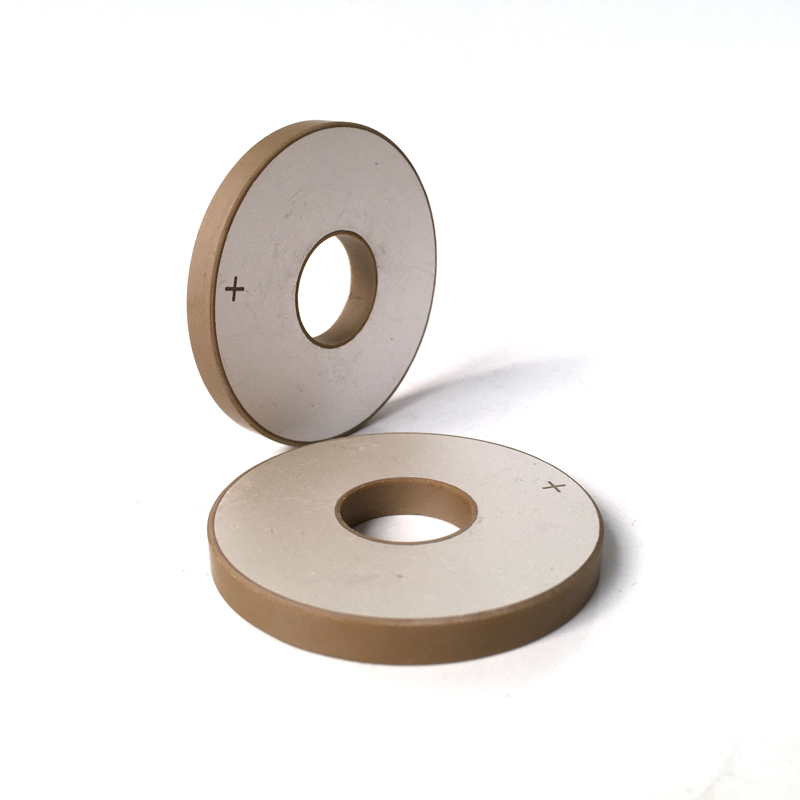

Ultrasonic Welding Mask Machine Piezo Ceramic Ring 60*30*10mm Ultrasonic Transducer Piezoelectric Ceramic Ring

Circular piezoelectric ceramic sheets, as a new type of high-tech inorganic non-metallic functional material, have been widely used in the fields of technology and industry in recent years. Its unique piezoelectric effect makes circular piezoelectric ceramic sheets play an irreplaceable role in multiple fields such a…

Circular piezoelectric ceramic sheets, as a new type of high-tech inorganic non-metallic functional material, have been widely used in the fields of technology and industry in recent years. Its unique piezoelectric effect makes circular piezoelectric ceramic sheets play an irreplaceable role in multiple fields such as sensors, drivers, and transducers. This article will delve into the principles, manufacturing processes, application fields, and future development trends of circular piezoelectric ceramic sheets, in order to demonstrate their important role in modern industrial and technological development.

The basic principle of circular piezoelectric ceramic sheets lies in their piezoelectric effect. The piezoelectric effect refers to the relative displacement of the positive and negative charge centers inside certain crystals when subjected to external forces, resulting in polarization and the generation of opposite sign bound charges on the surfaces of the two ends of the crystal. When the external force disappears, the crystal returns to an uncharged state. This phenomenon is called the positive piezoelectric effect. On the contrary, when a voltage is applied to both ends of a piezoelectric crystal, the positive and negative charges inside the crystal will rearrange, causing deformation of the crystal. This phenomenon is called the inverse piezoelectric effect. The circular piezoelectric ceramic sheet utilizes this piezoelectric effect to achieve the mutual conversion between mechanical energy and electrical energy.

