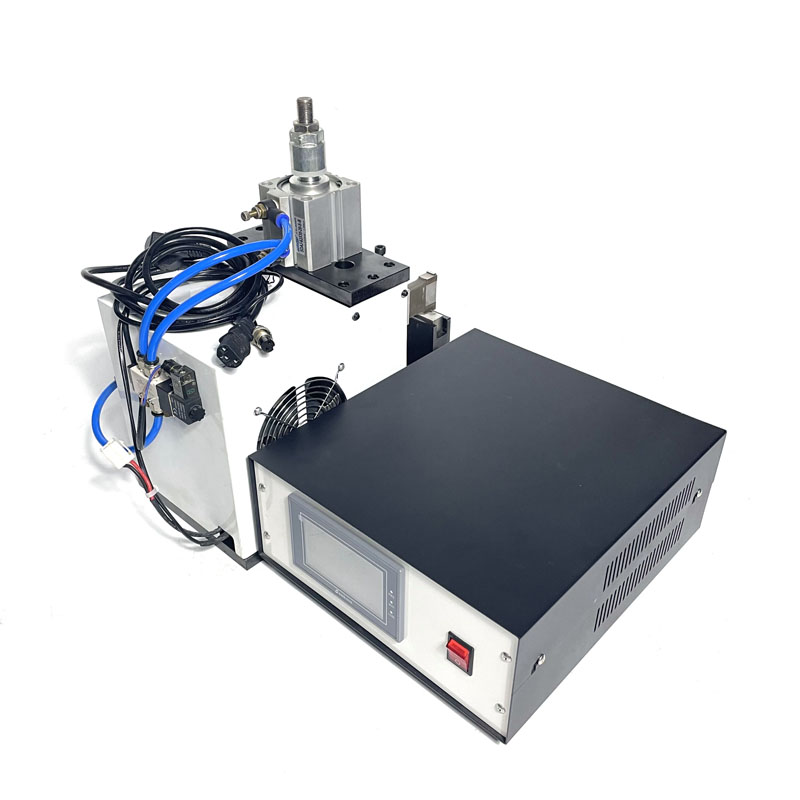

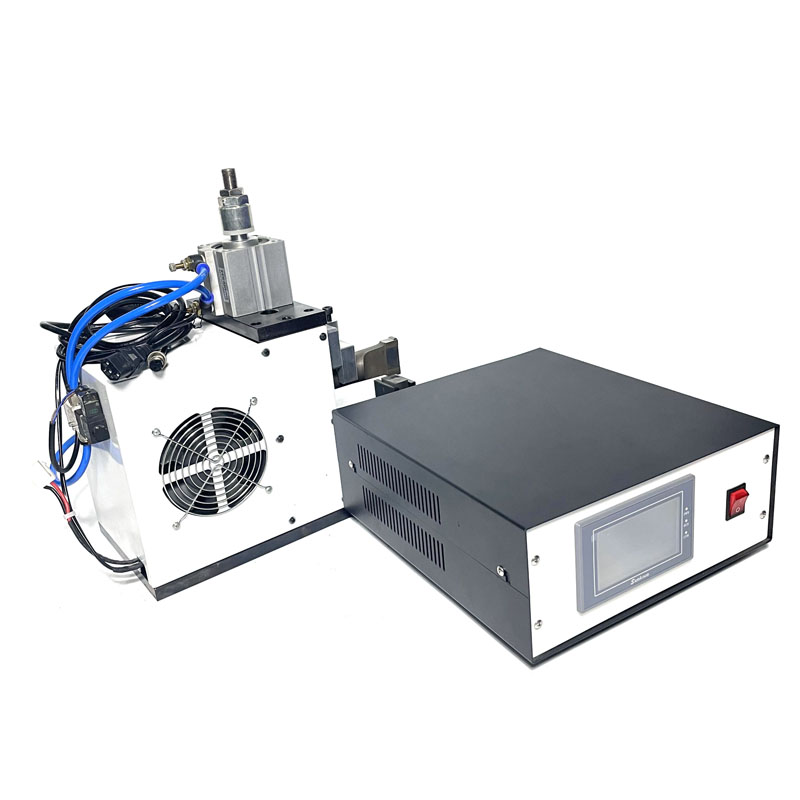

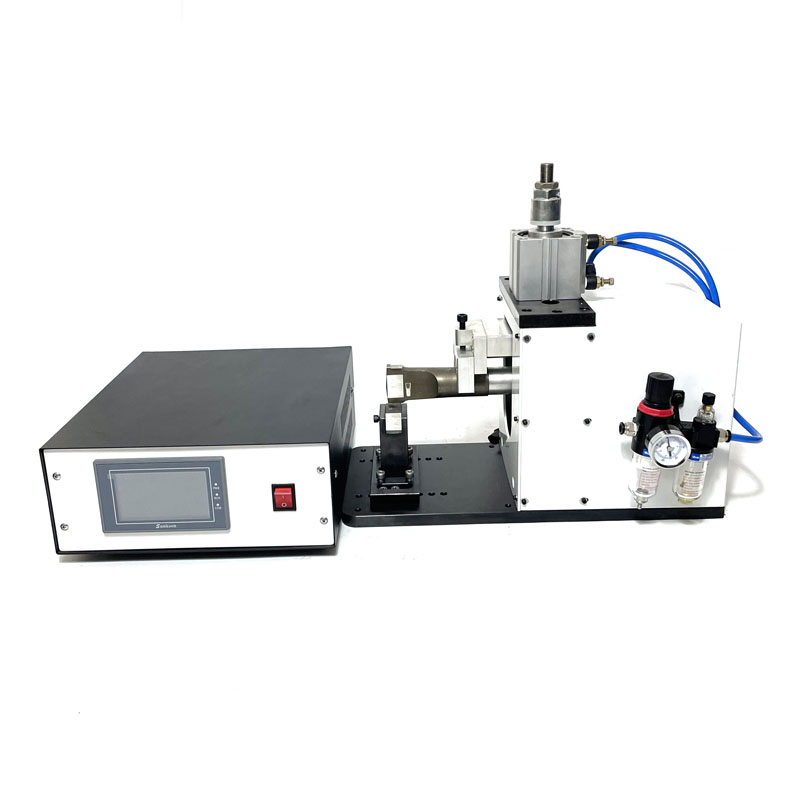

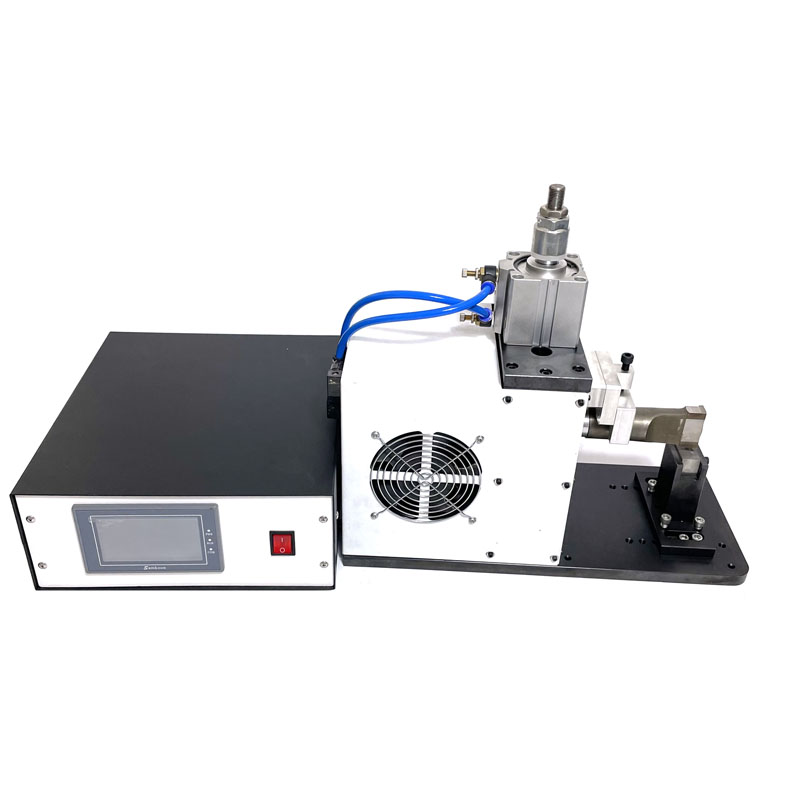

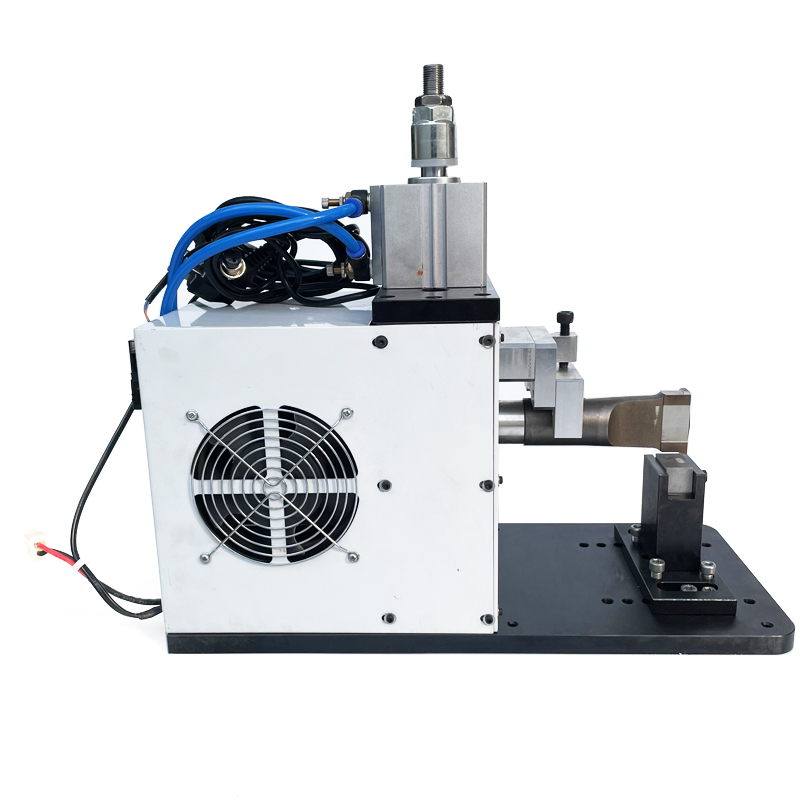

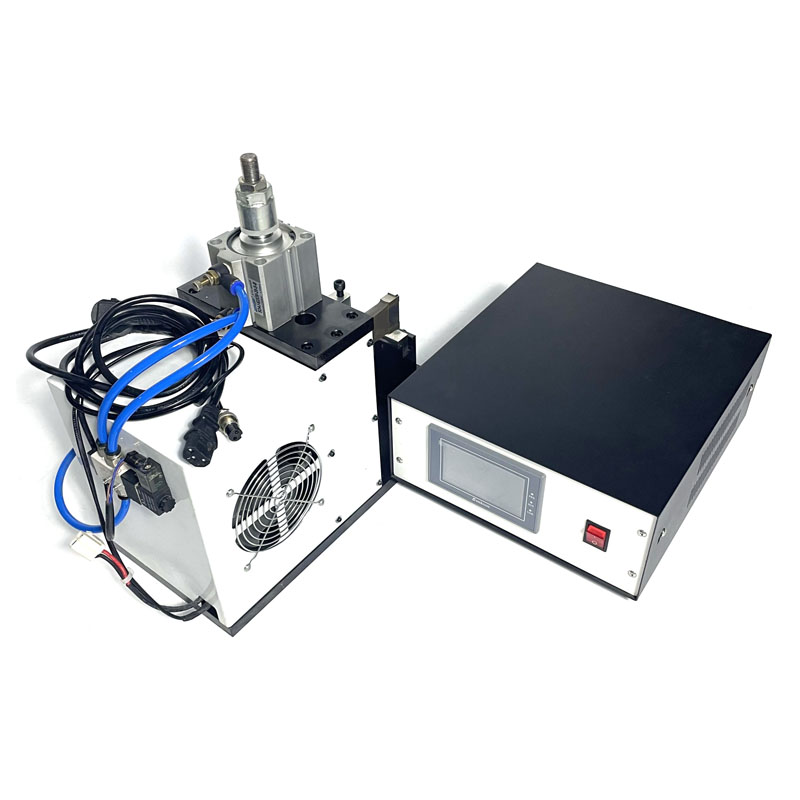

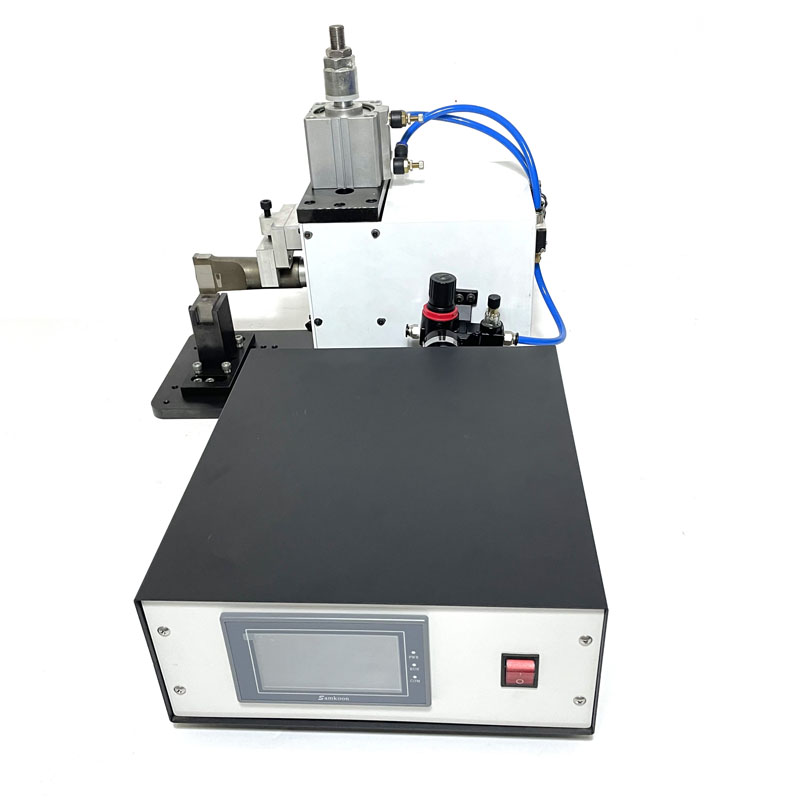

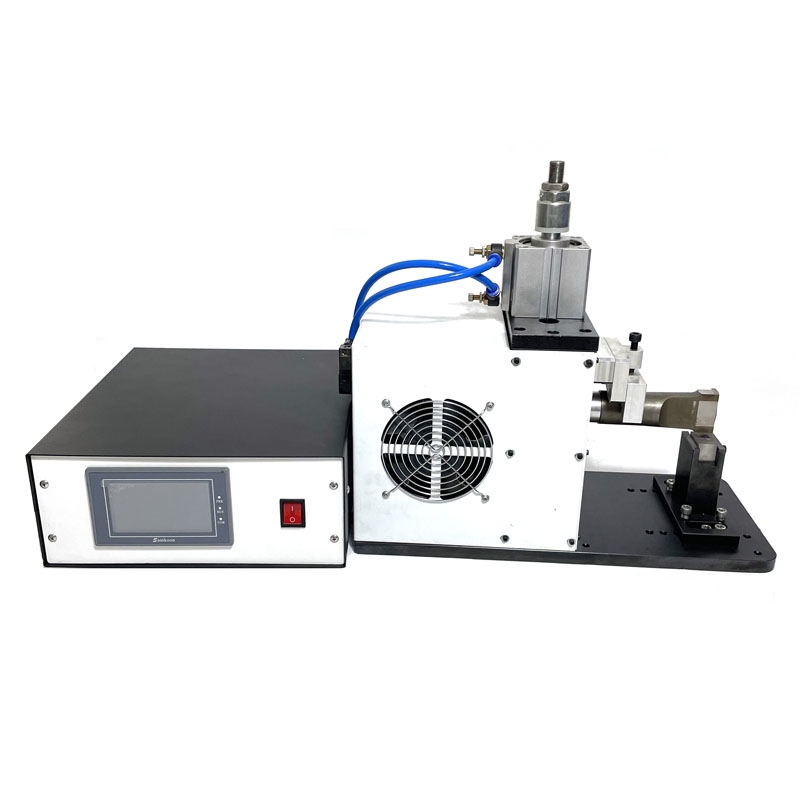

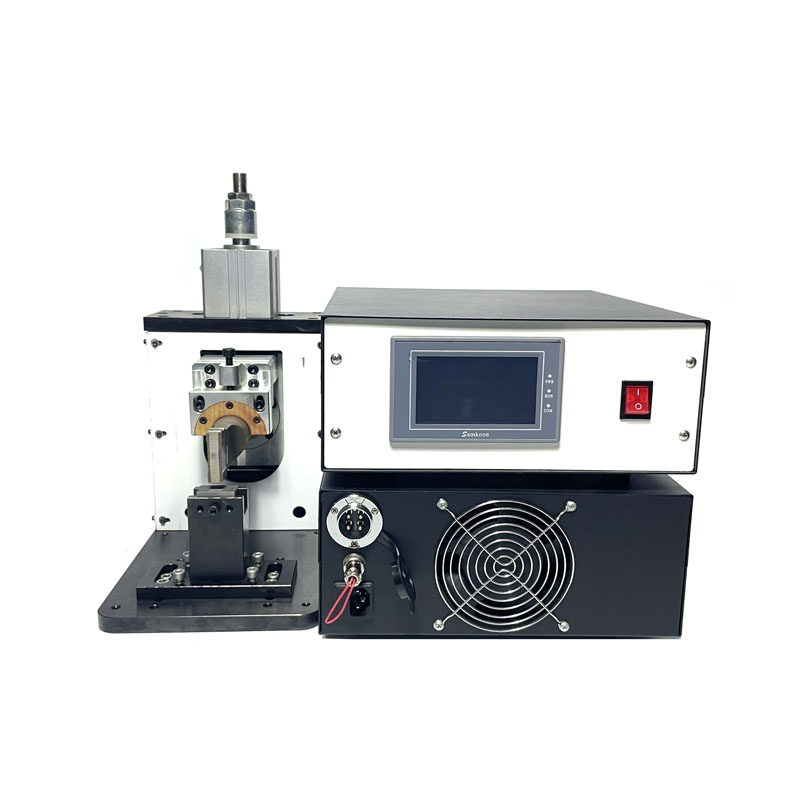

