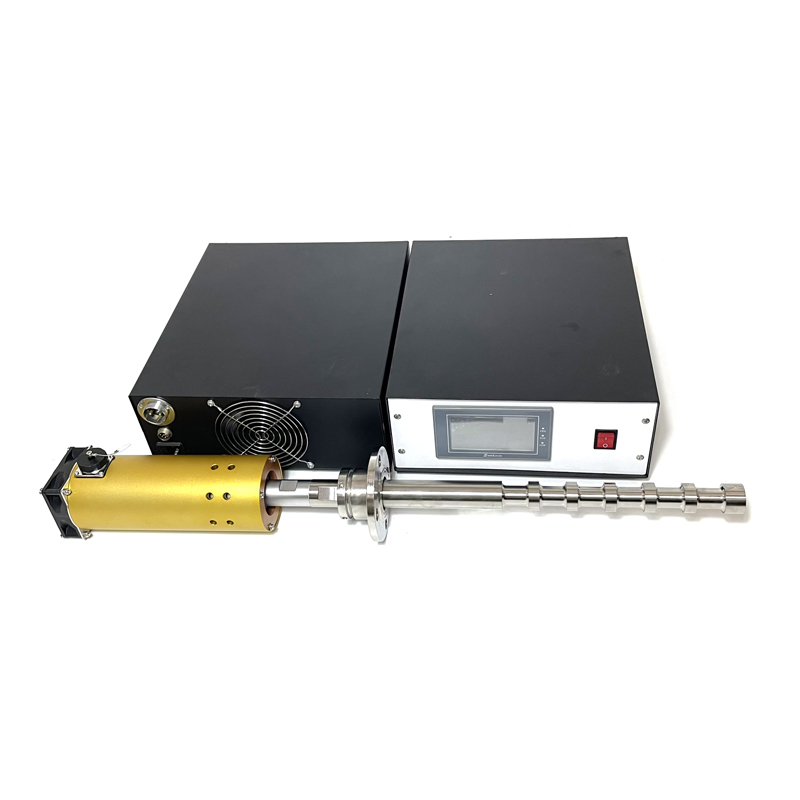

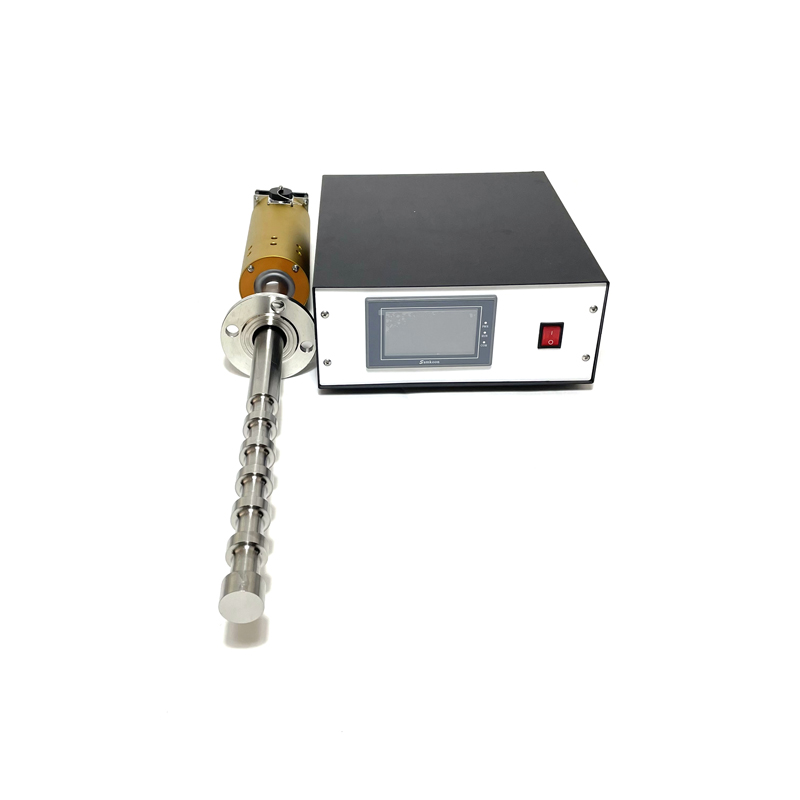

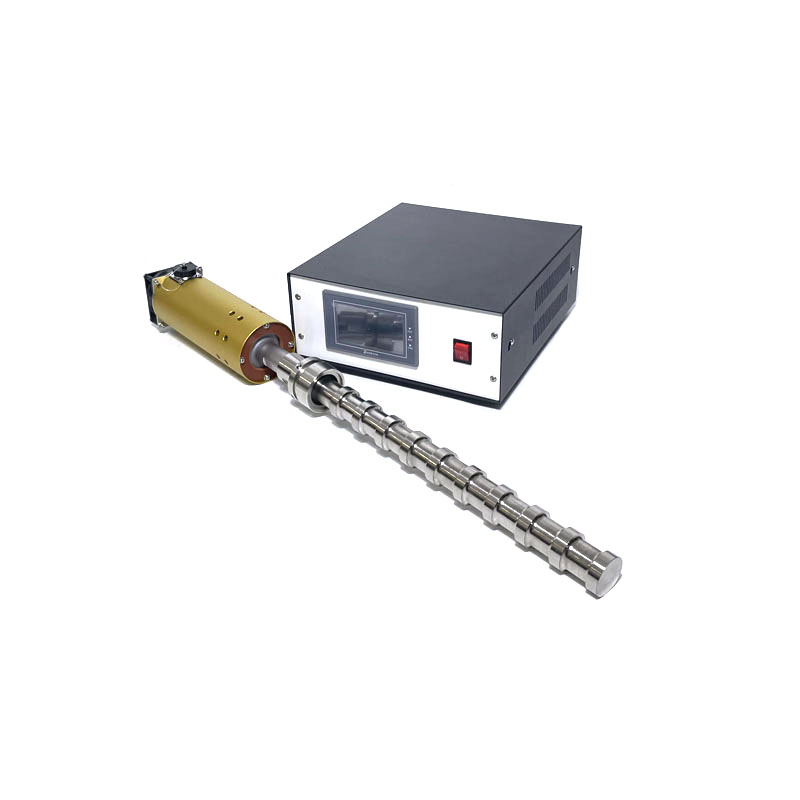

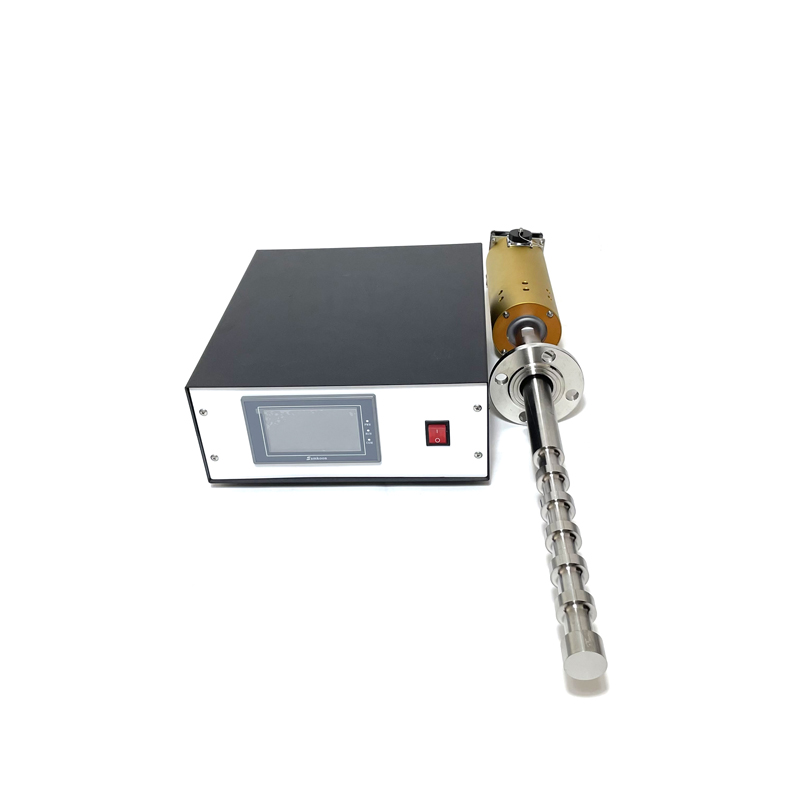

2000W 3000W 50L Vacuum Jacketed Glass Emulsifier Mixing Stirred Ultrasonic Homogenizer Reactor With Lcd Display Generator

Titanium alloy ultrasonic vibration rod extraction, with its advantages of low extraction temperature, high extraction rate, and short extraction time, is applied to the extraction of effective content in traditional Chinese medicine, chemical materials, petroleum, industrial raw materials, and plants. It is a modern…

Titanium alloy ultrasonic vibration rod extraction, with its advantages of low extraction temperature, high extraction rate, and short extraction time, is applied to the extraction of effective content in traditional Chinese medicine, chemical materials, petroleum, industrial raw materials, and plants. It is a modern high-tech means to replace traditional shear process methods and achieve efficient, energy-saving, and environmentally friendly extraction. Titanium alloy ultrasonic vibration rods are based on the special physical properties of ultrasound. Titanium alloy ultrasonic vibration rods mainly reduce the force between the target extract and the sample matrix through rapid mechanical vibration waves generated by piezoelectric transducers, thereby achieving solid-liquid extraction separation.

