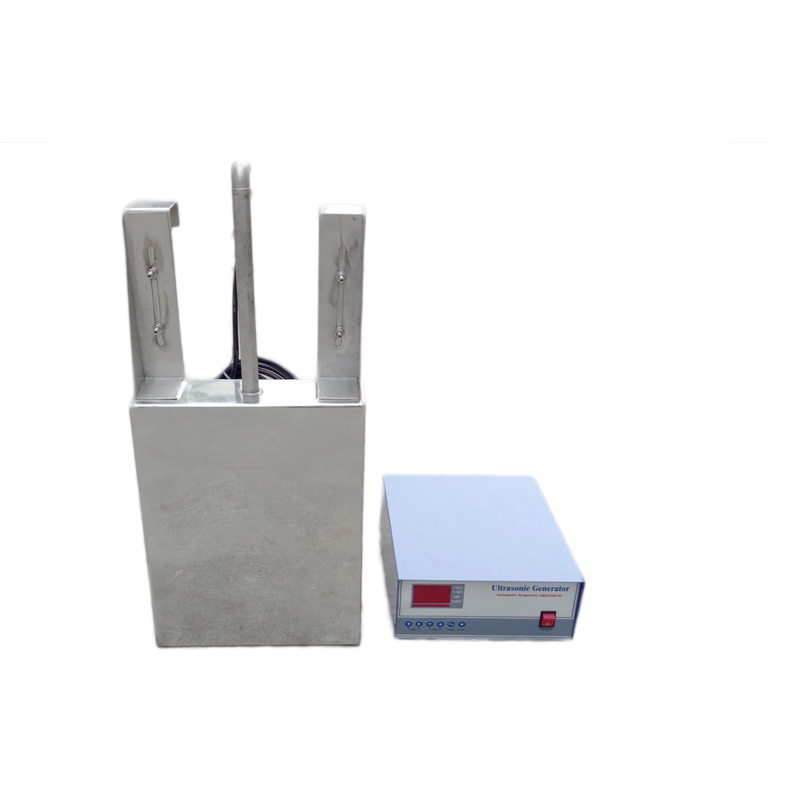

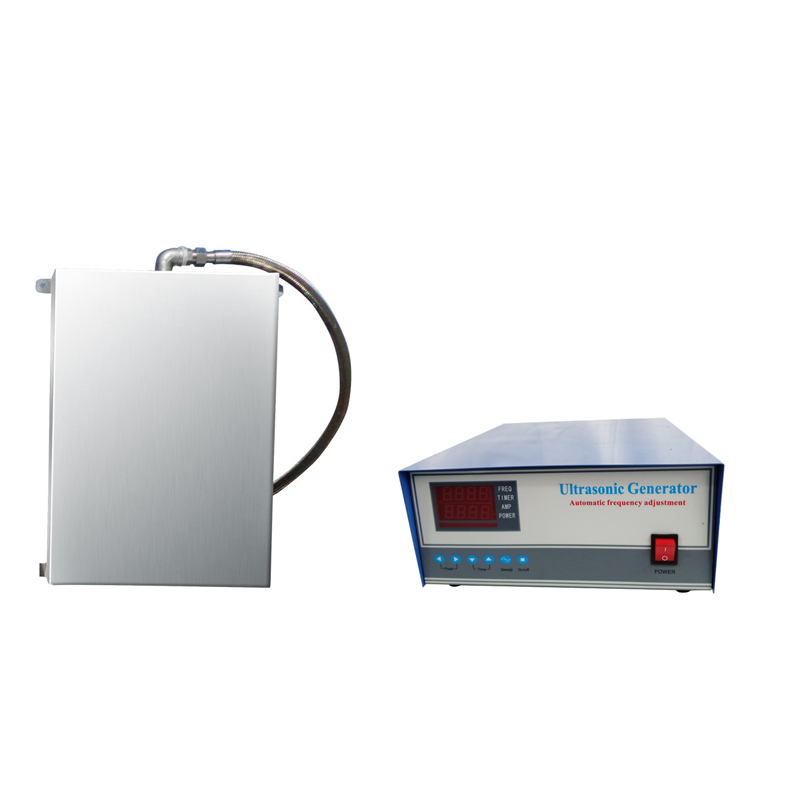

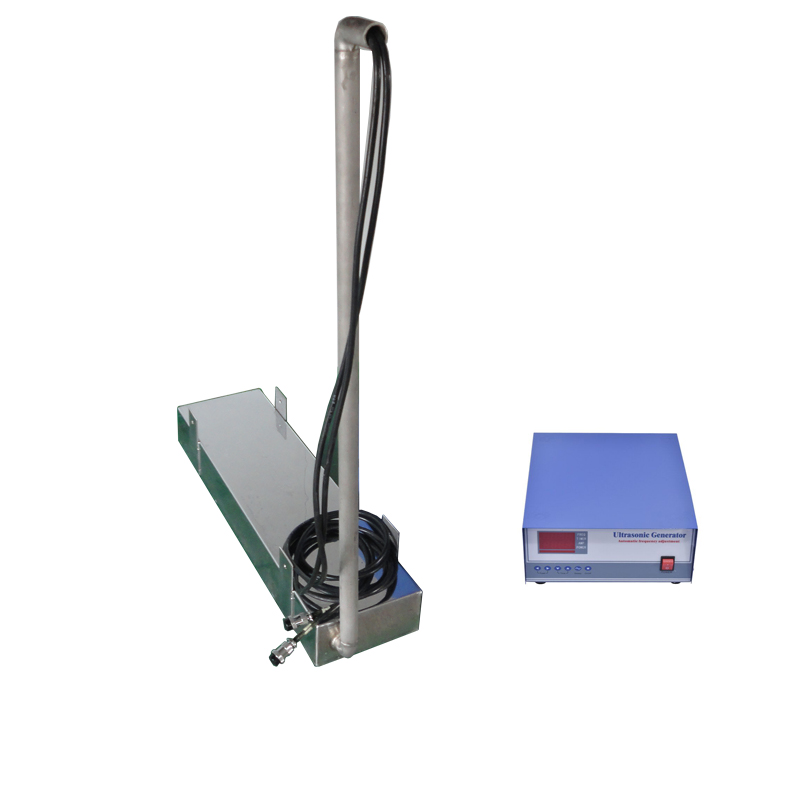

300W Immersible DPF Washing Machine Engine Parts Injector Hardware Rod Underwater Transducers Ultrasonic Cleaner

The design concept of the vibration plate is mainly determined by the requirements of the cleaning object, as well as from the perspective of installation and price maintenance. From the perspective of ultrasonic emission, it can also be divided into “bottom vibration” (from the bottom of the cleaning tan…

The design concept of the vibration plate is mainly determined by the requirements of the cleaning object, as well as from the perspective of installation and price maintenance. From the perspective of ultrasonic emission, it can also be divided into “bottom vibration” (from the bottom of the cleaning tank), “side vibration” (from one side of the cleaning tank), “bottom side combined vibration”, and “opposite vibration”.

- The bottom vibration plate, with the vibrator directly bonded to the bottom of the cleaning tank, is a commonly used style for making single tank cleaning machines. The advantages of this vibration plate are its simple structure, few additional functions, and low cost, making it suitable for small sample cleaning in factories, schools, and research institution laboratories.

The disadvantage is that if the vibration surface is corroded by cavitation, the entire cleaning machine cannot be repaired and can only be scrapped.

- Flange type vibration plate, the vibrator is directly bonded to a vibration plate, and the vibration plate is made into a flange plate, with thicker surroundings; 410 holes are drilled every 55-65mm interval, using Teflon as a pad and drilling in conjunction with the bottom flange of the cleaning tank. M8 screws are used to compress and seal the bottom of the cleaning tank. Its advantage is that there are corrosion spots on the vibration surface, which can replace the groove bottom. It is suitable for vibration plates with a small groove bottom area and a power of around 1200W. Used in the early days on multi slot cleaning assembly lines, it is particularly suitable for cleaning clock parts, hardware, and optical lenses.

