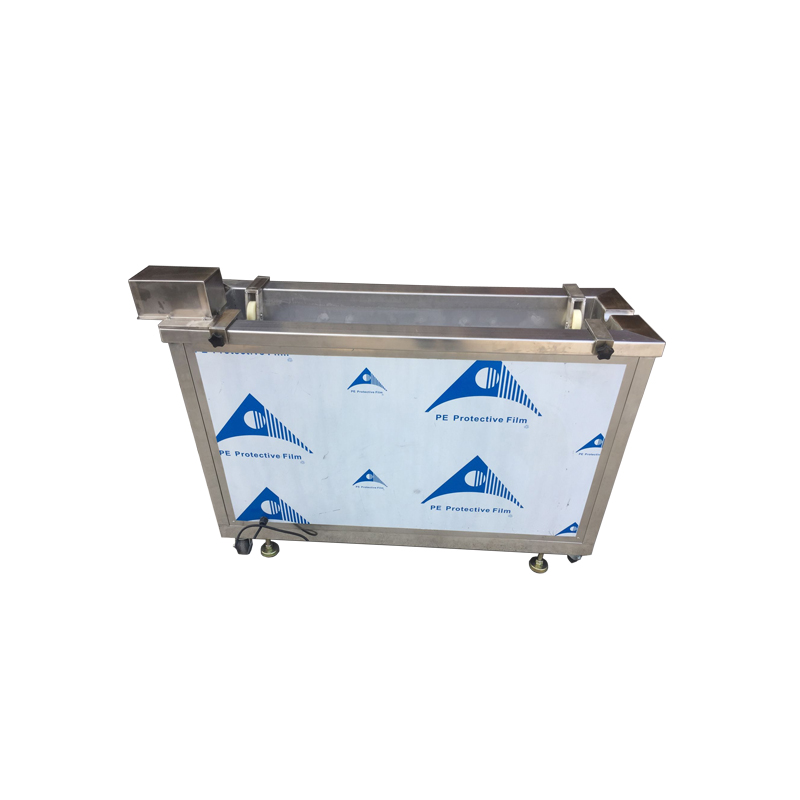

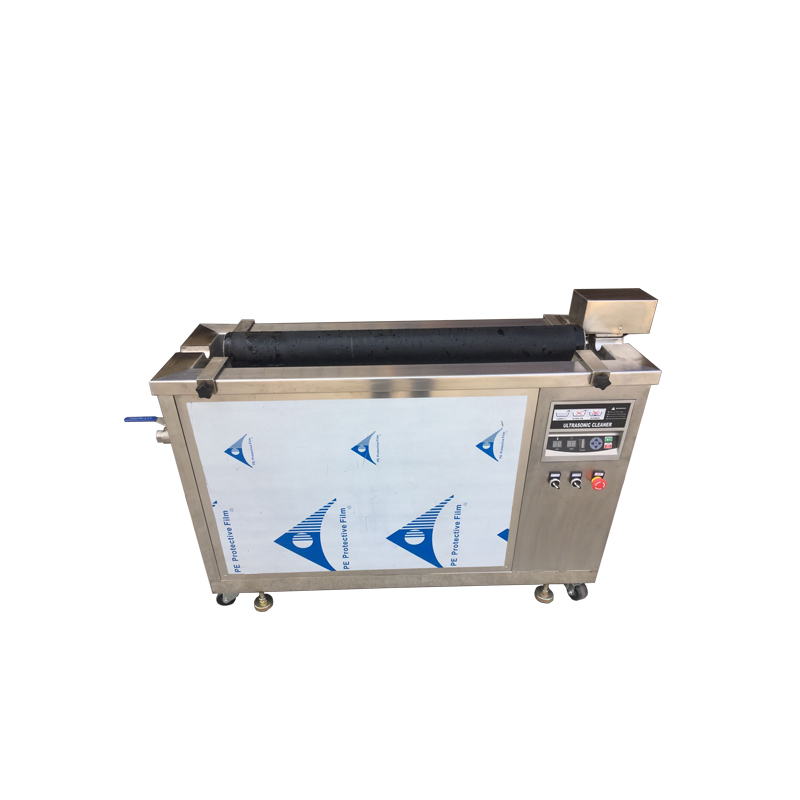

Flexographic Printing Anilox Roller Ultrasonic Cleaning Machine And Ultrasonic Generator

