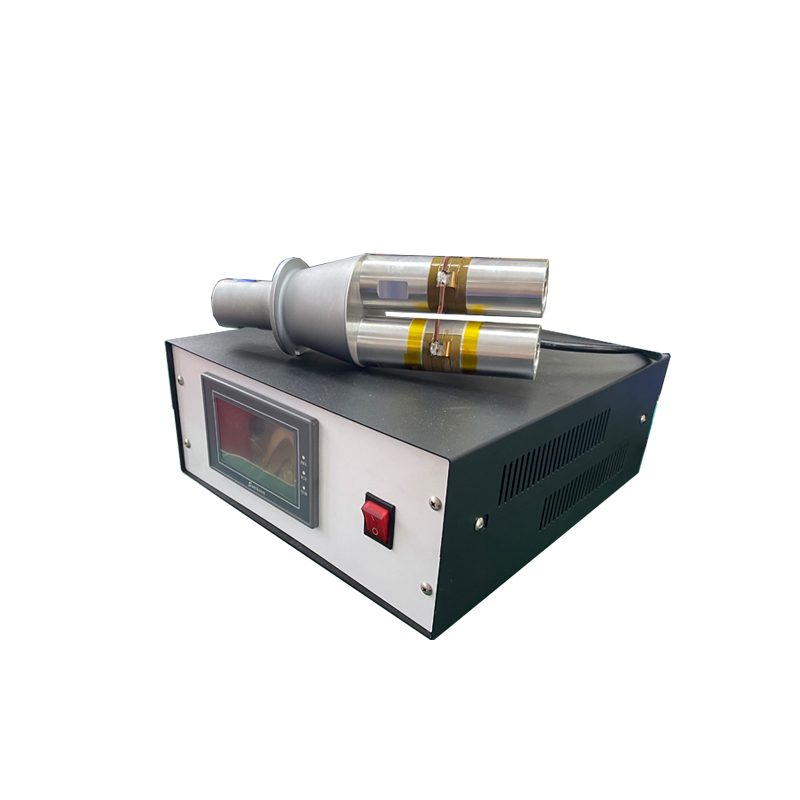

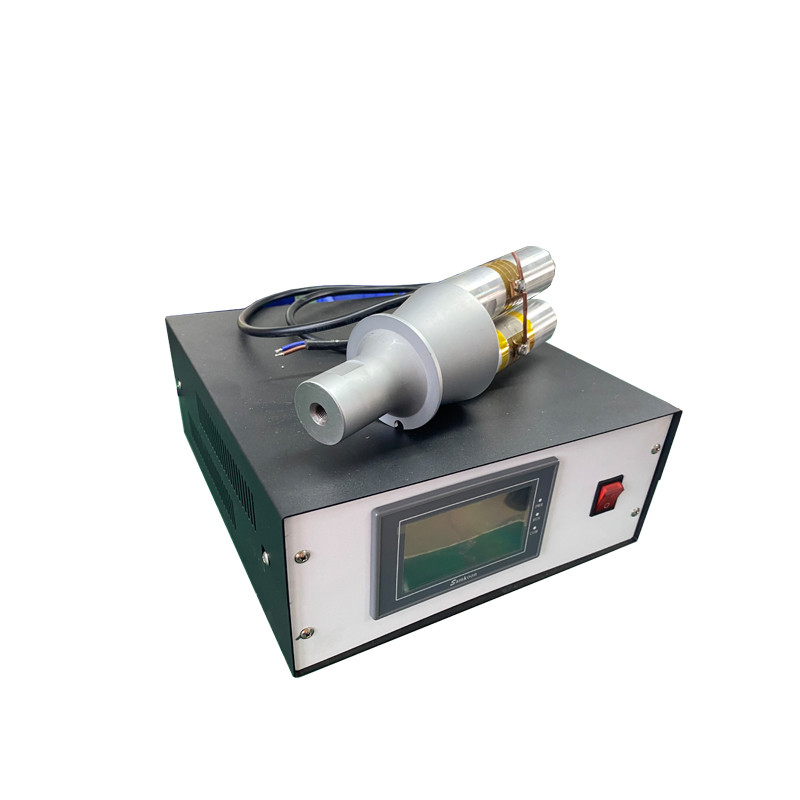

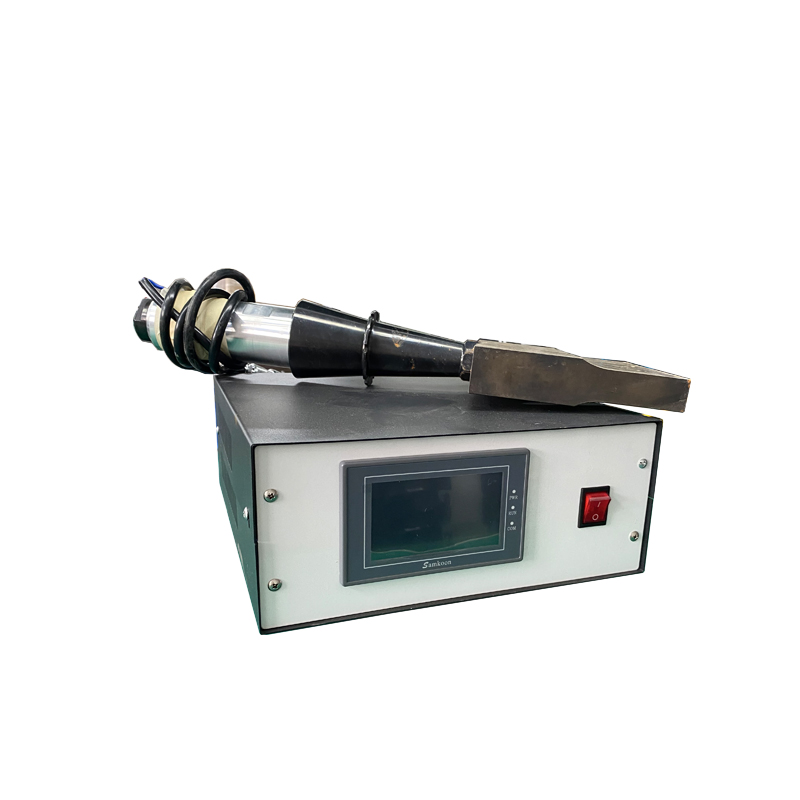

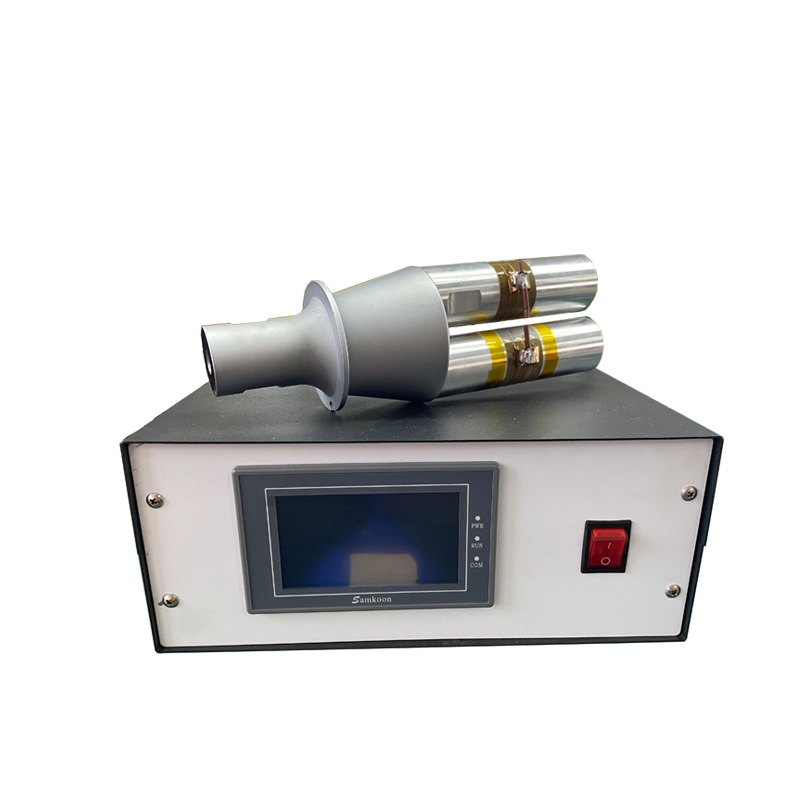

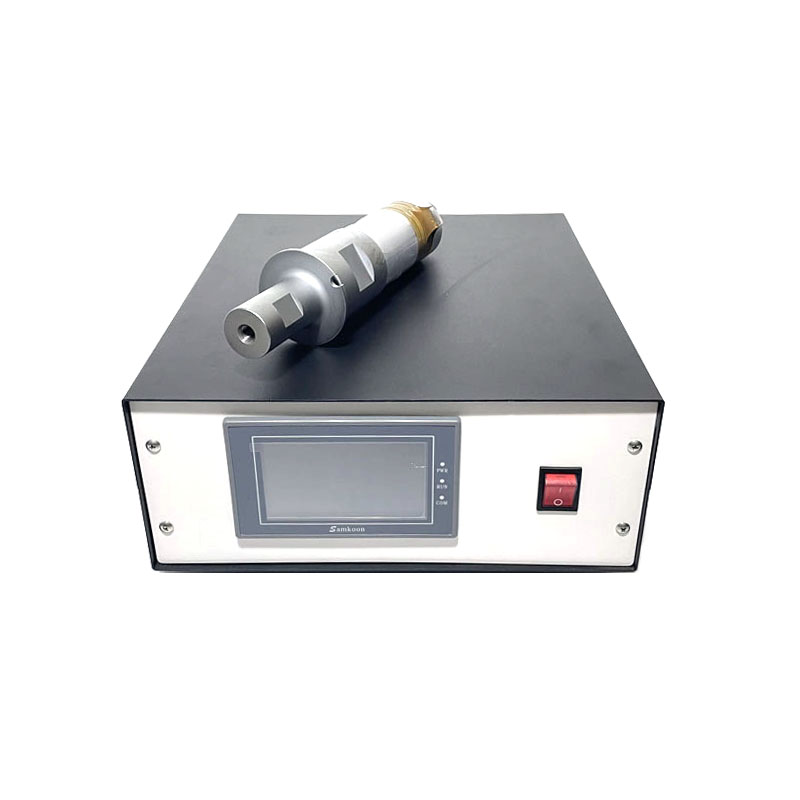

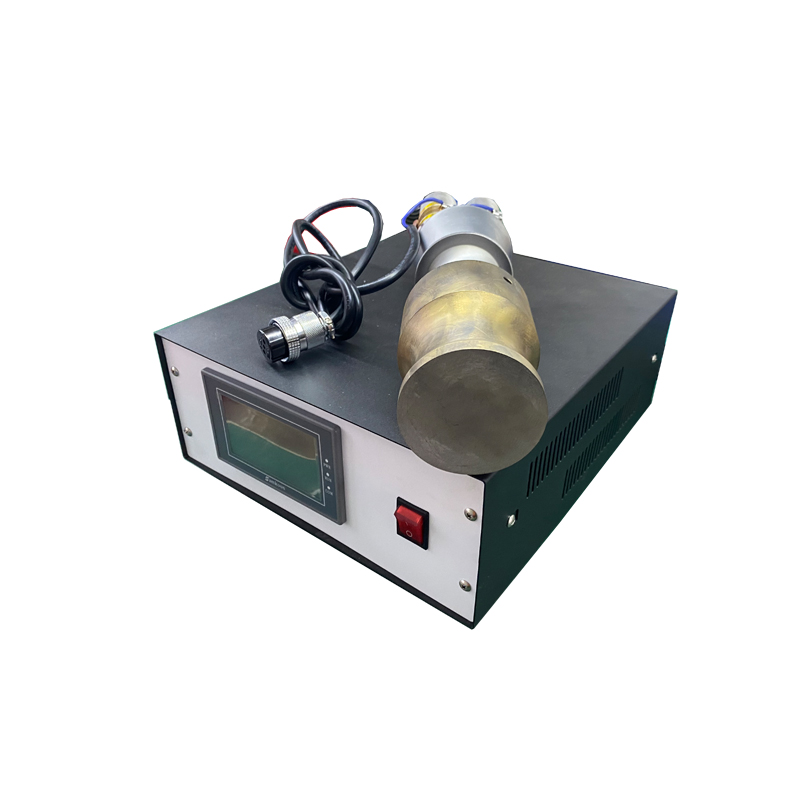

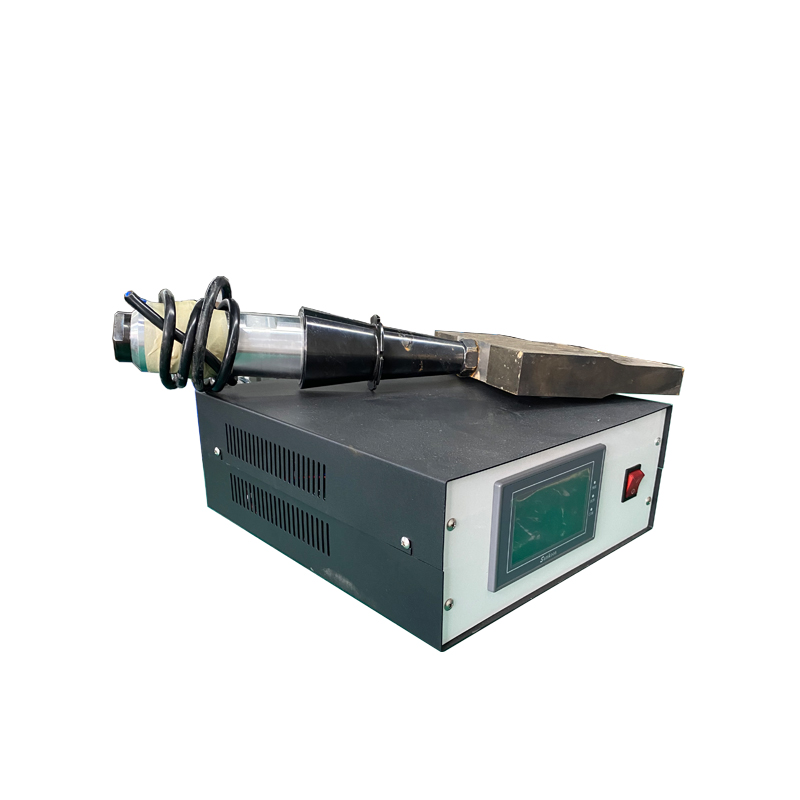

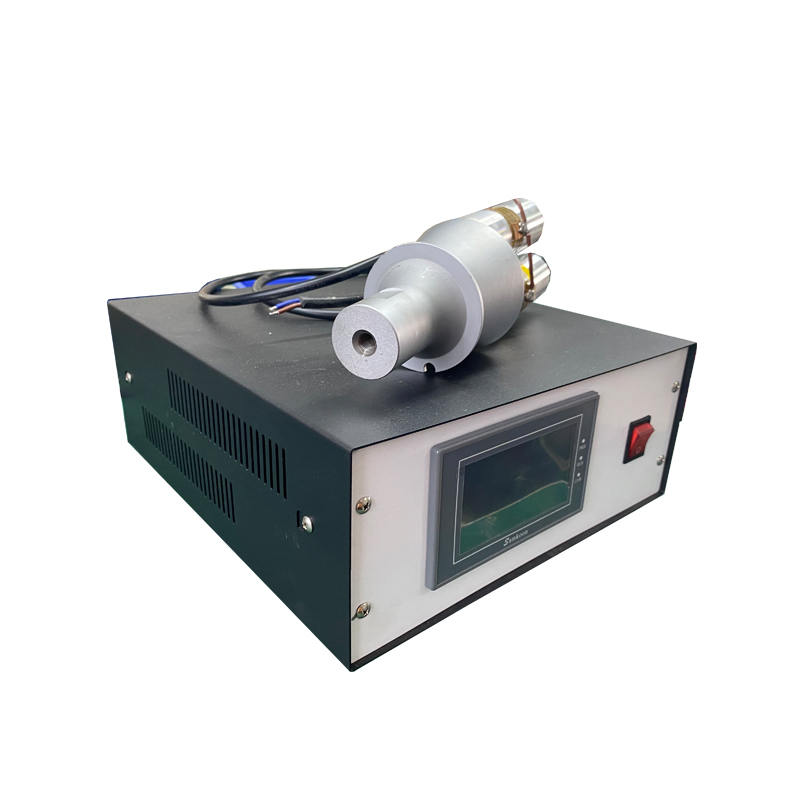

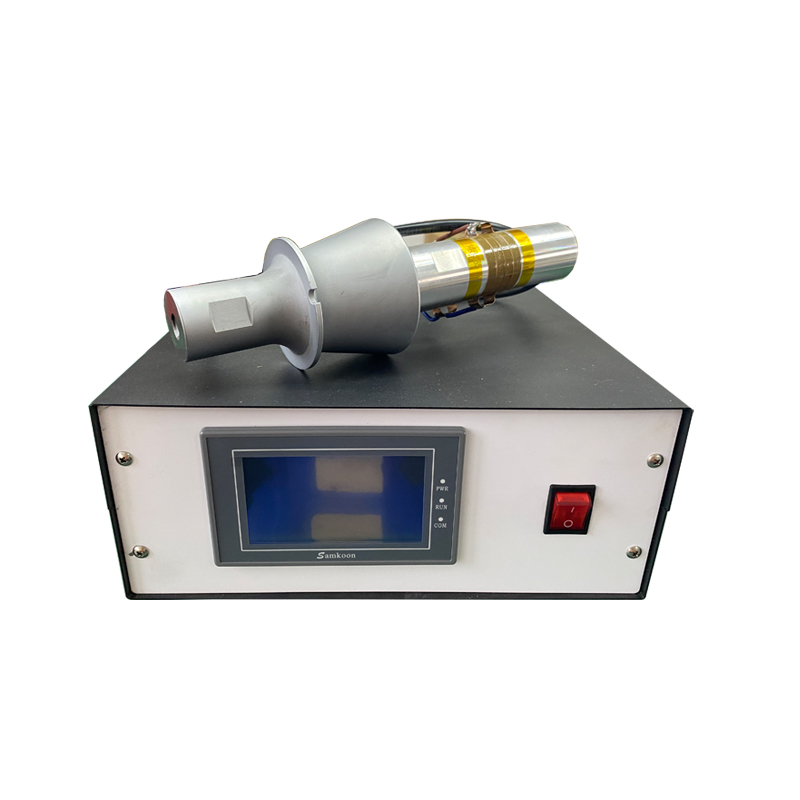

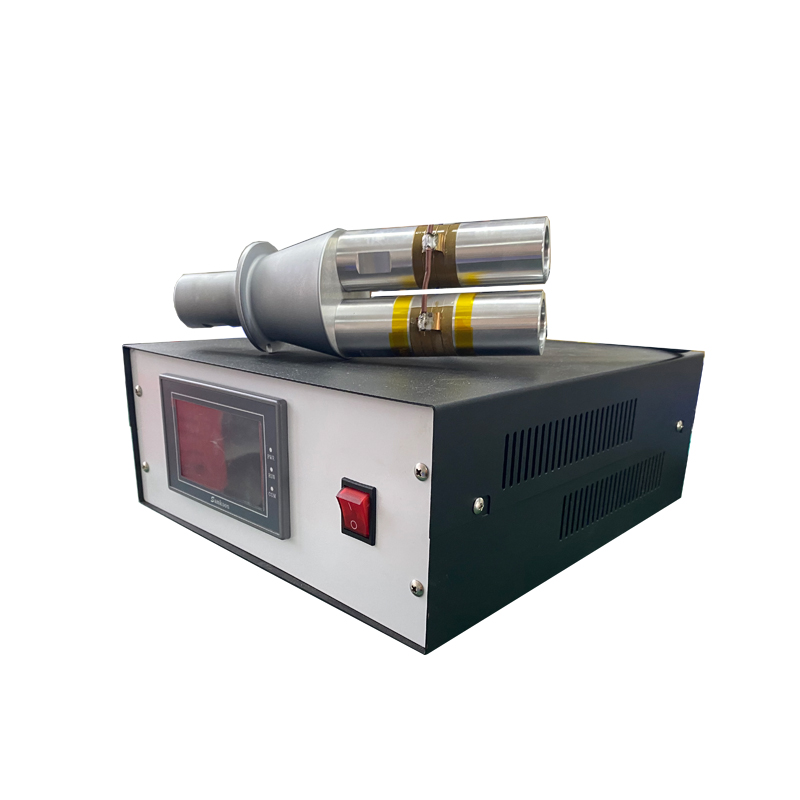

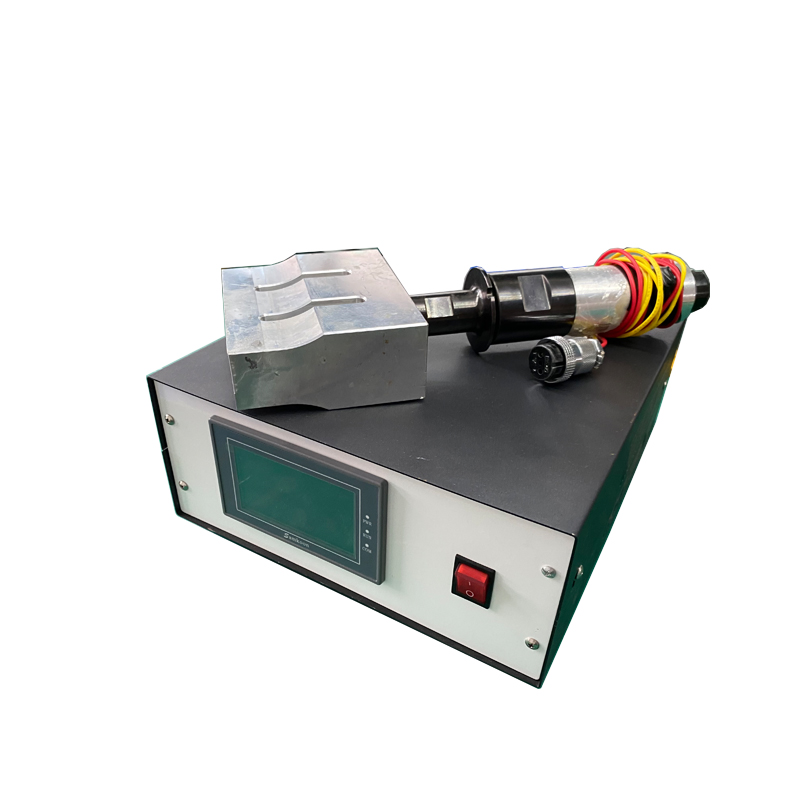

500W 28KHZ/35KHZ Ultrasonic Frequency Plastic Welding Generator With Transducer Booster Horn

First of all, the working methods are different. Generally, in ultrasonic plastic welding, the vibration