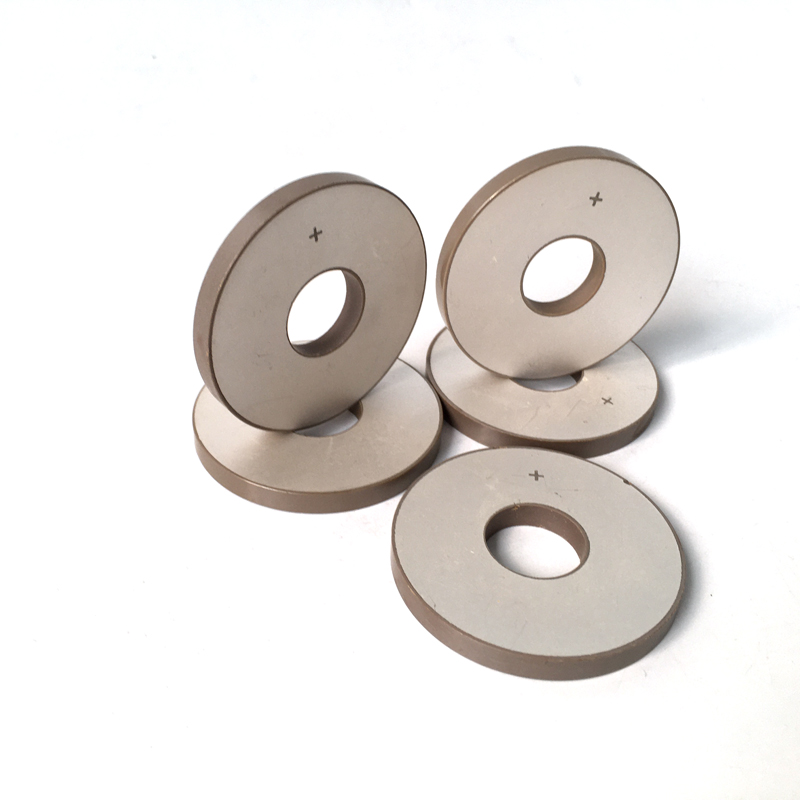

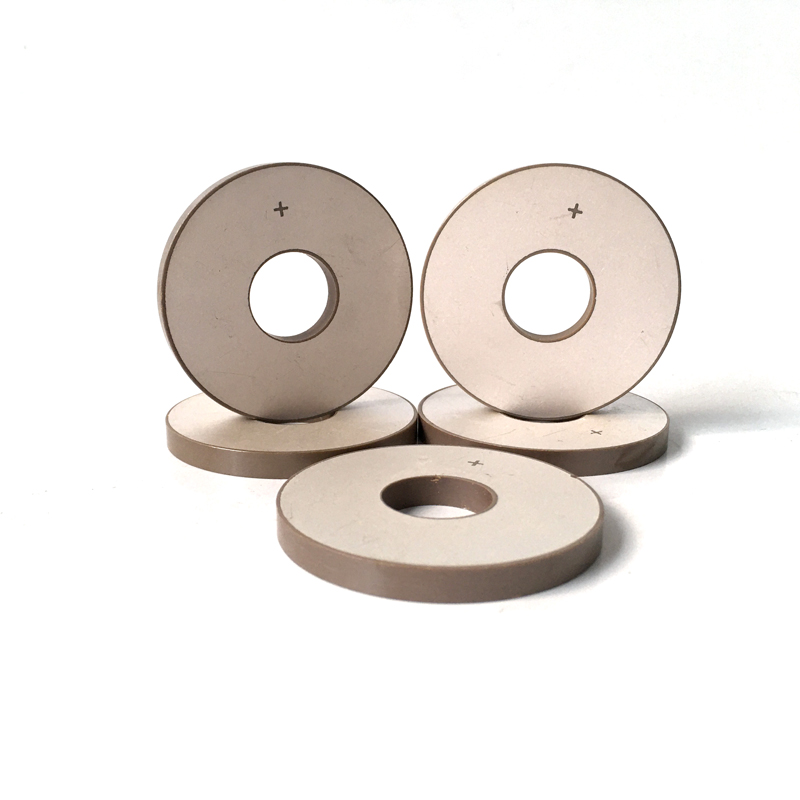

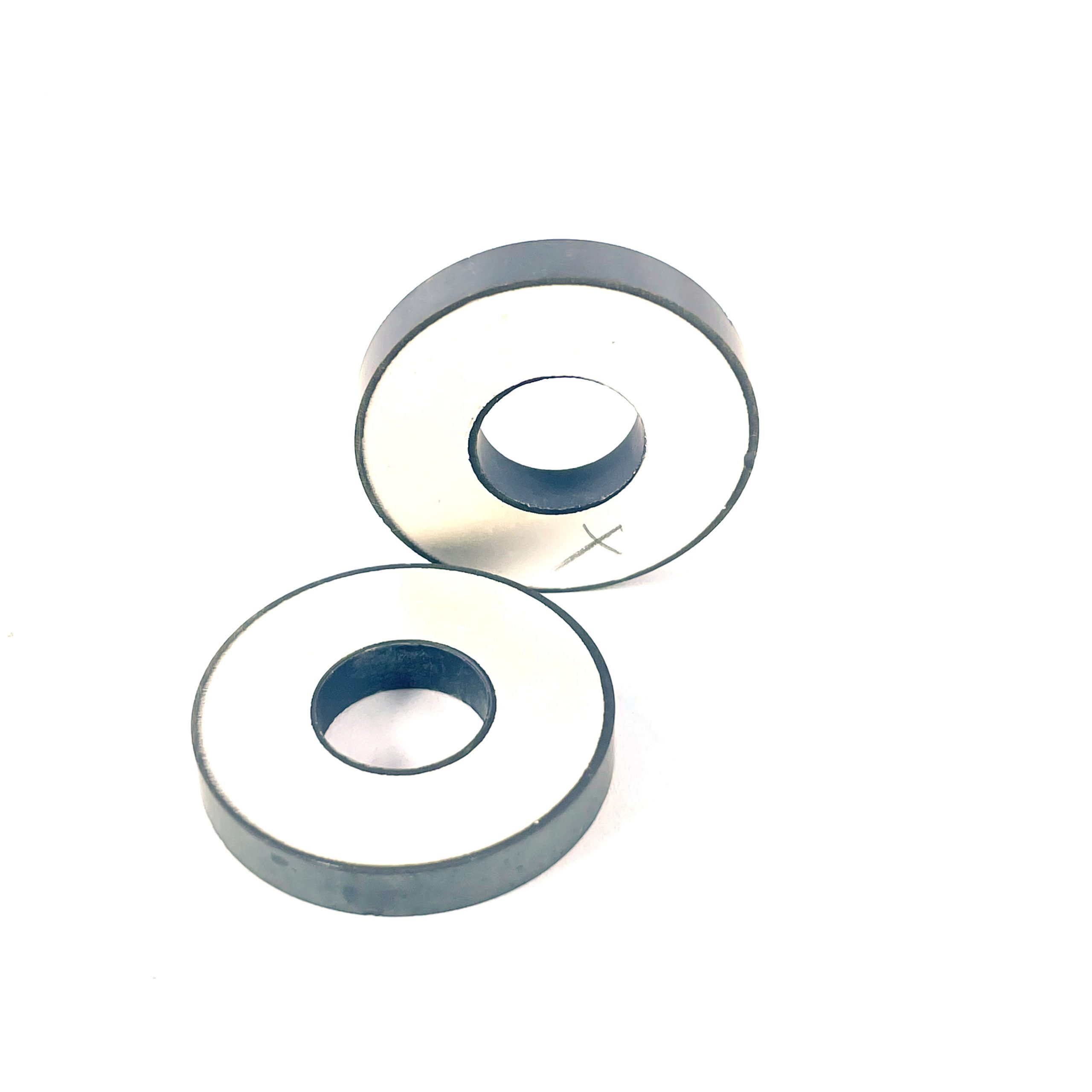

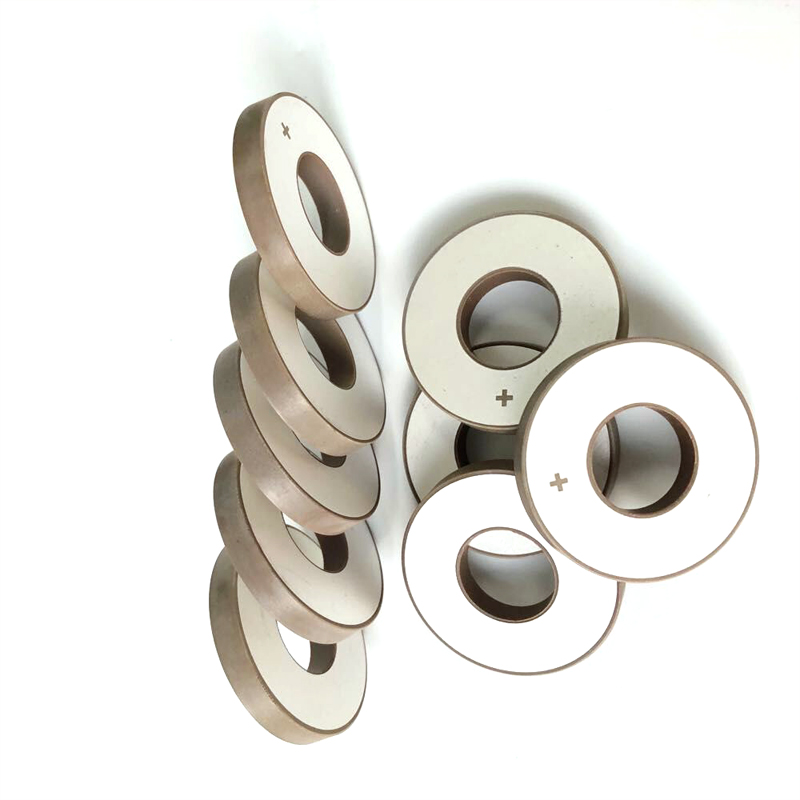

50x17x5mm PZT-8 Piezoelectric Ceramic Ring For Industrial Ultrasonic Welding Converter Sensor

Our company specializes in the production of piezoelectric ceramic chips of various specifications, conventional cleaning, welding, medical chips, and customized chips of various specifications, as well as ultrasonic cleaning transducers, ultrasonic beauty shovels, probes, etc Our company has been in operation for…

50x17x5mm PZT-8 Piezoelectric Ceramic Ring For Industrial Ultrasonic Welding Converter Sensor

Our company specializes in the production of piezoelectric ceramic chips of various specifications, conventional cleaning, welding, medical chips, and customized chips of various specifications, as well as ultrasonic cleaning transducers, ultrasonic beauty shovels, probes, etc

Our company has been in operation for 11 years, with mature technology, stable performance, favorable price, and a production capacity of more than 200000 pieces per month. We also carry out ISO9000 quality system certification every year. Welcome to contact us!

