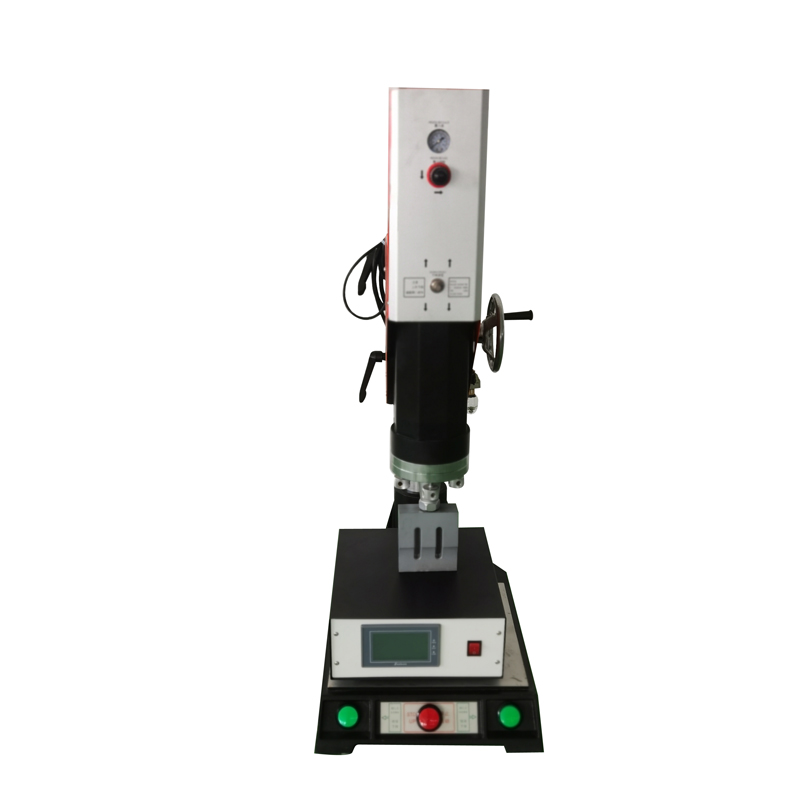

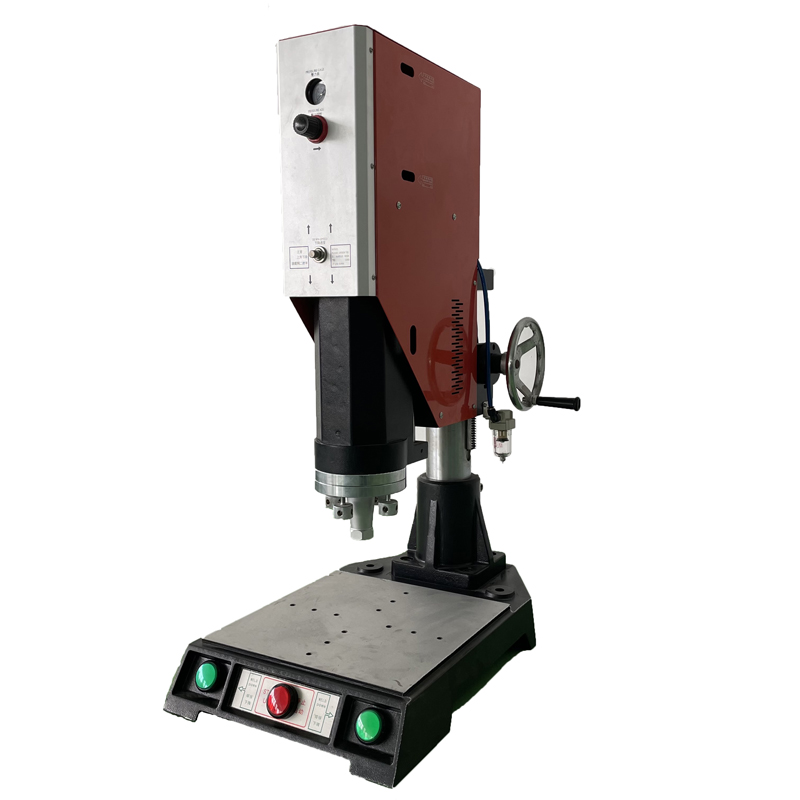

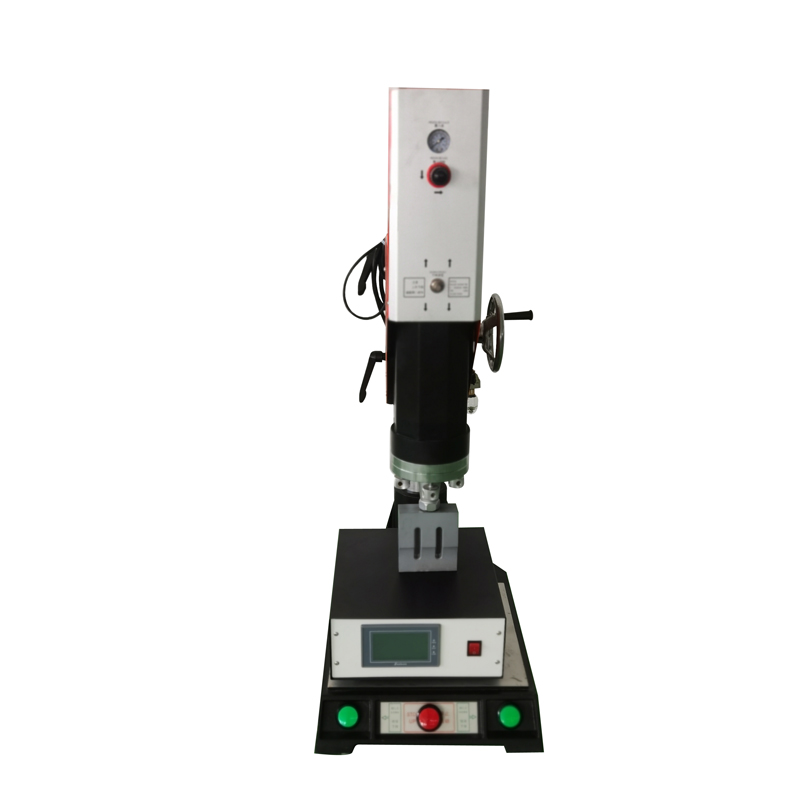

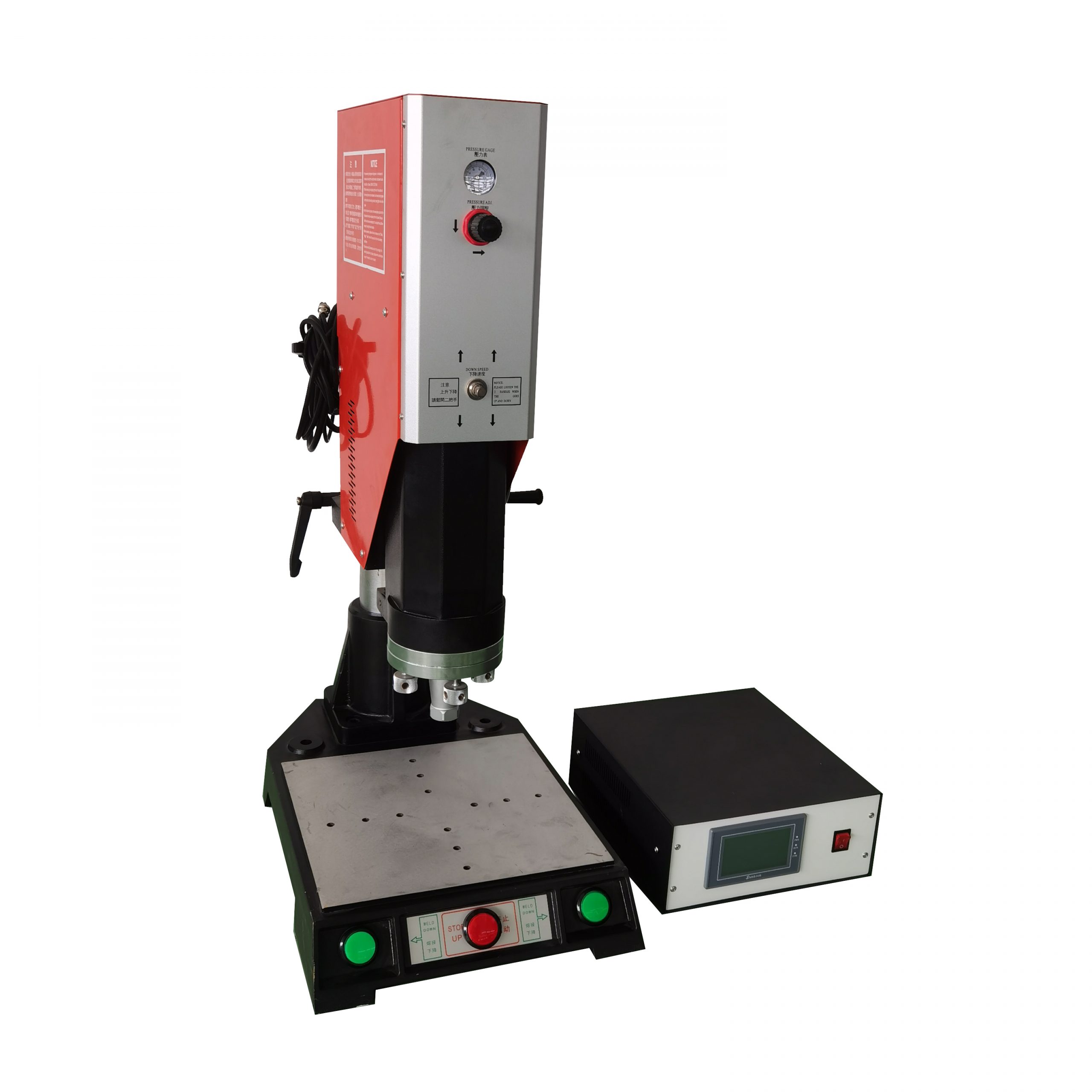

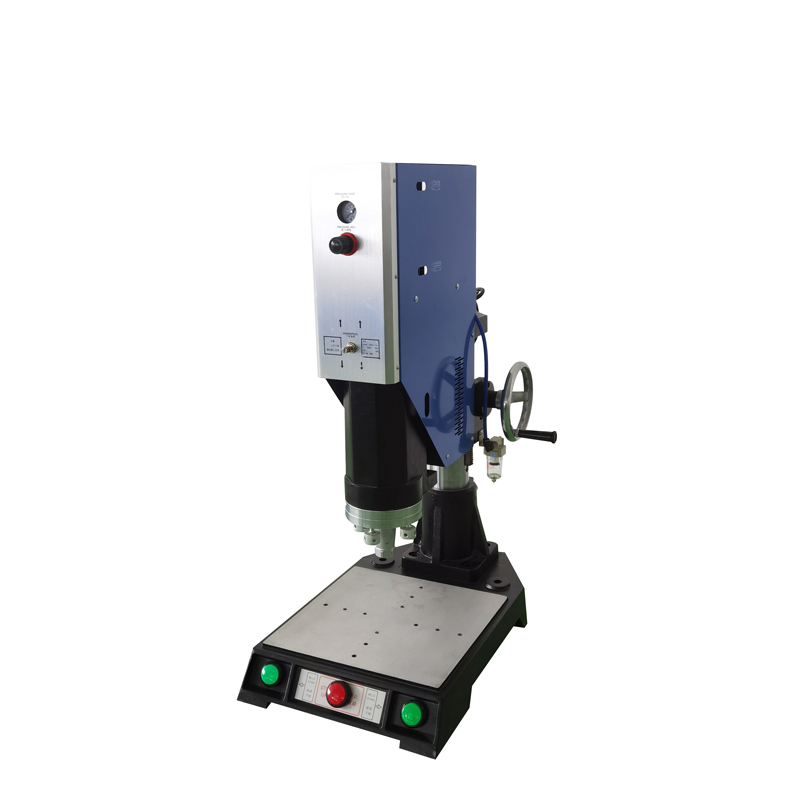

3200W 15KHZ Ultrasonic Welding Machine For Sponge Scourer Pad And Generator Control Box

The principle of ultrasonic plastic welding is that a generator generates a high-pressure and high-frequency signal of 20KHZ (or 15KHZ), which is converted into high-frequency mechanical vibration through an energy conversion system. The signal is applied to the plastic product workpiece, and the temperature from the…

3200W 15KHZ Ultrasonic Welding Machine For Sponge Scourer Pad And Generator Control Box

The principle of ultrasonic plastic welding is that a generator generates a high-pressure and high-frequency signal of 20KHZ (or 15KHZ), which is converted into high-frequency mechanical vibration through an energy conversion system. The signal is applied to the plastic product workpiece, and the temperature from