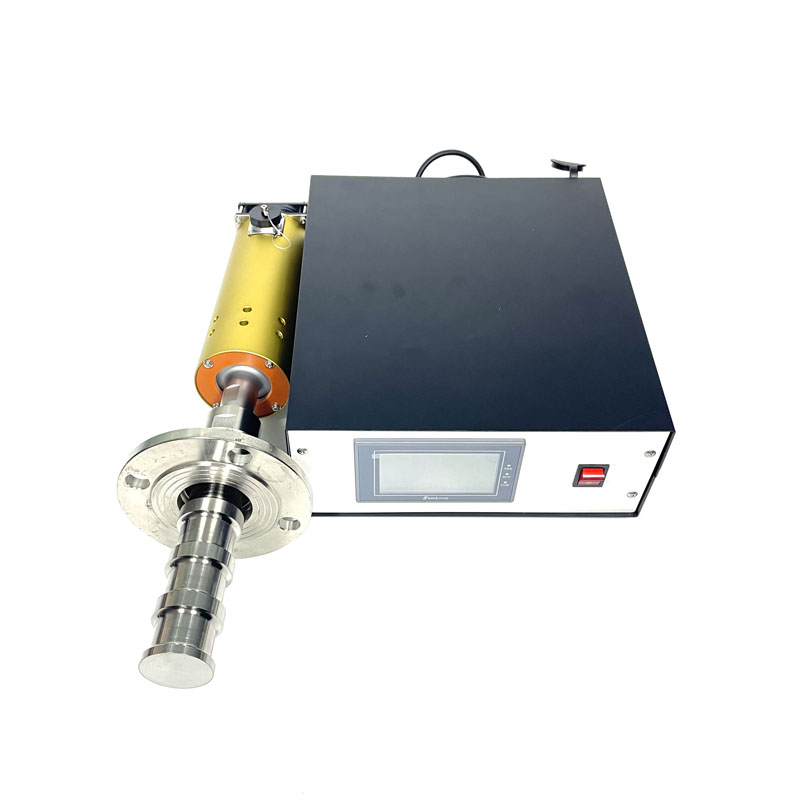

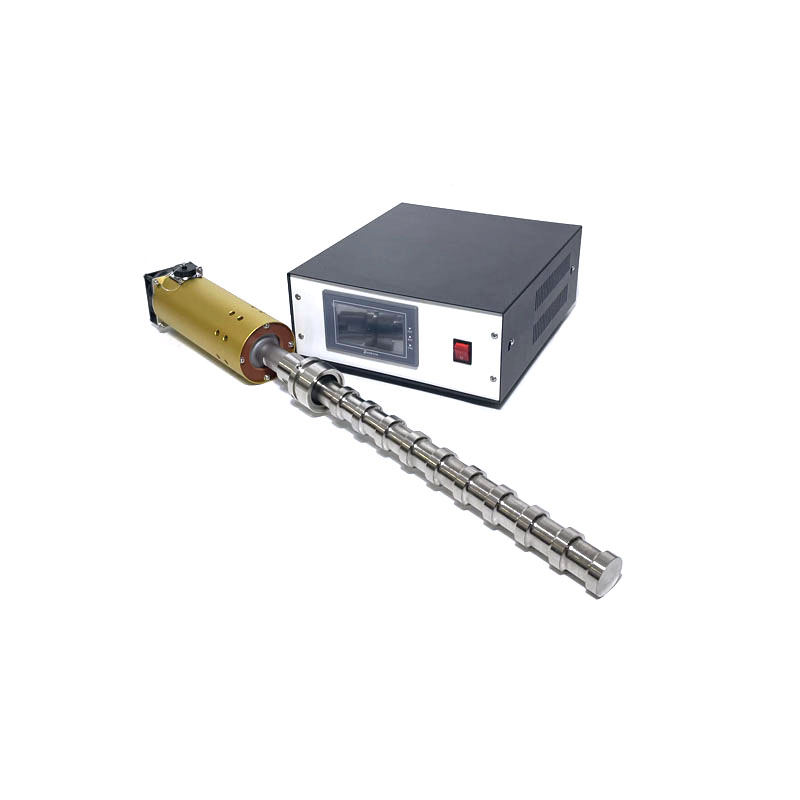

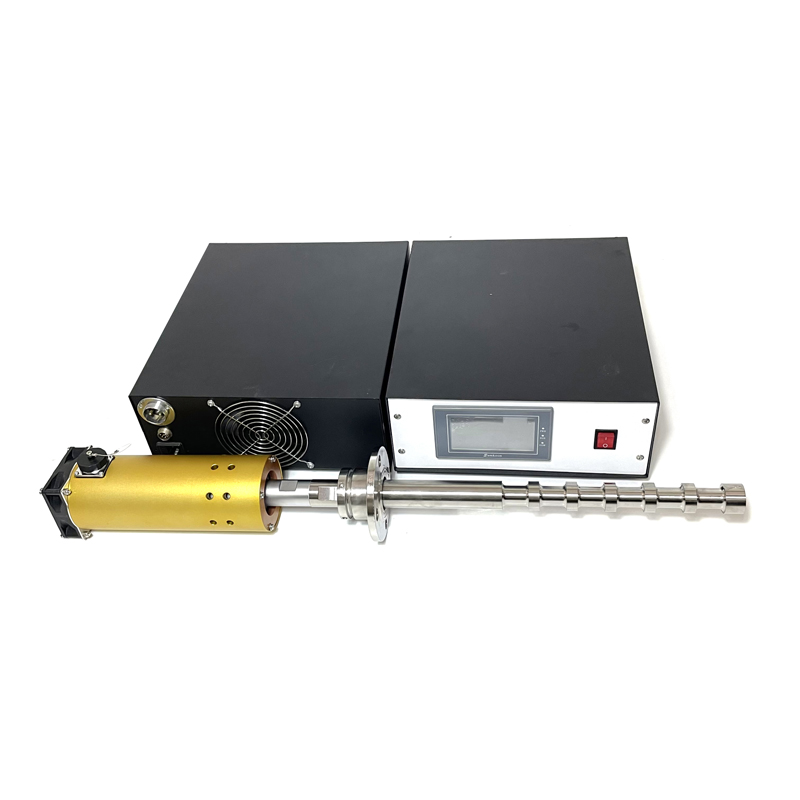

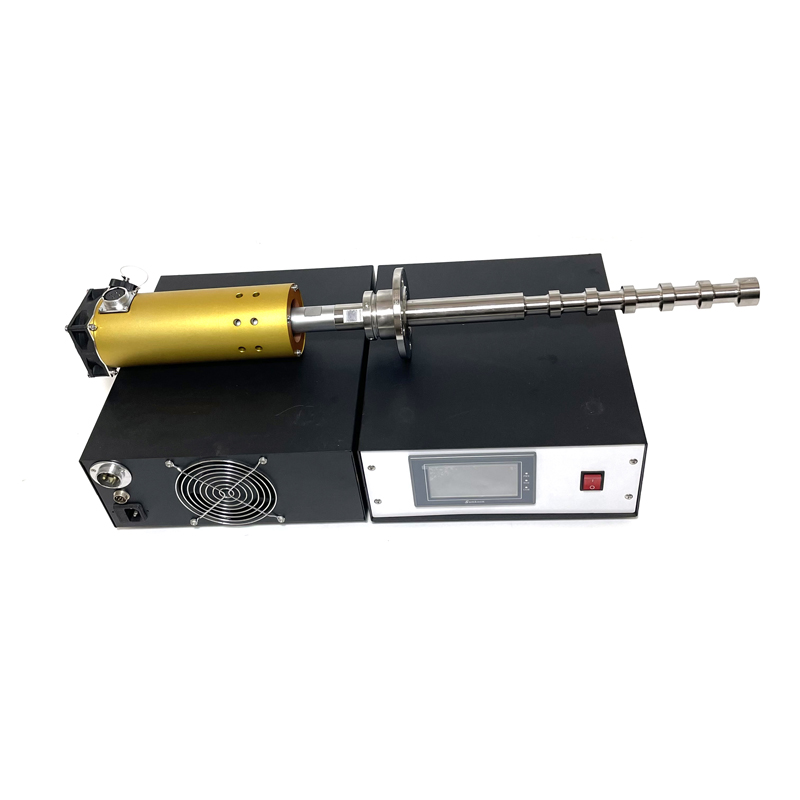

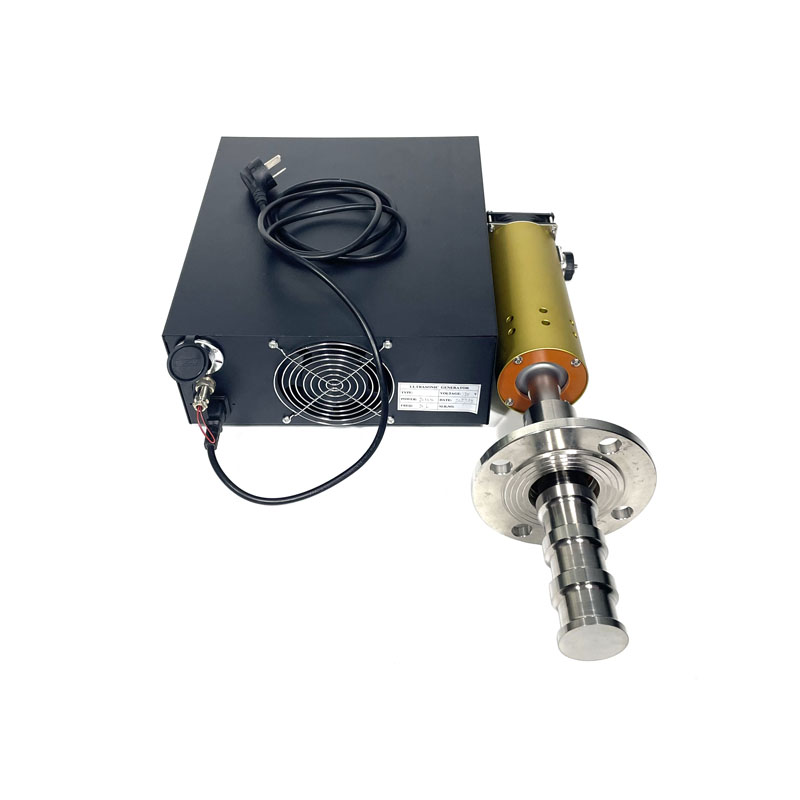

Ultrasonic Sonochemistry Reactor 2000W 20K Ultrasonic Chemical Liquid Processor With Generator

The ultrasonic vibrating rod is mainly composed of ultrasonic transducer, ultrasonic horn, ultrasonic tool head and ultrasonic driving power supply. Compared to traditional ultrasonic vibration plates, they have the characteristics of wider application range and longer service life. In industrial applications, the us…

Ultrasonic Sonochemistry Reactor 2000W 20K Ultrasonic Chemical Liquid Processor With Generator

The ultrasonic vibrating rod is mainly composed of ultrasonic transducer, ultrasonic horn, ultrasonic tool head and ultrasonic driving power supply. Compared to traditional ultrasonic vibration plates, they have the characteristics of wider application range and longer service life. In industrial applications, the use of ultrasonic vibration rods for dispersion, extraction, cleaning, chemical reactions, water treatment, etc. is a very mature and widely used technology.