The principle of piezoelectric ceramic transducer is that when pressure or tension is applied to the ceramic plate, opposite polarity charges will be generated at both ends of the ceramic plate, and current will be generated through the circuit. This effect is called piezoelectric effect. Therefore, in the design of ultrasonic transducers, various factors, such as acoustic impedance, frequency response, impedance matching, acoustic structure, vibration mode and conversion materials, should be considered, as well as how to design and coordinate these factors to achieve the optimal value of electroacoustic conversion. As an energy transmission network, piezoelectric ceramic transducer has the problem of energy conversion efficiency.

The conversion efficiency is related to the selection of transducer material, vibration form, structure of mechanical vibration system (including support mechanism) and working frequency. Therefore, the problem of ultrasonic transmitter is solved. Piezoelectric ceramic transducer has two materials: magnetostrictive metal and piezoelectric ceramic. Piezoelectric ceramic transducer is a kind of electronic ceramic material with piezoelectric characteristics. The main difference between the piezoelectric ceramic transducer and the typical piezoelectric quartz crystal without ferroelectric component is that the crystal phase of its main component is ferroelectric crystal Because ceramics are polycrystalline aggregates with randomly oriented grains, the spontaneous polarization vector of each ferroelectric grain is also disoriented.

If the transducer made of this piezoelectric ceramic is put into water, then under the action of sound wave, charges will be induced at both ends of the transducer, which is a sound wave receiver. In addition, the piezoelectric effect is reversible If the alternating electric field is applied to the piezoelectric ceramic sheet, the ceramic sheet will become thinner and thicker from time to time, and generate vibration and sound waves. In order to make the ceramics show macroscopic piezoelectric characteristics, the piezoelectric ceramics must be polarized in a strong DC electric field after firing, and the end faces are subjected to multiple electrodes, so that the polarization vector of the original disordered orientation is preferentially oriented in the direction of the electric field. After the electric field is eliminated, the piezoelectric ceramics after polarization treatment will maintain a certain macroscopic residual polarization strength, so that the ceramics will have a certain pressure.

