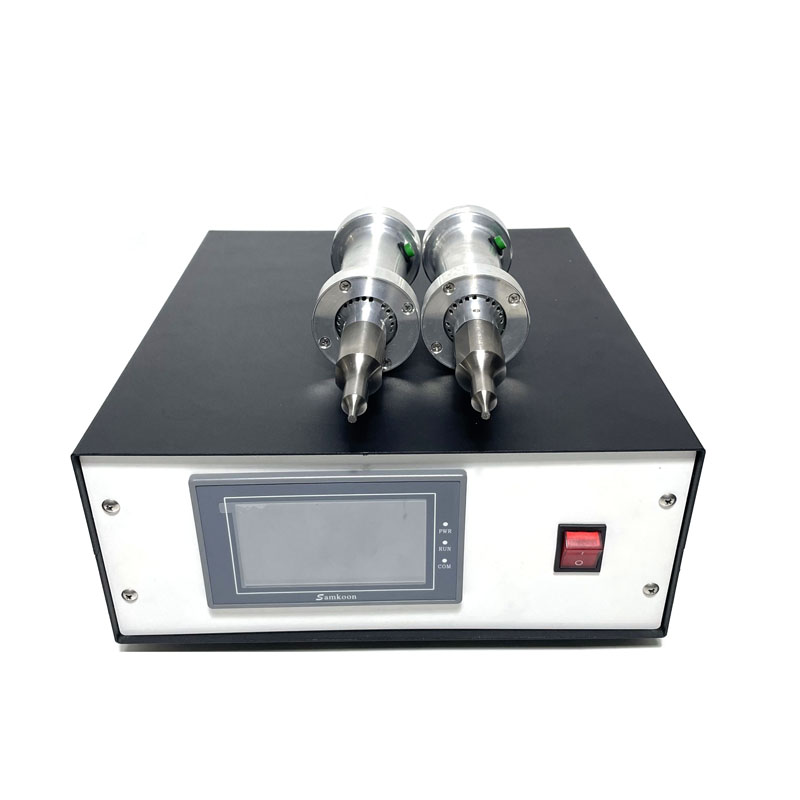

28KHZ Portable Nonwoven Fabric Mask Rar Loop Seam Ultrasonic Spot Welding Machine For Plastic Pvc Fabric

Application method of hand-held ultrasonic spot welding machine: 1、 Fusion welding method: under moderate pressure, the ultrasonic ultra high frequency vibration welding head can make the joint surface of two pieces of plastic produce friction heat and instantly melt the joint. The welding strength can be c…

Application method of hand-held ultrasonic spot welding machine:

1、 Fusion welding method: under moderate pressure, the ultrasonic ultra high frequency vibration welding head can make the joint surface of two pieces of plastic produce friction heat and instantly melt the joint. The welding strength can be comparable to the body. With appropriate workpieces and reasonable interface design, water and air tightness can be achieved, and the inconvenience caused by the use of auxiliary products can be eliminated, so as to achieve efficient and clean fusion (details are as follows:?).

2、 Rivet welding method: the ultrasonic ultra high frequency vibration welding head is pressed against the protruding tip of the plastic product to make it instantly heat and melt into the rivet shape, so that materials of different materials are mechanically riveted together. 3、 Embedding: By means of the passage of the welding head and appropriate pressure, the metal parts (such as nuts, screws, etc.) are squeezed into the reserved plastic holes in an instant and fixed at a certain depth. After completion, no matter the tension and torque, the strength of the molding in the traditional mold can be comparable to that of the molding in the traditional mold, and the defects of the damaged injection mold and the slow injection can be avoided.

4、 Molding: This method is similar to the riveting method. The concave welding head is pressed against the outer ring of the plastic product. After the welding head emits ultrasonic ultra-high frequency vibration, the plastic is melted into shape and coated on the metal product to fix it. The appearance is smooth and beautiful. This method is mostly used for the fixing and forming of electronics and speakers, and the fixing of cosmetics lenses.

5、 Spot welding: A. It is unnecessary to design welding lines in advance to weld the two pieces of plastic by points. B. For relatively large workpieces, it is not easy to design welding lines for spot welding, so as to achieve welding effect, multiple points can be spot welded at the same time.