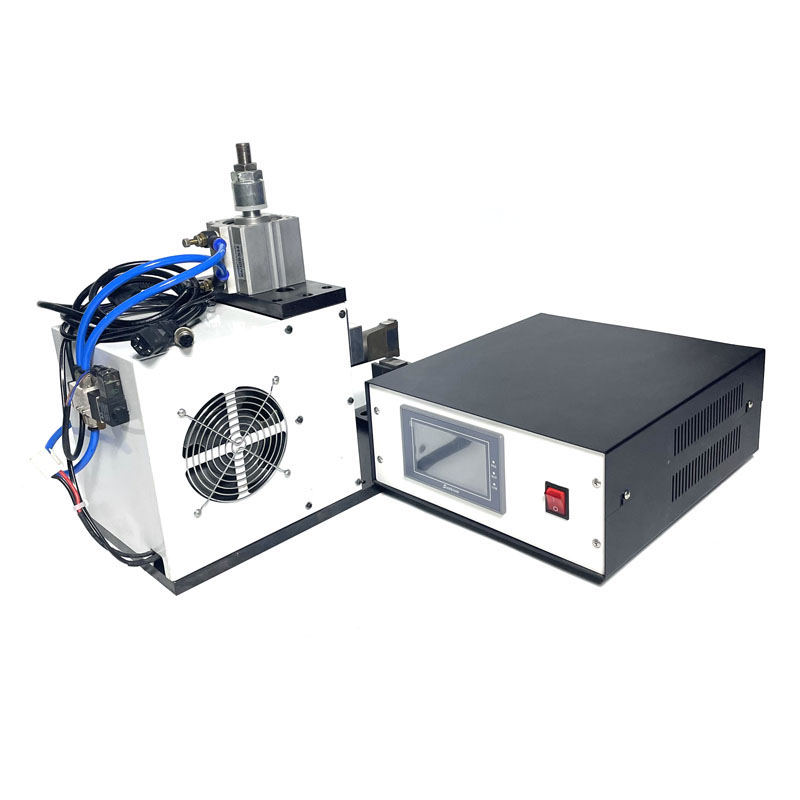

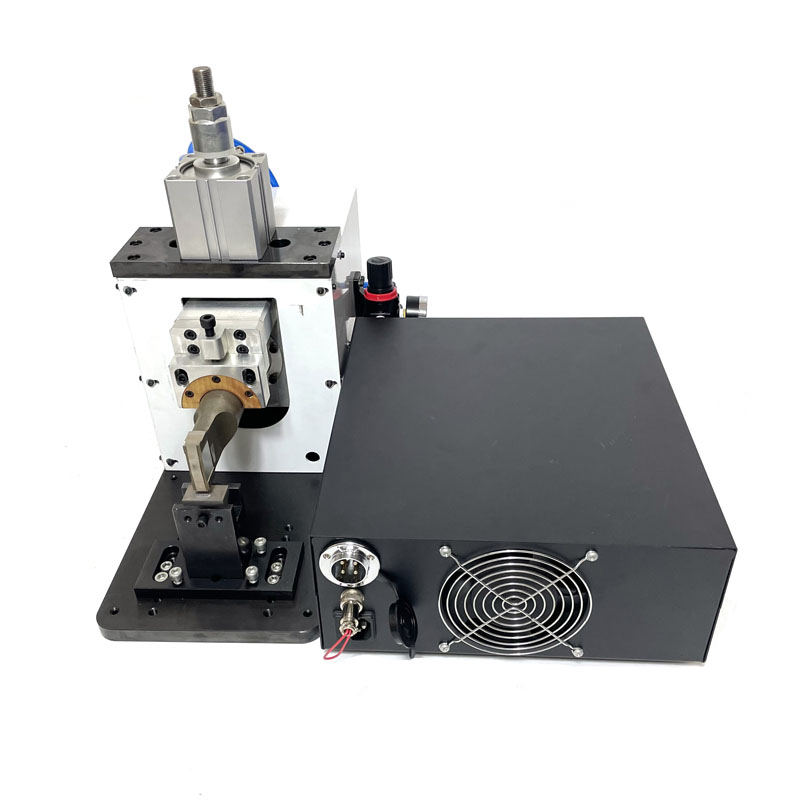

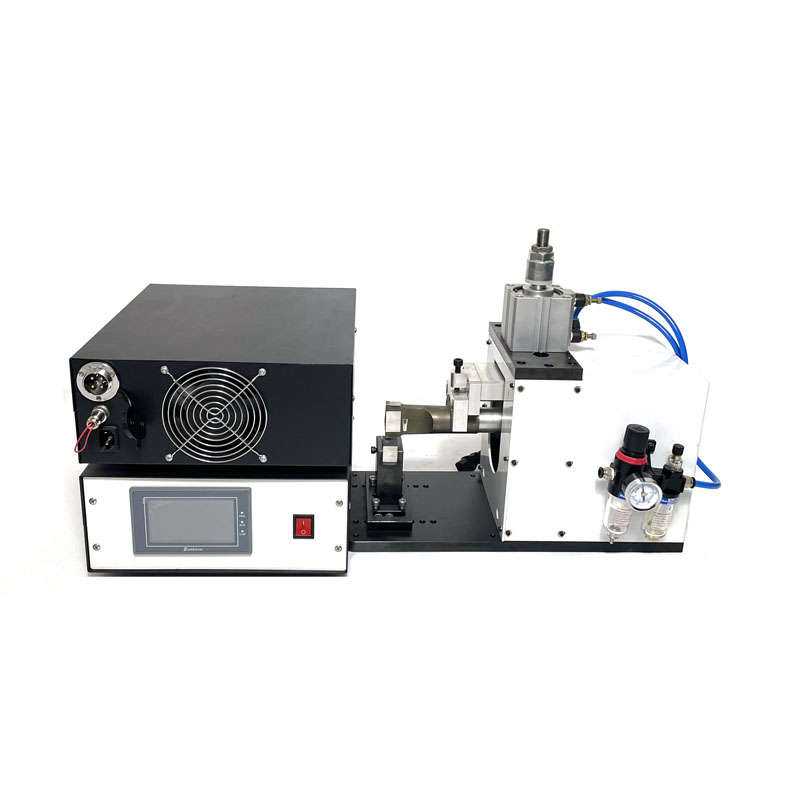

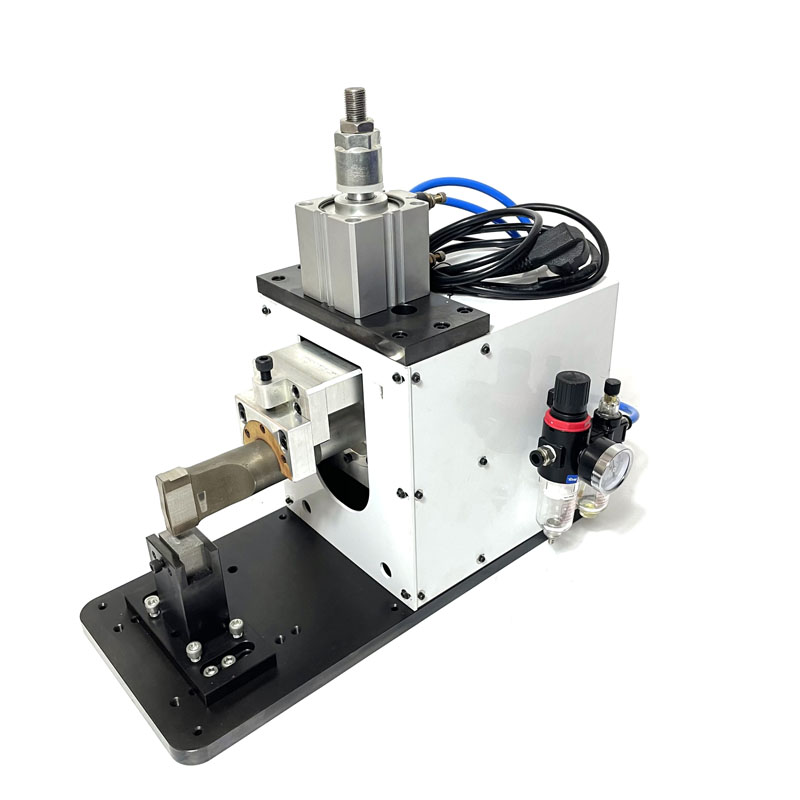

20khz 2000W Ultrasonic Spot Metal Welder for Multi Copper Wires With Copper Plate

Ultrasonic metal welding utilizes high-frequency vibration waves to transmit to two metal surfaces that need to be welded. Under pressure, the