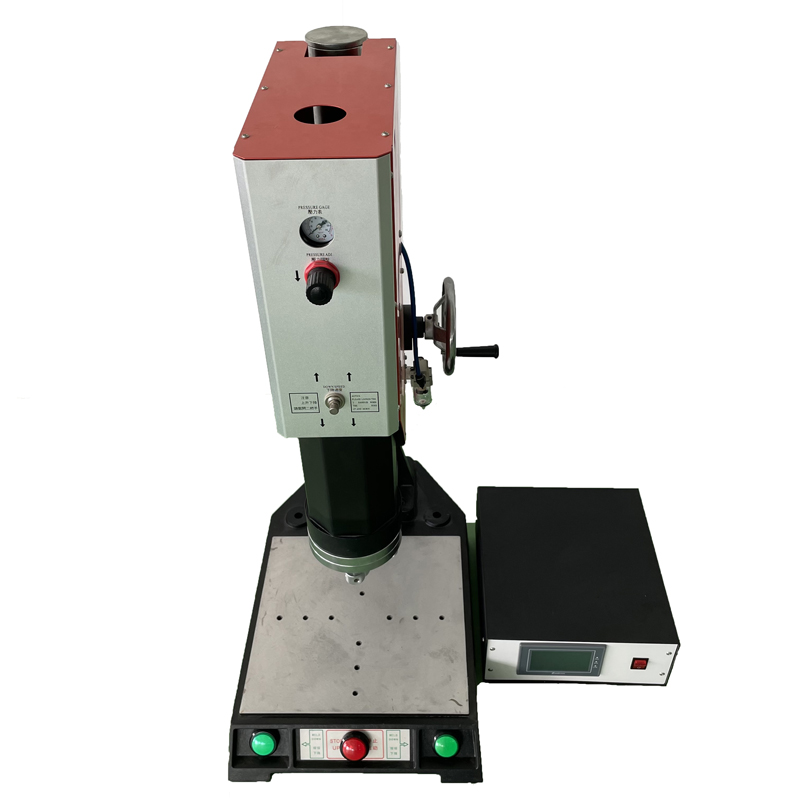

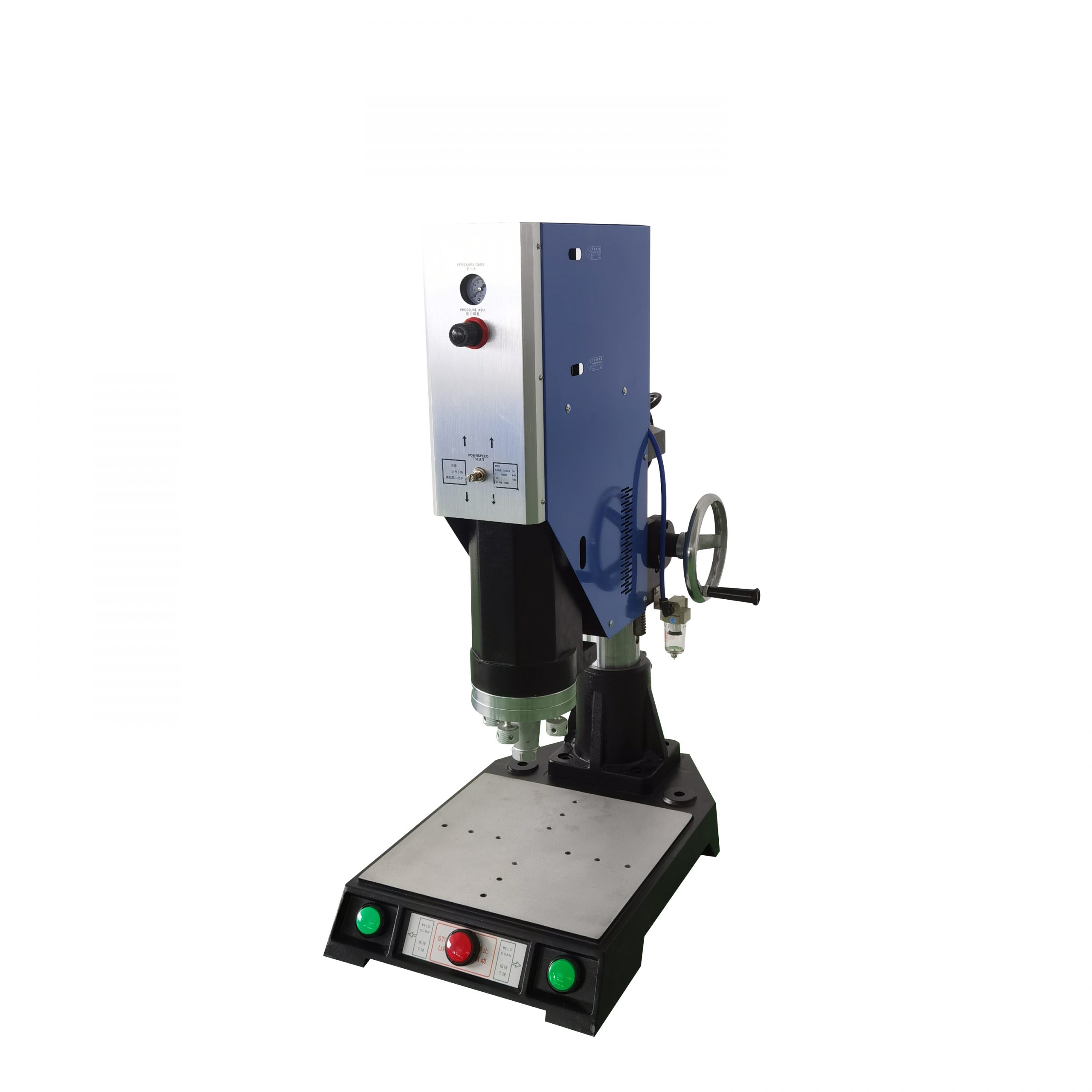

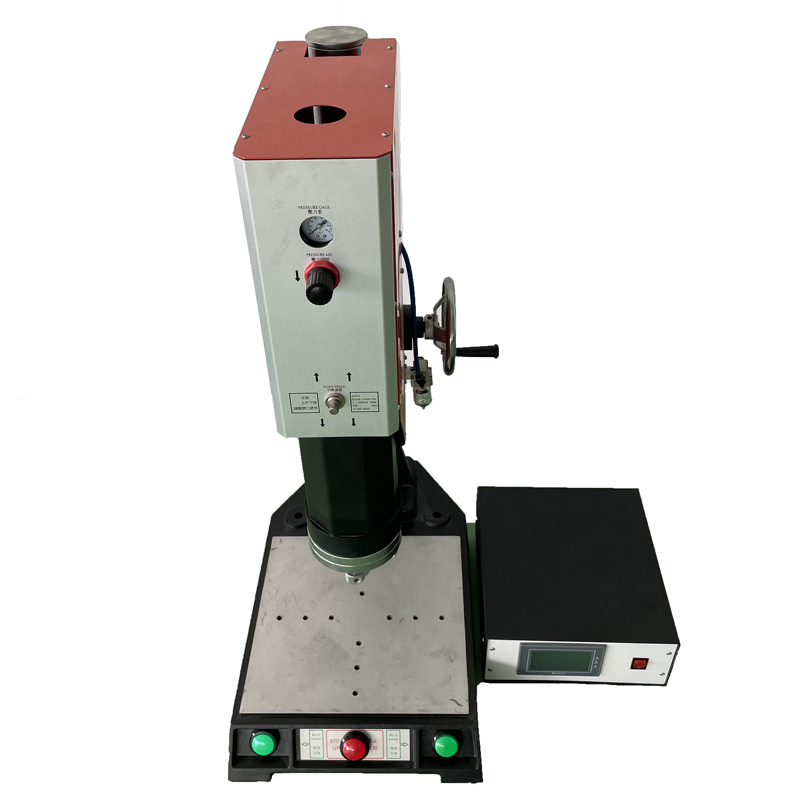

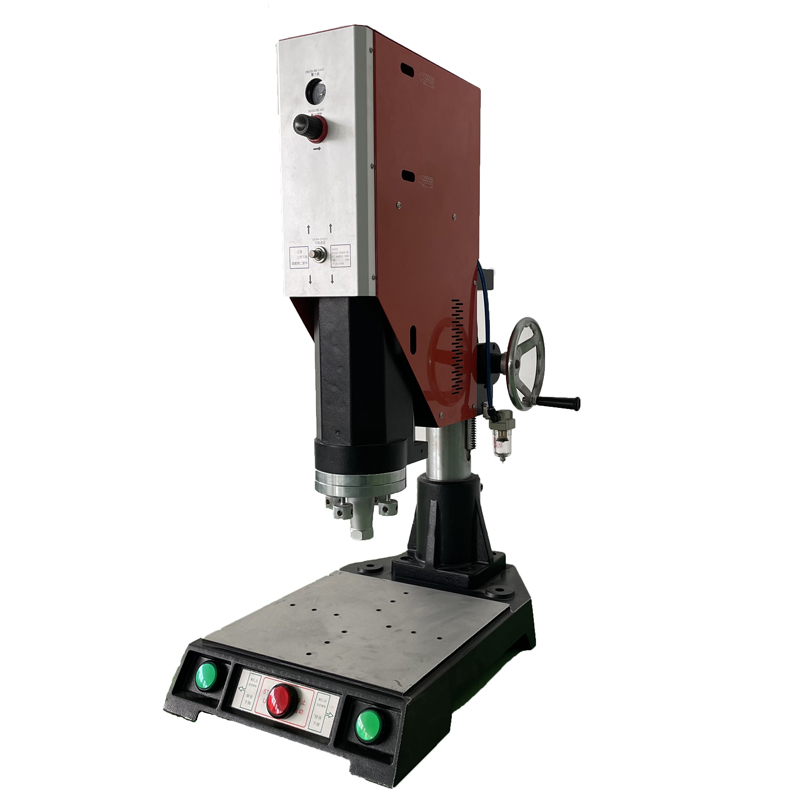

800W Acrylic Plastic Ultrasonic Plastic Welding Machine Spot Welder Sealing Machine

The working principle of an ultrasonic plastic welding machine is that when the welding head rubs against the surface of the workpiece, heat is generated, causing the fusion surface to melt and adhere, firmly connecting metal or non-metallic materials together. Due to its characteristics of good directionality and…

800W Acrylic Plastic Ultrasonic Plastic Welding Machine Spot Welder Sealing Machine

The working principle of an ultrasonic plastic welding machine is that when the welding head rubs against the surface of the workpiece, heat is generated, causing the fusion surface to melt and adhere, firmly connecting metal or non-metallic materials together.

Due to its characteristics of good directionality and strong penetration, ultrasound can be applied to the processing of various materials; Moreover, due to its inherent characteristics such as fast speed, high efficiency, and ease of automation, its application fields are becoming increasingly widespread.

There are currently three common types of ultrasonic plastic welding machines in the market:

- Screw type ultrasonic plastic welding machine:

The main feature of the screw type ultrasonic plastic welding machine is to use a screw transmission mechanism to drive the pressure device to generate pressure and drive the transducer to generate high-frequency vibration waves, which are transmitted to the welded material to complete the welding process; It has a simple and compact structure, convenient and flexible operation, and high production efficiency.

- Both drum and rotary ultrasonic plastic welding machines use gear transmission to drive the pressure device to generate pressure and drive the transducer to generate high-frequency vibration waves, which are transmitted to the welded material to complete the stitching process.