The disadvantage of flange type vibration plates is that during installation on a multi slot continuous cleaning line, the working space is limited during replacement, and there are many fastening screws for the flange vibration plates, which are prone to leakage and damage. In addition, it is not recommended to have drainage holes, testing holes, or other holes for flange type vibration plates. The reason is that the installation and disassembly of vibration plates involves the addition of pipeline interface engineering, and the stress on the bottom of the vibration plate can easily cause cracks in the nearby vibration element bonding and damage the entire block

- Strip vibration plates, with powers of 20W, 250W, 300W, 350W, etc., are widely used in vacuum cleaning tanks. Generally, direct air cleaning involves the tank having a straightness between 15-60kPa, a reduced pressure steam between 1-12kPa, and a straightness below 01kPa. The vacuum action time is 1-3 minutes, and the vibration plate box expands and contracts frequently under normal pressure and vacuum repeatedly. Without sufficient stiffness, it is not feasible. The force area of the strip vibration plate is small, and the vibration plate cover is a buckle type, with reinforcing ribs welded and supported. High transmission power and lower cost compared to ultrasonic rods

- Bottom mounted box vibration plate. Its advantages are convenient production, simple installation, small confined space, and almost no impact on the installation of pipelines through bottom openings. The power of the vibration box can be large or small, with a range of 250 to 2000 and a wide range of square applications.

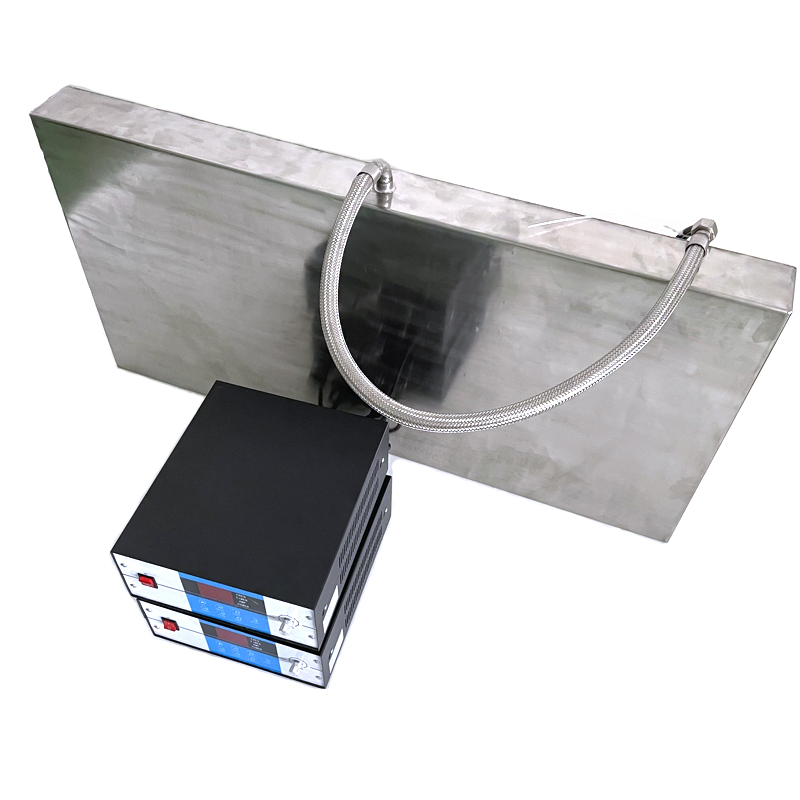

- The side mounted vibration plate has the same advantages as the bottom mounted box vibration plate. The difference is that the bottom of the groove is mostly rectangular (the ratio of length to width is very different), and it is installed on the side, so it is more convenient for wiring and disassembly. It should be noted that the symmetrical end face of the outlet of the vibration box needs to be welded with symmetrical and equally high folded pieces to ensure uniform force on the vibration plate, secure fixation, and prevent low-frequency oscillation and howling

- There are stainless steel tube type and stainless steel mesh armored Teflon hose type for input vibration plates and outgoing lines. The diagram shows a hard tube type. The manual vibration and extraction eliminates the hassle of installation, and the disassembly and replacement only involves lifting and lowering. However, it is not suitable for large machines and multi tank continuous cleaning machines. When designing the vibration plate, consideration should be given to welding the counterweight plate to overcome the buoyancy effect of the washing medium on the vibration plate

