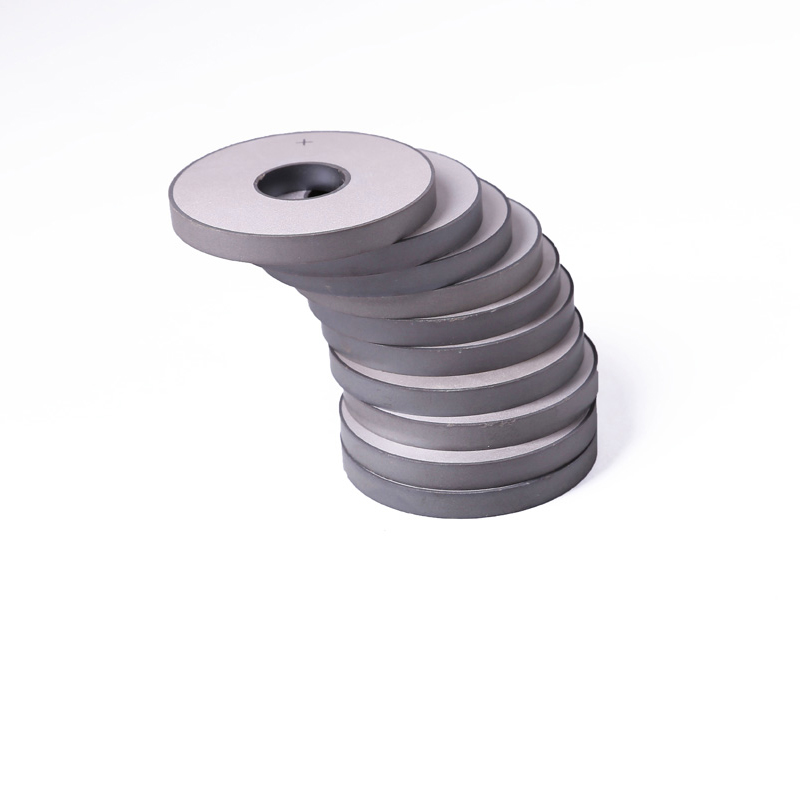

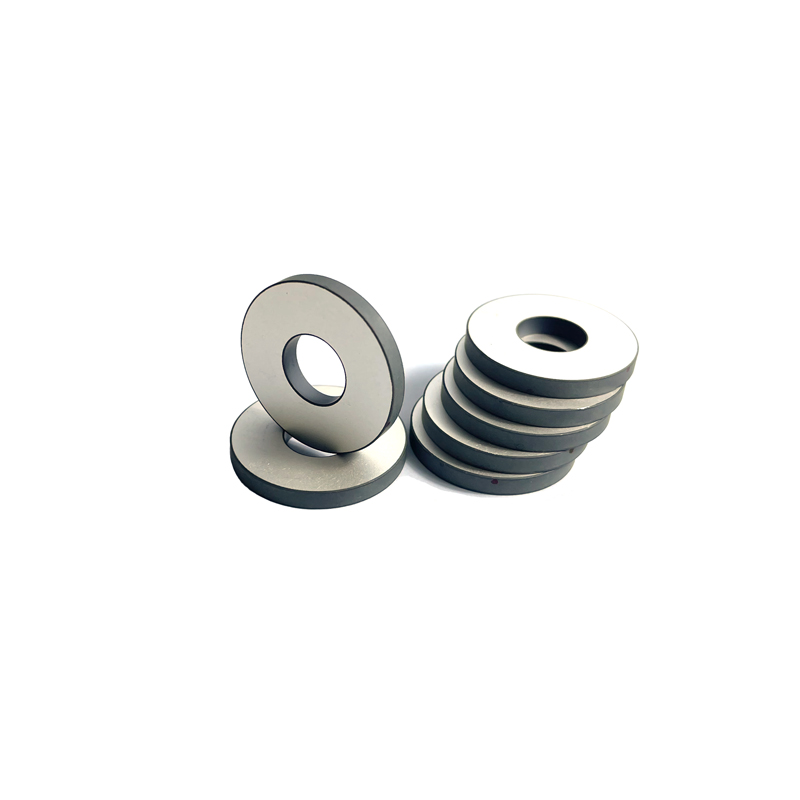

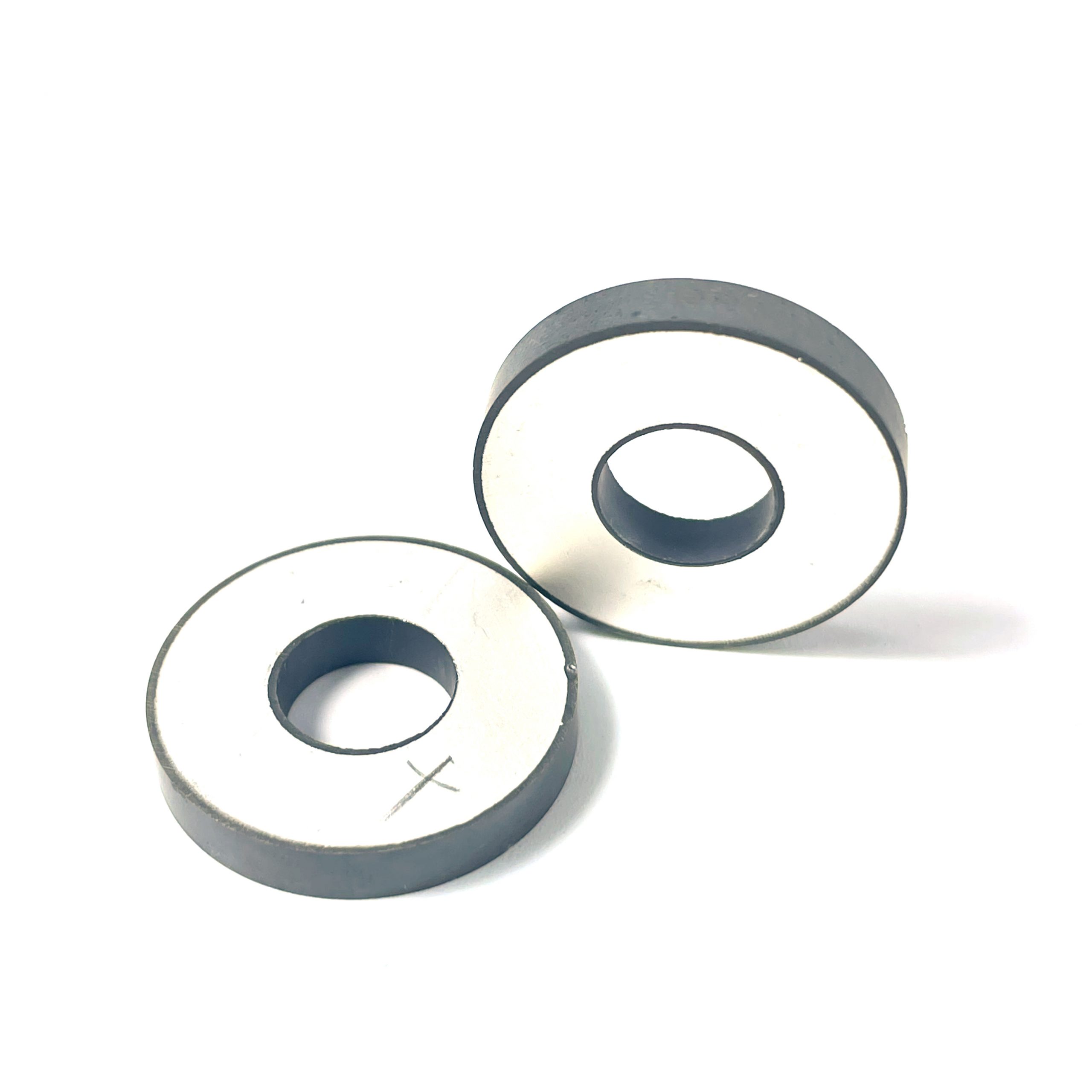

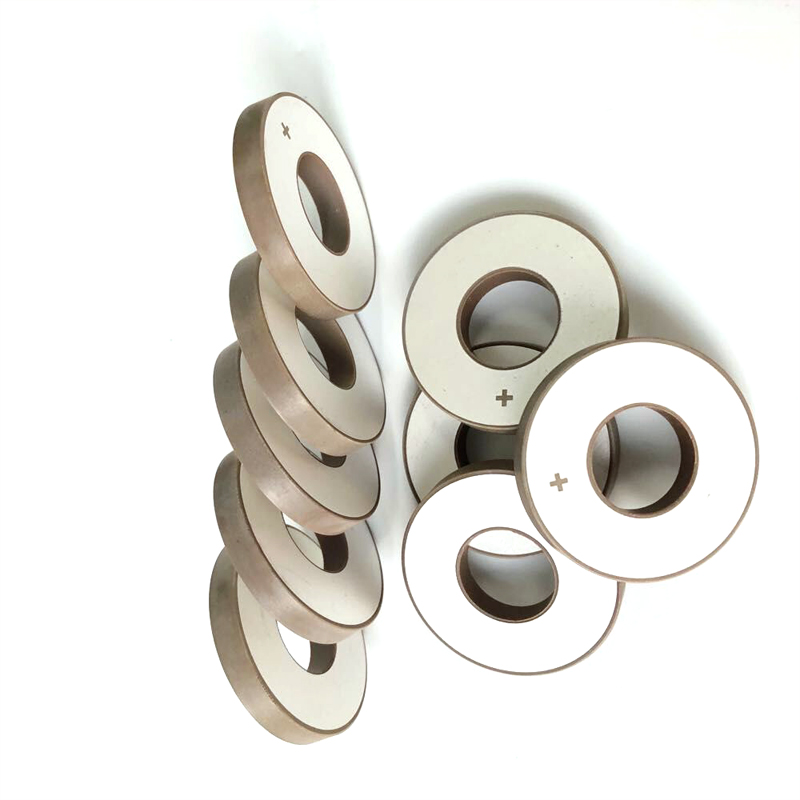

60*30*10mm PZT-8 Piezoelectric Ceramic Ring For 15khz 3200W And 4200W Ultrasonic Welding Machine Transducer

The commonly used electronic ceramics are barium titanate system and lead zirconate titanate binary system. The third common compound of ABO3 type is added to the binary system. If we continue to add a fourth or more compound to the ternary system. In this case, the electronic ceramics of quaternary system and mul…

The commonly used electronic ceramics are barium titanate system and lead zirconate titanate binary system. The third common compound of ABO3 type is added to the binary system.

If we continue to add a fourth or more compound to the ternary system. In this case, the electronic ceramics of quaternary system and multi-element system are formed. In addition, there is also a metaniobate system. The electronic ceramics that are hard to find are “potassium sodium metaniobate” and strontium barium metaniobate (Bax · Sr1-x · Nb2O5), etc. They do not contain toxic lead and other unqualified components, which is beneficial to the environmental protection industry. Therefore, it is recommended that the dielectric property formed by electronic ceramics reflects the degree of response of ceramic materials to the electromagnetic fields formed inside and outside. Normally, dielectric is used to compare constants ε 0. It indicates that the response of the dielectric to the electric field is linear when the external electromagnetic field is not large.

Piezoelectric ceramic alumina ceramics are the most widely used, widely used and most productive ceramic materials in oxide ceramics.

| spec | Dimension (mm) | Radial frequency (KHz) | Capacitance (pf) | Dielectric dissipation factor tanδ(%) | Electromechanical coupling coefficient (Kr) | Impedance Zr(Ω) | Thickness frequency (KHz) |

