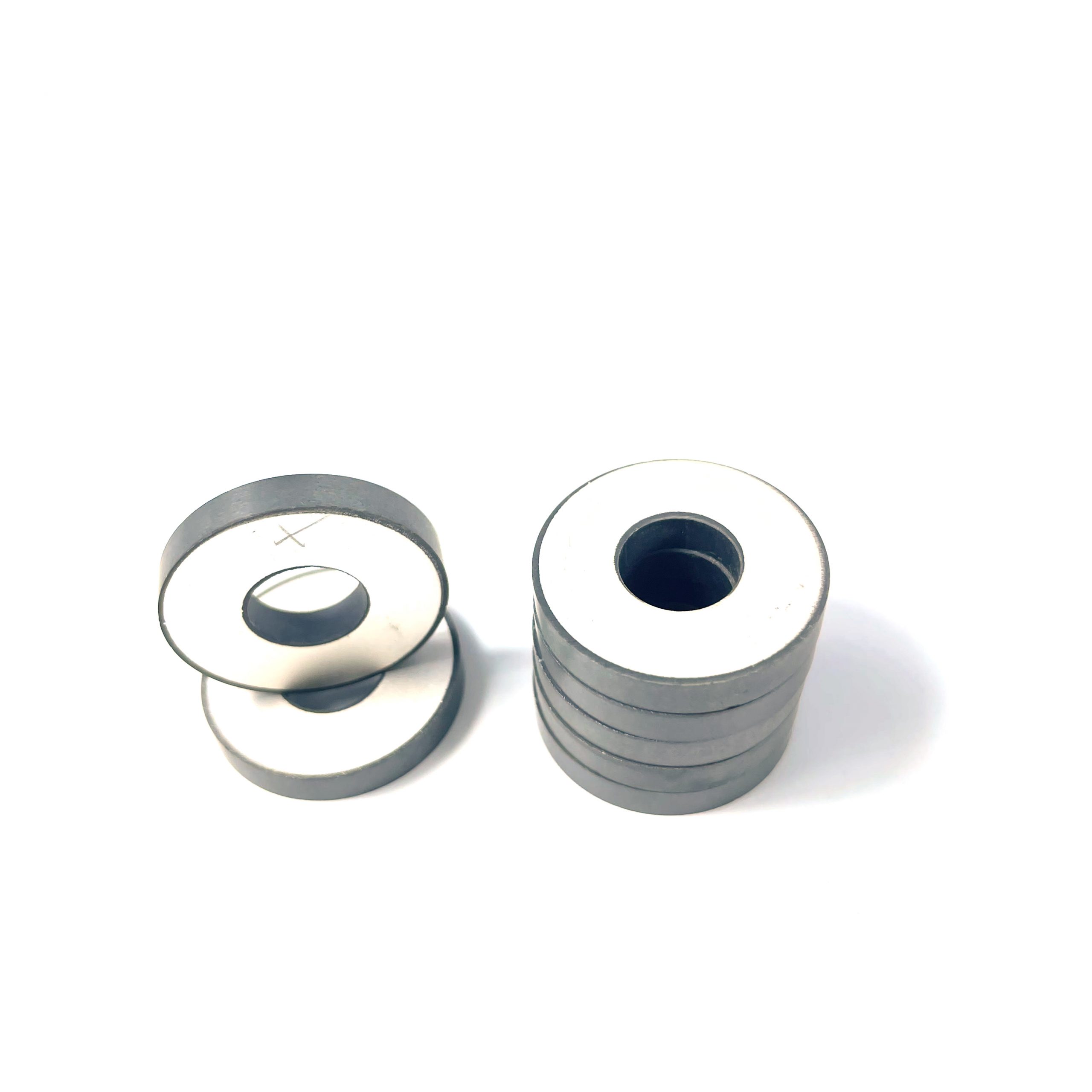

10x5x2mm PZT-8/PZT-4 Piezoelectric Ceramic Ring For 33khz 50W Medical Teeth Cleaning Ultrasonic Transducer

Electronic ceramics can be divided into five categories according to their functions and uses: insulating device ceramics, capacitor ceramics, ferroelectric ceramics, semiconductor ceramics and ionic ceramics. 1、 Application of Special Sensitive Ceramic Automotive Sensors It is required that the electron…

Electronic ceramics can be divided into five categories according to their functions and uses: insulating device ceramics, capacitor ceramics, ferroelectric ceramics, semiconductor ceramics and ionic ceramics.