6、 Cutting and sealing: using the working principle of ultrasonic instantaneous vibration, the chemical fiber fabric is cut, which has the advantages of smooth cut without cracking and wire drawing.

| Type | power (W) | Frequency | Welding time | Contains |

| PU-HH300W | 300W | 20khz,28khz,30khz,35khz,40khz | 0.1-3sec | generator , transducer ,horn,head |

| PU-HH500W | 500W | 20khz,28khz,30khz | 0.1-3sec | generator , transducer ,horn,head |

| PU-HH900W | 900W | 20khz,28khz,30khz | 0.1-3sec | generator , transducer ,horn,head |

| PU-HH1000W | 1000W | 20khz,28khz | 0.1-3sec | generator , transducer ,horn,head |

| PU-HH1200W | 1200W | 20khz,28khz | 0.1-3sec | generator , transducer ,horn,head |

标签:hand-held ultrasonic spot welding machine, ultrasonic spot welding machine, ultrasonic welding machine

Send Inquiry

28KHZ 1200W Ultrasonic Portable Spot Welding Machine For Pp Corrugated Sheet Box Hollow Board Carton Box

28KHZ 1200W Ultrasonic Portable Spot Welding Machine For Pp Corrugated Sheet Box Hollow Board Carton Box 40khz Masks Portable Ultrasonic Spot Welding Machine Ultrasonic Hand Welder With Generator

40khz Masks Portable Ultrasonic Spot Welding Machine Ultrasonic Hand Welder With Generator 500W 35KHZ Single Head Earloop Ultrasonic Spot Welding Machine And Power Generator

500W 35KHZ Single Head Earloop Ultrasonic Spot Welding Machine And Power Generator Handheld Ultrasonic Spot Welding Machine Portable Non-woven Spot Welding Machine Mask Welding

Handheld Ultrasonic Spot Welding Machine Portable Non-woven Spot Welding Machine Mask Welding Hand Held Portable Ultrasonic Spot Welder Handheld Manual Ultrasonic Plastic Welding Machine

Hand Held Portable Ultrasonic Spot Welder Handheld Manual Ultrasonic Plastic Welding Machine Ultrasonic Assembly Spot Welding System With Gun Type Hand Welder Plastic Spot Welding Machine Gun Type for Auto Parts

Ultrasonic Assembly Spot Welding System With Gun Type Hand Welder Plastic Spot Welding Machine Gun Type for Auto Parts 1200W 28KHZ Manual Ultrasonic Welding Machine Hand Held Portable Ultrasonic Spot Welding Machine

1200W 28KHZ Manual Ultrasonic Welding Machine Hand Held Portable Ultrasonic Spot Welding Machine 35khz Ultrasonic Handheld Welder Ultrasonic Spot Welding Machine Portable Spot Ultrasonic Welder Bonding Machine

35khz Ultrasonic Handheld Welder Ultrasonic Spot Welding Machine Portable Spot Ultrasonic Welder Bonding Machine 28Khz 1200W Handheld Ultrasonic Welder Gun Type Ultrasonic Plastic Welder Welding Portable Ultrasonic Spot Welder

28Khz 1200W Handheld Ultrasonic Welder Gun Type Ultrasonic Plastic Welder Welding Portable Ultrasonic Spot Welder 28KHZ/35KHZ Portable Ultrasonic Plastic Welding Machine Ultrasonic Spot Welding Machine

28KHZ/35KHZ Portable Ultrasonic Plastic Welding Machine Ultrasonic Spot Welding Machine Mask Non-woven Fabric Welding Ultrasonic Handheld Machine Spot Welder Hand Held Welding Machine

Mask Non-woven Fabric Welding Ultrasonic Handheld Machine Spot Welder Hand Held Welding Machine Manual Ultrasonic Spot Welder Welding Hand Held Portable Ultrasonic Spot Welder With Wave Generator

Manual Ultrasonic Spot Welder Welding Hand Held Portable Ultrasonic Spot Welder With Wave Generator