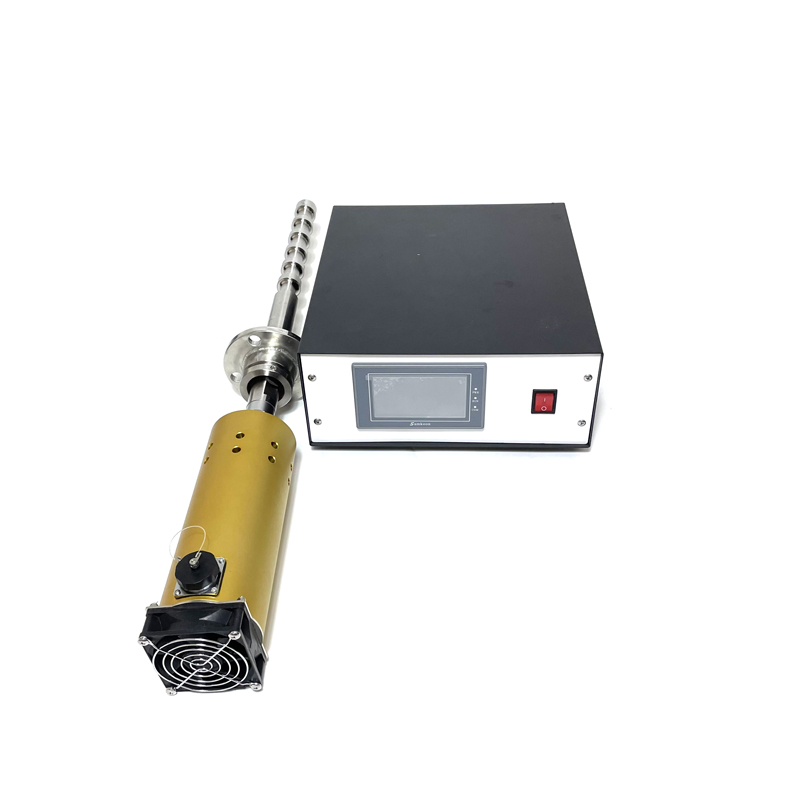

Ultrasonic Emulsification Disperser Cosmetic Mixing Extraction Ultrasonic Extraction Equipment

The principle of ultrasonic vibration rod: Ultrasonic technology is mainly used as a physical means and tool to form a series of conditions close to extreme critical when generating chemical reactions. This energy can not only stimulate chemical reactions, accelerate the speed and efficiency of chemical reactions, bu…

Ultrasonic Emulsification Disperser Cosmetic Mixing Extraction Ultrasonic Extraction Equipment

The principle of ultrasonic vibration rod: Ultrasonic technology is mainly used as a physical means and tool to form a series of conditions close to extreme critical when generating chemical reactions. This energy can not only stimulate chemical reactions, accelerate the speed and efficiency of chemical reactions, but also change the properties of certain chemical reactions, making the original chemical components produce some unexpected effects and functions, This is called sonochemistry. Almost all chemical reactions can use sonochemistry as a physical aid, such as extraction and separation, synthesis, biodiesel production, microbial treatment, degradation of toxic organic pollutants, biodegradation treatment, biological cell crushing, dispersion and condensation, etc. So ultrasonic vibration rods can not only be used to clean objects, peel dirt off their surfaces, but also promote further success in scientific research.

The working principle and function of ultrasonic vibration rod

The following is an explanation of the three functions of ultrasonic vibration rods.

Ultrasonic dispersion: The process of dispersing and de aggregating particulate matter in a liquid through the “cavitation” effect of ultrasound in the liquid, using a liquid as the medium. Ultrasonic dispersion can be divided into emulsion dispersion, that is, the dispersion of liquid and liquid; And the dispersion of suspensions, that is, the dispersion of solids and liquids. Its functions have been effectively practiced and applied in many fields. The dispersion application of ultrasound for suspensions, such as the dispersion of titanium oxide into water or solvents in coatings and plastic industries, and the dispersion of dyes into molten paraffin; Dispersion of drug particles in the pharmaceutical industry; And the dispersion of powder emulsions in the food industry.