| spec | Dimension (mm) | Radial frequency (KHz) | Capacitance (pf) | Dielectric dissipation factor tanδ(%) | Electromechanical coupling coefficient (Kr) | Impedance Zr(Ω) | Thickness frequency (KHz) |

| PU-PC25103 | Φ25×Φ10×3 | 66.4 | 1240±12.5% | ≤0.3 | ≥0.46 | ≤15 | 683±5% |

| PU-PC225104 | Φ25×Φ10×4 | 66.4 | 930±12.5% | ≤0.3 | ≥0.46 | ≤15 | 512±5% |

| PU-PC40155 | Φ40×Φ12×5 | 45.9 | 2070±12.5% | ≤0.3 | ≥0.46 | ≤15 | 410±5% |

| PU-PC40155 | Φ40×Φ15×5 | 42.2 | 1960±12.5% | ≤0.3 | ≥0.46 | ≤15 | 323±5% |

| PU-PC40176 | Φ40×Φ17×6 | 40.5 | 1555±12.5% | ≤0.3 | ≥0.46 | ≤15 | 341±5% |

| PU-PC40205 | Φ40×Φ20×5 | 37.9 | 1700±12.5% | ≤0.3 | ≥0.47 | ≤15 | 410±5% |

| PU-PC50206 | Φ50×Φ20×6 | 33.2 | 2490±12.5% | ≤0.3 | ≥0.46 | ≤15 | 341±5% |

| PU-PC501765 | Φ50×Φ17×6.5 | 34.8 | 2430±12.5% | ≤0.3 | ≥0.46 | ≤15 | 315±5% |

| PU-PC50236 | Φ50×Φ23×6 | 31.2 | 2340±12.5% | ≤0.3 | ≥0.47 | ≤15 | 341±5% |

| PU-PC50276 | Φ50×Φ27×6 | 29.3 | 2100±12.5% | ≤0.3 | ≥0.47 | ≤15 | 341±5% |

| PU-PC603010 | Φ60×Φ30×10 | 25.3 | 1922±12.5% | ≤0.3 | ≥0.47 | ≤18 | 205±5% |

50x17x5mm PZT-8 Piezoelectric Ceramic Ring For Industrial Ultrasonic Welding Converter Sensor

标签:50x17x5mm PZT-8 Piezoelectric Ceramic Ring, piezoelectric ceramic chips, Piezoelectric Ceramic Ring, piezoelectric ceramic transducer, Ultrasonic Welding Converter Sensor

Send Inquiry

Custom Ultrasonic Transducer Piezo Ceramic Ring Pzt 5A Humidifier Disc Plate Piezoelectric 40khz Element

Custom Ultrasonic Transducer Piezo Ceramic Ring Pzt 5A Humidifier Disc Plate Piezoelectric 40khz Element Piezo Vibration Piezoelectric Ceramic Transducer Ultrasonic Piezo Ring 40*20*5mm