The ‘cavitation effect’ generated by titanium alloy ultrasonic vibration rods in extracting nanomaterials and dispersing graphene. In some cases, the generation of ultrasonic effect is related to the cavitation mechanism. Acoustic cavitation refers to a series of dynamic processes generated by small bubbles (holes) existing in the liquid under the action of sound waves: oscillation, expansion, contraction, and even collapse. At the point of cavitation, the local state of the liquid undergoes significant changes, resulting in high temperatures and pressures.

Titanium alloy ultrasonic vibration rods are widely used in traditional ultrasonic cleaning, biochemistry, food, chemical, pharmaceutical and other industries. In biochemistry, titanium alloy ultrasonic vibration rods are widely used in emulsification, separation, homogenization, extraction, catalytic reactions, and other fields.

| Tubular EquipmentType | Tubular TransducerType | Frequency(KHz) | UltrasoundOutput(W) | Total Length(mm) | Diameter(mm) | Static Capacity(pF±10%) |

| PU-UE1 | US-61 | 15-28 | 1000 | 500 | Φ50-55 | 68000 |

| PU-UE5 | US-25 | 15-28 | 1500 | 850 | Φ50-55 | 68000 |

| PU-UE6 | US-16 | 15-28 | 2000 | 1100 | Φ50-55 | 132000 |

标签:Emulsifier Mixing Stirred Ultrasonic Homogenizer Reactor, Titanium alloy ultrasonic vibration rod extraction, Ultrasonic Homogenizer Reactor With Lcd Display Generator

Send Inquiry

20KHZ Ultrasonic Emulsifier Biodiesel Reactor Industrial Ultrasonic Liquid Sonochemistry Processor

20KHZ Ultrasonic Emulsifier Biodiesel Reactor Industrial Ultrasonic Liquid Sonochemistry Processor Plant Ultrasonic Extractor 20khz Ultrasonic Sonochemistry Biodiesel Extraction Emulsifying Homogenizer Sonochemistry Equipment

Plant Ultrasonic Extractor 20khz Ultrasonic Sonochemistry Biodiesel Extraction Emulsifying Homogenizer Sonochemistry Equipment Ultrasonic Extractor Ultrasonic Traditional Chinese Medicine Extraction Equipment Ultrasonic Extraction Rod

Ultrasonic Extractor Ultrasonic Traditional Chinese Medicine Extraction Equipment Ultrasonic Extraction Rod Ultrasonic Biodiesel Sonochemistry Reactor Chemical Homogenizing Emulsified Vibrating Rod

Ultrasonic Biodiesel Sonochemistry Reactor Chemical Homogenizing Emulsified Vibrating Rod Titanium Alloy 1000watt Ultrasonic Extraction Equipment For Plant Essential Oil Sonochemistry Biodiesel Reactor Disperser

Titanium Alloy 1000watt Ultrasonic Extraction Equipment For Plant Essential Oil Sonochemistry Biodiesel Reactor Disperser 20Khz 2600W Industrial Ultrasonic Assisted Herb Extraction Dispersing Emulsification Homogenizer

20Khz 2600W Industrial Ultrasonic Assisted Herb Extraction Dispersing Emulsification Homogenizer Lab Ultrasonic Processor Probe Reactor Mixer Nano Emulsifier Ultrasonic Extraction Machine Ultrasonic Homogenizer

Lab Ultrasonic Processor Probe Reactor Mixer Nano Emulsifier Ultrasonic Extraction Machine Ultrasonic Homogenizer 3000W 20KHZ Ultrasonic Biodiesel Ultrasonic Sonochemistry Biodiesel Reactor

3000W 20KHZ Ultrasonic Biodiesel Ultrasonic Sonochemistry Biodiesel Reactor Industrial Extractor Extraction Equipment Laboratory Ultrasonic Liquid Sonochemistry Processor Reactor

Industrial Extractor Extraction Equipment Laboratory Ultrasonic Liquid Sonochemistry Processor Reactor Industrial Ultrasonic Nano Dispersing Machine Ultrasonic Homogenize Emulsify System With Signal Generator

Industrial Ultrasonic Nano Dispersing Machine Ultrasonic Homogenize Emulsify System With Signal Generator 20kHz Ultrasonic Sonochemistry Tube Flow-Through Reactor Ultrasonic Reactor Suppliers

20kHz Ultrasonic Sonochemistry Tube Flow-Through Reactor Ultrasonic Reactor Suppliers 20KHZ 1000W Ultrasonic Tissue Extraction Machine Extractor Homogenizer Reactor

20KHZ 1000W Ultrasonic Tissue Extraction Machine Extractor Homogenizer Reactor