In industrial production, anilox roller is a common type of roller, widely used in fields such as printing, papermaking, and leather making. However, as the usage time increases, various impurities and dirt will accumulate on the surface of the anilox roller, affecting its normal operation and product quality. To sol…

Flexographic Printing Anilox Roller Ultrasonic Cleaning Machine And Ultrasonic Generator

In industrial production, anilox roller is a common type of roller, widely used in fields such as printing, papermaking, and leather making. However, as the usage time increases, various impurities and dirt will accumulate on the surface of the anilox roller, affecting its normal operation and product quality. To solve this problem, we can use an ultrasonic cleaning machine for the anilox roller to clean the surface of the anilox roller.

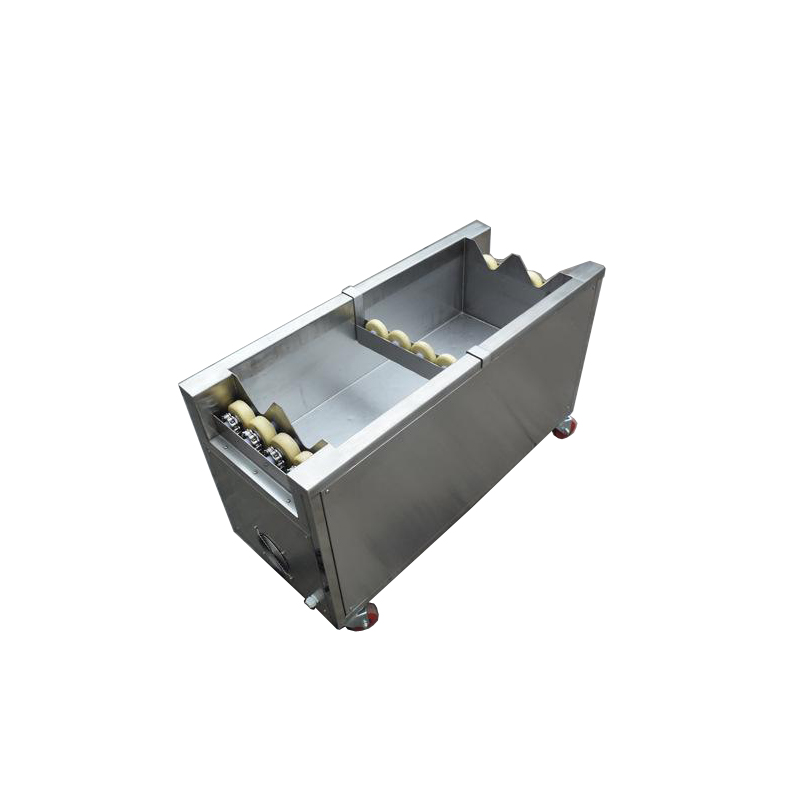

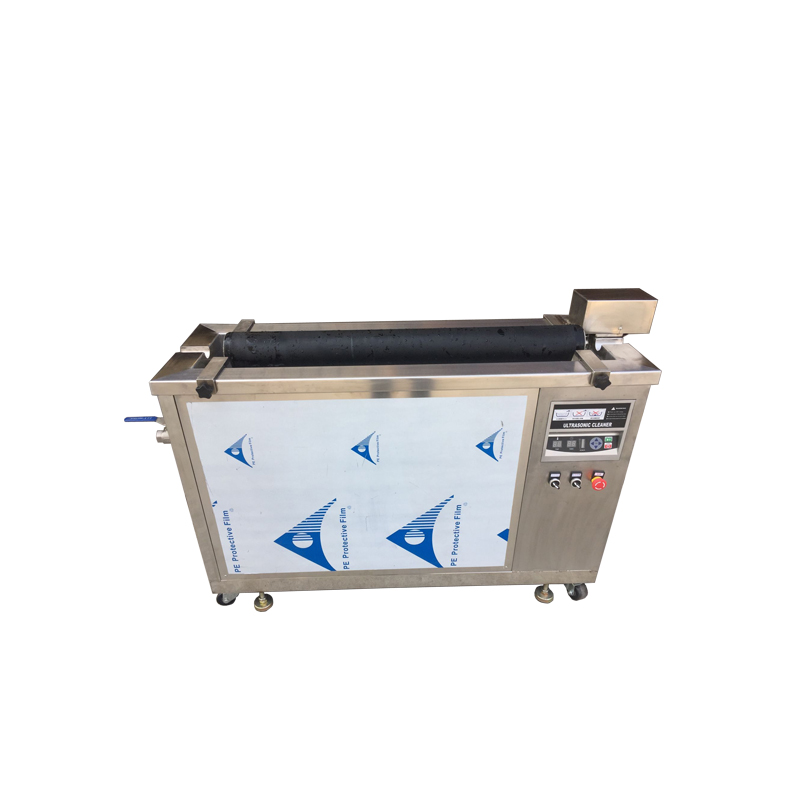

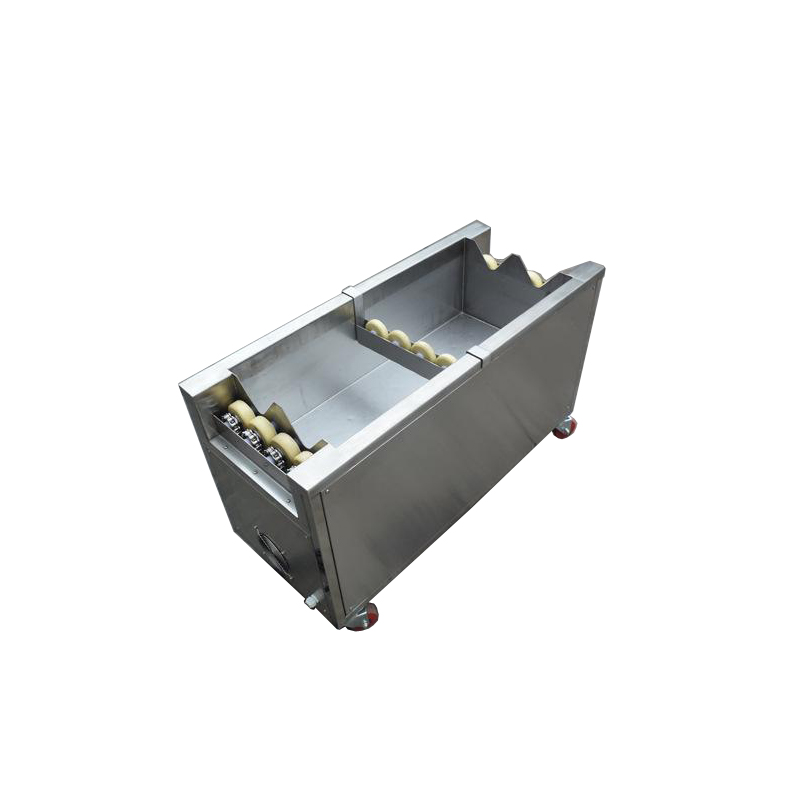

The anilox roller ultrasonic cleaning machine is an advanced cleaning equipment that utilizes the vibration and cavitation effects of ultrasound to thoroughly clean the dirt and impurities attached to the surface of the anilox roller. Compared with traditional cleaning methods, ultrasonic cleaning has a higher net cleaning effect, higher roll cleaning efficiency, and higher sound and wave cleaning efficiency, resulting in a clearer and cleaner sound effect for the color washing machine. Composed of generator, transducer, cleaning tank, and anilox roller. Firstly, place the anilox roller into the cleaning tank, and then turn on the ultrasonic generator to convert electrical energy into mechanical