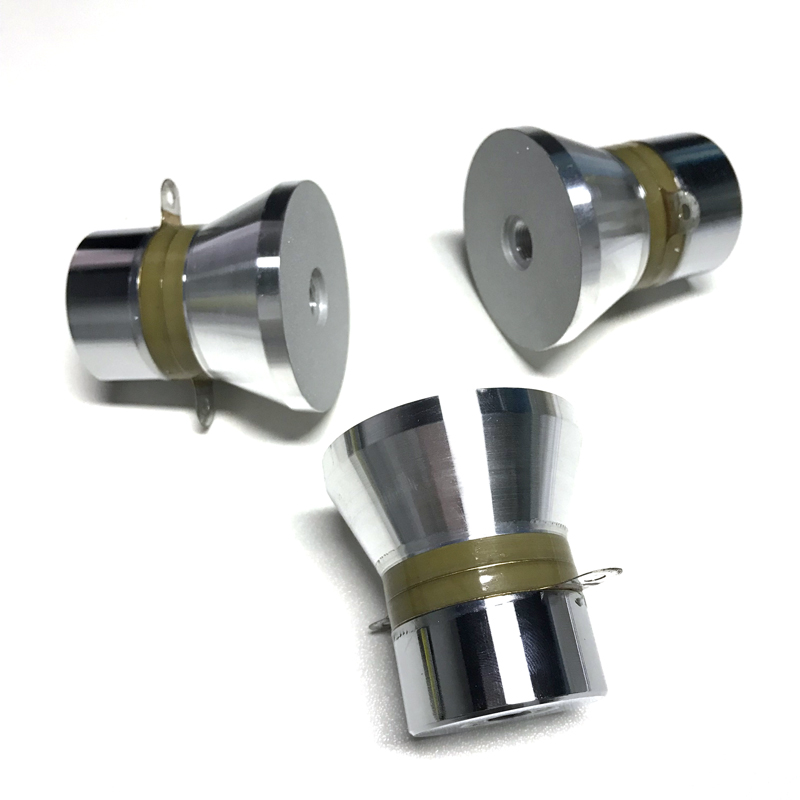

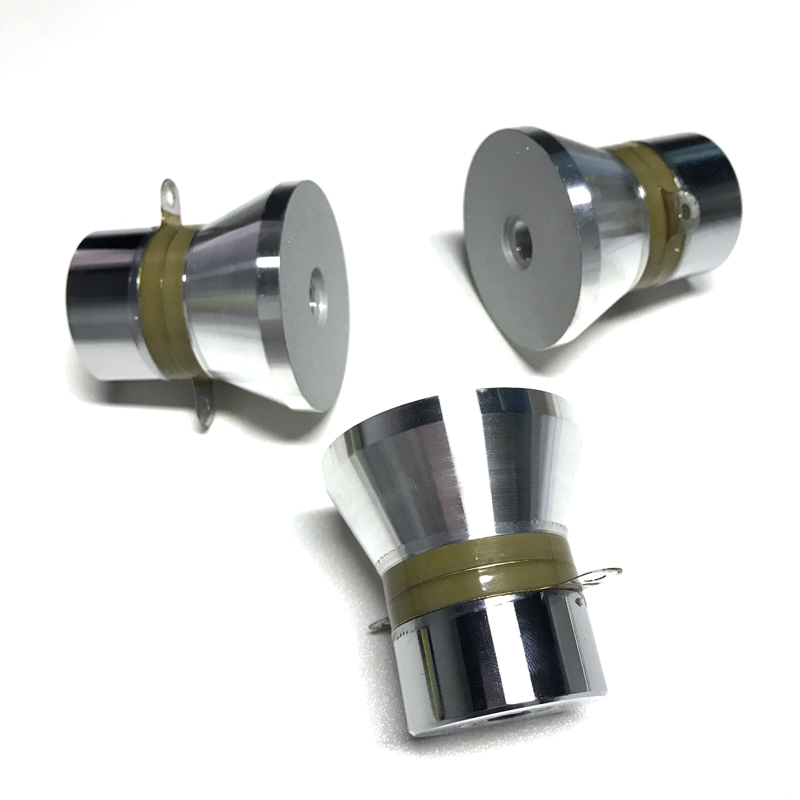

60W Ultrasonic Transducer 40Khz Two Frequency For Car Engine/Block/Plastic Parts Ultrasound Cleaner Machine

Ultrasonic vibrator, also known as ultrasonic vibrator, refers to the overall structure of the transducer connected to the amplitude converter in the industry. The ultrasonic vibrator uses the Piezoelectricity of piezoelectric ceramics to realize the mutual conversion of electrical energy and mechanical energy (ac…

Ultrasonic vibrator, also known as ultrasonic vibrator, refers to the overall structure of the transducer connected to the amplitude converter in the industry.

