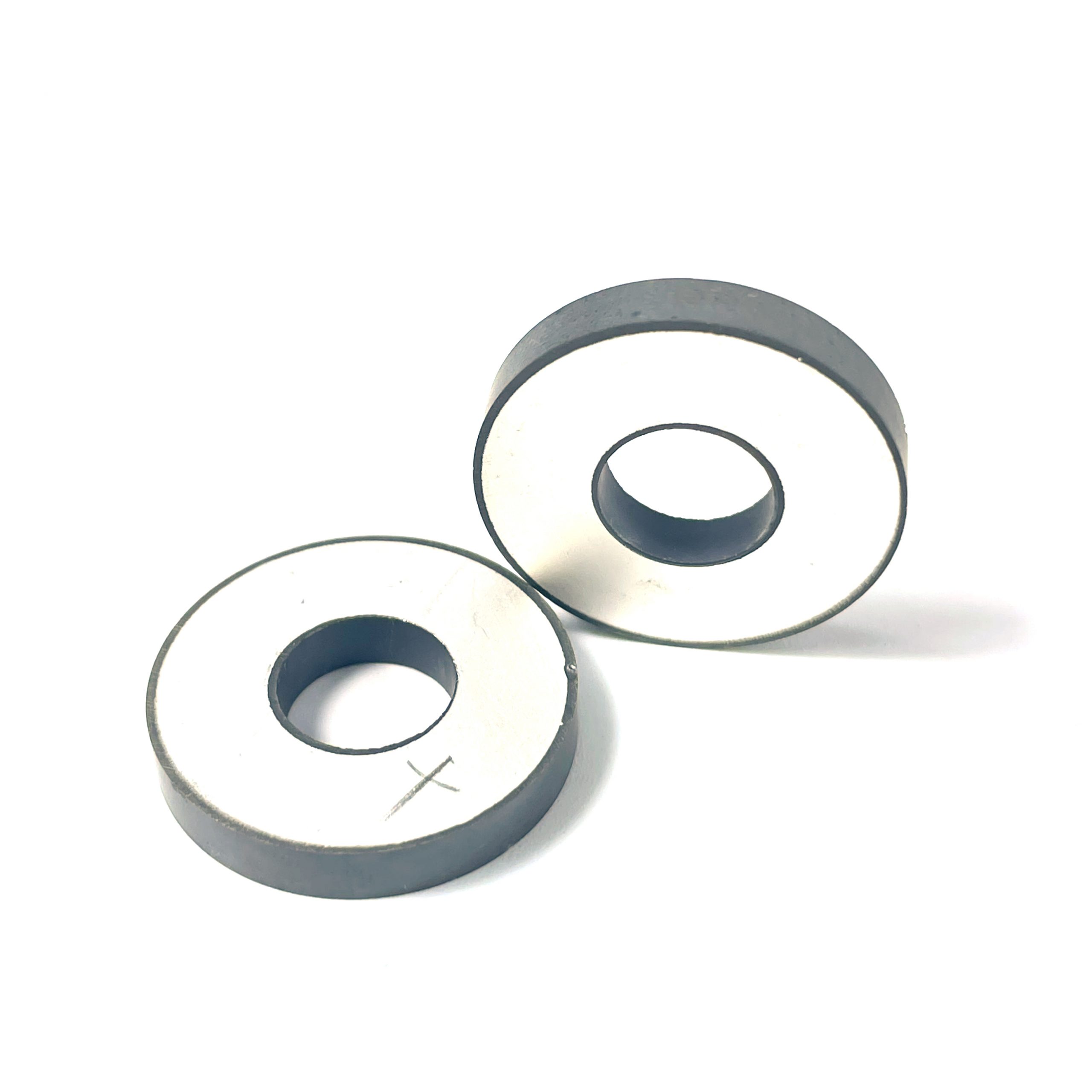

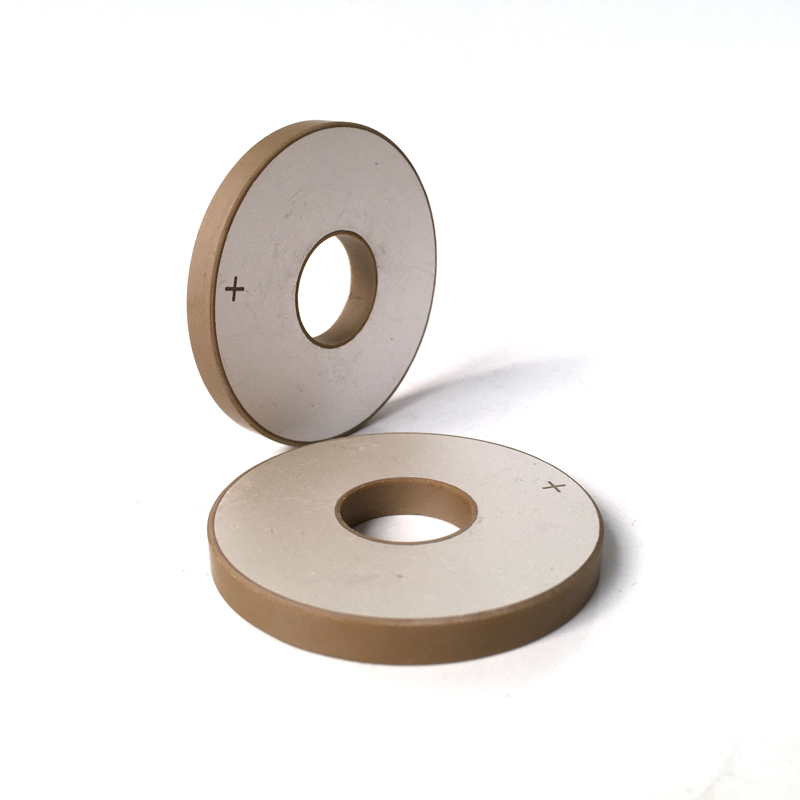

50*20*6mm Piezo Ceramic Ring PZT Electronic Ceramic Ring Piezoelectric Ceramic

In order to better utilize the application effect of piezoelectric ceramic vibration plates, it is necessary to design and optimize their driving circuits reasonably. The function of the driving circuit is to convert the input electrical signal into a voltage and frequency suitable for the piezoelectric ceramic vibra…

50*20*6mm Piezo Ceramic Ring PZT Electronic Ceramic Ring Piezoelectric Ceramic

In order to better utilize the application effect of piezoelectric ceramic vibration plates, it is necessary to design and optimize their driving circuits reasonably. The function of the driving circuit is to convert the input electrical signal into a voltage and frequency suitable for the piezoelectric ceramic vibration plate, thereby controlling its vibration behavior. By optimizing the design of the driving circuit, the performance and stability of piezoelectric ceramic vibration plates can be further improved, enabling them to achieve optimal results in different application scenarios.

When applying piezoelectric ceramic vibration plates, there are also some issues that need to be noted. For example, due to its high-frequency vibration characteristics, measures need to be taken to reduce interference and noise to the surrounding environment. In addition, it is necessary to select appropriate driving voltage, frequency, waveform and other parameters according to different application scenarios and requirements to ensure the safety and stability of piezoelectric ceramic vibration plates.

| spec | Dimension (mm) | Radial frequency (KHz) | Capacitance (pf) | Dielectric dissipation factor tanδ(%) | Electromechanical coupling coefficient (Kr) | Impedance Zr(Ω) | Thickness frequency (KHz) |

