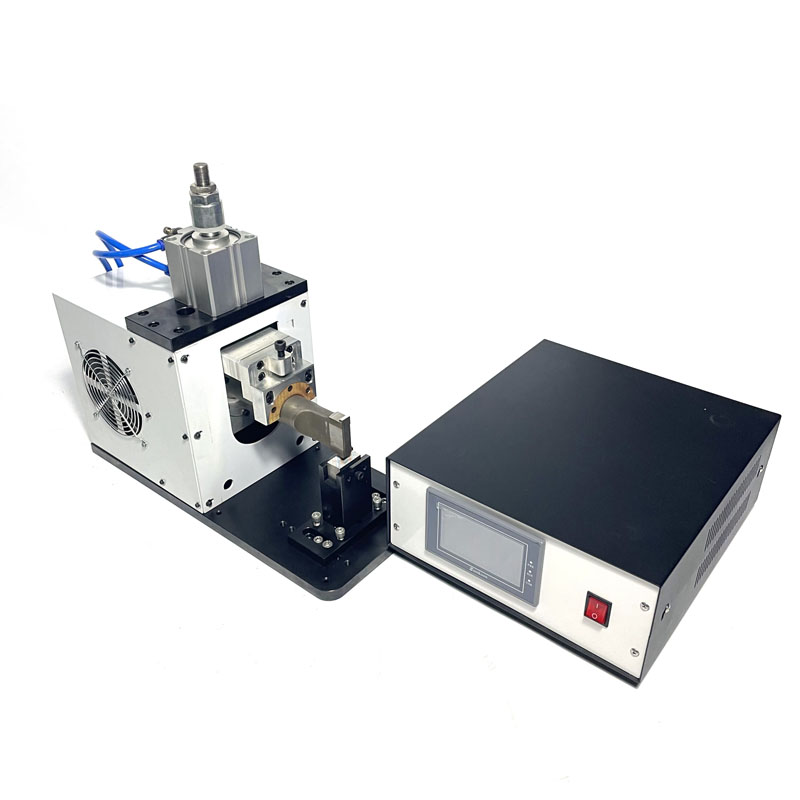

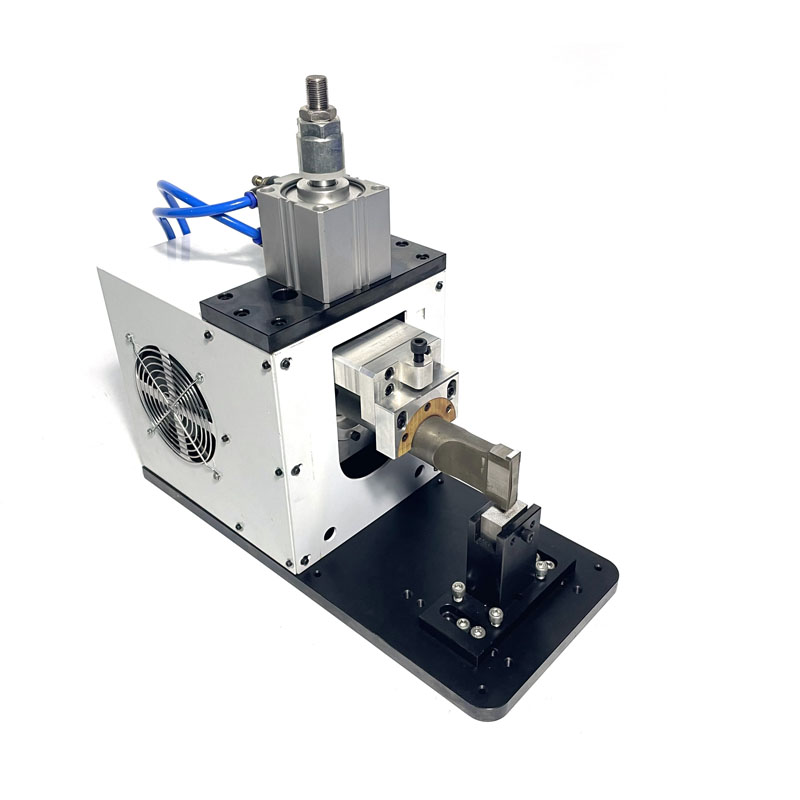

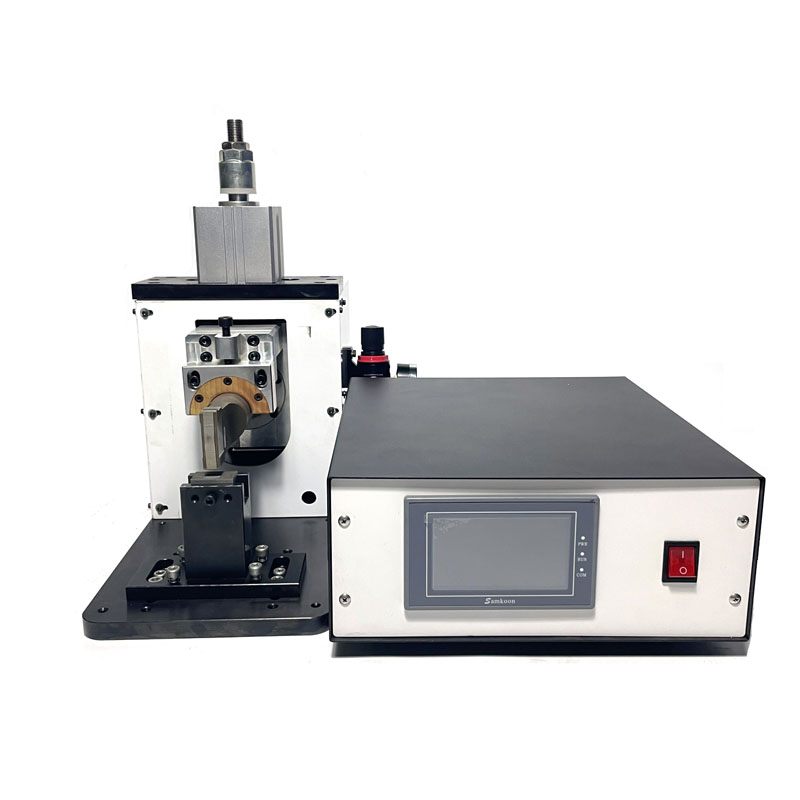

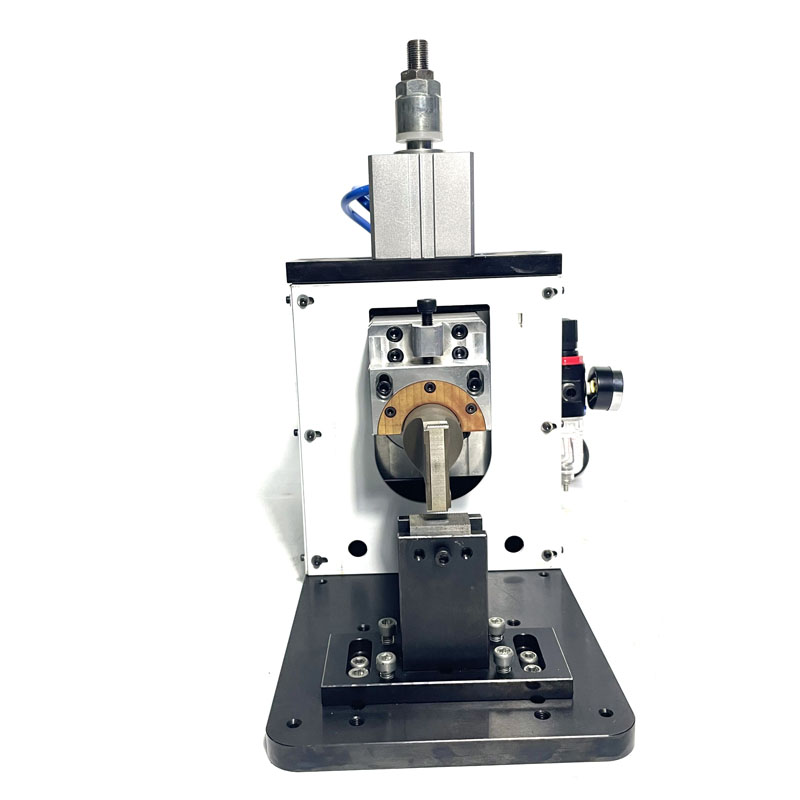