energy through a transducer, driving the liquid in the cleaning tank to generate high-frequency vibration. During the vibration process, the liquid generates friction with the surface of the anilox roller, peeling off the dirt and impurities attached to the surface. At the same time, bubbles in the liquid produce cavitation when the surface of the anilox roller ruptures, further enhancing the cleaning effect. The ultrasonic cleaning machine has high cleaning efficiency and can complete the cleaning of the anilox roller in a short time. In addition, due to the cavitation effect of ultrasound, it can penetrate into the fine parts of the surface of the anilox roller, effectively cleaning the surface and impurities of the anilox roller after ultrasonic wave cleaning method. Cleanliness not only improves the quality of the product, but also helps to extend the service life of the anilox roller.

Flexographic Printing Anilox Roller Ultrasonic Cleaning Machine And Ultrasonic Generator

标签:Anilox Roller Ultrasonic Cleaning Machine, Ultrasonic Cleaning Machine And Ultrasonic Generator

Send Inquiry

Anilox Roller Washing Machine Water Wash or Chemical Wash Ultrasonic Cleaning Machine Flexo Printing Line

Anilox Roller Washing Machine Water Wash or Chemical Wash Ultrasonic Cleaning Machine Flexo Printing Line 3KW Ultrasonic Anilox Roller Cleaning Machine With Heater SUS304 Tank And Generator Control Box

3KW Ultrasonic Anilox Roller Cleaning Machine With Heater SUS304 Tank And Generator Control Box Customized Tank Built-in Motor Rotate Automatically Industrial Anilox Rolerl Ultrasonic Cleaning Machine