1、 Application of Special Sensitive Ceramic Automotive Sensors

It is required that the electronic ceramic sensors for automobiles can be applied to the specific harsh environment of automobiles for a long time (high temperature, low temperature, vibration, acceleration, humidity, sound, exhaust gas), and should have the characteristics of small size, light weight, good reusability, wide output range, etc. Ceramic is heat-resistant, corrosion-resistant, wear-resistant and has potential excellent electromagnetic and optical functions. In recent years, with the progress of manufacturing technology, it has been fully utilized. Sensors made of sensitive ceramic materials can fully meet the above requirements.

2、 Application of Ceramic Material in Automobile Spraying Technology

In recent years, aerospace technology has been widely applied to ceramic film spraying technology, which has been applied to automobiles. This technology has the advantages of good thermal effect, high temperature and pressure resistance, mature process and stable quality. In order to achieve the goal of low heat dissipation, ceramic coating can be applied to the engine combustion chamber components, such as zirconia sprayed on the piston top and zirconia sprayed on the cylinder liner. After this treatment, the engine can reduce heat loss, reduce the engine’s own mass, reduce the engine size, and reduce fuel consumption.

3、 Application of alumina ceramic shock absorber in automobile

The smart shock absorber for premium cars has been successfully developed by comprehensively utilizing the positive piezoelectric effect of sensitive ceramics and the electrostriction effect of the reverse piezoelectric effect of alumina ceramics. Due to the use of highly sensitive ceramic components, this kind of shock absorber has the function of road surface identification and self adjustment, which can minimize the vibration caused by the rough road surface of the car.

| spec | Dimension (mm) | Radial frequency (KHz) | Capacitance (pf) | Dielectric dissipation factor tanδ(%) | Electromechanical coupling coefficient (Kr) | Impedance Zr(Ω) | Thickness frequency (KHz) |

| PU-PC25103 | Φ25×Φ10×3 | 66.4 | 1240±12.5% | ≤0.3 | ≥0.46 | ≤15 | 683±5% |

| PU-PC225104 | Φ25×Φ10×4 | 66.4 | 930±12.5% | ≤0.3 | ≥0.46 | ≤15 | 512±5% |

| PU-PC40155 | Φ40×Φ12×5 | 45.9 | 2070±12.5% | ≤0.3 | ≥0.46 | ≤15 | 410±5% |

| PU-PC40155 | Φ40×Φ15×5 | 42.2 | 1960±12.5% | ≤0.3 | ≥0.46 | ≤15 | 323±5% |

| PU-PC40176 | Φ40×Φ17×6 | 40.5 | 1555±12.5% | ≤0.3 | ≥0.46 | ≤15 | 341±5% |

| PU-PC40205 | Φ40×Φ20×5 | 37.9 | 1700±12.5% | ≤0.3 | ≥0.47 | ≤15 | 410±5% |

| PU-PC50206 | Φ50×Φ20×6 | 33.2 | 2490±12.5% | ≤0.3 | ≥0.46 | ≤15 | 341±5% |

| PU-PC501765 | Φ50×Φ17×6.5 | 34.8 | 2430±12.5% | ≤0.3 | ≥0.46 | ≤15 | 315±5% |

| PU-PC50236 | Φ50×Φ23×6 | 31.2 | 2340±12.5% | ≤0.3 | ≥0.47 | ≤15 | 341±5% |

| PU-PC50276 | Φ50×Φ27×6 | 29.3 | 2100±12.5% | ≤0.3 | ≥0.47 | ≤15 | 341±5% |

| PU-PC603010 | Φ60×Φ30×10 | 25.3 | 1922±12.5% | ≤0.3 | ≥0.47 | ≤18 | 205±5% |

标签:Medical Teeth Cleaning Ultrasonic Transducer, Piezoelectric Ceramic Ring, PZT-8/PZT-4 Piezoelectric Ceramic Ring