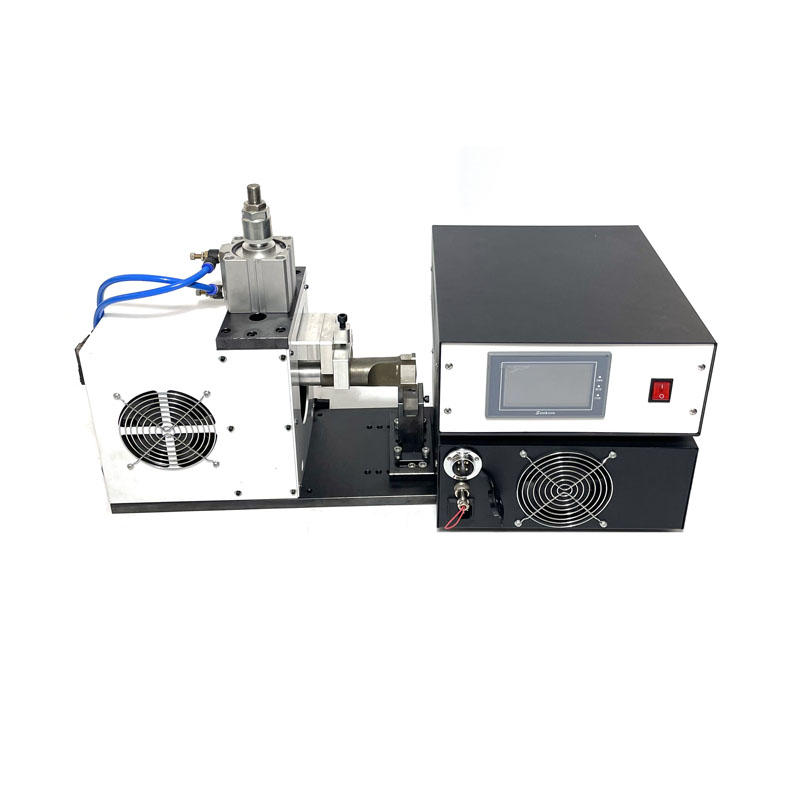

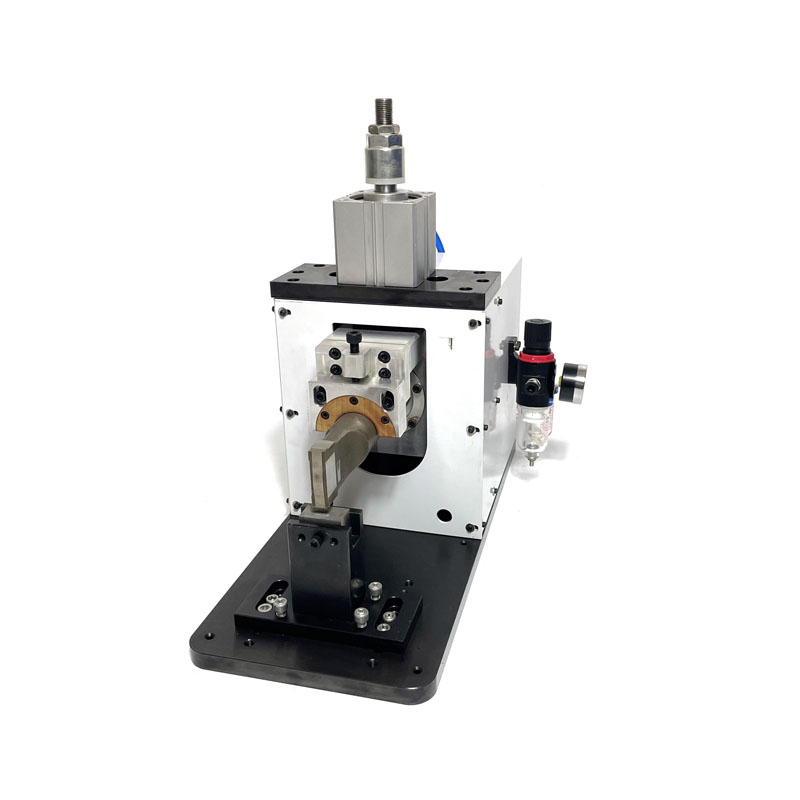

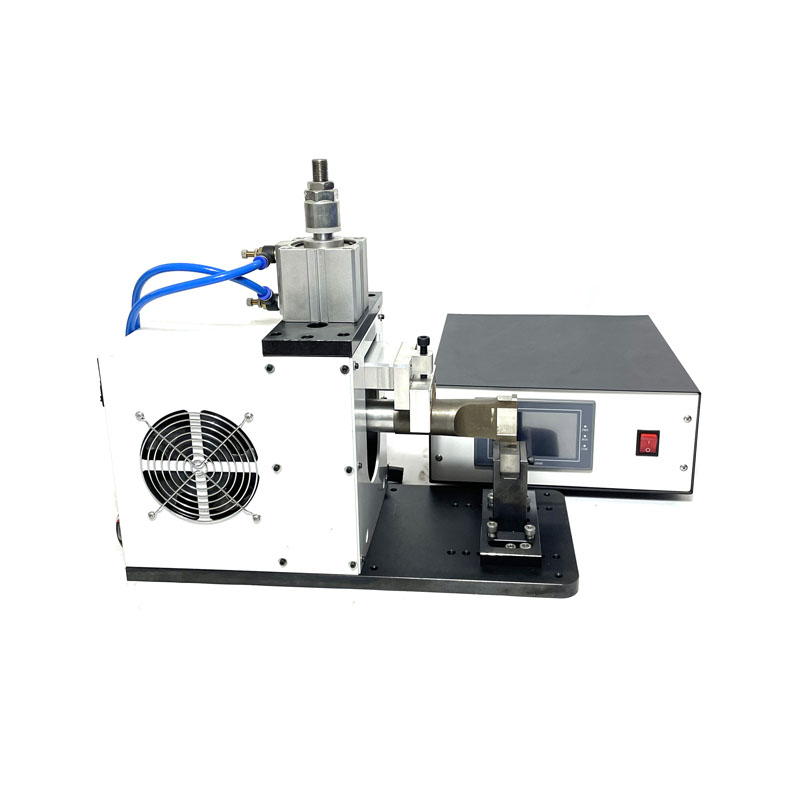

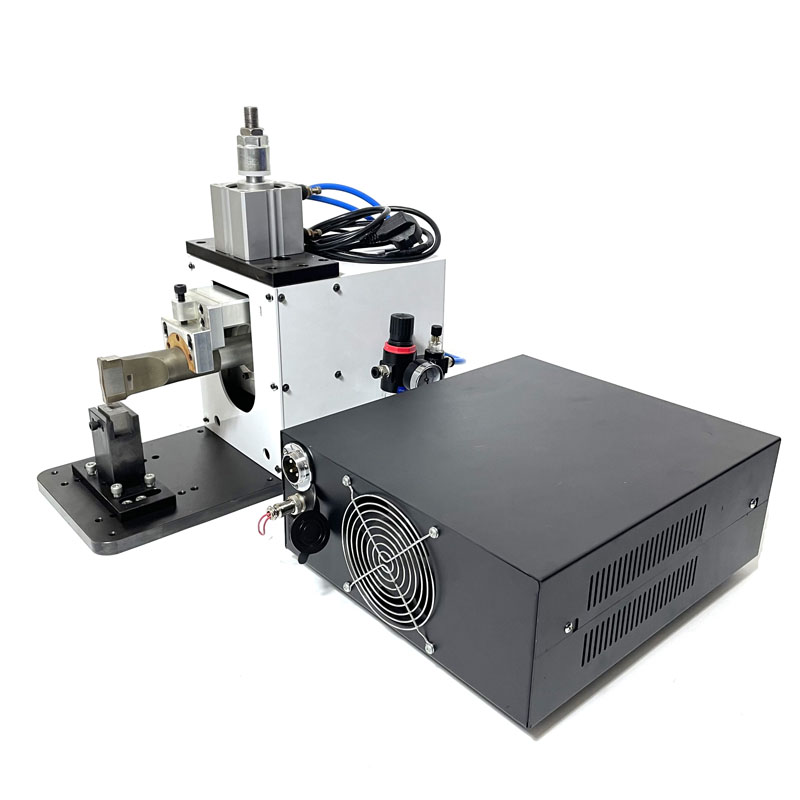