The ultrasonic vibrator uses the Piezoelectricity of piezoelectric ceramics to realize the mutual conversion of electrical energy and mechanical energy (acoustic vibration), and uses the front and rear radiation cover blocks matched with acoustic impedance to amplify the device. The frequency is fixed during production. You can customize transducers with different frequencies according to customer needs. The produced transducer vibrator can only be fixed at this frequency. In fact, the ultrasonic cavitation threshold is closely related to frequency. The higher the frequency, the higher the cavitation threshold. The lower the frequency, the lower the cavitation threshold, and the easier it is to generate cavitation.

At low frequencies, the time interval between compression and sparsity of liquids is longer. Enabling bubbles to grow to a larger size, enhancing cavitation strength, and facilitating cleaning effects. So low-frequency ultrasonic cleaning is generally used on the surface of large components or when the adhesion between dirt and workpiece surface is high. But it is easy to damage and corrode the surface of the workpiece. Therefore, parts with high surface requirements for the workpiece are not suitable for selecting lower frequencies. Moreover, the frequency is low and the generated noise is correspondingly high. High frequency ultrasound has strong penetration power, and it is recommended to clean components with high surface smoothness requirements or complex surfaces with many blind holes.

On the one hand, the noise of high-frequency ultrasound is also relatively low, making it suitable for cleaning some precision parts, such as electronic parts, small bearing processing, magnetic materials, etc. For some special workpieces such as integrated circuit chips and silicon wafers, it is advisable to choose higher frequency ultrasound for cleaning. For some large workpieces such as car engines, valves, etc., low-frequency ultrasound should be chosen for cleaning.

On the other hand, considering the effectiveness and economy of ultrasonic cleaning, the frequency is generally selected between 20~130KHz. The specific frequency selection should be determined through corresponding experiments. In summary, the frequency of the ultrasonic oscillator is fixed, so during production, there will be continuous testing procedures to determine whether the frequency is qualified, and production will be strictly carried out according to requirements.

| Type | Length(mm) | Weight(g) | Frequency(KHz) | Resonance Impedance (Ω) | Static Capacity (pF)±10% | Input Power(W) |