direction of the welding head is perpendicular to the welding position, and in ultrasonic metal welding, the vibration direction of the welding head is parallel to the welding position. In some special cases, the …

500W 28KHZ/35KHZ Ultrasonic Frequency Plastic Welding Generator With Transducer Booster Horn

- First of all, the working methods are different. Generally, in ultrasonic plastic welding, the vibration direction of the welding head is perpendicular to the welding position, and in ultrasonic metal welding, the vibration direction of the welding head is parallel to the welding position. In some special cases, the parallel direction can also be used for plastic welding, such as thin plastic parts.

- Secondly, because ultrasonic is applied to welding metal, higher requirements are put forward for ultrasonic welding technology; Compared with ordinary plastic welding, the requirements for power capacity, power density, stability and automatic control are not the same level. At present, the generators for ultrasonic plastic welding in China are basically self-excited circuits. Typical examples are 8400 and 8700 full bridge circuits and half bridge circuits commonly used by Taiwan’s machines, which are characterized by a tuning inductor. If the existing mature technology used for plastic welding is directly transferred to metal welding, its technical deficiencies will lead to unstable use of products; Its only advantage is that it is cheap, but for the high requirements of metal welding itself, this advantage is very pale.

- High power capacity, stable ultrasonic generator:

The first requirement of a stable Ultrasonic Generator is: automatic frequency tracking. Automatic frequency tracking can ensure that the transducer system can work in a resonant state, that is, the maximum amplitude of the welding head. The basic requirement for metal welding is to adopt the frequency automatic tracking technology, and no frequency modulation is required when replacing the mold and working. Equipment with adjustable inductance and manual frequency adjustment can hardly meet the requirements.

Stable ultrasonic generator also requires constant amplitude function and stepless amplitude adjustment. Constant amplitude function, which can ensure the consistency of welding and is the key to stable production; The stepless adjustment of amplitude is the basis to ensure the use of equipment. For example, copper and aluminum materials can be welded on the same equipment through parameter adjustment.

High power capacity: compared with plastic welding, metal welding requires high energy density, so there must be relatively high power capacity. For example, a 20kHz machine basically requires a power capacity of more than 3000W. Many companies often have false ratings for power capacity, so we just need to compare them with their plastic welding machines, because the plastic welding machines have too high ratings.

- High quality welding head: metal welding, as an industrial use, inevitably requires a welding head with long service life.

- High quality transducer: such as 20kHz ultrasonic welding transducer, it must be able to withstand the load above 3kw for a long time. It is irresponsible to distinguish the transducers of many companies with ordinary plastic welding.