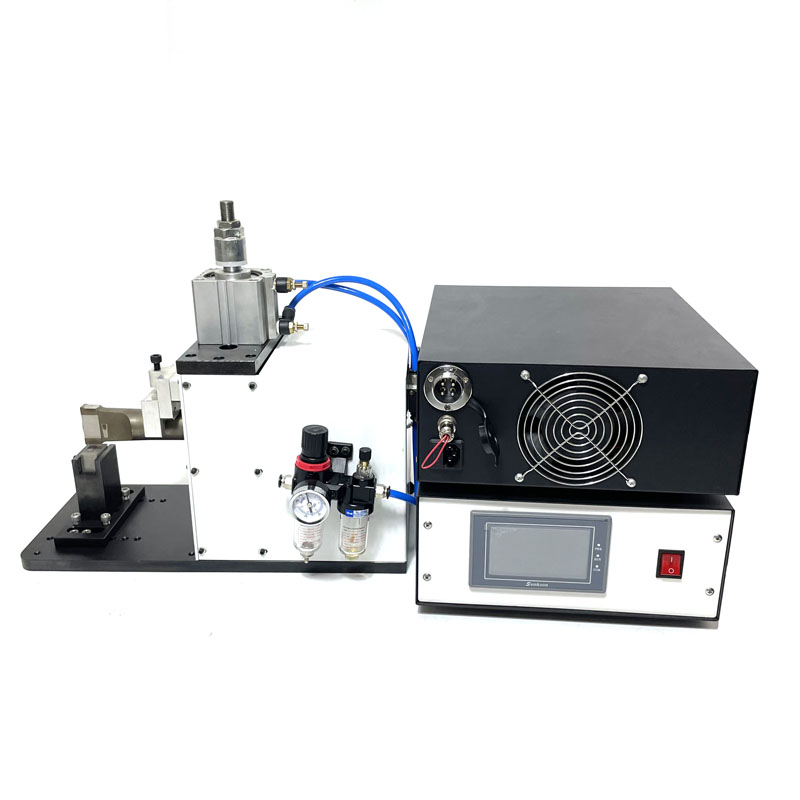

800W-4000W Lithium Battery Cap Pneumatic Ultrasonic Metal Spot Welder Welding Machine for Pouch Cell Electrode Tab/Foil

The working principle of the wire harness machine is that the ultrasonic metal wire harness welding machine uses a transducer to transmit vibration waves to the surfaces of two metal wire harnesses or metal parts to be welded. Under pressure, the surfaces of the two metal wire harnesses rub against each other to form…