| Type | Diamention(mm) | Frequency (Khz) | Power(W) | Ultrasonic Transducer |

| PU-UITP300W | 300*190*100 | 25,28,33,40,80,130 | 300 | 6 |

| PU-UITP600W | 360*275*100 | 25,28,33,40,80,130 | 600 | 12 |

| PU-UITP1000W | 450*350*100 | 25,28,33,40,80,130 | 1000 | 20 |

| PU-UITP1200W | 470*380*100 | 25,28,33,40,80,130 | 1200 | 24 |

| PU-UITP1500W | 520*450*100 | 25,28,33,40,80,130 | 1500 | 30 |

| PU-UITP1800W | 560*450*100 | 25,28,33,40,80,130 | 1800 | 36 |

| PU-UITP2000W | 650*450*100 | 25,28,33,40,80,130 | 2000 | 40 |

| PU-UITP2400W | 740*520*100 | 25,28,33,40,80,130 | 2400 | 48 |

| PU-UITP3000W | 820*540*100 | 25,28,33,40,80,130 | 3000 | 60 |

| PU-UITP5000W | 1200*590*100 | 25,28,33,40,80,130 | 5000 | 100 |

| OEM Ultrasonic Immersible Transducer Pack(Size, Frequency,Power) |

标签:300W Immersible DPF Washing Machine, Rod Underwater Transducers Ultrasonic Cleaner

Send Inquiry

Industrial Ultrasound Cleaning Machine Vibration Generator Immersible Ultrasonic Cleaning Machine

Industrial Ultrasound Cleaning Machine Vibration Generator Immersible Ultrasonic Cleaning Machine Submersible Ultrasonic Transducers Immersible Underwater Ultrasonic Transducer Vibrator Plate

Submersible Ultrasonic Transducers Immersible Underwater Ultrasonic Transducer Vibrator Plate 1800W Underwater Ultrasound Rod Vibrator Transducer Printer Automotive Golf Ball Ultrasonic Sonicator Bath Screw Rinse Oil Rust

1800W Underwater Ultrasound Rod Vibrator Transducer Printer Automotive Golf Ball Ultrasonic Sonicator Bath Screw Rinse Oil Rust 2400W 40KH Immersible Ultrasonic Vibrator Cleaning Submersible Ultrasonic Cleaner Transducers Plate

2400W 40KH Immersible Ultrasonic Vibrator Cleaning Submersible Ultrasonic Cleaner Transducers Plate Customized Submersible Ultrasonic Vibration Plate 28/40KHZ 300-2400W SUS304/316 Ultrasonic Immersible Trandsucer Packs

Customized Submersible Ultrasonic Vibration Plate 28/40KHZ 300-2400W SUS304/316 Ultrasonic Immersible Trandsucer Packs Ultrasonic Immersed Transducer Plate For Cleaning Oil Rust Wax Auto Engine And Degreasing

Ultrasonic Immersed Transducer Plate For Cleaning Oil Rust Wax Auto Engine And Degreasing Industrial Ultrasonic Cleaning Machine Immersible Ultrasonic plate Ultrasonic Transducer Vibration Plate

Industrial Ultrasonic Cleaning Machine Immersible Ultrasonic plate Ultrasonic Transducer Vibration Plate Customized 28/40KHZ Ultrasound Cleaning Machine Immersible Ultrasonic Cleaner Vibrating Transducer Plate

Customized 28/40KHZ Ultrasound Cleaning Machine Immersible Ultrasonic Cleaner Vibrating Transducer Plate 300W Underwater Ultra Sonic Plate Oil Rust Degreaser Gear Block Metal Parts Immersible Ultrasonic Cleaner

300W Underwater Ultra Sonic Plate Oil Rust Degreaser Gear Block Metal Parts Immersible Ultrasonic Cleaner Underwater Ultrasonic Cleaner Machine Ultrasonic Piezo Transducer Submersible 40kHz Ultrasonic Transducers

Underwater Ultrasonic Cleaner Machine Ultrasonic Piezo Transducer Submersible 40kHz Ultrasonic Transducers 2500W Submersible Ultrasonic Transducer Cleaning Wash Oil Engine Degreasing Tank

2500W Submersible Ultrasonic Transducer Cleaning Wash Oil Engine Degreasing Tank 1800W High Vibration Power Submersible Ultrasonic Cleaner For Parts Cleaning System

1800W High Vibration Power Submersible Ultrasonic Cleaner For Parts Cleaning System