Ultrasonic extraction: Ultrasonic extraction separation is a scientific and reasonable new process designed based on the existence state, polarity, solubility, and other factors of active ingredients and active ingredient groups in a substance. It utilizes ultrasonic oscillation to quickly spread solvents to various corners of the surface of solid substances, fully dissolve the organic components contained in the substance as much as possible in the solvent, and obtain a multi-component mixed extraction liquid, By using appropriate separation methods to separate the chemical components in the extraction solution, and then refining and purifying them, the final required monomer chemical components can be obtained through such a complete process.

Ultrasonic emulsification: Ultrasonic emulsification refers to the process of mixing two (or more) immiscible liquids uniformly under the action of ultrasonic energy to form a dispersed system, where one liquid is evenly distributed in the other liquid and then forms an emulsion liquid. The physical mechanism of crushing insoluble solids (or liquids) is the cavitation effect of ultrasound. Ultrasonic cavitation effect refers to the generation of a large number of bubbles in a liquid under the action of ultrasound. Small bubbles will gradually increase with ultrasonic vibration, and then suddenly burst and split. Tens of thousands of small bubbles will repeatedly increase and burst. When they collapse rapidly, high temperature and pressure will be generated inside the bubble, and strong local oscillation waves will be generated in the liquid near the bubble due to the high speed of the liquid around the bubble rushing into the bubble, This also creates local high temperature and pressure, resulting in ultrasonic crushing and emulsification.

