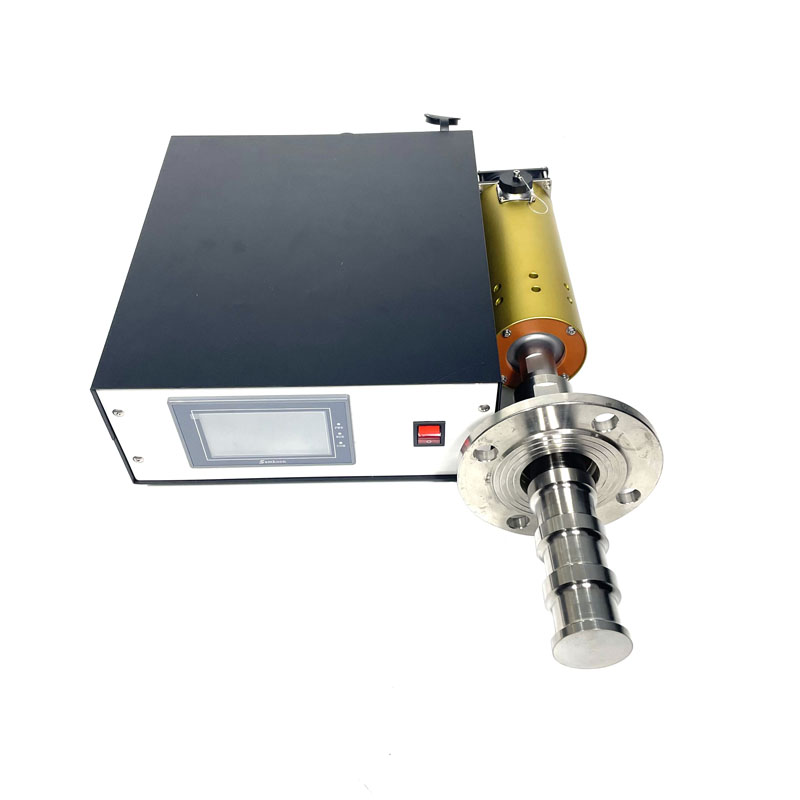

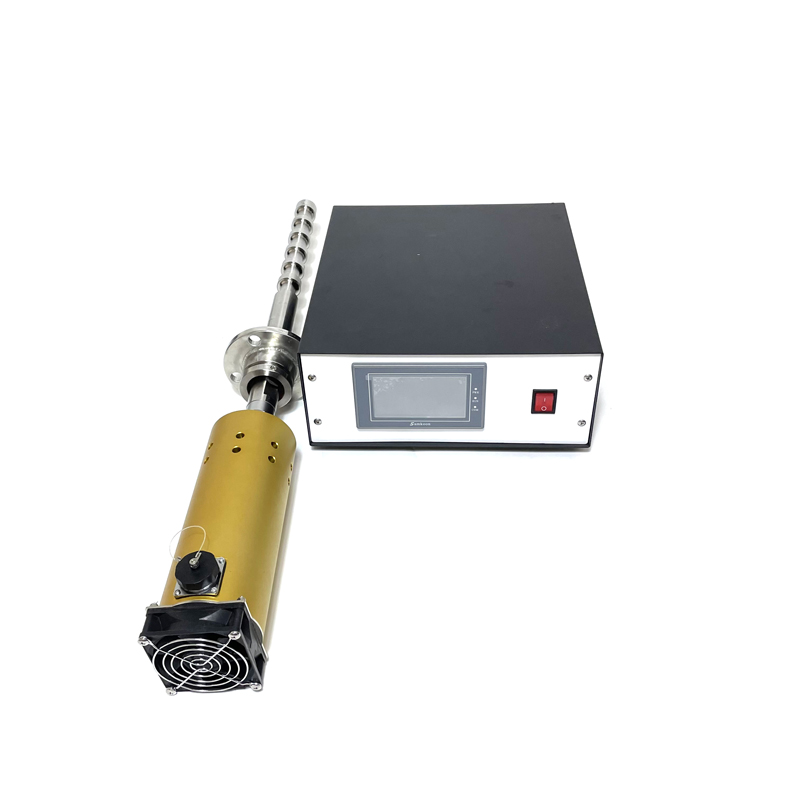

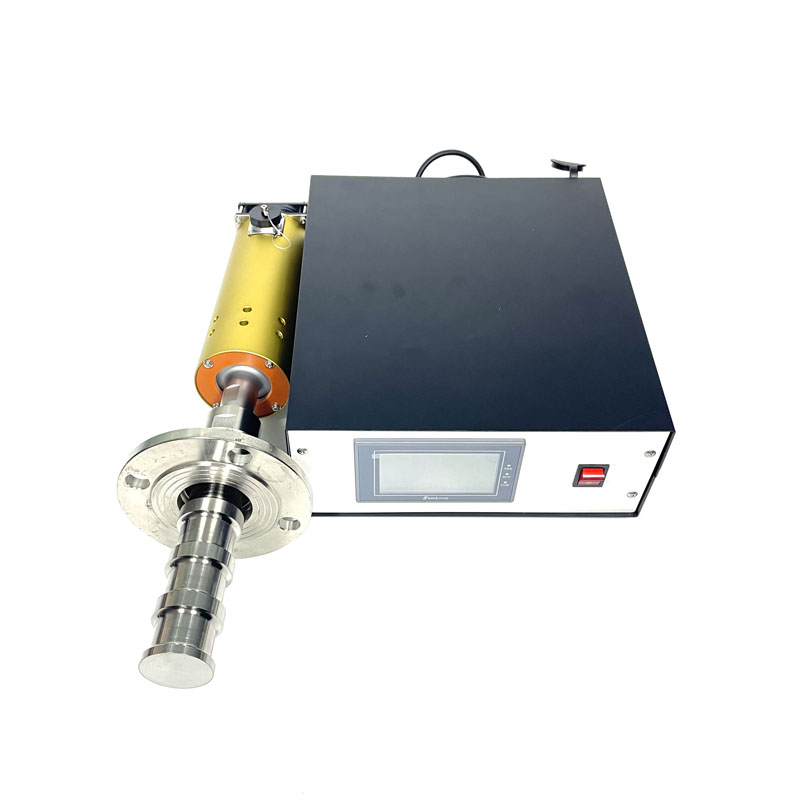

3000W Laboratory Industrial Ultrasonic Food Homogenizer Ultrasonic Homogenizer And Vibrating Generator

The shaped ultrasonic vibrating rod uses cavitation to generate vibration from around the vibrating rod. The ultrasonic energy of the shaped ultrasonic vibrating rod is evenly distributed around the tank reactor, in order to achieve the best emulsification, mixing and dispersion effect. The concentrated energy ultras…

The shaped ultrasonic vibrating rod uses cavitation to generate vibration from around the vibrating rod. The ultrasonic energy of the shaped ultrasonic vibrating rod is evenly distributed around the tank reactor, in order to achieve the best emulsification, mixing and dispersion effect. The concentrated energy ultrasonic vibrating rod is applied in emulsification, separation, homogenization, extraction, macromolecules, and other aspects to improve production capacity. The use of concentrated energy ultrasonic vibration rods has played an undeniable role in uniform mixing, as they play a crucial role in homogenization. The catalytic effect of the concentrated energy ultrasonic vibration rod is extremely amazing, with an efficiency increase of multiple times, which needs to be applied in the chemical industry or has broad prospects.

In my opinion, the concentrated energy ultrasonic vibration rod has unique advantages in low extraction temperature, high extraction rate, and short extraction time. It is applied to extract the effective content of traditional Chinese medicinal materials, oils, and various animals and plants. In my opinion, it is an alternative to traditional shear technology methods to achieve efficient, energy-saving, and environmentally friendly old-fashioned extraction. In short, modern technology and high-tech means.

