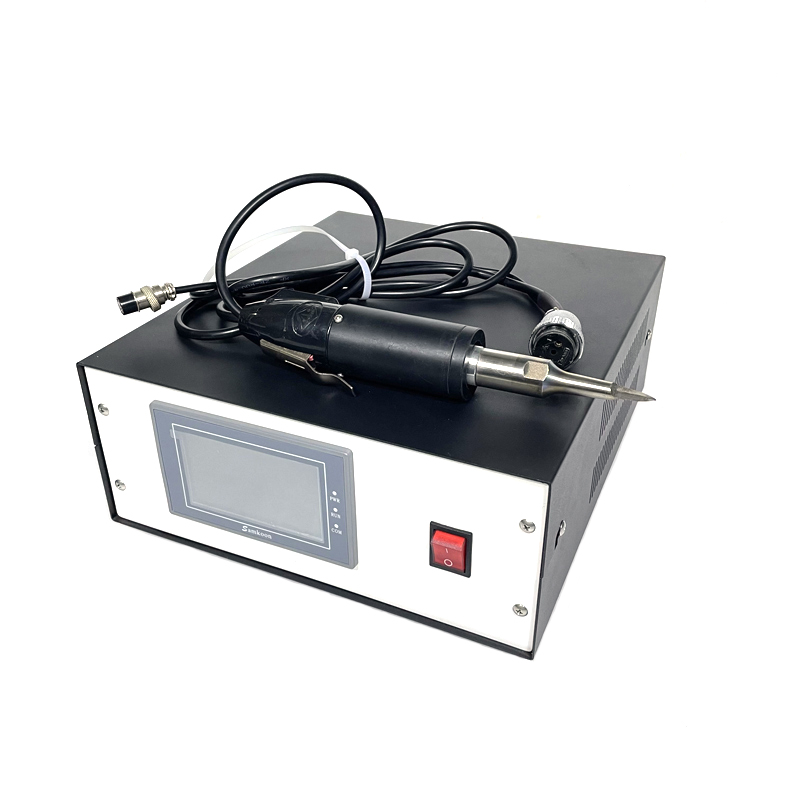

500W Ultrasonic Cloth Cutting Machine Curtain Manual Plastic Fabric Textile Cutting Machine

The characteristics of ultrasonic cutting machines are that they do not require sharp blades, do not require significant pressure, and do not cause edge collapse or damage to cutting materials. At the same time of cutting, the cutting area has a fusion effect, and the cutting area will be sealed to prevent the loose …

500W Ultrasonic Cloth Cutting Machine Curtain Manual Plastic Fabric Textile Cutting Machine

The characteristics of ultrasonic cutting machines are that they do not require sharp blades, do not require significant pressure, and do not cause edge collapse or damage to cutting materials. At the same time of cutting, the cutting area has a fusion effect, and the cutting area will be sealed to prevent the loose organization of the cut material (such as textile material flash).

The basic components of the ultrasonic cutting machine are ultrasonic transducer, amplitude transformer, cutting knife (tool head) and driving power supply. The ultrasonic driving power converts the mains power into high-frequency high-voltage AC current, which is transmitted to the ultrasonic transducer. Ultrasonic transducer is actually equivalent to an energy converter, which can convert the input electrical energy into mechanical energy, namely ultrasonic. Its manifestation is that the transducer moves back and forth in the longitudinal direction. The frequency of the telescopic motion is equivalent to the high-frequency AC current frequency supplied by the driving power supply. The function of the amplitude converter is to fix the entire ultrasonic vibration system, and to amplify the output amplitude of the transducer. On the one hand, the cutting knife (tool head) further amplifies the amplitude and focuses the ultrasonic wave. On the other hand, it outputs ultrasonic waves, using a cutting blade like edge to concentrate ultrasonic energy into the cutting area of the material being cut. Under the action of enormous ultrasonic energy, this area instantly softens and melts, resulting in a significant decrease in temperature. At this point, as long as a small cutting force is applied, the purpose of cutting the material can be achieved.

| Type | power (W) | Frequency | Welding time | Contains |

| PU-QG100W | 100W | 30khz,35khz,40khz | 0.1-3sec | generator , transducer ,horn,head |

| PU-QG300W | 300W | 30khz,35khz,40khz | 0.1-3sec | generator , transducer ,horn,head |

| PU-QG500W | 500W | 30khz,35khz,40khz | 0.1-3sec | generator , transducer ,horn,head |

500W Ultrasonic Cloth Cutting Machine Curtain Manual Plastic Fabric Textile Cutting Machine

标签:500W Ultrasonic Cloth Cutting Machine, Manual Plastic Fabric Textile Cutting Machine

Send Inquiry

35KHZ 600W Ultrasonic Fabric Hand Cutting Machine Cutter Knife And Multi-Function Generator

35KHZ 600W Ultrasonic Fabric Hand Cutting Machine Cutter Knife And Multi-Function Generator 35khz Ultrasonic Plastic Cutter Equipment Ultrasonic Cutting Knife With Blade Replaceable

35khz Ultrasonic Plastic Cutter Equipment Ultrasonic Cutting Knife With Blade Replaceable Ultrasonic Cutting Machine Industrial Plastic Ultrasonic Cutter Ultrasonic Cutter Knife Machine

Ultrasonic Cutting Machine Industrial Plastic Ultrasonic Cutter Ultrasonic Cutter Knife Machine 1000W 35KHZ Ultrasonic Textile Cutting Machine With Digital Ultrasonic Generator

1000W 35KHZ Ultrasonic Textile Cutting Machine With Digital Ultrasonic Generator 28khz 1000W Hand Held Ultrasonic Knife Ultrasonic Cutting Ultrasonic Cheese Cutter Machine

28khz 1000W Hand Held Ultrasonic Knife Ultrasonic Cutting Ultrasonic Cheese Cutter Machine Portable Hand Held Ultrasonic Cutter Fabric Leather Plastic Label Fiber Rubber Cutting Machine

Portable Hand Held Ultrasonic Cutter Fabric Leather Plastic Label Fiber Rubber Cutting Machine 800W Ultrasonic Plastic Cutting Blade Machine With Ultrasonic Vibration Generator

800W Ultrasonic Plastic Cutting Blade Machine With Ultrasonic Vibration Generator Ultrasonic Textile Cutter Cutting Machine Ultrasonic Cutter Knife Ultrasonic Multifunctional Hand-held Cutter

Ultrasonic Textile Cutter Cutting Machine Ultrasonic Cutter Knife Ultrasonic Multifunctional Hand-held Cutter Ultrasound Cutter Consumption Plastic Sheet Cutting Machine And Ultrasonic Vibration Generator

Ultrasound Cutter Consumption Plastic Sheet Cutting Machine And Ultrasonic Vibration Generator Hand Held Ultrasonic Cutting Knife Machine And Adjustable Frequency Ultrasonic Generator

Hand Held Ultrasonic Cutting Knife Machine And Adjustable Frequency Ultrasonic Generator 35KHZ Ultrasonic Cutter Knife Hand Held Ultrasonic Cutting Machine For Cutting Nonwoven With Glass Fibre

35KHZ Ultrasonic Cutter Knife Hand Held Ultrasonic Cutting Machine For Cutting Nonwoven With Glass Fibre 35KHZ 500W Plastic Ultrasonic Box Cutter Utility Hot Knife Cutting Machine And Generator Control Box

35KHZ 500W Plastic Ultrasonic Box Cutter Utility Hot Knife Cutting Machine And Generator Control Box