Send Inquiry

Custom 15khz 18khz 20khz 40khz 35 khz Piezoelectric Crystal Ring Material for Ultrasonic Cleaner Welding PZT Piezo 60*30*10mm

Custom 15khz 18khz 20khz 40khz 35 khz Piezoelectric Crystal Ring Material for Ultrasonic Cleaner Welding PZT Piezo 60*30*10mm Pzt4 Pzt5 Pzt8 Piezoelectric Pzt Piezoelectric Ceramic Element Piezo Sensor Vibrator Piezo Ceramic Ring

Pzt4 Pzt5 Pzt8 Piezoelectric Pzt Piezoelectric Ceramic Element Piezo Sensor Vibrator Piezo Ceramic Ring Piezo Vibration Piezoelectric Ceramic Transducer Ultrasonic Piezo Ring 40*20*5mm

Piezo Vibration Piezoelectric Ceramic Transducer Ultrasonic Piezo Ring 40*20*5mm 38*15*5 Piezoelectric Ceramic Element Ring Piezoelectric Ceramic For Ultrasonic Vibration Trasnducer

38*15*5 Piezoelectric Ceramic Element Ring Piezoelectric Ceramic For Ultrasonic Vibration Trasnducer Piezoelectric Ceramic Element Ultrasonic Piezo Electric Ceramics Ring Usd For Ultrasonic Welding Mask Machine

Piezoelectric Ceramic Element Ultrasonic Piezo Electric Ceramics Ring Usd For Ultrasonic Welding Mask Machine Piezo Ring 50*17*6.5mm Piezoelectric Ceramic Element Customized Ultrasonic Piezoelectric Ceramic Ring

Piezo Ring 50*17*6.5mm Piezoelectric Ceramic Element Customized Ultrasonic Piezoelectric Ceramic Ring Piezoelectric ring ceramic ultrasonic piezoelectric ceramic piezo disc piezoelectric ceramic vibration sensor

Piezoelectric ring ceramic ultrasonic piezoelectric ceramic piezo disc piezoelectric ceramic vibration sensor 50x17x6.5mm Pzt8 Piezo Electric Piezoelectric Ceramic Element For Ultrasonic Transducer 50*17*6.5mm

50x17x6.5mm Pzt8 Piezo Electric Piezoelectric Ceramic Element For Ultrasonic Transducer 50*17*6.5mm 38.1*12.75*6.35mm Pzt4 Material Ultrasonic Ceramic Piezo Element For Ultrasonic Sensor

38.1*12.75*6.35mm Pzt4 Material Ultrasonic Ceramic Piezo Element For Ultrasonic Sensor 38*15*5mm Ring Ultrasonic Piezo Crystal Piezo Ceramic Ultrasonic Transducers Customization Ultrasonic Piezo Transducer

38*15*5mm Ring Ultrasonic Piezo Crystal Piezo Ceramic Ultrasonic Transducers Customization Ultrasonic Piezo Transducer 38*15*5mm PZT-8/PZT-4 Piezoelectric Ceramic Ring For 60W/100W 40khz/28khz Ultrasonic Cleaner Transducer

38*15*5mm PZT-8/PZT-4 Piezoelectric Ceramic Ring For 60W/100W 40khz/28khz Ultrasonic Cleaner Transducer PZT8 Ceramic Piezo Ring 50*17*6.5mm Piezoelectric Ring Ceramic transducer for Ultrasonic transducer

PZT8 Ceramic Piezo Ring 50*17*6.5mm Piezoelectric Ring Ceramic transducer for Ultrasonic transducer