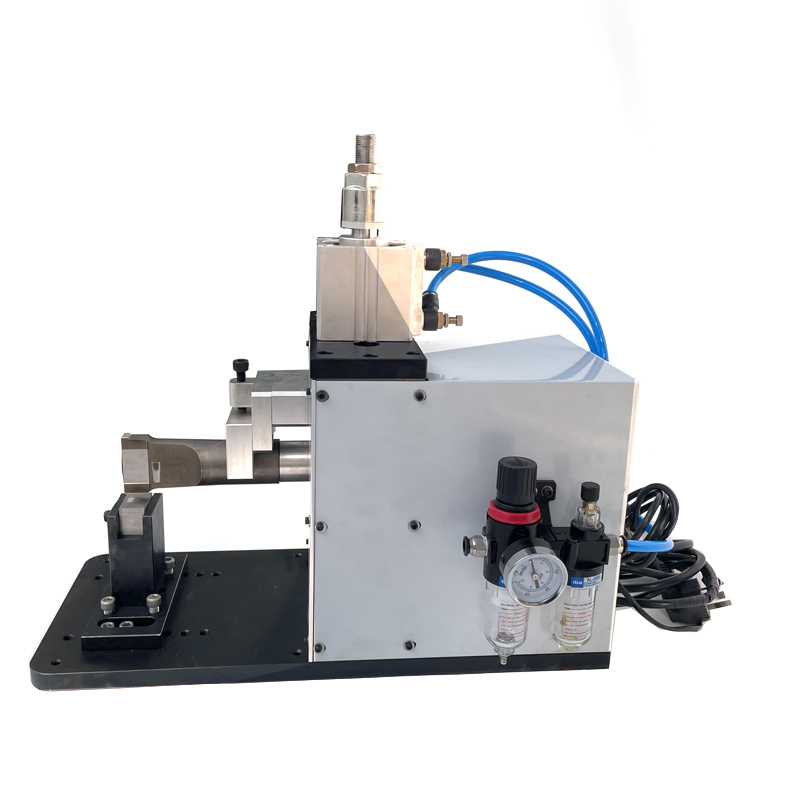

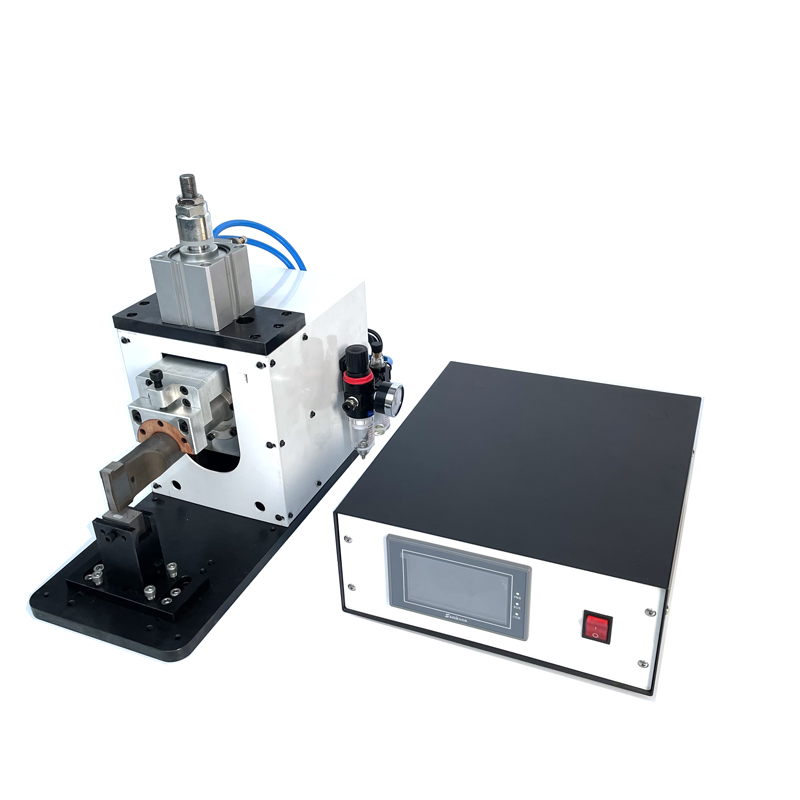

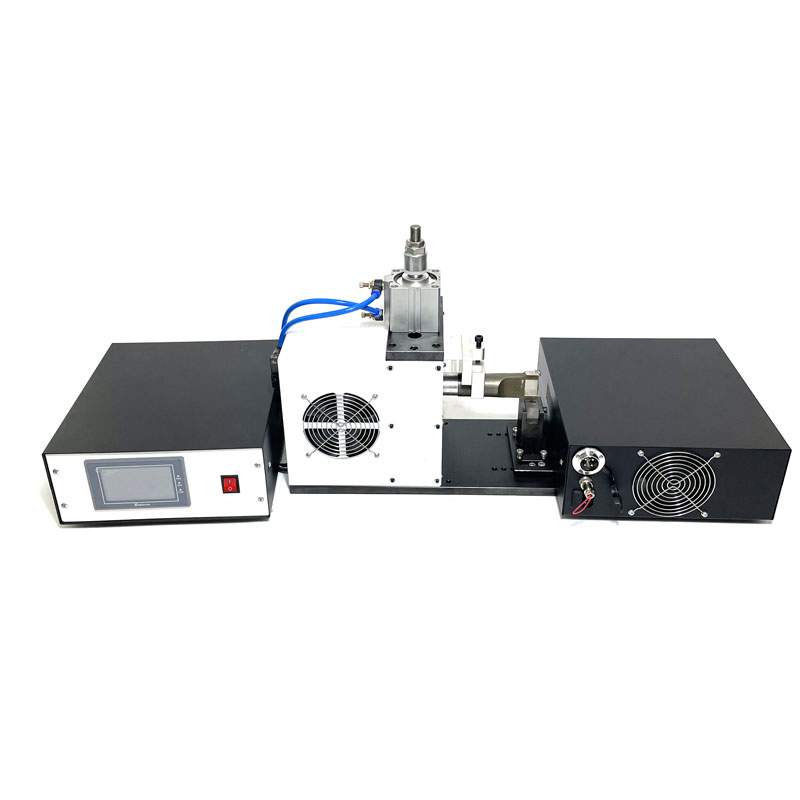

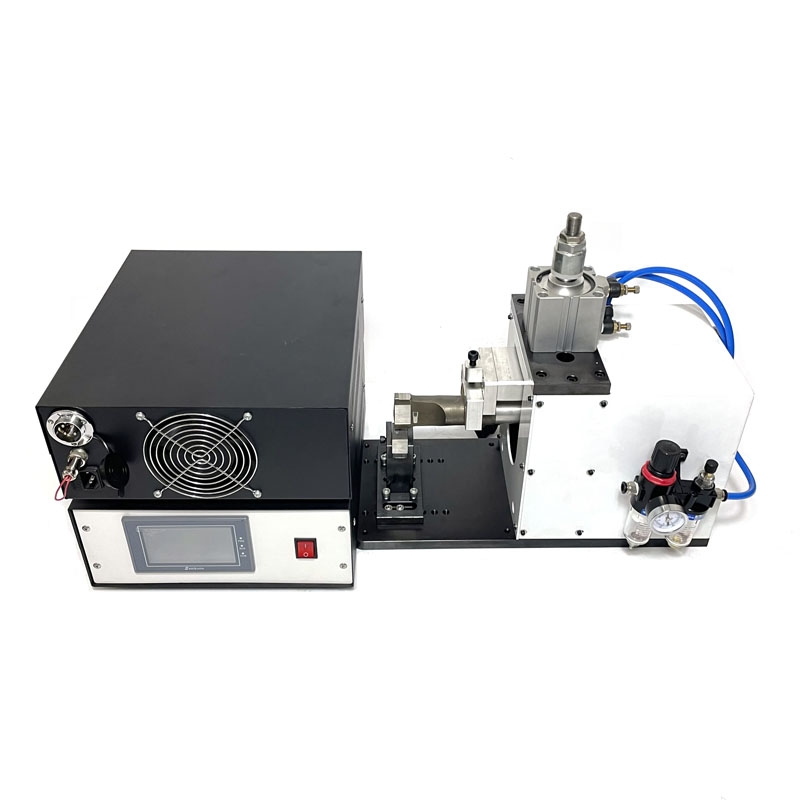

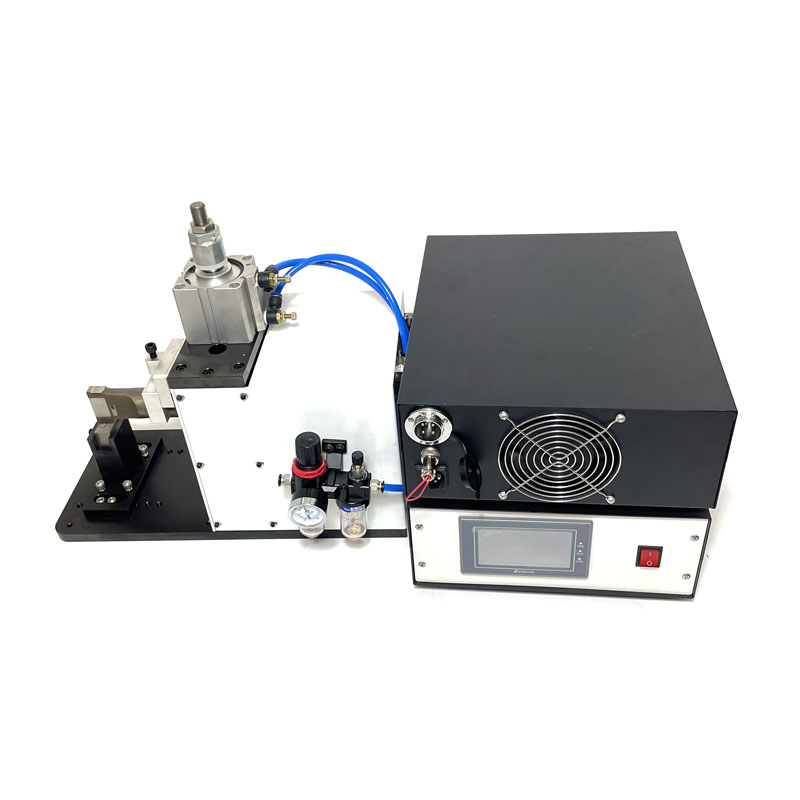

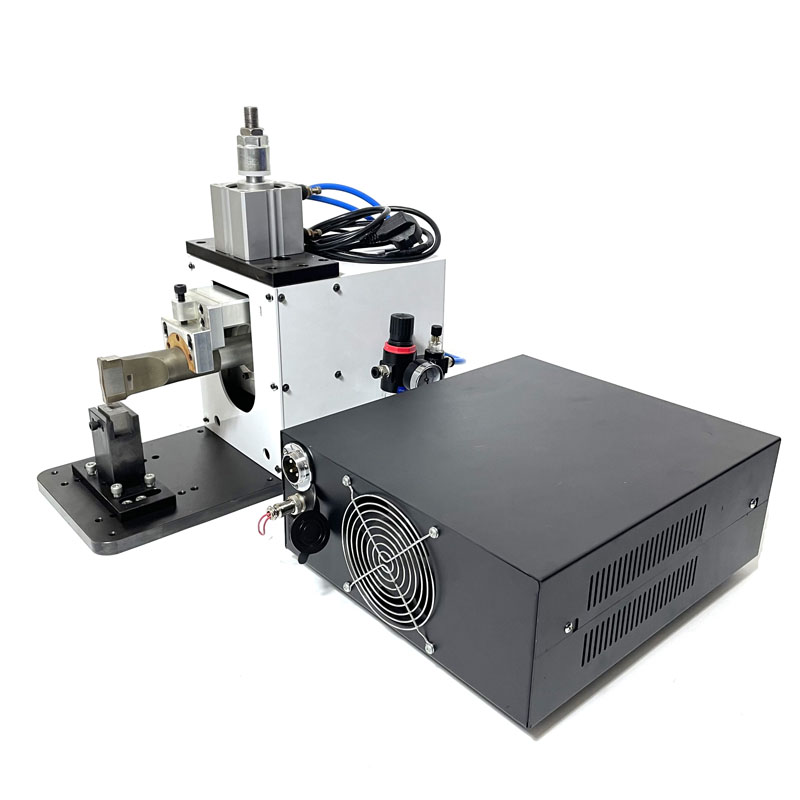

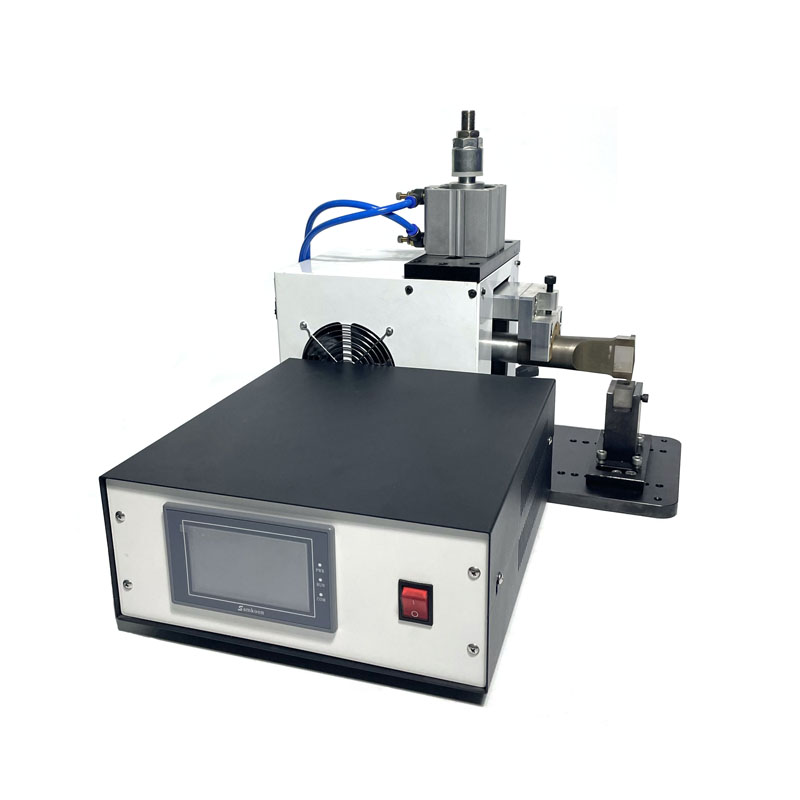

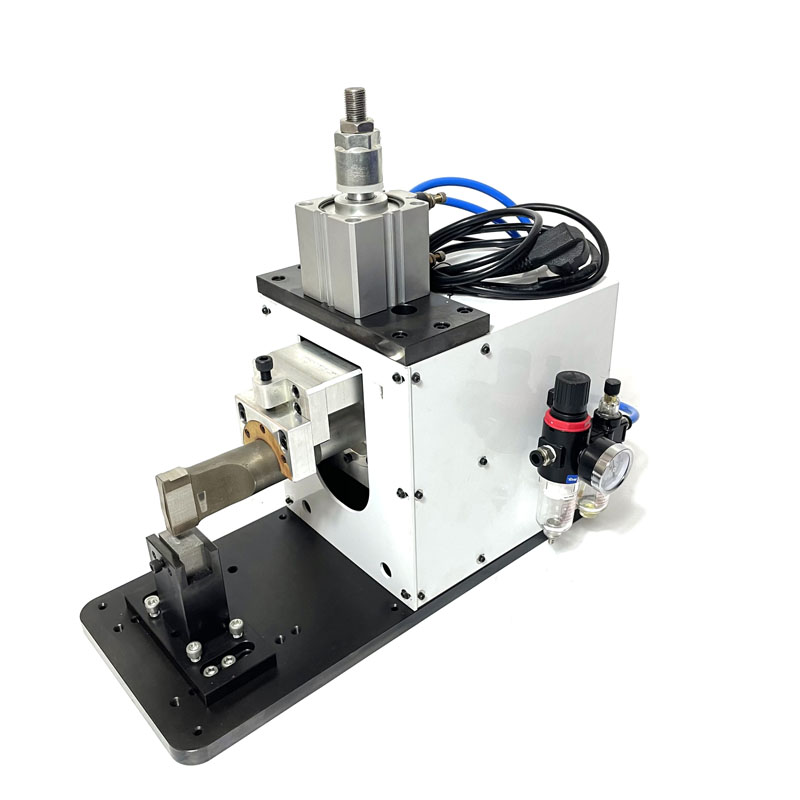

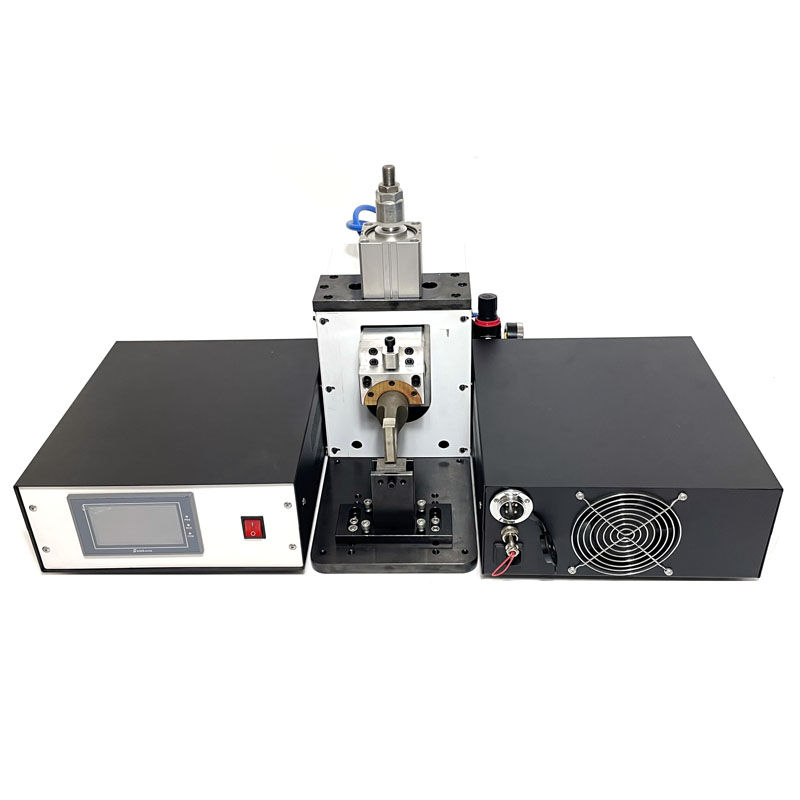