two metal surfaces rub against each other to form fusion between molecular layers. Its advantages include fast, energy-saving, high fusion strength, good conductivity, no spar…

20khz 2000W Ultrasonic Spot Metal Welder for Multi Copper Wires With Copper Plate

Ultrasonic metal welding utilizes high-frequency vibration waves to transmit to two metal surfaces that need to be welded. Under pressure, the two metal surfaces rub against each other to form fusion between molecular layers. Its advantages include fast, energy-saving, high fusion strength, good conductivity, no spark, and close to cold processing; The disadvantages are that the welded metal parts cannot be too thick (usually less than or equal to 5mm), the welding points cannot be too large, and pressure needs to be applied. In short, a metal welding machine is a machine that utilizes the energy generated by high-frequency vibration to infiltrate the surface molecules of the same or different metals under appropriate pressure through cold grinding and horizontal movement, achieving the purpose of welding. Both metal rolling welding and metal sealing cutting use this welding principle.

Principles of Metal Spot Welding

Ultrasonic metal spot welding is the welding of individual points on the contact surface of a welded component at a joint. Spot welding requires the metal to have good plasticity. When welding, first clean the surface of the weldment, and then overlap and assemble the welded sheet metal. Press it between two cylindrical copper electrodes and apply force to tighten it. When a sufficiently large current is applied, a large amount of resistive heat is generated at the contact of the plate, heating the metal in the hottest central area to a highly plastic or molten state, forming a lens shaped liquid melt pool. Continue to maintain pressure, disconnect the current, and after the metal cools, a solder joint is formed.