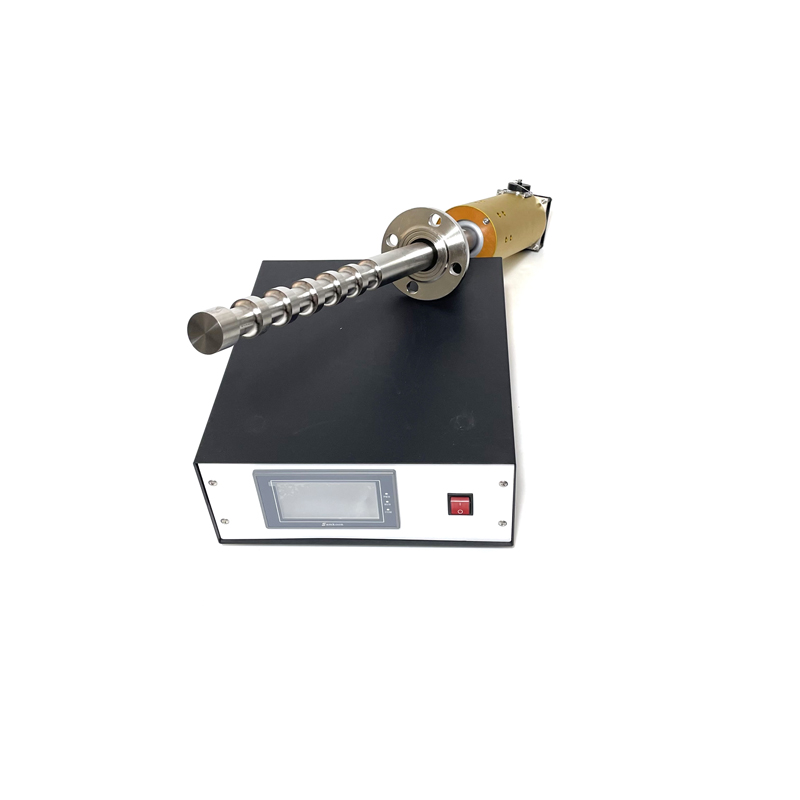

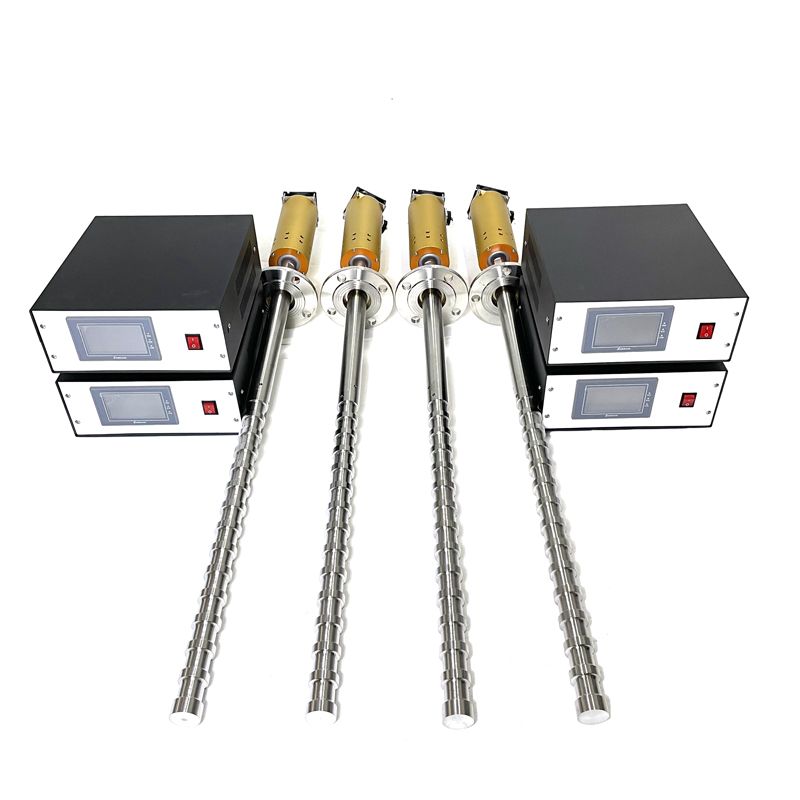

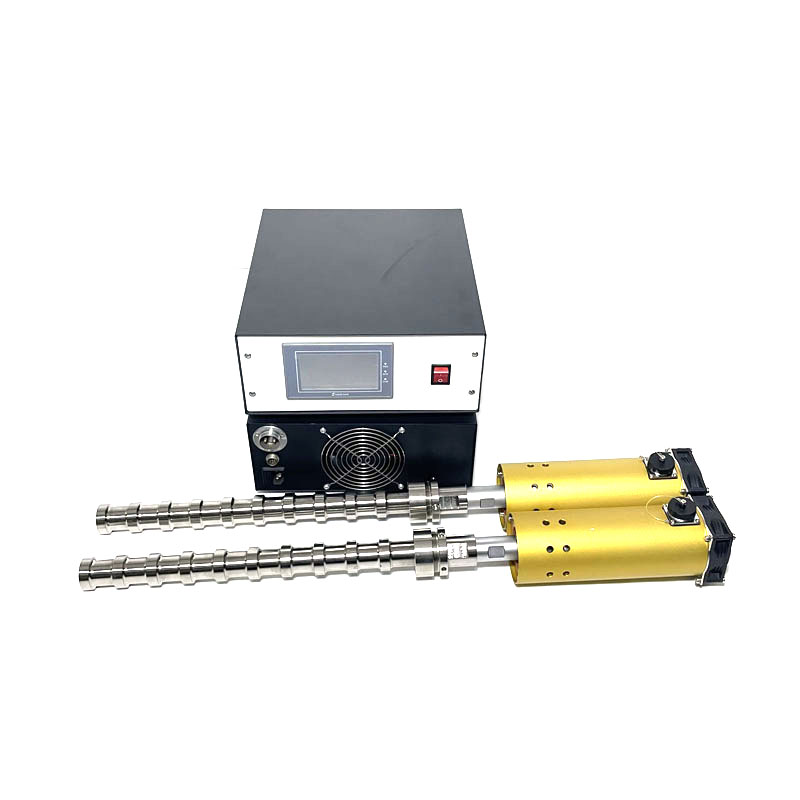

| Tubular EquipmentType | Tubular TransducerType | Frequency(KHz) | UltrasoundOutput(W) | Total Length(mm) | Diameter(mm) | Static Capacity(pF±10%) |