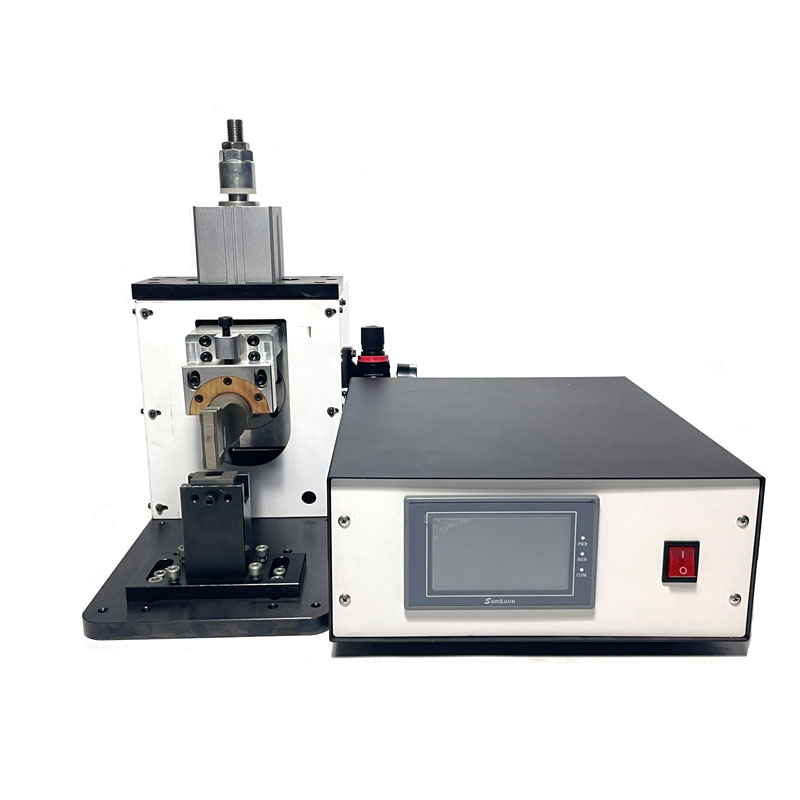

6000W Desktop Ultrasonic Electrical Wire Splicing and Joint Spot Welding Machine And Signal Generator

Applicable products of ultrasonic metal welding machine: The wires are fused to each other, forming one and several wires.Nickel metal hydride battery Nickel metal hydride battery Nickel mesh and nickel sheet are mutually melted and nickel sheet is mutually melted.The wires are fused with electronic components, co…

Applicable products of ultrasonic metal welding machine:

- The wires are fused to each other, forming one and several wires.

- Nickel metal hydride battery Nickel metal hydride battery Nickel mesh and nickel sheet are mutually melted and nickel sheet is mutually melted.

- The wires are fused with electronic components, contacts and connectors of various types.

- Copper foil and nickel foil of lithium battery and polymer battery are mutually melted, and aluminum foil and aluminum foil are mutually melted.

- Sealing and cutting of ultrasonic metal pipe can be water and gas tight.

- Large heat sinks, heat exchange fins, bees for household appliances and automotive products

Mutual melting of the nest core.

- High current contacts such as electromagnetic switch and fuse free switch, and mutual melting of dissimilar metal chips. characteristic:

(1) The two objects to be welded are overlapped and joined into a solid form through ultrasonic vibration and pressure. The joint time is short, and the joint part does not produce casting structure (rough surface) defects.