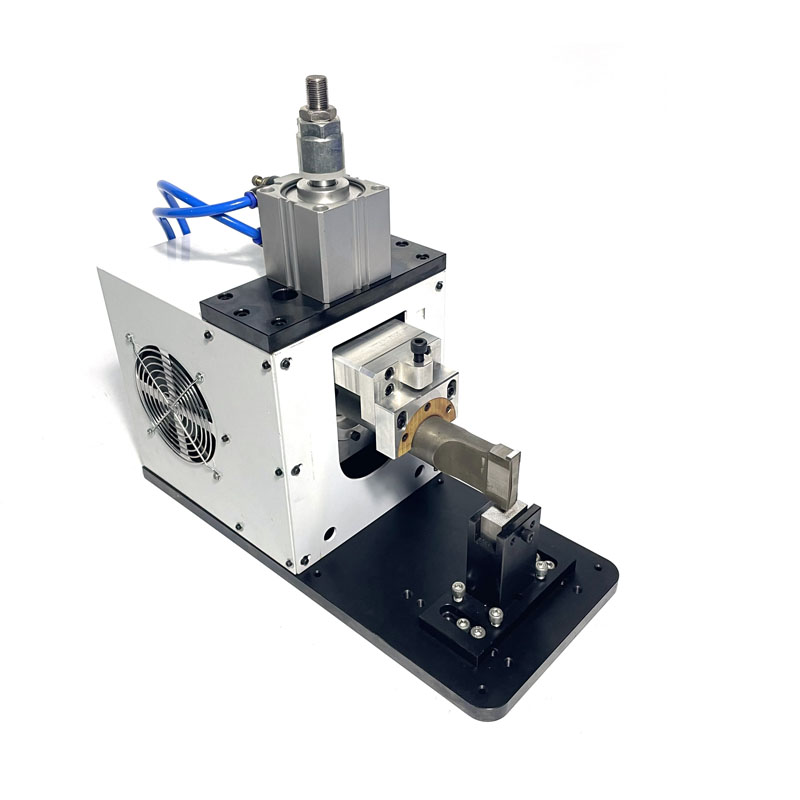

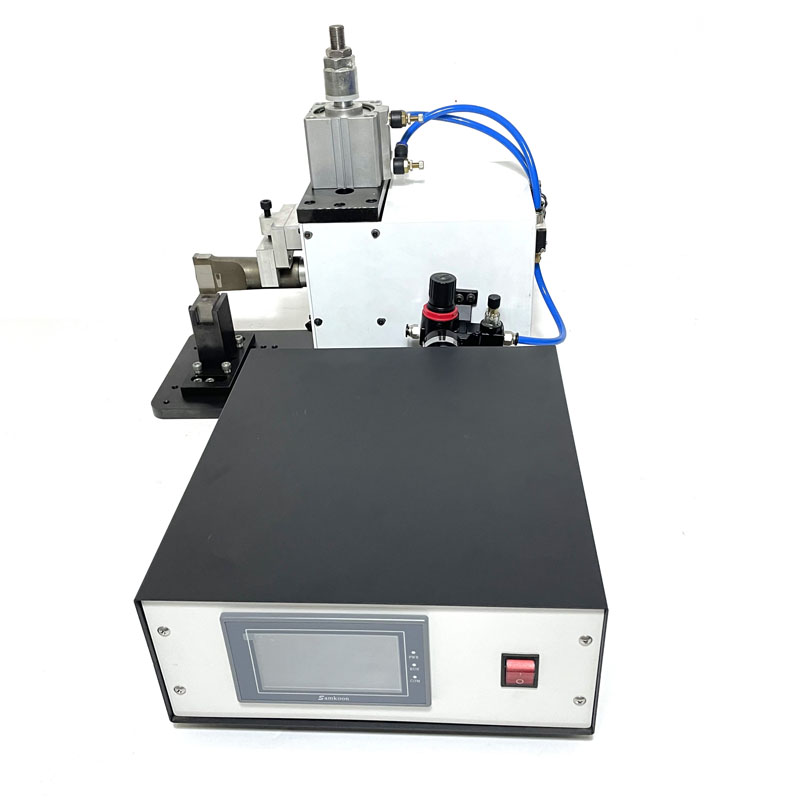

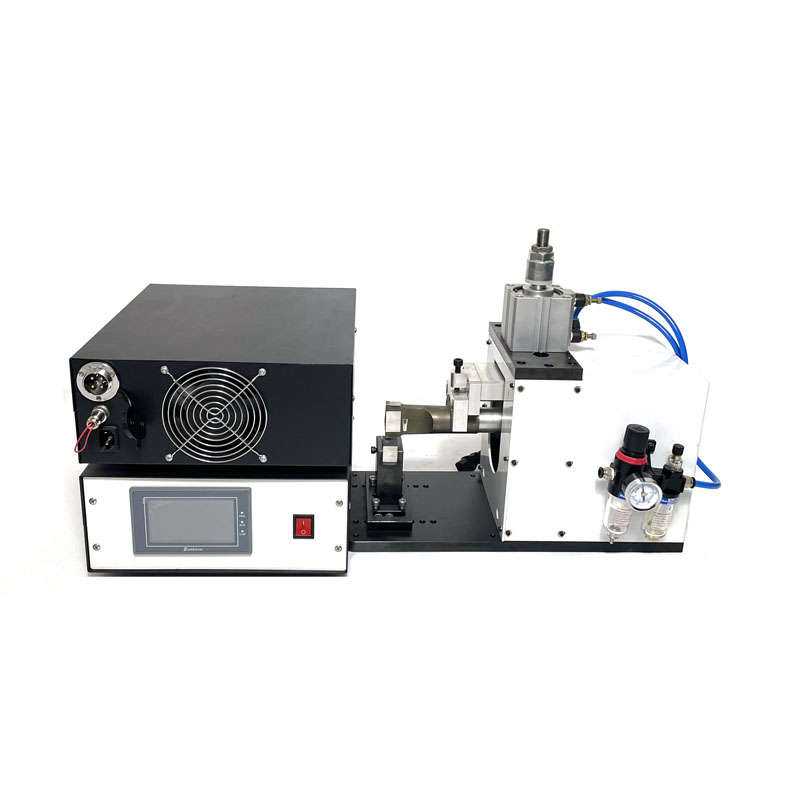

The working principle of the wire harness machine is that the ultrasonic metal wire harness welding machine uses a transducer to transmit vibration waves to the surfaces of two metal wire harnesses or metal parts to be welded. Under pressure, the surfaces of the two metal wire harnesses rub against each other to form fusion between molecular layers. Mainly used for the welding of copper and aluminum wires such as automotive wire harnesses and motorcycle wire harnesses, it is often called an automotive wire harness welding machine.

Characteristics of wire harness machine equipment

- Original imported piezoelectric ceramic transducer with high output power;

- Digital display makes it easier to adjust the welding of metal wire harnesses;

- The wire harness welding machine is controlled using a human-machine interface and stores multiple parameters;

- The whole machine has small size, light weight, beautiful appearance, and convenient movement;

- The wire harness welding machine adjusts the amplitude steplessly, eliminating the need for frequent replacement of the amplifier.