the transmission point to the interface is increased through friction between the workpiece surface and internal molecular components. When the temperature reaches the melting point of the workpiece itself, the workpiece interface quickly melts, and then fills the gap between the interfaces. When the vibration stops, The workpiece is simultaneously cooled and shaped under a certain pressure to achieve welding.

When ultrasonic waves act on the contact surface of thermoplastic plastics, they generate high-frequency vibrations of tens of thousands of times per second. This high-frequency vibration reaches a certain amplitude and transmits ultrasonic energy to the welding area through the upper weldment. Due to the high sound resistance at the interface between the two welding areas, local high temperatures are generated. Due to the poor thermal conductivity of plastic, it cannot be released in a timely manner and accumulates in the welding area, causing the contact surface of the two plastics to quickly melt. After applying a certain amount of pressure, it merges into one. After the ultrasound stops working, let the pressure continue for a few seconds to solidify and form a solid molecular chain, achieving the purpose of welding. The welding strength can be close to the strength of the raw material. The quality of ultrasonic plastic welding depends on three factors: the amplitude of the transducer welding head, the applied pressure and the welding time. The welding time and the pressure of the welding head are adjustable, and the amplitude is determined by the transducer and the amplitude transformer. There is a suitable value for the interaction of these three quantities. When the energy exceeds the appropriate value, the melting amount of plastic is large, and the welded material is prone to deformation; If the energy is low, it is not easy to weld firmly, and the applied pressure should not be too large. This pressure is the product of the edge length of the welded part and the pressure per 1mm of the edge.