| spec | Dimension (mm) | Radial frequency (KHz) | Capacitance (pf) | Dielectric dissipation factor tanδ(%) | Electromechanical coupling coefficient (Kr) | Impedance Zr(Ω) | Thickness frequency (KHz) |

| PU-PC25103 | Φ25×Φ10×3 | 66.4 | 1240±12.5% | ≤0.3 | ≥0.46 | ≤15 | 683±5% |

| PU-PC225104 | Φ25×Φ10×4 | 66.4 | 930±12.5% | ≤0.3 | ≥0.46 | ≤15 | 512±5% |

| PU-PC40155 | Φ40×Φ12×5 | 45.9 | 2070±12.5% | ≤0.3 | ≥0.46 | ≤15 | 410±5% |

| PU-PC40155 | Φ40×Φ15×5 | 42.2 | 1960±12.5% | ≤0.3 | ≥0.46 | ≤15 | 323±5% |

| PU-PC40176 | Φ40×Φ17×6 | 40.5 | 1555±12.5% | ≤0.3 | ≥0.46 | ≤15 | 341±5% |

| PU-PC40205 | Φ40×Φ20×5 | 37.9 | 1700±12.5% | ≤0.3 | ≥0.47 | ≤15 | 410±5% |

| PU-PC50206 | Φ50×Φ20×6 | 33.2 | 2490±12.5% | ≤0.3 | ≥0.46 | ≤15 | 341±5% |

| PU-PC501765 | Φ50×Φ17×6.5 | 34.8 | 2430±12.5% | ≤0.3 | ≥0.46 | ≤15 | 315±5% |

| PU-PC50236 | Φ50×Φ23×6 | 31.2 | 2340±12.5% | ≤0.3 | ≥0.47 | ≤15 | 341±5% |

| PU-PC50276 | Φ50×Φ27×6 | 29.3 | 2100±12.5% | ≤0.3 | ≥0.47 | ≤15 | 341±5% |

| PU-PC603010 | Φ60×Φ30×10 | 25.3 | 1922±12.5% | ≤0.3 | ≥0.47 | ≤18 | 205±5% |

Send Inquiry

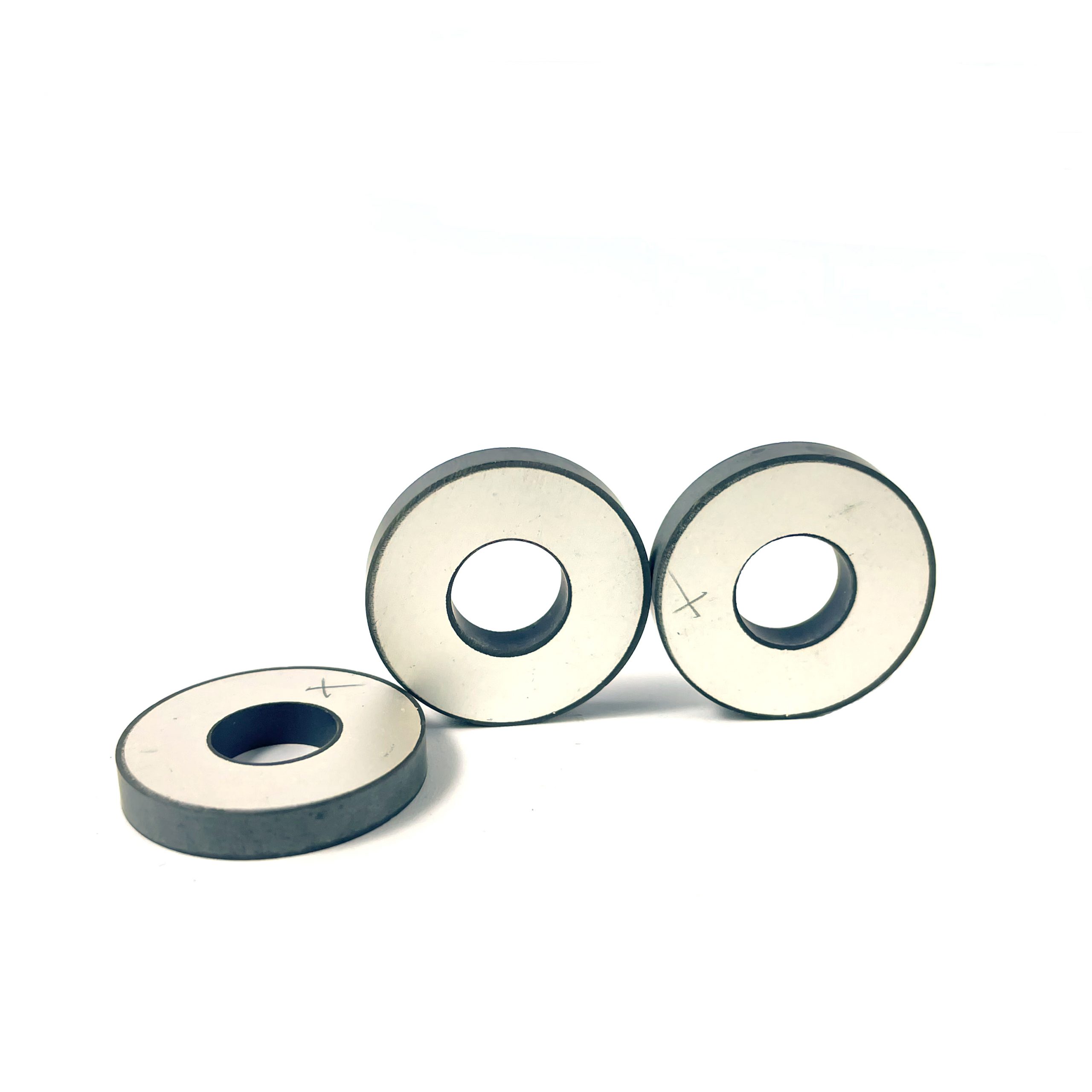

45*15*5 Pzt Piezo Ceramic Element Piezo Crystal Ring Ultrasonic Piezo Ceramic Element Cylinder

45*15*5 Pzt Piezo Ceramic Element Piezo Crystal Ring Ultrasonic Piezo Ceramic Element Cylinder 50*20*5mm PZT-8 Piezoelectric Ceramic Ring For 2000W 20khz/15khz High Power Ultrasonic Transducer

50*20*5mm PZT-8 Piezoelectric Ceramic Ring For 2000W 20khz/15khz High Power Ultrasonic Transducer 38.1*12.75*6.35mm Piezoelectric Ceramic Ring For 100W 28khz Ultrasonic Washing Machine Transducer

38.1*12.75*6.35mm Piezoelectric Ceramic Ring For 100W 28khz Ultrasonic Washing Machine Transducer Pzt ultrasonic transducer 40khz components piezo igniter piezoelectric pzt actuator 45*15*5 Pzt Piezo Ceramic Element