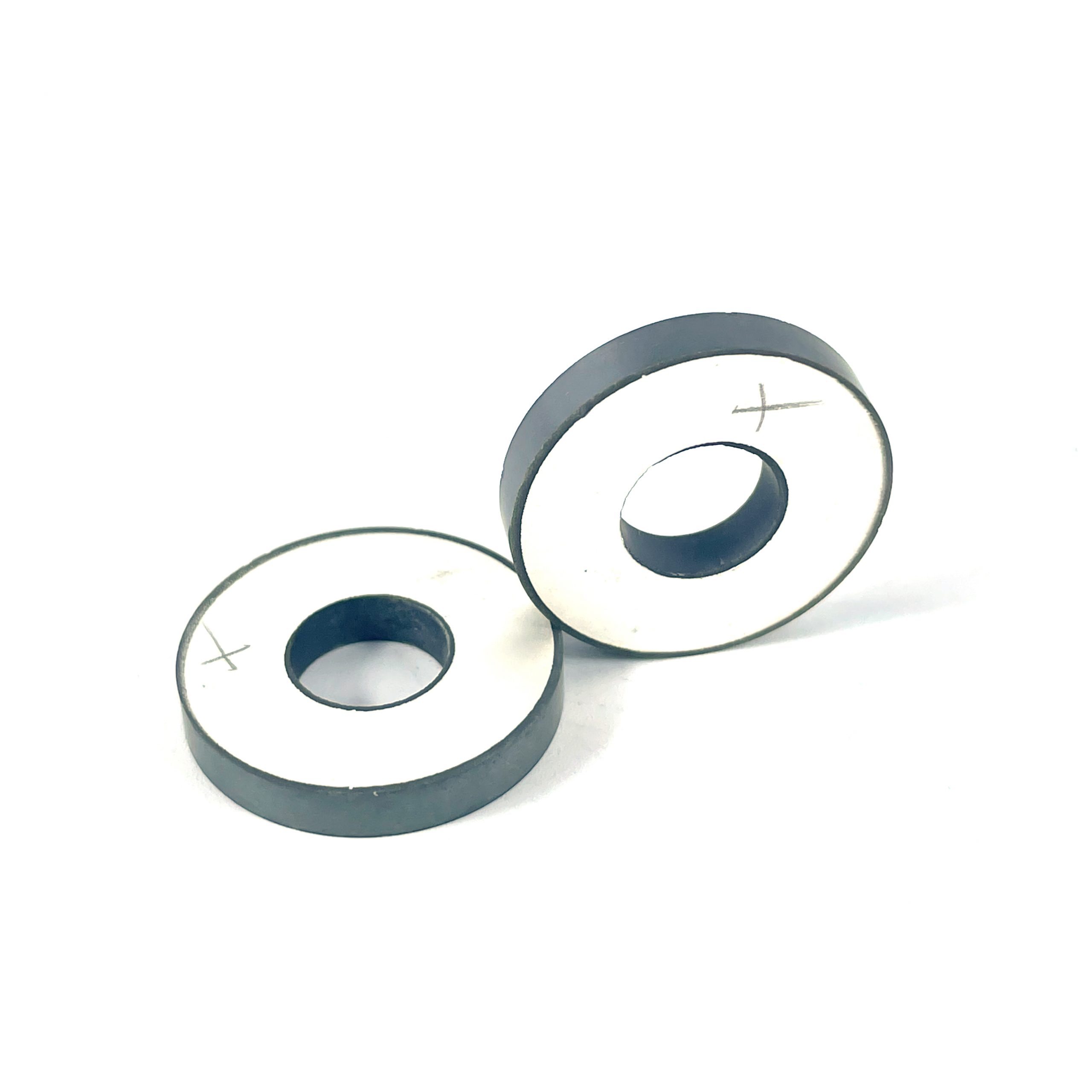

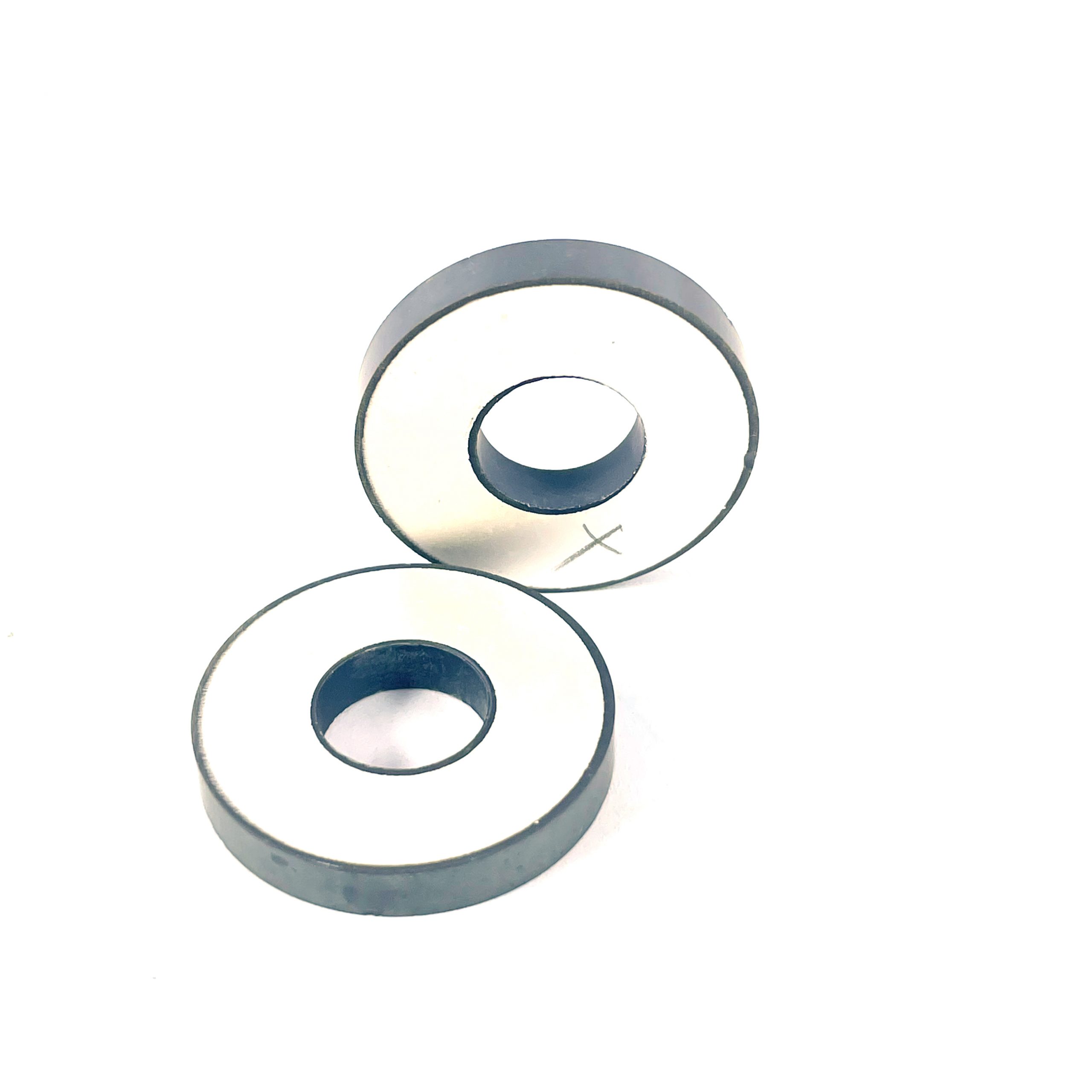

Piezo Vibration Piezoelectric Ceramic Transducer Ultrasonic Piezo Ring 40*20*5mm PZT-8 PZT-4 Material Piezoelectric Ceramic Ring/Disc/Sheet for Ultrasonic Transducer

PZT-8 PZT-4 Material Piezoelectric Ceramic Ring/Disc/Sheet for Ultrasonic Transducer Piezoelectric Ceramic Element Ultrasonic Piezo Electric Ceramics Ring Usd For Ultrasonic Welding Mask Machine

Piezoelectric Ceramic Element Ultrasonic Piezo Electric Ceramics Ring Usd For Ultrasonic Welding Mask Machine Ring Piezoelectric Ceramic Piezo Piezoelectric Ceramic Pzt Element Pzt8 Piezo Ceramic Ring Piezoelectric Transducer Piezo Sensor

Ring Piezoelectric Ceramic Piezo Piezoelectric Ceramic Pzt Element Pzt8 Piezo Ceramic Ring Piezoelectric Transducer Piezo Sensor 35*15*5mm PZT-8/PZT-4 Piezoelectric Ceramic Ring For 50W 28khz/40khz Ultrasonic Cleaning Machine Transducer

35*15*5mm PZT-8/PZT-4 Piezoelectric Ceramic Ring For 50W 28khz/40khz Ultrasonic Cleaning Machine Transducer 35*15*5mm PZT-4 Ultrasonic Transducer Pzt8 Ring Ultrasonic Piezo Element Pzt Ceramic Piezoelectric Crystal

