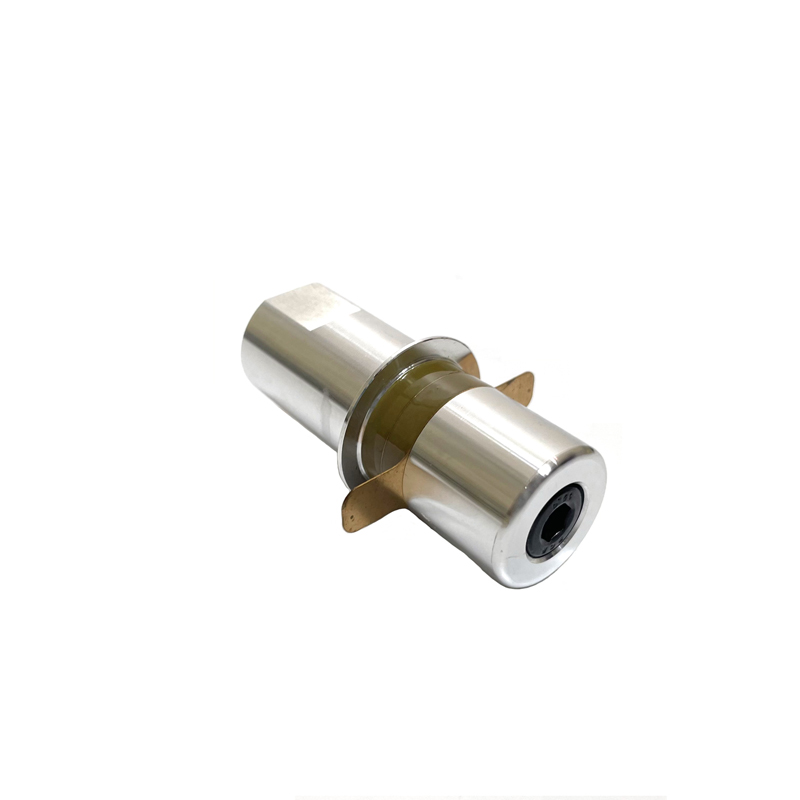

35KHZ Ultrasonic Mask Plastic Spot Welding Transducer Machine Ultrasonic Welding Transducer

Ultrasonic transducers transmit ultrasonic waves through welding heads to plastic processing parts, causing severe friction between two plastic joint surfaces due to the action of ultrasonic waves. The heat of friction causes the plastic joint surface to melt and complete bonding. This technology has the advantages o…

35KHZ Ultrasonic Mask Plastic Spot Welding Transducer Machine Ultrasonic Welding Transducer

Ultrasonic transducers transmit ultrasonic waves through welding heads to plastic processing parts, causing severe friction between two plastic joint surfaces due to the action of ultrasonic waves. The heat of friction causes the plastic joint surface to melt and complete bonding. This technology has the advantages of fast speed, firm welding seams, and more importantly, it can automate the production and processing of plastic products. The ultrasonic plastic welding machine can perform plastic fusion, embedding, forming, riveting, spot welding, cutting, sewing, and other operations. As long as the welding head is changed, it can be used for multiple applications in one machine.

Our company specializes in the production of Ultrasonic welding transducers, which have high performance, long life, good welding effect and other properties. The ultrasonic wave used in plastic processing has several working frequencies, including 15KHZ, 18KHZ, 20KHZ, and 40KHZ. Its principle is to use the peak position of the longitudinal wave to transmit the amplitude to the gap of the plastic part. Under pressure, two plastic parts or other parts collide with the molecules at the contact area of the plastic part to melt, causing the plastic at the contact area to fuse and achieve the processing purpose

For ultrasonic processing of thermoplastic adhesive, Ultrasonic welding transducer uses high-frequency friction between working surfaces to rapidly generate heat between molecules. When the heat is enough to melt, stop ultrasonic vibration. At this time, the working surface is solidified from melting to complete the processing procedure. The frequencies commonly used for plastic processing are 20KHZ and 15KHZ, which are outside of human hearing and are therefore called ultrasound. Ultrasonic welding machine is used in PP, PE, ABS, acrylic and other materials such as electronics, stationery, transportation equipment, toys, cosmetics, motors, etc.