| Type | Power(W) | Frequency (KHz) |

| PU-UWM600W | 600W | 15KHZ/20KHZ/28KHZ/40KHZ |

| PU-UWM900W | 900W | 15KHZ/20KHZ/28KHZ/40KHZ |

| PU-UWM1000W | 1000W | 15KHZ/20KHZ/28KHZ/30KHZ |

| PU-UWM1500W | 1500W | 15KHZ/20KHZ |

| PU-UWM1800W | 1800W | 15KHZ/20KHZ |

| PU-UWM2000W | 2000W | 15KHZ/20KHZ |

| PU-UWM2600W | 2600W | 15KHZ |

| PU-UWM3200W | 3200W | 15KHZ |

| PU-UWM4200W | 4200W | 15KHZ |

3200W 15KHZ Ultrasonic Welding Machine For Sponge Scourer Pad And Generator Control Box

标签:3200W 15KHZ Ultrasonic Welding Machine, Ultrasonic Welding Machine For Sponge Scourer Pad, Ultrasonic Welding Machine For Sponge Scourer Pad And Generator Control Box

Send Inquiry

20KHz Ultrasonic Sealing Machine For Fabric Auto Plastic Parts Ultrasonic Welding Machine

20KHz Ultrasonic Sealing Machine For Fabric Auto Plastic Parts Ultrasonic Welding Machine 15kh 20kh PSA Sports Grading Card Slab Plastic Welders PSA Case Ultrasonic Sealing Welding Machine

15kh 20kh PSA Sports Grading Card Slab Plastic Welders PSA Case Ultrasonic Sealing Welding Machine Trading Card Slab Ultrasonic Welding Machine 15k 20k 2600w Sports PSA Card Slabs Ultra Sonic Welder for Pokemon Card With Mold

Trading Card Slab Ultrasonic Welding Machine 15k 20k 2600w Sports PSA Card Slabs Ultra Sonic Welder for Pokemon Card With Mold 15K 2600W Automatic Frequency Tracking Ultrasonic Welding Machine for ABS PP Plastic Welding PSA Slabs Case

15K 2600W Automatic Frequency Tracking Ultrasonic Welding Machine for ABS PP Plastic Welding PSA Slabs Case 3200W 15KHZ Ultrasonic Welding Machine For Sponge Scourer Pad And Generator Control Box

3200W 15KHZ Ultrasonic Welding Machine For Sponge Scourer Pad And Generator Control Box 15K 2600W PSA Rigid Plastic Sealing Ultrasonic Grading Playing Card Slab Cases Welding Machine

15K 2600W PSA Rigid Plastic Sealing Ultrasonic Grading Playing Card Slab Cases Welding Machine 15khz 2600W Ultrasonic Sealing Plastic Welding Machine Popular Ultrasonic Plastic Welding Machine For Welding Auto Parts

15khz 2600W Ultrasonic Sealing Plastic Welding Machine Popular Ultrasonic Plastic Welding Machine For Welding Auto Parts 15kHz Ultrasonic Plastic Welding Machine Pp Hdpe Pvc Welder Ultrasonic Plastic Welding Machine

15kHz Ultrasonic Plastic Welding Machine Pp Hdpe Pvc Welder Ultrasonic Plastic Welding Machine PSA Grading slab Card Cases Ultrasonic Welder Ultrasonic Plastic Welding Machine And Power Supply Generator

PSA Grading slab Card Cases Ultrasonic Welder Ultrasonic Plastic Welding Machine And Power Supply Generator Ear Loop Face Mask Making Machine Sewing Ultrasonic Spot Welding 35khz Ultrasonic Spot Welding Machine

Ear Loop Face Mask Making Machine Sewing Ultrasonic Spot Welding 35khz Ultrasonic Spot Welding Machine 15KHZ/20KHZ Auto Frequency Manual Ultrasonic Welding Machine For Plastic And Textile

15KHZ/20KHZ Auto Frequency Manual Ultrasonic Welding Machine For Plastic And Textile 20KHz Ultrasonic Plastic Welding Machine For Automotive Seat Keyboard Plate And Sound Generator

20KHz Ultrasonic Plastic Welding Machine For Automotive Seat Keyboard Plate And Sound Generator