| PU-UT-20100 PZT-8 | 94 | 900 | 20 | 10-20 | 5200 | 100 |

| PU-UT-25100 PZT-4 | 77 | 710 | 25 | 10-20 | 6600 | 100 |

| PU-UT-28120 PZT-4 | 66 | 720 | 28 | 10-20 | 7800 | 120 |

| PU-UT-28100 PZT-8 | 66 | 625 | 28 | 10-20 | 5200 | 100 |

| PU-UT-28100 PZT-4 | 66 | 624 | 28 | 10-20 | 6600 | 100 |

| PU-UT-30100 PZT-8 | 61 | 555 | 30 | 10-20 | 5200 | 100 |

| PU-UT-2560 PZT-4 | 77 | 530 | 25 | 10-20 | 5400 | 60 |

| PU-UT-2860 PZT-8 | 68 | 470 | 28 | 10-20 | 3800 | 60 |

| PU-UT-2850 PZT-4 | 82 | 425 | 28 | 10-20 | 4100 | 50 |

| PU-UT-3360 PZT-8 | 58 | 420 | 33 | 10-20 | 3800 | 60 |

| PU-UT-4060 PZT-8 | 55 | 300 | 40 | 10-20 | 3800 | 60 |

| PU-UT-4060 PZT-4 | 56 | 310 | 40 | 10-20 | 5400 | 60 |

| PU-UT-4050 PZT-4 | 54 | 260 | 40 | 10-20 | 4100 | 50 |

| PU-UT-4050-1 PZT-4 | 57 | 300 | 40 | 10-20 | 4100 | 50 |

| PU-UT-5435 PZT-4 | 36 | 135 | 54 | 10-20 | 3200 | 35 |

| PU-UT-6860 PZT-8 | 80 | 460 | 68 | 10-20 | 3800 | 60 |

| PU-UT-68120 PZT-4 | 67 | 588 | 68 | 10-20 | 7800 | 120 |

| PU-UT-8060 PZT-4 | 60 | 325 | 80 | 10-20 | 5400 | 60 |

| PU-UT-12060 PZT-4 | 56 | 260 | 120 | 10-20 | 5400 | 60 |

| PU-UT-13550 PZT-4 | 54 | 215 | 135 | 10-20 | 4200 | 50 |

Send Inquiry

Ultrasonic Cleaning Transducer 28khz 60W Transducer Piezoelectric Vibration Sensor For Ultrasonic Cleaning Bath

Ultrasonic Cleaning Transducer 28khz 60W Transducer Piezoelectric Vibration Sensor For Ultrasonic Cleaning Bath 33KHZ 60W Piezo High Power Ultrasonic Transducer Ultrasonic Cleaning Transducer For Ultrasonic Cleaners Equipment

33KHZ 60W Piezo High Power Ultrasonic Transducer Ultrasonic Cleaning Transducer For Ultrasonic Cleaners Equipment 25KHZ-40KHZ Industrial Piezoelectric Ultrasonic Transducer For Ultrasonic Cleaning Equipment

25KHZ-40KHZ Industrial Piezoelectric Ultrasonic Transducer For Ultrasonic Cleaning Equipment 25KHZ PZT-4 Ultrasonic Cavitation Cleaning Transducer Ultrasonic Transducer For Single Tank Ultrasonic Cleaner

25KHZ PZT-4 Ultrasonic Cavitation Cleaning Transducer Ultrasonic Transducer For Single Tank Ultrasonic Cleaner 40KHZ 60W Piezo Ceramic Ultrasonic Cleaning Transducer Piezo Transducers For Ultrasonic Cleaning Machine

40KHZ 60W Piezo Ceramic Ultrasonic Cleaning Transducer Piezo Transducers For Ultrasonic Cleaning Machine 33KHZ PZT-4 Ultrasonic Waves Cleaner Transducer Ultrasonic Transducer For Large Capacity Ultrasonic Cleaner

33KHZ PZT-4 Ultrasonic Waves Cleaner Transducer Ultrasonic Transducer For Large Capacity Ultrasonic Cleaner 60W Ultrasonic Cleaning Oscillator Ultrasonic Piezoelectric Ceramic Sensor Ultrasonic Cleaning Transducer

60W Ultrasonic Cleaning Oscillator Ultrasonic Piezoelectric Ceramic Sensor Ultrasonic Cleaning Transducer 40KHZ PZT-4 Ultrasonic Customized Power Transducer Ultrasonic Transducer For Large Digital Ultrasonic Cleaner

40KHZ PZT-4 Ultrasonic Customized Power Transducer Ultrasonic Transducer For Large Digital Ultrasonic Cleaner Industrial Ultrasonic Cleaning Transducer For Cleaner Machine 33Khz 60 Watt Ultrasonic Transducer

Industrial Ultrasonic Cleaning Transducer For Cleaner Machine 33Khz 60 Watt Ultrasonic Transducer 25KHZ 40KHZ Piezo Ultrasonic Cleaner Transducer For Ultrasonic Engine Cleaning Machine

25KHZ 40KHZ Piezo Ultrasonic Cleaner Transducer For Ultrasonic Engine Cleaning Machine 25KHZ 60W Ultrasonic Transducer Cleaner Ultrasonic Vibrator Ultrasonic Piezoelectric Transducer

25KHZ 60W Ultrasonic Transducer Cleaner Ultrasonic Vibrator Ultrasonic Piezoelectric Transducer Ultrasonic Industrial Vibrator Sensor Ultrasonic Cleaning Transducer For Ultrasonic Cleaning Equipment

Ultrasonic Industrial Vibrator Sensor Ultrasonic Cleaning Transducer For Ultrasonic Cleaning Equipment