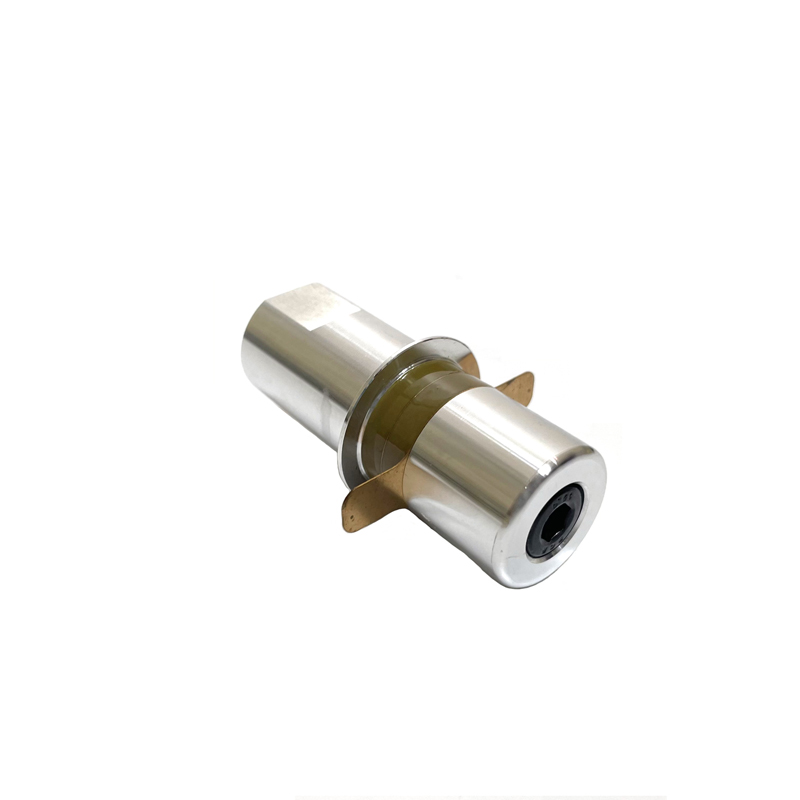

30kHz 800W High Quality Ultrasonic Plastic Welding Transducer Piezoelectric Ceramic Transducer

When a voltage is applied to the two poles of a piezoelectric chip, due to the inverse piezoelectric effect of the piezoelectric ceramic material, the piezoelectric chip undergoes deformation in the thickness direction (i.e. the axial direction of the transducer), which is repeatedly stretched and compressed under th…

30kHz 800W High Quality Ultrasonic Plastic Welding Transducer Piezoelectric Ceramic Transducer

When a voltage is applied to the two poles of a piezoelectric chip, due to the inverse piezoelectric effect of the piezoelectric ceramic material, the piezoelectric chip undergoes deformation in the thickness direction (i.e. the axial direction of the transducer), which is repeatedly stretched and compressed under the action of alternating current to convert electrical energy into mechanical energy. Under the action of alternating current, the oscillator undergoes periodic stretching and compression deformation at the resonant frequency, which also drives the amplitude modulator to resonate. In this way, the oscillator and the amplitude modulator each become a simple harmonic vibration unit. The oscillator is excited by the electrical signal, and then the amplitude modulator is excited, causing both to resonate. While each resonant unit outputs axial amplitude, it also undergoes periodic deformation in the radial direction. At both ends of the unit, the axial deformation is maximum, while the radial deformation is minimum, while the position of the intermediate node is opposite. The structural gain of the resonance unit is proportional to the mass ratio at both ends of the node. The amplitude generated by the ultrasonic transducer depends on the structural gain of the vibrator and the amplitude modulator, and also on the applied voltage. The output amplitude affects the output power of the ultrasonic transducer. The greater the amplitude, the higher the voltage, and the higher the output power.