Customized Tank Built-in Motor Rotate Automatically Industrial Anilox Rolerl Ultrasonic Cleaning Machine Rotation Clean Ink Glue Oil Anilox Roller Industrial Ultrasonic Cleaning Machine Ultrasonic Cleaner

Rotation Clean Ink Glue Oil Anilox Roller Industrial Ultrasonic Cleaning Machine Ultrasonic Cleaner Anilox Rolls and Sleeves Flexo Printing Ultrasonic Cleaner And Ultrasonic Generator

Anilox Rolls and Sleeves Flexo Printing Ultrasonic Cleaner And Ultrasonic Generator Printing Ultrasonic Anilox Roller Cleaning Machine And Digital Ultrasonic Generator

Printing Ultrasonic Anilox Roller Cleaning Machine And Digital Ultrasonic Generator Printing Rollers And Anilox Ultrasonic Cleaning Nachine And Digital Ultrasonic Generator

Printing Rollers And Anilox Ultrasonic Cleaning Nachine And Digital Ultrasonic Generator Automatic Ultrasonic Printing Cylinder Cleaner Anilox Roll Ultrasonic Cleaning Machine For Dirty Anilox Cleaner

Automatic Ultrasonic Printing Cylinder Cleaner Anilox Roll Ultrasonic Cleaning Machine For Dirty Anilox Cleaner Ceramic Roller Anilox Roller Ultrasonic Cleaning Machine Printer Head Ultrasonic Washing System

Ceramic Roller Anilox Roller Ultrasonic Cleaning Machine Printer Head Ultrasonic Washing System 1500W 40KHZ Anilox Roller Ultrasonic Washing Cleaning Machine With Transducer Generator

1500W 40KHZ Anilox Roller Ultrasonic Washing Cleaning Machine With Transducer Generator Coating Anilox Roller Ultrasonic Cleaning Machine With Ultrasonic Cleaner Generator

Coating Anilox Roller Ultrasonic Cleaning Machine With Ultrasonic Cleaner Generator 2000W 40KHZ Anilox Roll Ultrasonic Cleaning Equipment And Generator Control Box

2000W 40KHZ Anilox Roll Ultrasonic Cleaning Equipment And Generator Control Box