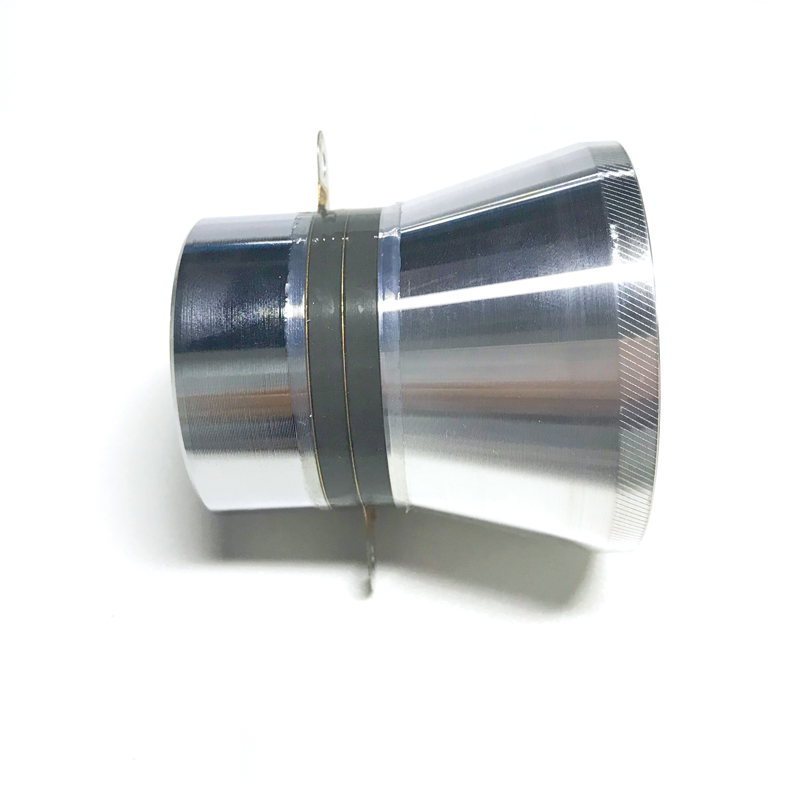

40KHz 50W Ultrasonic Transducer For Industrial Ultrasonic Cleaning Machine

The ultrasonic vibrator should be placed in a dry place to prevent moisture from affecting its normal operation. If the ultrasonic oscillator is damp, place it in the oven and set it to dry at around 100 ℃ for 2 hours, or use a hair dryer to remove moisture until the resistance value is normal; Ultrasonic oscil…

40KHz 50W Ultrasonic Transducer For Industrial Ultrasonic Cleaning Machine

The ultrasonic vibrator should be placed in a dry place to prevent moisture from affecting its normal operation. If the ultrasonic oscillator is damp, place it in the oven and set it to dry at around 100 ℃ for 2 hours, or use a hair dryer to remove moisture until the resistance value is normal; Ultrasonic oscillator debonding: After the ultrasonic oscillator debonding, the output power of the ultrasonic power supply is normal. However, due to poor connection between the oscillator and the vibration surface, the oscillator may burn out if operated for a long time. Ultrasonic oscillator debonding generally requires professional ultrasonic manufacturers to repair or replace it.

Maintenance of ultrasonic oscillator:

If not used for more than a week, please cover it with a dust cover (plastic bag); Except for the lifting screw that has received lubricating oil before leaving the factory, all other parts do not need to be coated with any oil; Regularly check whether the internal oscillator output line is worn; If there is dust on the appearance, please wipe it with a clean cloth. The dust inside the machine should be blown clean with dry compressed air every six months. It is strictly prohibited to use various fluxes when cleaning the side plate and surface of the welding machine. Neutral detergent should be used and gently wiped; When the water level of the filter cup reaches 13, please drain the water; After every month of use of the welding machine, the sliding parts should be wiped clean and reapplied with high-quality lubricating grease; Always pay attention to the safety of the machine position.

| Type | Length(mm) | Weight(g) | Frequency(KHz) | Resonance Impedance (Ω) | Static Capacity (pF)±10% | Input Power(W) |