| Type | Full-length(mm) | Joint Bolt(mm) | Frequency(KHz) | Resonance Impedance(Ω) | Capacity(pF) | Input Power (W) |

| PU-UWT30500 P8 | 77 | M10×1.5 | 30 | 5 | 5500 | 500 |

| PU-UWT28200 P4 | 92.1 | M10×1 | 28 | 20 | 3000 | 200 |

| PU-UWT28100 P8 | 91 | M8×1 | 28 | 25 | 2200 | 100 |

| PU-UWT28250 P8 | 94 | 1/2-20 UNF | 28 | 20 | 4000 | 250 |

| PU-UWT35100 P8 | 71 | M8×1 | 35 | 25 | 2200 | 100 |

| PU-UWT38100 P8 | 66 | M8×1.25 | 38 | 40 | 1200 | 100 |

| PU-UWT38200 P4 | 65 | M8×1 | 38 | 14 | 3300 | 200 |

30kHz 800W High Quality Ultrasonic Plastic Welding Transducer Piezoelectric Ceramic Transducer

标签:30kHz 800W High Quality Ultrasonic Plastic Welding Transducer, Ultrasonic Plastic Welding Transducer Piezoelectric Ceramic Transducer

Send Inquiry

40KHZ 100W Ultrasonic Spot Welder Transducer For Handheld Manual Spot Welder Ultrasonic Welding Machine

40KHZ 100W Ultrasonic Spot Welder Transducer For Handheld Manual Spot Welder Ultrasonic Welding Machine 40KHz High Frequency Ultrasonic Welding Transducer For Ultrasonic Spot Welder Machine

40KHz High Frequency Ultrasonic Welding Transducer For Ultrasonic Spot Welder Machine 30khz Ultrasonic Spot Welding Transducer With Booster For PVC PE PP Plastic Welder

30khz Ultrasonic Spot Welding Transducer With Booster For PVC PE PP Plastic Welder Welding Transducer High Power 28KHz Spot Welder Machine Parts Piezoelectric Ceramic Sensor Ultrasonic Welding Transducer

Welding Transducer High Power 28KHz Spot Welder Machine Parts Piezoelectric Ceramic Sensor Ultrasonic Welding Transducer 30Khz Plastic Spot Welder Ultrasonic Piezo Transducer For Plastic Ultrasonic Welding System

30Khz Plastic Spot Welder Ultrasonic Piezo Transducer For Plastic Ultrasonic Welding System 40khz Ultrasonic Spot Welder Transducer For Prismatic Battery Semi-automatic Ultrasonic Spot Welder

40khz Ultrasonic Spot Welder Transducer For Prismatic Battery Semi-automatic Ultrasonic Spot Welder 35KHZ Plastic Handheld Ultrasonic Spot Welder Transducer For Ultrasonic Plastic Spot Welder Machine

35KHZ Plastic Handheld Ultrasonic Spot Welder Transducer For Ultrasonic Plastic Spot Welder Machine 28khz Ultrasonic Handheld Spot Welder Plastic Welding Machine Transducer Booster Horn

28khz Ultrasonic Handheld Spot Welder Plastic Welding Machine Transducer Booster Horn 35KHZ 300W Ultrasonic Welder Transducers 25mm 35k Welding 300 Watt Ultrasonic Transducer 35khz For Mask Machine

35KHZ 300W Ultrasonic Welder Transducers 25mm 35k Welding 300 Watt Ultrasonic Transducer 35khz For Mask Machine 28KHz Ultrasonic Oscillator System With Transducer and Booster Applied for Spot Welding Machinary

28KHz Ultrasonic Oscillator System With Transducer and Booster Applied for Spot Welding Machinary 28KHZ 1000W Ultrasonic Spot Welder Transducer For Portable Hand Ultrasonic Plastic Spot Welder Machine

28KHZ 1000W Ultrasonic Spot Welder Transducer For Portable Hand Ultrasonic Plastic Spot Welder Machine 28KHZ 1000W Industrial Ultrasonic Spot Welding Machine Transducer Cutting Skin Scrubber Cavitation Pressure Transducer

28KHZ 1000W Industrial Ultrasonic Spot Welding Machine Transducer Cutting Skin Scrubber Cavitation Pressure Transducer