35*15*5mm PZT-4 Ultrasonic Transducer Pzt8 Ring Ultrasonic Piezo Element Pzt Ceramic Piezoelectric Crystal 10×5*x2mm PZT8 Piezo Ceramic for Tooth Cleaning Ultrasonic Beauty Transducer

10×5*x2mm PZT8 Piezo Ceramic for Tooth Cleaning Ultrasonic Beauty Transducer Piezoelectric Ceramic Pzt Element for knock Sensor Ceramic Piezoceramic Vibrator Piezo Electric Ring

Piezoelectric Ceramic Pzt Element for knock Sensor Ceramic Piezoceramic Vibrator Piezo Electric Ring 38.1*12.75*6.35mm Piezoelectric Ceramic Ring For 100W 28khz Ultrasonic Washing Machine Transducer

38.1*12.75*6.35mm Piezoelectric Ceramic Ring For 100W 28khz Ultrasonic Washing Machine Transducer 50*17*5mm PZT-8 Piezoelectric Ceramic Ring Ultrasonic Welder Machine Parts For 2000W Ultrasonic Welding Transducer

50*17*5mm PZT-8 Piezoelectric Ceramic Ring Ultrasonic Welder Machine Parts For 2000W Ultrasonic Welding Transducer 50*20*5mm Piezoelectric Ceramic Ring PZT Electronic Ceramic Piezoceramic Ring Elements

50*20*5mm Piezoelectric Ceramic Ring PZT Electronic Ceramic Piezoceramic Ring Elements