Wiring harness welding principle

Ultrasonic wire harness welding is a physical change process that utilizes the principle of ultrasonic friction to achieve surface welding of different media. Firstly, the head end of the metal wire must be treated to form a spherical shape (this machine uses negative electron high-pressure balling), and the welded metal surface must be preheated first; Then under the combined action of time and pressure, the gold wire ball produces plastic deformation on the metal welding surface, making the two mediums reach reliable contact. Through ultrasonic friction vibration, the two metal atoms form metallic bond under the action of atomic affinity, realizing the welding of gold wire leads. Gold wire ball welding is superior to silicon aluminum wire welding in terms of electrical performance and environmental applications, but due to the need for heating of welding parts using precious metals, the application range is relatively narrow

| Type | Power(W) | Frequency (KHz) |

| PU-MSW2000W | 2000W | 20KHZ |

| PU-MSW2600W | 2600W | 20KHZ |

| PU-MSW3200W | 3200W | 20KHZ |

| PU-MSW4000W | 4000W | 20KHZ |

| PU-MSW800W | 800W | 40khz |

20khz 2000W Ultrasonic Spot Metal Welder for Multi Copper Wires With Copper Plate

标签:20khz 2000W Ultrasonic Spot Metal Welder, Ultrasonic Spot Metal Welder for Multi Copper Wires

Send Inquiry

2000W 20KHZ Ultrasonic Welding Machine for 0.5-20sqmm Copper Wire Splice Machine for Copper Wire and Aluminium

2000W 20KHZ Ultrasonic Welding Machine for 0.5-20sqmm Copper Wire Splice Machine for Copper Wire and Aluminium Desktop Spot Welder Splice Ultrasound Copper Aluminum Metal Wire Harness Terminal Welding Machine for Tab Foil Joint

Desktop Spot Welder Splice Ultrasound Copper Aluminum Metal Wire Harness Terminal Welding Machine for Tab Foil Joint Ultrasonic Metal Spot Welding Machine For Copper Silver Aluminum Nickel Lithium Battery Cap Pneumatic

Ultrasonic Metal Spot Welding Machine For Copper Silver Aluminum Nickel Lithium Battery Cap Pneumatic 4000W Lithium Battery Cap Pneumatic Ultrasonic Metal Spot Welder Welding Machine With Piezo Generator

4000W Lithium Battery Cap Pneumatic Ultrasonic Metal Spot Welder Welding Machine With Piezo Generator 28khz 20khz Ultrasonic Metal Welding Machine For Aluminum Wire Copper Wire Spot Bonding Machines

28khz 20khz Ultrasonic Metal Welding Machine For Aluminum Wire Copper Wire Spot Bonding Machines 0.5-20 mm Copper Aluminum Braided Wire haness Ultrasonic Metal Welding Machine Welder And Generator Control Box

0.5-20 mm Copper Aluminum Braided Wire haness Ultrasonic Metal Welding Machine Welder And Generator Control Box Metal Ultrasonic Spot Welding Machine For Al Tab And Aluminum Foil Welding Machine

Metal Ultrasonic Spot Welding Machine For Al Tab And Aluminum Foil Welding Machine 20kHz Ultrasonic Metal Spot Welding Lithium Battery Welder For Stacked Electrode Sheets Tabs

20kHz Ultrasonic Metal Spot Welding Lithium Battery Welder For Stacked Electrode Sheets Tabs 20kHz Ultrasonic Metal Spot Welder For Lithium Ion Battery Tabs Lithium Battery Cathode Ultrasonic Welder

20kHz Ultrasonic Metal Spot Welder For Lithium Ion Battery Tabs Lithium Battery Cathode Ultrasonic Welder Desk-Top Automatic Ultrasonic Metal Welding Machine for Welding Li-ion Battery Stacked Electrode Sheets and Tabs

Desk-Top Automatic Ultrasonic Metal Welding Machine for Welding Li-ion Battery Stacked Electrode Sheets and Tabs 0.35-12mm Ultrasonic Multi Core Conduct Automotive Car Copper Aluminum Wire Cable Splicing Welding Crimp Machine

0.35-12mm Ultrasonic Multi Core Conduct Automotive Car Copper Aluminum Wire Cable Splicing Welding Crimp Machine Lab Ultrasonic Battery Spot Welder Welding Machine For Li-ion Battery Cathode Electrode Sheets

Lab Ultrasonic Battery Spot Welder Welding Machine For Li-ion Battery Cathode Electrode Sheets