Pzt ultrasonic transducer 40khz components piezo igniter piezoelectric pzt actuator 45*15*5 Pzt Piezo Ceramic Element Piezoelectric Ceramic Material PZT4 PZT5 PZT8 Tube Disc Ring Piezo Ceramic

Piezoelectric Ceramic Material PZT4 PZT5 PZT8 Tube Disc Ring Piezo Ceramic PZT8 Piezo Disk Element Discs Cleaning Welding Piezoelectric Ceramic Chip Ring

PZT8 Piezo Disk Element Discs Cleaning Welding Piezoelectric Ceramic Chip Ring Piezoelectric Ceramic Wafers for Ultrasound Testing piezoelectric plate Ultrasonic teeth cleaning

Piezoelectric Ceramic Wafers for Ultrasound Testing piezoelectric plate Ultrasonic teeth cleaning 40*20*5mm PZT-8 Piezoelectric Ceramic Ring For 800W 28khz Piezo Ultrasonic Vibrator Transducer

40*20*5mm PZT-8 Piezoelectric Ceramic Ring For 800W 28khz Piezo Ultrasonic Vibrator Transducer 50*20*6mm Piezo Ceramic Ring PZT Electronic Ceramic Ring Piezoelectric Ceramic

50*20*6mm Piezo Ceramic Ring PZT Electronic Ceramic Ring Piezoelectric Ceramic 38.1*12.75*6.35mm Pzt4 Material Ultrasonic Ceramic Piezo Element Cylinder Piezoelectric Crystal Ultrasound Transducer Ring Piezo

38.1*12.75*6.35mm Pzt4 Material Ultrasonic Ceramic Piezo Element Cylinder Piezoelectric Crystal Ultrasound Transducer Ring Piezo 60*30*10mm Piezoelectric Ceramic Materials PZT-8 China 25khz Piezoelectric Material Pzt Piezo Ceramic

60*30*10mm Piezoelectric Ceramic Materials PZT-8 China 25khz Piezoelectric Material Pzt Piezo Ceramic Vibration 45*15*5 Piezo Sensors PZT Rings Piezoelectric Ceramics Piezo Ceramic Ring Transducer 44 KHz

Vibration 45*15*5 Piezo Sensors PZT Rings Piezoelectric Ceramics Piezo Ceramic Ring Transducer 44 KHz