| Type | Full-length(mm) | Joint Bolt(mm) | Frequency(KHz) | Resonance Impedance(Ω) | Capacity(pF) | Input Power (W) |

| PU-UWT30500 P8 | 77 | M10×1.5 | 30 | 5 | 5500 | 500 |

| PU-UWT28200 P4 | 92.1 | M10×1 | 28 | 20 | 3000 | 200 |

| PU-UWT28100 P8 | 91 | M8×1 | 28 | 25 | 2200 | 100 |

| PU-UWT28250 P8 | 94 | 1/2-20 UNF | 28 | 20 | 4000 | 250 |

| PU-UWT35100 P8 | 71 | M8×1 | 35 | 25 | 2200 | 100 |

| PU-UWT38100 P8 | 66 | M8×1.25 | 38 | 40 | 1200 | 100 |

| PU-UWT38200 P4 | 65 | M8×1 | 38 | 14 | 3300 | 200 |

35KHZ Ultrasonic Mask Plastic Spot Welding Transducer Machine Ultrasonic Welding Transducer

标签:35KHZ Ultrasonic Mask Plastic Spot Welding Transducer, Ultrasonic Mask Plastic Spot Welding Transducer

Send Inquiry

40KHz High Frequency Ultrasonic Welding Transducer For Ultrasonic Spot Welder Machine

40KHz High Frequency Ultrasonic Welding Transducer For Ultrasonic Spot Welder Machine High Vibration 28KHz Ultrasonic Welding Transducer For Spot Welder Machine

High Vibration 28KHz Ultrasonic Welding Transducer For Spot Welder Machine 28KHZ 800W Handheld Ultrasonic Welding System Transducer For Plastic Ultrasonic Welder Machine

28KHZ 800W Handheld Ultrasonic Welding System Transducer For Plastic Ultrasonic Welder Machine 28KHZ 500W Ultrasonic Spot Welder Transducer For Hand Held Ultrasonic Spot Welding Machine

28KHZ 500W Ultrasonic Spot Welder Transducer For Hand Held Ultrasonic Spot Welding Machine High Power 28KHz Spot Welder Machine parts Piezoelectric Ceramic Sensor Ultrasonic welding Transducer

High Power 28KHz Spot Welder Machine parts Piezoelectric Ceramic Sensor Ultrasonic welding Transducer Welding Transducer High Power 28KHz Spot Welder Machine Parts Piezoelectric Ceramic Sensor Ultrasonic Welding Transducer

Welding Transducer High Power 28KHz Spot Welder Machine Parts Piezoelectric Ceramic Sensor Ultrasonic Welding Transducer 28kHz Hand Held Spot Welder Converter Welding Machine Parts Ultrasonic Welding Transducer

28kHz Hand Held Spot Welder Converter Welding Machine Parts Ultrasonic Welding Transducer 28khz Ultrasonic Spot Welder Transducer For Handheld Ultrasonic Spot Welder Auto Parts Welding Machine

28khz Ultrasonic Spot Welder Transducer For Handheld Ultrasonic Spot Welder Auto Parts Welding Machine 28KHZ 1000W Industrial Ultrasonic Spot Welding Machine Transducer Cutting Skin Scrubber Cavitation Pressure Transducer

28KHZ 1000W Industrial Ultrasonic Spot Welding Machine Transducer Cutting Skin Scrubber Cavitation Pressure Transducer High Power 40KHz Spot Welder Machine Parts Piezoelectric Ceramic Sensor Ultrasonic Welding Transducer

High Power 40KHz Spot Welder Machine Parts Piezoelectric Ceramic Sensor Ultrasonic Welding Transducer 30Khz Plastic Spot Welder Ultrasonic Piezo Transducer For Plastic Ultrasonic Welding System

30Khz Plastic Spot Welder Ultrasonic Piezo Transducer For Plastic Ultrasonic Welding System 28KHZ 300W Ultrasonic Spot Welder Transducer For Portable Ultrasonic Plastic Welding Machine

28KHZ 300W Ultrasonic Spot Welder Transducer For Portable Ultrasonic Plastic Welding Machine