(2) Compared with resistance welding, ultrasonic welding has a long service life, less time for mold repair and replacement, and is easy to realize automation.

(3) Ultrasonic welding can be carried out between the same metal and different metals, which consumes much less energy than electrical welding.

(4) Compared with other pressure welding, ultrasonic welding requires less pressure and less than 10% deformation, while cold pressure welding requires 40% – 90% deformation of the workpiece.

(5) Ultrasonic welding does not require pretreatment of the surface to be welded and post-treatment after welding as other welding does.

(6) No external factors such as flux, metal filler and external heating are required for ultrasonic welding.

(7) Ultrasonic welding can minimize the temperature effect of materials (the temperature of the welding area shall not exceed 50% of the absolute melting temperature of the metal to be welded), so as not to change the metal structure, so it is very suitable for welding applications in the electronic field.

| Type | Power(W) | Frequency (KHz) |

| PU-MSW2000W | 2000W | 20KHZ |

| PU-MSW2600W | 2600W | 20KHZ |

| PU-MSW3200W | 3200W | 20KHZ |

| PU-MSW4000W | 4000W | 20KHZ |

| PU-MSW800W | 800W | 40khz |

Send Inquiry

Lab Polymer Battery Ni Al Tab Automatic Ultrasonic Metal Spot Welder Welding Machine

Lab Polymer Battery Ni Al Tab Automatic Ultrasonic Metal Spot Welder Welding Machine Metal Spot Welder Ultrasonic Battery Welding Machine For Battery Nickel Pole Ear Terminal Electrode Spot Welding Bonding Device

Metal Spot Welder Ultrasonic Battery Welding Machine For Battery Nickel Pole Ear Terminal Electrode Spot Welding Bonding Device Customized Metal Weld machine Ultrasonic Cable Connector Wire Terminal Welding Machine Ultrasonic Wire Splicing Machine

Customized Metal Weld machine Ultrasonic Cable Connector Wire Terminal Welding Machine Ultrasonic Wire Splicing Machine Ultrasonic Copper Aluminum Metal Wire Harness Terminal Welding Machine for New Energy Wiring Harness Equipment

Ultrasonic Copper Aluminum Metal Wire Harness Terminal Welding Machine for New Energy Wiring Harness Equipment Battery Ultrasonic Spot Welder Machine For 18650 & Pouch Cell Al/Ni/Cu Metal Tab Foil Welding

Battery Ultrasonic Spot Welder Machine For 18650 & Pouch Cell Al/Ni/Cu Metal Tab Foil Welding Ultrasonic Wire Harness Bonding Machine Copper Wire Ultrasonic Metal Welding Machine For Aluminum Wire

Ultrasonic Wire Harness Bonding Machine Copper Wire Ultrasonic Metal Welding Machine For Aluminum Wire Lab Ultrasonic Battery Spot Welder Welding Machine For Li-ion Battery Cathode Electrode Sheets

Lab Ultrasonic Battery Spot Welder Welding Machine For Li-ion Battery Cathode Electrode Sheets 3000W 20KHZ Ultrasonic Wire Splicing Machine Solder Wire Machine Copper Wire Spot Welding Machine

3000W 20KHZ Ultrasonic Wire Splicing Machine Solder Wire Machine Copper Wire Spot Welding Machine Pouch Cell Tab Ultrasonic Metal Spot Welder Welding Machine Ultrasonic Spot Welding Machine For Cathode Electrode

Pouch Cell Tab Ultrasonic Metal Spot Welder Welding Machine Ultrasonic Spot Welding Machine For Cathode Electrode 2000W 20KHZ Ultrasonic Metal Welding Machine for Battery Cell with Aluminum Foils Welded to Copper Mesh

2000W 20KHZ Ultrasonic Metal Welding Machine for Battery Cell with Aluminum Foils Welded to Copper Mesh Battery Ultrasonic Spot Welder For 18650 & Pouch Cell Al/Ni/Cu Metal Tab Foil Welding Machine

Battery Ultrasonic Spot Welder For 18650 & Pouch Cell Al/Ni/Cu Metal Tab Foil Welding Machine Pouch Cell Ultrasonic Spot Welder Welding Machine For Al Tab Or Aluminum Foil Welding Machines

Pouch Cell Ultrasonic Spot Welder Welding Machine For Al Tab Or Aluminum Foil Welding Machines