The power output of the shaped ultrasonic vibration rod is not affected by load changes such as liquid level, tank capacity, and temperature difference, and the power output is stable and uniform. The shaped ultrasonic vibrating rod has a service life and effect that is more than twice that of a traditional ultrasonic vibrating plate.

| Tubular EquipmentType | Tubular TransducerType | Frequency(KHz) | UltrasoundOutput(W) | Total Length(mm) | Diameter(mm) | Static Capacity(pF±10%) |

| PU-UE1 | US-61 | 15-28 | 1000 | 500 | Φ50-55 | 68000 |

| PU-UE5 | US-25 | 15-28 | 1500 | 850 | Φ50-55 | 68000 |

| PU-UE6 | US-16 | 15-28 | 2000 | 1100 | Φ50-55 | 132000 |

标签:3000W Laboratory Industrial Ultrasonic Food Homogenizer, shaped ultrasonic vibrating rod, Ultrasonic Homogenizer And Vibrating Generator

Send Inquiry

3000W 20KHZ Industrial Ultrasonic Nano Dispersing Machine And Generator Control Box

3000W 20KHZ Industrial Ultrasonic Nano Dispersing Machine And Generator Control Box 300ml Cell Disruption Emulsifying Mini Handheld Ultrasonic Liquid Processor Homogenizer Sonicator

300ml Cell Disruption Emulsifying Mini Handheld Ultrasonic Liquid Processor Homogenizer Sonicator 20KHZ 900W 220V Ultrasonic Emulsification Homogenizer Plant Oil Extraction For Nanoemulsion Mixing

20KHZ 900W 220V Ultrasonic Emulsification Homogenizer Plant Oil Extraction For Nanoemulsion Mixing Industrial Ultrasonic Emulsifier Biodiesel Processor Reactor 20khz 1000W Sonochemistry Ultrasonic Biodiesel

Industrial Ultrasonic Emulsifier Biodiesel Processor Reactor 20khz 1000W Sonochemistry Ultrasonic Biodiesel 3000W 20KHZ Ultrasonic Flow-Through Reactor Processor Dispersion Extraction Sonochemistry Reactor

3000W 20KHZ Ultrasonic Flow-Through Reactor Processor Dispersion Extraction Sonochemistry Reactor Biodiesel Ultrasonic Sonochemistry Reactor Ultrasonic Emulsifying Homogenizer Sonochemistry Processor Reactor

Biodiesel Ultrasonic Sonochemistry Reactor Ultrasonic Emulsifying Homogenizer Sonochemistry Processor Reactor 20KHZ Ultrasonic Emulsifier Biodiesel Reactor Industrial Ultrasonic Liquid Sonochemistry Processor

20KHZ Ultrasonic Emulsifier Biodiesel Reactor Industrial Ultrasonic Liquid Sonochemistry Processor Laboratory Ultrasonic Emulsifier Homogenizer And Processor Mixer Disrupter Reactor With Ultrasonic Generator

Laboratory Ultrasonic Emulsifier Homogenizer And Processor Mixer Disrupter Reactor With Ultrasonic Generator Industrial Plant Herb Oil Extraction Machine Centrifugal Extractor Extraction

Industrial Plant Herb Oil Extraction Machine Centrifugal Extractor Extraction Industrial Ultrasonic Extraction Machine Biodiesl Reactor Ultrasonic Liquid Processor Reactor Homogenizer Liquid Processor

Industrial Ultrasonic Extraction Machine Biodiesl Reactor Ultrasonic Liquid Processor Reactor Homogenizer Liquid Processor 3000W Ultrasonic Tubular Transducer Submersible Cleaner Vibration Rods For Biodiesel Refining Mixed Emulsification

3000W Ultrasonic Tubular Transducer Submersible Cleaner Vibration Rods For Biodiesel Refining Mixed Emulsification 20KHZ 2000W 220V Ultrasonic Sonochemistry Reactor Disperser Emulsifying Homogenizer For Hemp Oil Extraction

20KHZ 2000W 220V Ultrasonic Sonochemistry Reactor Disperser Emulsifying Homogenizer For Hemp Oil Extraction