| PU-PC25103 | Φ25×Φ10×3 | 66.4 | 1240±12.5% | ≤0.3 | ≥0.46 | ≤15 | 683±5% |

| PU-PC225104 | Φ25×Φ10×4 | 66.4 | 930±12.5% | ≤0.3 | ≥0.46 | ≤15 | 512±5% |

| PU-PC40155 | Φ40×Φ12×5 | 45.9 | 2070±12.5% | ≤0.3 | ≥0.46 | ≤15 | 410±5% |

| PU-PC40155 | Φ40×Φ15×5 | 42.2 | 1960±12.5% | ≤0.3 | ≥0.46 | ≤15 | 323±5% |

| PU-PC40176 | Φ40×Φ17×6 | 40.5 | 1555±12.5% | ≤0.3 | ≥0.46 | ≤15 | 341±5% |

| PU-PC40205 | Φ40×Φ20×5 | 37.9 | 1700±12.5% | ≤0.3 | ≥0.47 | ≤15 | 410±5% |

| PU-PC50206 | Φ50×Φ20×6 | 33.2 | 2490±12.5% | ≤0.3 | ≥0.46 | ≤15 | 341±5% |

| PU-PC501765 | Φ50×Φ17×6.5 | 34.8 | 2430±12.5% | ≤0.3 | ≥0.46 | ≤15 | 315±5% |

| PU-PC50236 | Φ50×Φ23×6 | 31.2 | 2340±12.5% | ≤0.3 | ≥0.47 | ≤15 | 341±5% |

| PU-PC50276 | Φ50×Φ27×6 | 29.3 | 2100±12.5% | ≤0.3 | ≥0.47 | ≤15 | 341±5% |

| PU-PC603010 | Φ60×Φ30×10 | 25.3 | 1922±12.5% | ≤0.3 | ≥0.47 | ≤18 | 205±5% |

50*20*6mm Piezo Ceramic Ring PZT Electronic Ceramic Ring Piezoelectric Ceramic

Send Inquiry

45*15*5 Pzt Piezo Ceramic Element Piezo Crystal Ring Ultrasonic Piezo Ceramic Element Cylinder

45*15*5 Pzt Piezo Ceramic Element Piezo Crystal Ring Ultrasonic Piezo Ceramic Element Cylinder 50*20*6 PZT8 Piezoelectric ceramic chip Ultrasonic Piezoelectric ceramic sheet Transducer chip Spot

50*20*6 PZT8 Piezoelectric ceramic chip Ultrasonic Piezoelectric ceramic sheet Transducer chip Spot 35*15*5mm Piezoelectric Ceramic Ring PZT Electronic Ceramic Piezoelectric Pressure Sensors

35*15*5mm Piezoelectric Ceramic Ring PZT Electronic Ceramic Piezoelectric Pressure Sensors 25*10*4mm PZT-8 Piezoelectric Ceramic Ring For 28khz/40khz 100W Ultrasonic Welder Converters Transducer

25*10*4mm PZT-8 Piezoelectric Ceramic Ring For 28khz/40khz 100W Ultrasonic Welder Converters Transducer Piezoelectric ring ceramic ultrasonic piezoelectric ceramic piezo disc piezoelectric ceramic vibration sensor

Piezoelectric ring ceramic ultrasonic piezoelectric ceramic piezo disc piezoelectric ceramic vibration sensor Piezo Ring 50*17*6.5mm Piezoelectric Ceramic Element Customized Ultrasonic Piezoelectric Ceramic Ring

Piezo Ring 50*17*6.5mm Piezoelectric Ceramic Element Customized Ultrasonic Piezoelectric Ceramic Ring Pzt-4/Pzt-8 Piezo Ultrasonic Transducer Sensors 50*17*6.5 Piezoelectric Ceramic Components

Pzt-4/Pzt-8 Piezo Ultrasonic Transducer Sensors 50*17*6.5 Piezoelectric Ceramic Components 38*15*5 Pzt Piezoelectric Ceramic Piezo Element For Ultrasonic Sensor

38*15*5 Pzt Piezoelectric Ceramic Piezo Element For Ultrasonic Sensor 40*20*5mm PZT-8 Piezoelectric Ceramic Ring For 800W 28khz Piezo Ultrasonic Vibrator Transducer

40*20*5mm PZT-8 Piezoelectric Ceramic Ring For 800W 28khz Piezo Ultrasonic Vibrator Transducer 50x17x6.5mm Piezoceramic Rings Piezoelectric Elements PZT82 Material For Ultrasonic Welding Transducer

50x17x6.5mm Piezoceramic Rings Piezoelectric Elements PZT82 Material For Ultrasonic Welding Transducer Ultrasonic Welding Mask Machine Piezo Ceramic Ring 60*30*10mm Ultrasonic Transducer Piezoelectric Ceramic Ring

Ultrasonic Welding Mask Machine Piezo Ceramic Ring 60*30*10mm Ultrasonic Transducer Piezoelectric Ceramic Ring 38*15*5 Ring Piezoelectric Ceramic Element Ring For Ultrasonic Cleaning Trasnducer Machine

38*15*5 Ring Piezoelectric Ceramic Element Ring For Ultrasonic Cleaning Trasnducer Machine