| PU-UT-20100 PZT-8 | 94 | 900 | 20 | 10-20 | 5200 | 100 |

| PU-UT-25100 PZT-4 | 77 | 710 | 25 | 10-20 | 6600 | 100 |

| PU-UT-28120 PZT-4 | 66 | 720 | 28 | 10-20 | 7800 | 120 |

| PU-UT-28100 PZT-8 | 66 | 625 | 28 | 10-20 | 5200 | 100 |

| PU-UT-28100 PZT-4 | 66 | 624 | 28 | 10-20 | 6600 | 100 |

| PU-UT-30100 PZT-8 | 61 | 555 | 30 | 10-20 | 5200 | 100 |

| PU-UT-2560 PZT-4 | 77 | 530 | 25 | 10-20 | 5400 | 60 |

| PU-UT-2860 PZT-8 | 68 | 470 | 28 | 10-20 | 3800 | 60 |

| PU-UT-2850 PZT-4 | 82 | 425 | 28 | 10-20 | 4100 | 50 |

| PU-UT-3360 PZT-8 | 58 | 420 | 33 | 10-20 | 3800 | 60 |

| PU-UT-4060 PZT-8 | 55 | 300 | 40 | 10-20 | 3800 | 60 |

| PU-UT-4060 PZT-4 | 56 | 310 | 40 | 10-20 | 5400 | 60 |

| PU-UT-4050 PZT-4 | 54 | 260 | 40 | 10-20 | 4100 | 50 |

| PU-UT-4050-1 PZT-4 | 57 | 300 | 40 | 10-20 | 4100 | 50 |

| PU-UT-5435 PZT-4 | 36 | 135 | 54 | 10-20 | 3200 | 35 |

| PU-UT-6860 PZT-8 | 80 | 460 | 68 | 10-20 | 3800 | 60 |

| PU-UT-68120 PZT-4 | 67 | 588 | 68 | 10-20 | 7800 | 120 |

| PU-UT-8060 PZT-4 | 60 | 325 | 80 | 10-20 | 5400 | 60 |

| PU-UT-12060 PZT-4 | 56 | 260 | 120 | 10-20 | 5400 | 60 |

| PU-UT-13550 PZT-4 | 54 | 215 | 135 | 10-20 | 4200 | 50 |

40KHz 50W Ultrasonic Transducer For Industrial Ultrasonic Cleaning Machine

标签:40KHz 50W Ultrasonic Transducer, Ultrasonic Transducer for Industrial Ultrasonic Cleaning Machine

Send Inquiry

Ultrasonic Cleaning Transducer 28khz 60W Transducer Piezoelectric Vibration Sensor For Ultrasonic Cleaning Bath

Ultrasonic Cleaning Transducer 28khz 60W Transducer Piezoelectric Vibration Sensor For Ultrasonic Cleaning Bath 40KHz 60W Ultrasonic Transducer Piezo Vibration Sensor Ultrasonic Cleaning Transducer For Ultrasonic Cleaning Machine

40KHz 60W Ultrasonic Transducer Piezo Vibration Sensor Ultrasonic Cleaning Transducer For Ultrasonic Cleaning Machine 33KHZ PZT-4 Ultrasonic Waves Cleaner Transducer Ultrasonic Transducer For Large Capacity Ultrasonic Cleaner

33KHZ PZT-4 Ultrasonic Waves Cleaner Transducer Ultrasonic Transducer For Large Capacity Ultrasonic Cleaner High Power 28khz Pzt4 Ultrasonic Piezoelectric Transducer For Ultrasonic Cleaning Tank

High Power 28khz Pzt4 Ultrasonic Piezoelectric Transducer For Ultrasonic Cleaning Tank 100W 28khz Ultrasonic Transducer Ultrasonic Piezoelectric Transducer Cleaner Transducer

100W 28khz Ultrasonic Transducer Ultrasonic Piezoelectric Transducer Cleaner Transducer PZT-8 40KHZ Piezo Ultrasonic Cleaning Transducer For Ultrasonic Electrolysis Mold Cleaning Machine

PZT-8 40KHZ Piezo Ultrasonic Cleaning Transducer For Ultrasonic Electrolysis Mold Cleaning Machine 100W 28KHZ Ultrasonic Frequency Cleaning Transducer For Immersible Ultrasonic Cleaner

100W 28KHZ Ultrasonic Frequency Cleaning Transducer For Immersible Ultrasonic Cleaner 100W 28KHZ Ultrasonic Dishwasher Machine Transducer For Ultrasonic Cleaner

100W 28KHZ Ultrasonic Dishwasher Machine Transducer For Ultrasonic Cleaner 25KHZ Piezoelectric Vibration Transducer Low Frequency Piezoelectric Vibration Cleaning Sensor Transducer

25KHZ Piezoelectric Vibration Transducer Low Frequency Piezoelectric Vibration Cleaning Sensor Transducer 25KHZ PZT-4 Ultrasonic Cavitation Cleaning Transducer Ultrasonic Transducer For Single Tank Ultrasonic Cleaner

25KHZ PZT-4 Ultrasonic Cavitation Cleaning Transducer Ultrasonic Transducer For Single Tank Ultrasonic Cleaner 28KHz 60W Ultrasonic Machine Ultrasonic Piezoelectric Transducer DIY Ultrasonic Cleaner Parts

28KHz 60W Ultrasonic Machine Ultrasonic Piezoelectric Transducer DIY Ultrasonic Cleaner Parts Variable Pulse Piezoelectric Ultrasonic Transducer Ultrasonic Cleaning Transducer For Powerful Stainless Steel Ultrasonic Cleaner

Variable Pulse Piezoelectric Ultrasonic Transducer Ultrasonic Cleaning Transducer For Powerful Stainless Steel Ultrasonic Cleaner