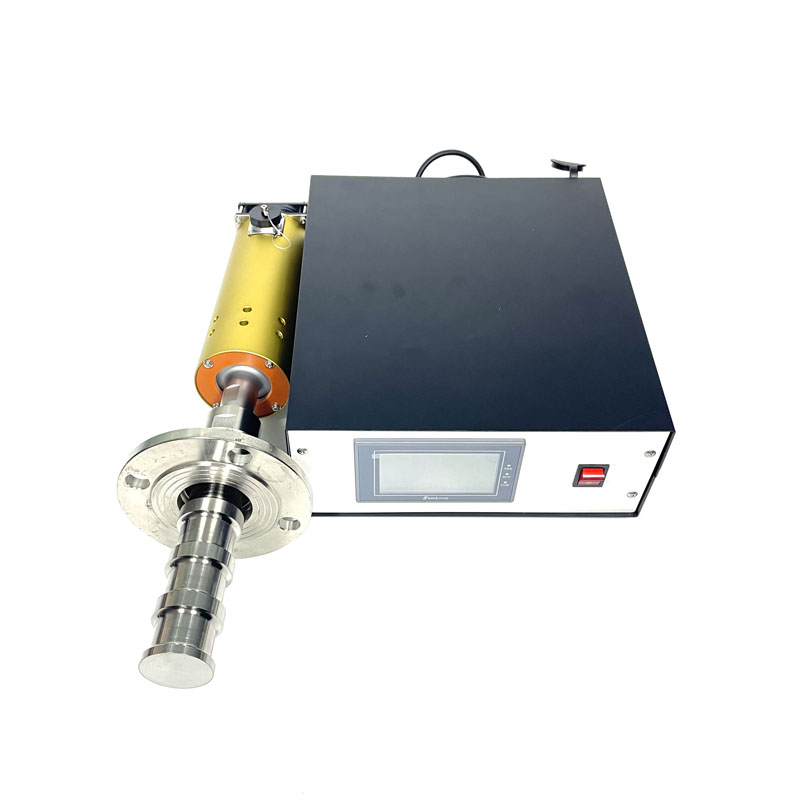

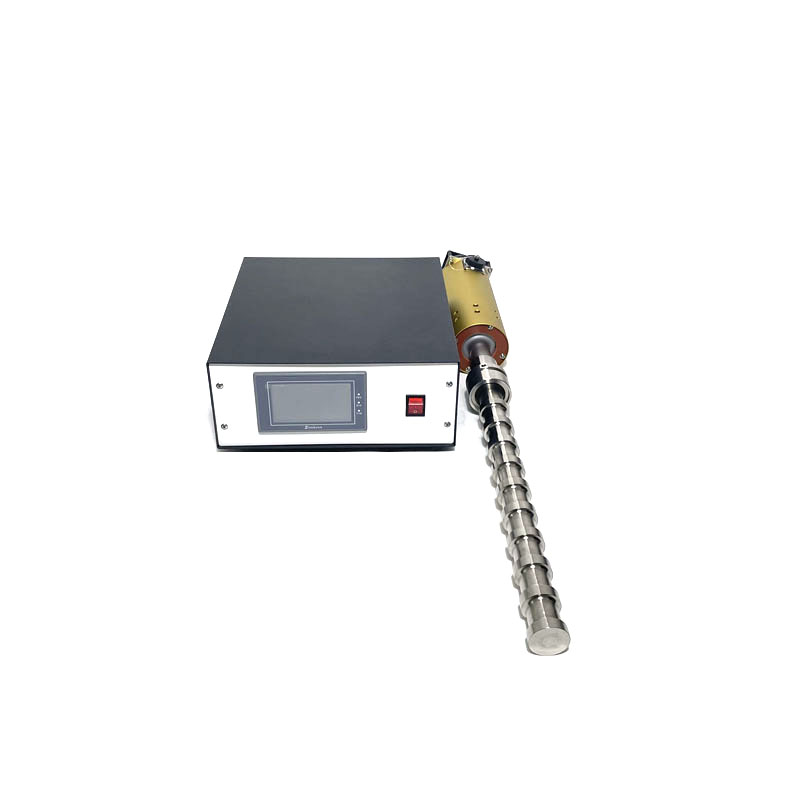

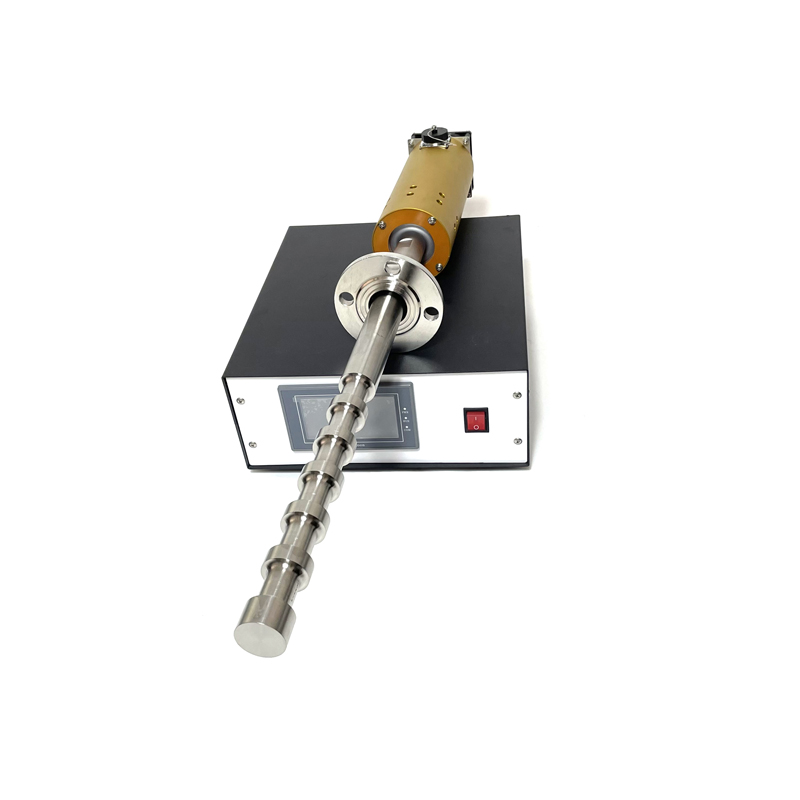

3000W Ultrasonic Tubular Transducer Submersible Cleaner Vibration Rods For Biodiesel Refining Mixed Emulsification

The structure design of high-power concentrated ultrasonic vibration rod is scientific and reasonable. By introducing room temperature air with a lower temperature than the inner cavity into the sealed ultrasonic vibration rod cavity, the heat generated by ultrasonic vibration can be adsorbed and carried out of the u…

The structure design of high-power concentrated ultrasonic vibration rod is scientific and reasonable. By introducing room temperature air with a lower temperature than the inner cavity into the sealed ultrasonic vibration rod cavity, the heat generated by ultrasonic vibration can be adsorbed and carried out of the ultrasonic vibration rod cavity by the relatively low temperature room temperature air during the use of the ultrasonic vibration rod, thereby avoiding the piezoelectric ceramic oscillator inside the ultrasonic vibration rod from continuously maintaining a certain high temperature state, Greatly eliminates damage to piezoelectric ceramic oscillators during high-temperature use.

The high-power concentrated energy ultrasonic vibrating rod includes an ultrasonic vibrating rod, which is connected to the ultrasonic transducer through a horn, and the ultrasonic transducer is connected to the ultrasonic generator. A cavity is set in the ultrasonic vibrating rod, and a number of piezoelectric ceramic vibrators are fixed on the inner wall of the cavity. The piezoelectric ceramic vibrators are electrically connected to the horn through wires, and the horn is electrically connected to the ultrasonic transducer through wires.