| PU-PC25103 | Φ25×Φ10×3 | 66.4 | 1240±12.5% | ≤0.3 | ≥0.46 | ≤15 | 683±5% |

| PU-PC225104 | Φ25×Φ10×4 | 66.4 | 930±12.5% | ≤0.3 | ≥0.46 | ≤15 | 512±5% |

| PU-PC40155 | Φ40×Φ12×5 | 45.9 | 2070±12.5% | ≤0.3 | ≥0.46 | ≤15 | 410±5% |

| PU-PC40155 | Φ40×Φ15×5 | 42.2 | 1960±12.5% | ≤0.3 | ≥0.46 | ≤15 | 323±5% |

| PU-PC40176 | Φ40×Φ17×6 | 40.5 | 1555±12.5% | ≤0.3 | ≥0.46 | ≤15 | 341±5% |

| PU-PC40205 | Φ40×Φ20×5 | 37.9 | 1700±12.5% | ≤0.3 | ≥0.47 | ≤15 | 410±5% |

| PU-PC50206 | Φ50×Φ20×6 | 33.2 | 2490±12.5% | ≤0.3 | ≥0.46 | ≤15 | 341±5% |

| PU-PC501765 | Φ50×Φ17×6.5 | 34.8 | 2430±12.5% | ≤0.3 | ≥0.46 | ≤15 | 315±5% |

| PU-PC50236 | Φ50×Φ23×6 | 31.2 | 2340±12.5% | ≤0.3 | ≥0.47 | ≤15 | 341±5% |

| PU-PC50276 | Φ50×Φ27×6 | 29.3 | 2100±12.5% | ≤0.3 | ≥0.47 | ≤15 | 341±5% |

| PU-PC603010 | Φ60×Φ30×10 | 25.3 | 1922±12.5% | ≤0.3 | ≥0.47 | ≤18 | 205±5% |

标签:60*30*10mm PZT-8 Piezoelectric Ceramic, piezoelectric ceramic, Piezoelectric Ceramic Ring, Ultrasonic Welding Machine Transducer

Send Inquiry

35*15*5mm PZT-8/PZT-4 Piezoelectric Ceramic Ring For 50W 28khz/40khz Ultrasonic Cleaning Machine Transducer

35*15*5mm PZT-8/PZT-4 Piezoelectric Ceramic Ring For 50W 28khz/40khz Ultrasonic Cleaning Machine Transducer 38.1*12.75*6.35mm Piezoelectric Ceramic Ring For 100W 28khz Ultrasonic Washing Machine Transducer

38.1*12.75*6.35mm Piezoelectric Ceramic Ring For 100W 28khz Ultrasonic Washing Machine Transducer 42*17*5 mm Piezoceramic Ring Performance of PZT8 Versus PZT4 Piezoceramic Materials Piezo Ring

42*17*5 mm Piezoceramic Ring Performance of PZT8 Versus PZT4 Piezoceramic Materials Piezo Ring Disc Piezo 25-10-4 Ultrasonic Transducer Sensors Piezoelectric Ceramic Components Piezo Crystal pzt4 OD25*ID10*4mm

Disc Piezo 25-10-4 Ultrasonic Transducer Sensors Piezoelectric Ceramic Components Piezo Crystal pzt4 OD25*ID10*4mm 35*15*5mm PZT-8/PZT-4 Piezoelectric Ceramic Ring For 50W 28khz/40khz Ultrasonic Cleaning Machine Transducer

35*15*5mm PZT-8/PZT-4 Piezoelectric Ceramic Ring For 50W 28khz/40khz Ultrasonic Cleaning Machine Transducer PZT4 PZT5 PZT8 Crystals Piezoelectric Ultrasonic Element For Ultrasonic Transducer

PZT4 PZT5 PZT8 Crystals Piezoelectric Ultrasonic Element For Ultrasonic Transducer 50x17x6.5mm Piezoelectric Element Piezo Ceramic Ring Piezo Element Piezoelectric Ceramic Ring For Ultrasonic Cleaner Piezo

50x17x6.5mm Piezoelectric Element Piezo Ceramic Ring Piezo Element Piezoelectric Ceramic Ring For Ultrasonic Cleaner Piezo 60*30*10mm PZT-8 Piezoelectric Ceramic Ring For 15khz 3200W And 4200W Ultrasonic Welding Machine Transducer

60*30*10mm PZT-8 Piezoelectric Ceramic Ring For 15khz 3200W And 4200W Ultrasonic Welding Machine Transducer Piezo Ring PZT8 60*30*10mm Piezo Ultrasonic Transducer For Welding Ultrasonic Welding For Mask Machine

Piezo Ring PZT8 60*30*10mm Piezo Ultrasonic Transducer For Welding Ultrasonic Welding For Mask Machine 24*7*3mm Ultrasonic Piezo Element Ultrasound Ceramic Piezoelectric Ceramic Ultrasonic Transducer Piezoelectric Ring Ceramic

24*7*3mm Ultrasonic Piezo Element Ultrasound Ceramic Piezoelectric Ceramic Ultrasonic Transducer Piezoelectric Ring Ceramic PZT4 PZT5 PZT8 Customization 40mm Ultrasonic Piezo Transducer Ceramic Element Piezoelectric Sensor

PZT4 PZT5 PZT8 Customization 40mm Ultrasonic Piezo Transducer Ceramic Element Piezoelectric Sensor 50*17*5mm PZT-8 Piezoelectric Ceramic Ring Ultrasonic Welder Machine Parts For 2000W Ultrasonic Welding Transducer

50*17*5mm PZT-8 Piezoelectric Ceramic Ring Ultrasonic Welder Machine Parts For 2000W Ultrasonic Welding Transducer