Application field of wire harness machine

Ultrasonic metal wire harness welding machine (automobile wire harness welding machine) is a specialized equipment for multi-strand wire crimping welding. It can reliably and conveniently weld multi-strand wire sections of 0.5-30MM each. It is widely used in the production of automotive wire harnesses, relays, electrical connectors, and other electronic, electrical, lithium battery electrodes, dielectric capacitors, transistors, electrical wiring terminals, thermocouples, thyristor components, refrigerators, and other products. Commonly used in industries such as automobiles, electronics, electrical appliances, batteries, and motors

| Type | Power(W) | Frequency (KHz) |

| PU-MSW2000W | 2000W | 20KHZ |

| PU-MSW2600W | 2600W | 20KHZ |

| PU-MSW3200W | 3200W | 20KHZ |

| PU-MSW4000W | 4000W | 20KHZ |

| PU-MSW800W | 800W | 40khz |

标签:Lithium Battery Cap Pneumatic Ultrasonic Metal Spot Welder Welding Machine, Ultrasonic Metal Spot Welder Welding Machine For Pouch Cell Electrode Tab/Foil, ultrasonic metal wire harness welding machine

Send Inquiry

Copper And Aluminum Sheet Welding Wire Harness Terminal Welding Equipment Ultrasonic Metal Welding Machine

Copper And Aluminum Sheet Welding Wire Harness Terminal Welding Equipment Ultrasonic Metal Welding Machine Pneumatic Ultrasonic Metal Spot Welder Welding Machine Ultrasonic Wire Harness Welding Machine

Pneumatic Ultrasonic Metal Spot Welder Welding Machine Ultrasonic Wire Harness Welding Machine Lab 2000W 20KHZ Ultrasonic Metal Spot Welder Welding Machine for Pouch Cell Battery Research

Lab 2000W 20KHZ Ultrasonic Metal Spot Welder Welding Machine for Pouch Cell Battery Research 800W-4000W Lithium Battery Cap Pneumatic Ultrasonic Metal Spot Welder Welding Machine for Pouch Cell Electrode Tab/Foil

800W-4000W Lithium Battery Cap Pneumatic Ultrasonic Metal Spot Welder Welding Machine for Pouch Cell Electrode Tab/Foil 0.5-20 mm Copper Aluminum Braided Wire haness Ultrasonic Metal Welding Machine Welder And Generator Control Box

0.5-20 mm Copper Aluminum Braided Wire haness Ultrasonic Metal Welding Machine Welder And Generator Control Box 0.35-12mm Ultrasonic Multi Core Conduct Automotive Car Copper Aluminum Wire Cable Splicing Welding Crimp Machine

0.35-12mm Ultrasonic Multi Core Conduct Automotive Car Copper Aluminum Wire Cable Splicing Welding Crimp Machine 3000W 20KHZ Ultrasonic Wire Splicing Machine Solder Wire Machine Copper Wire Spot Welding Machine

3000W 20KHZ Ultrasonic Wire Splicing Machine Solder Wire Machine Copper Wire Spot Welding Machine 2600W Laboratory Ultrasonic Metal Spot Welder For Battery Pack Electrode Tab Welding Machine

2600W Laboratory Ultrasonic Metal Spot Welder For Battery Pack Electrode Tab Welding Machine Ultrasonic Metal Welder Battery Spot Welding Machines Ultrasonic Metal Spot Welder Machine For Welding Lithium Battery

Ultrasonic Metal Welder Battery Spot Welding Machines Ultrasonic Metal Spot Welder Machine For Welding Lithium Battery Ultrasonic Copper Aluminum Metal Wire Harness Terminal Welding Machine for New Energy Wiring Harness Equipment

Ultrasonic Copper Aluminum Metal Wire Harness Terminal Welding Machine for New Energy Wiring Harness Equipment Ultrasonic Copper Aluminum Metal Wire Harness Spot Welding Machine For Wire Harness Solar Splicing Welding Machine

Ultrasonic Copper Aluminum Metal Wire Harness Spot Welding Machine For Wire Harness Solar Splicing Welding Machine Ultrasonic Metal Wire Welding Machine Copper Wire Aluminum Wire Ultrasonic Welder Machine With Transducer Generator

Ultrasonic Metal Wire Welding Machine Copper Wire Aluminum Wire Ultrasonic Welder Machine With Transducer Generator