- High quality control system: It has three basic control modes of welding energy, time and height, and a variety of quality control software to meet different needs.

| Model | Power | Frequency |

| PLS-HJDY300 | 300W | 28KHZ,30KHZ,35KHZ,40KHZ |

| PLS-HJDY500 | 500W | 28KHZ,30KHZ,35KHZ,40KHZ |

| PLS-HJDY800 | 800W | 28KHZ,30KHZ,35KHZ,40KHZ |

| PLS-HJDY1000 | 1000W | 15KHZ,20KHZ,28KHZ |

| PLS-HJDY1200 | 1200W | 15KHZ,20KHZ,28KHZ |

| PLS-HJDY1500 | 1500W | 15KHZ,20KHZ |

| PLS-HJDY2000 | 2000W | 15KHZ,20KHZ |

| PLS-HJDY2600 | 2600W | 15KHZ,20KHZ |

| PLS-HJDY3200 | 3200W | 15KHZ |

| PLS-HJDY4200 | 4200W | 15KHZ |

500W 28KHZ/35KHZ Ultrasonic Frequency Plastic Welding Generator With Transducer Booster Horn

标签:20kHz ultrasonic welding transducer, 28KHZ/35KHZ Ultrasonic Frequency Plastic Welding Generator, Ultrasonic Frequency Plastic Welding Generator, Ultrasonic Generator

Send Inquiry

1000W 28KHZ/35KHZ Single Frequency Ultrasonic Plastic Welding Generator With Transducer Booster Horn

1000W 28KHZ/35KHZ Single Frequency Ultrasonic Plastic Welding Generator With Transducer Booster Horn 2000W Automatic Control Ultrasonic Welding Generator Transducer Booster Horn For Ultrasonic Plastic Bag Pulse Welder Machine

2000W Automatic Control Ultrasonic Welding Generator Transducer Booster Horn For Ultrasonic Plastic Bag Pulse Welder Machine 3000W 20KHZ Ultrasonic Welding Generator And 20khz Ultrasonic Welding Transducer With Booster Horn

3000W 20KHZ Ultrasonic Welding Generator And 20khz Ultrasonic Welding Transducer With Booster Horn 3200W Industrial Ultrasonic Welding Control Generator Transducer Booster Horn For Ultrasonic Acrylic Plastic Welding Machine

3200W Industrial Ultrasonic Welding Control Generator Transducer Booster Horn For Ultrasonic Acrylic Plastic Welding Machine 3200W 20khz Digital Ultrasonic Welding Generator For Automobile Parts Machine

3200W 20khz Digital Ultrasonic Welding Generator For Automobile Parts Machine Industrial Ultrasonic Welding Convertor Transducer Generator System For Pvc Non-woven Ultrasonic Turntable Plastic Welders

Industrial Ultrasonic Welding Convertor Transducer Generator System For Pvc Non-woven Ultrasonic Turntable Plastic Welders 2000W 15KHZ/20KHZ Low Frequency Ultrasonic Plastic Welding Generator With Ultrasonic Transducer Booster Horn For Metal Welder

2000W 15KHZ/20KHZ Low Frequency Ultrasonic Plastic Welding Generator With Ultrasonic Transducer Booster Horn For Metal Welder 3000W Industrial Ultrasonic High Power Welding Generator Transducer Booster Horn For Handheld Spot Earloop Welding Machine

3000W Industrial Ultrasonic High Power Welding Generator Transducer Booster Horn For Handheld Spot Earloop Welding Machine 1800W Various Frequency Ultrasonic Metal Welding Generator Transducer Booster Horn For Pvc Conveyor Belts Welding Machine

1800W Various Frequency Ultrasonic Metal Welding Generator Transducer Booster Horn For Pvc Conveyor Belts Welding Machine 2000W Industrial Pulse Ultrasonic Welding Generator Transducer Booster Horn For Automatic Plastic Ultrasonic Welding Machine

2000W Industrial Pulse Ultrasonic Welding Generator Transducer Booster Horn For Automatic Plastic Ultrasonic Welding Machine 3200W Industrial Ultrasonic Welding Control Generator Transducer Booster Horn For Ultrasonic Acrylic Plastic Welding Machine

3200W Industrial Ultrasonic Welding Control Generator Transducer Booster Horn For Ultrasonic Acrylic Plastic Welding Machine Ultrasonic Plastic Welding Generator Sonotrodes And Booster Horn For High Power Ultrasonic Welding Equipment

Ultrasonic Plastic Welding Generator Sonotrodes And Booster Horn For High Power Ultrasonic Welding Equipment