| PU-UE1 | US-61 | 15-28 | 1000 | 500 | Φ50-55 | 68000 |

| PU-UE5 | US-25 | 15-28 | 1500 | 850 | Φ50-55 | 68000 |

| PU-UE6 | US-16 | 15-28 | 2000 | 1100 | Φ50-55 | 132000 |

Ultrasonic Emulsification Disperser Cosmetic Mixing Extraction Ultrasonic Extraction Equipment

标签:Ultrasonic Emulsification Disperser Cosmetic Mixing Extraction, ultrasonic extraction equipment

Send Inquiry

220V Ultrasonic Sonochemistry Reactor Disperser Emulsifying Homogenizer For Hemp Oil Extraction

220V Ultrasonic Sonochemistry Reactor Disperser Emulsifying Homogenizer For Hemp Oil Extraction 20KHZ 1000W Ultrasonic Tissue Extraction Machine Extractor Homogenizer Reactor

20KHZ 1000W Ultrasonic Tissue Extraction Machine Extractor Homogenizer Reactor Ultrasonic Oil Extractor Ultrasonic Sonochemistry Reactor Disperser Emulsifying Homogenizer Liquid Processor

Ultrasonic Oil Extractor Ultrasonic Sonochemistry Reactor Disperser Emulsifying Homogenizer Liquid Processor 20khz 2000W Ultrasonic Rod Transducer Biodiesel Ultrasonic Homogenizing Emulsification Ultrasonic

20khz 2000W Ultrasonic Rod Transducer Biodiesel Ultrasonic Homogenizing Emulsification Ultrasonic 20khz 1000W Industrial Ultrasonic Emulsifier Biodiesel Processor Reactor Sonochemistry Ultrasonic Biodiesel

20khz 1000W Industrial Ultrasonic Emulsifier Biodiesel Processor Reactor Sonochemistry Ultrasonic Biodiesel Ultrasound & Microwave Reactor Ultrasonic And Microwave Combined Reaction System

Ultrasound & Microwave Reactor Ultrasonic And Microwave Combined Reaction System Ultrasonic Sonochemistry Reactor Disperser Emulsifying Homogenizer For Hemp Oil Extraction

Ultrasonic Sonochemistry Reactor Disperser Emulsifying Homogenizer For Hemp Oil Extraction 2000W Ultrasound Reactor Biodiesel Ultrasonic Tube Assisted Synthesis Of Biodiesel With Wave Generator

2000W Ultrasound Reactor Biodiesel Ultrasonic Tube Assisted Synthesis Of Biodiesel With Wave Generator 20KHZ 300W Titanium Alloy Anti-corrosion Biodiesel Ultrasonic Herbal Extraction Machine

20KHZ 300W Titanium Alloy Anti-corrosion Biodiesel Ultrasonic Herbal Extraction Machine 20KHZ 500W/1000W Ultrasonic Laboratory Processors Ultrasonic Sonochemistry With Power Generator

20KHZ 500W/1000W Ultrasonic Laboratory Processors Ultrasonic Sonochemistry With Power Generator Industrial Ultrasonic Extractor Dispersion Liquid Sonochemistry Reactor Laboratory Ultrasonic Emulsifier Equipment

Industrial Ultrasonic Extractor Dispersion Liquid Sonochemistry Reactor Laboratory Ultrasonic Emulsifier Equipment Ultrasonic Sonochemistry System With 600-3000w Generator Biodiesel Reactor

Ultrasonic Sonochemistry System With 600-3000w Generator Biodiesel Reactor