High power shaped ultrasonic vibrator can be used in industry for cleaning, extraction, chemical reaction, scale prevention or water treatment. Ultrasonic treatment can be carried out by turning on the ultrasonic generator and ultrasonic transducer.

| Tubular EquipmentType | Tubular TransducerType | Frequency(KHz) | UltrasoundOutput(W) | Total Length(mm) | Diameter(mm) | Static Capacity(pF±10%) |

| PU-UE1 | US-61 | 15-28 | 1000 | 500 | Φ50-55 | 68000 |

| PU-UE5 | US-25 | 15-28 | 1500 | 850 | Φ50-55 | 68000 |

| PU-UE6 | US-16 | 15-28 | 2000 | 1100 | Φ50-55 | 132000 |

标签:high-power concentrated ultrasonic vibration rod, Ultrasonic Tubular Transducer Submersible Cleaner Vibration Rods

Send Inquiry

20KHZ 2000W 220V Ultrasonic Chemical Sonochemistry Dispersed Reactor For Laboratory Industry

20KHZ 2000W 220V Ultrasonic Chemical Sonochemistry Dispersed Reactor For Laboratory Industry 2000W 20KHZ Ultrasonic Processor Sonochemistry Biodiesel Reactor Laboratory Ultrasonic Sonochemistry Biodiesel Reactor

2000W 20KHZ Ultrasonic Processor Sonochemistry Biodiesel Reactor Laboratory Ultrasonic Sonochemistry Biodiesel Reactor Ultrasonic Disruption And Extraction Ultrasonic Processor Homogenizer Mixer Extraction Sonicator Dispersion

Ultrasonic Disruption And Extraction Ultrasonic Processor Homogenizer Mixer Extraction Sonicator Dispersion 1000W Ultrasonic Liquid Sonochemistry Reactor And Power Generator For Ultrasonic Sonochemistry Machine

1000W Ultrasonic Liquid Sonochemistry Reactor And Power Generator For Ultrasonic Sonochemistry Machine Ultrasonic Processor Laboratory Ultrasonic Emulsifying Homogenizer And Generator Control Box

Ultrasonic Processor Laboratory Ultrasonic Emulsifying Homogenizer And Generator Control Box 1000W Industry Ultrasonic Biodiesel Oil Ultrasonic Sonochemistry Reactor And Power Supply Generator

1000W Industry Ultrasonic Biodiesel Oil Ultrasonic Sonochemistry Reactor And Power Supply Generator 20KHZ 500W/1000W Ultrasonic Laboratory Processors Ultrasonic Sonochemistry Homogenize Liquids

20KHZ 500W/1000W Ultrasonic Laboratory Processors Ultrasonic Sonochemistry Homogenize Liquids 2000W Ultrasonic Cavitation Reactor Biodiesel Underwater Acoustic Ultrasonic Tubular Transducer

2000W Ultrasonic Cavitation Reactor Biodiesel Underwater Acoustic Ultrasonic Tubular Transducer 20khz 2000W Ultrasonic Rod Transducer Biodiesel Ultrasonic Homogenizing Emulsification Ultrasonic

20khz 2000W Ultrasonic Rod Transducer Biodiesel Ultrasonic Homogenizing Emulsification Ultrasonic 2000W Ultrasonic Sonochemistry Reactor Ultrasonic Assisted Extraction Method

2000W Ultrasonic Sonochemistry Reactor Ultrasonic Assisted Extraction Method Industrial Ultrasonic Vibrating Rod Reactor Separation Emulsification Homogenization Refining

Industrial Ultrasonic Vibrating Rod Reactor Separation Emulsification Homogenization Refining 2000W 3000W 50L Vacuum Jacketed Glass Emulsifier Mixing Stirred Ultrasonic Homogenizer Reactor With Lcd Display Generator

2000W 3000W 50L Vacuum Jacketed Glass Emulsifier Mixing Stirred Ultrasonic Homogenizer Reactor With Lcd Display Generator