- It is suitable for various high-power industrial liquid processing, such as homogenization, emulsification, dispersion, depolymerization and wet grinding (particle size reduction), cell fragmentation and disintegration, extraction, degassing and sonochemistry processes.

- Heavy load 24-hour continuous operation, industrial grade design, external PLC remote control, automatic frequency search matching;

Market application:

Traditional Chinese Medicine Extraction: Refers to the efficient extraction of useful substances by ultrasound for the crushing (fragmentation) of traditional Chinese medicine cells. Compared with conventional extraction techniques, ultrasonic assisted extraction is fast, cost-effective, efficient, safe, cost-effective, and widely applicable.

Biodiesel production: The use of ultrasonic emulsification to produce a biomass oil diesel mixed emulsion actually involves dispersing the bio oil droplets into another immiscible diesel liquid. Compared with other technologies, it can make the prepared droplets disperse fine and narrow, with high efficiency, good dispersion effect, and can increase the stability of lotion.

Ultrasonic prevention of marine life: It is based on the cavitation effect of ultrasound. When small bubble nuclei in a liquid are activated by ultrasound, they exhibit a series of dynamic processes such as oscillation, growth, contraction, and collapse of bubbles. The bubbles in the liquid produce over a few hundred atmospheres of pressure and a high temperature of thousands of degrees Celsius at the moment of rupture, which can quickly peel off and crush the epidermal cells of marine organisms, thus achieving the goal of preventing marine organisms.

Ultrasonic catalysis: The application of ultrasound in catalytic reaction processes can simulate high-temperature and high-pressure reactions in reactors at a micro scale, providing a very special physical and chemical environment for catalytic reactions that are difficult or impossible to achieve under general conditions, allowing catalytic reactions to occur in milder environments. It can further improve its reaction speed, shorten reaction time, and increase the yield of the target product. The main applications include catalysis on metal surfaces, phase transfer catalysis reactions, and enzyme catalyzed reactions.