- Compared with the drum type, the rotary type has a wider applicability (suitable for materials of different thicknesses and shapes) and better efficiency (saving more than 30% compared to the former under the same power).

| Type | Power(W) | Frequency (KHz) |

| PU-UWM600W | 600W | 15KHZ/20KHZ/28KHZ/40KHZ |

| PU-UWM900W | 900W | 15KHZ/20KHZ/28KHZ/40KHZ |

| PU-UWM1000W | 1000W | 15KHZ/20KHZ/28KHZ/30KHZ |

| PU-UWM1500W | 1500W | 15KHZ/20KHZ |

| PU-UWM1800W | 1800W | 15KHZ/20KHZ |

| PU-UWM2000W | 2000W | 15KHZ/20KHZ |

| PU-UWM2600W | 2600W | 15KHZ |

| PU-UWM3200W | 3200W | 15KHZ |

| PU-UWM4200W | 4200W | 15KHZ |

800W Acrylic Plastic Ultrasonic Plastic Welding Machine Spot Welder Sealing Machine

标签:Acrylic Plastic Ultrasonic Plastic Welding Machine, Ultrasonic Plastic Welding Machine Spot Welder Sealing Machine

Send Inquiry

15KHZ 4200W Ultrasonic Welder Plastic Welding Machine for Rear Bumper Reflector Auto Car Part

15KHZ 4200W Ultrasonic Welder Plastic Welding Machine for Rear Bumper Reflector Auto Car Part ABS PP Ultrasonic High Frequency Plastic Welder Plastic Welding Machine For PSA Grading Card Plastic Slabs Case Sealing

ABS PP Ultrasonic High Frequency Plastic Welder Plastic Welding Machine For PSA Grading Card Plastic Slabs Case Sealing 20Khz 2000W High Power Ultrasonic Welding Machine For Nonwoven Fabric Plastic ABS Polyethylene Sealer

20Khz 2000W High Power Ultrasonic Welding Machine For Nonwoven Fabric Plastic ABS Polyethylene Sealer PSA Graded Slab Sport Card Welders Adjustable Amplitude Ultrasonic Welding Machine for PSA Grading Slab

PSA Graded Slab Sport Card Welders Adjustable Amplitude Ultrasonic Welding Machine for PSA Grading Slab PSA Grading Card Plastic Slabs Case Sealing 15khz/28khz/35khz Ultrasonic Welding Machine Ultrasonic Card Welding Machine

PSA Grading Card Plastic Slabs Case Sealing 15khz/28khz/35khz Ultrasonic Welding Machine Ultrasonic Card Welding Machine Grading Card Coin Psa Slabs Ultrasonic Welding Machine Graded Card Slab

Grading Card Coin Psa Slabs Ultrasonic Welding Machine Graded Card Slab Automatic Frequency Tracking 15K 2600W Ultrasonic Welding Machine for Plastic PSA Slabs Case ABS PP Welding Machine

Automatic Frequency Tracking 15K 2600W Ultrasonic Welding Machine for Plastic PSA Slabs Case ABS PP Welding Machine Ultrasonic Welder Plastic 15Khz Welding Machine For Thermoplastic Material Plastic Collecting Eggs Belt Manure Belt/Farm Conveyor

Ultrasonic Welder Plastic 15Khz Welding Machine For Thermoplastic Material Plastic Collecting Eggs Belt Manure Belt/Farm Conveyor Auto Digital Tracking 15Khz 20Khz Ultrasonic Welding Machine For Welding Small Car Light Automobile Application

Auto Digital Tracking 15Khz 20Khz Ultrasonic Welding Machine For Welding Small Car Light Automobile Application 15khz 2600w Ultrasonic Plastic Welding Machine For Ps Plastic Cards Cases Grading Playing Cards Hard Ultrasonic Welder

15khz 2600w Ultrasonic Plastic Welding Machine For Ps Plastic Cards Cases Grading Playing Cards Hard Ultrasonic Welder 35khz Semi Automatic Manual Nonwoven Flat Mask Ear Loop Ultrasonic Spot Welder Ultrasonic Spot Welding Machine

35khz Semi Automatic Manual Nonwoven Flat Mask Ear Loop Ultrasonic Spot Welder Ultrasonic Spot Welding Machine 4200W Nylon Acrylic Plastic Welding Melt Machine Spot Welder Sealing Machine Ultrasonic Plastic Welding Machine

4200W Nylon Acrylic Plastic Welding Melt Machine Spot Welder Sealing Machine Ultrasonic Plastic Welding Machine