Sewage treatment: During the sewage treatment process, the cavitation effect of ultrasound has a strong ability to degrade organic matter, and the degradation rate is fast, providing the possibility of degrading harmful organic matter in water, thus achieving the purpose of ultrasonic sewage treatment.

Ultrasonic dispersion: refers to the process of dispersing and de aggregating particles in a liquid through the “cavitation” effect of ultrasound in the liquid, using a liquid as the medium. Ultrasonic dispersion can be divided into emulsion dispersion (liquid liquid dispersion) and suspension dispersion (solid liquid dispersion), which have been applied in many fields. The application of ultrasound in the dispersion of suspensions includes the dispersion of titanium oxide into water or solvents in the coating industry, and the dispersion of dyes into molten paraffin; The dispersion of drug particles in the pharmaceutical industry and the dispersion of powder emulsions in the food industry.

| Tubular EquipmentType | Tubular TransducerType | Frequency(KHz) | UltrasoundOutput(W) | Total Length(mm) | Diameter(mm) | Static Capacity(pF±10%) |

| PU-UE1 | US-61 | 15-28 | 1000 | 500 | Φ50-55 | 68000 |

| PU-UE5 | US-25 | 15-28 | 1500 | 850 | Φ50-55 | 68000 |

| PU-UE6 | US-16 | 15-28 | 2000 | 1100 | Φ50-55 | 132000 |

Ultrasonic Sonochemistry Reactor 2000W 20K Ultrasonic Chemical Liquid Processor With Generator

标签:2000W 20K Ultrasonic Chemical Liquid Processor With Generator, Ultrasonic Chemical Liquid Processor With Generator, Ultrasonic Sonochemistry Reactor

Send Inquiry

2000W Ultrasonic Cavitation Reactor Biodiesel Underwater Acoustic Ultrasonic Tubular Transducer

2000W Ultrasonic Cavitation Reactor Biodiesel Underwater Acoustic Ultrasonic Tubular Transducer 20kHz Ultrasonic Sonochemistry Tube Flow-Through Reactor Ultrasonic Reactor Suppliers

20kHz Ultrasonic Sonochemistry Tube Flow-Through Reactor Ultrasonic Reactor Suppliers 1000W 20KHZ Industrial Ultrasonic Emulsifier Biodiesel Processor Reactor

1000W 20KHZ Industrial Ultrasonic Emulsifier Biodiesel Processor Reactor 3000W Ultrasonic Tubular Transducer Submersible Cleaner Vibration Rods For Biodiesel Refining Mixed Emulsification

3000W Ultrasonic Tubular Transducer Submersible Cleaner Vibration Rods For Biodiesel Refining Mixed Emulsification Ultrasonic Sonochemistry Cell Diffusion Emulsion Industrial Ultrasonic Sonochemical Equipment

Ultrasonic Sonochemistry Cell Diffusion Emulsion Industrial Ultrasonic Sonochemical Equipment 300ml Cell Disruption Emulsifying Mini Handheld Ultrasonic Liquid Processor Homogenizer Sonicator

300ml Cell Disruption Emulsifying Mini Handheld Ultrasonic Liquid Processor Homogenizer Sonicator Ultrasonic Liquid Emulsification Equipment Ultrasonic Assisted Dispersion Homogenizer And Generator Control Box

Ultrasonic Liquid Emulsification Equipment Ultrasonic Assisted Dispersion Homogenizer And Generator Control Box 50L Glass Ultrasonic Liquid Processor Homogenizer Extraction Reactor For Biodiesel With Power Generator

50L Glass Ultrasonic Liquid Processor Homogenizer Extraction Reactor For Biodiesel With Power Generator Ultrasonic Sonochemistry Tube Flow-Through Reactor Ultrasonic Crystallization And Sound Generator

Ultrasonic Sonochemistry Tube Flow-Through Reactor Ultrasonic Crystallization And Sound Generator Ultrasonic Sonochemistry System Biodiesel Reactor Ultrasonic Sonochemistry System With Signal Generator

Ultrasonic Sonochemistry System Biodiesel Reactor Ultrasonic Sonochemistry System With Signal Generator 3000W 50L Vacuum Jacketed Glass Emulsifier Mixing Stirred Ultrasonic Homogenizer Reactor

3000W 50L Vacuum Jacketed Glass Emulsifier Mixing Stirred Ultrasonic Homogenizer Reactor 20L 2000W Ultrasonic Glass Reactor Ultrasonic Biodiesel Reactor And Frequency Generator With Digital Generator

20L 2000W Ultrasonic Glass Reactor Ultrasonic Biodiesel Reactor And Frequency Generator With Digital Generator