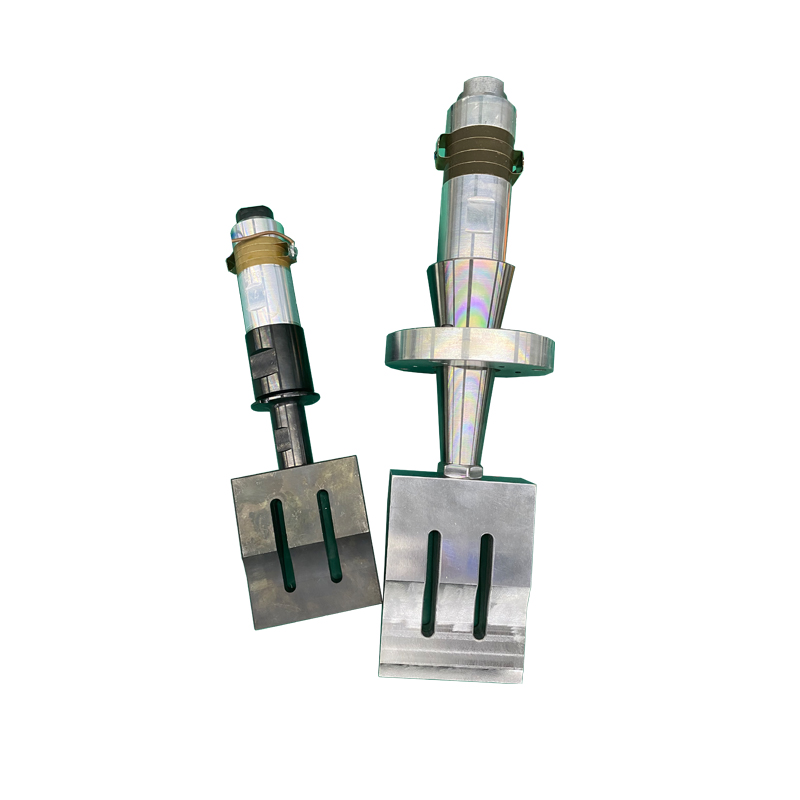

3000W 20KHZ Ultrasonic Welding Transducer With Booster Horn For Plastic Slabs Case Sealing Ultrasonic Welding Machine

The application of ultrasonic welding transducers is very extensive, mainly involving fields such as electronics, automotive, medical, packaging, etc. In the field of electronics, ultrasonic welding transducers are mainly used to connect components on printed circuit boards, such as capacitors, resistors, etc. In the…

The application of ultrasonic welding transducers is very extensive, mainly involving fields such as electronics, automotive, medical, packaging, etc. In the field of electronics, ultrasonic welding transducers are mainly used to connect components on printed circuit boards, such as capacitors, resistors, etc. In the automotive field, ultrasonic welding transducers are mainly used for connecting body structural components, such as car doors, roofs, etc. In the medical field, ultrasonic welding transducers are mainly used in the manufacturing and repair of medical devices, such as surgical knives, syringes, etc. In the field of packaging, ultrasonic welding transducers are mainly used for connecting and fixing packaging materials, such as paper boxes, plastic bags, etc.

With the continuous progress of technology and the increasing demand for applications, the development trend of ultrasonic welding transducers is mainly manifested in the following aspects: first, efficiency, that is, improving welding speed and reducing energy consumption; The second is miniaturization, which means achieving smaller areas and finer welding; The third is intelligence, which means realizing the automation and intelligence of the welding process through automatic control systems; The fourth is multifunctionality, which means realizing the welding of multiple materials and the realization of multiple connection methods.

| Type | Full-length(mm) | Joint Bolt(mm) | Frequency(KHz) | Resonance Impedance(Ω) | Capacity(pF) | Input Power (W) |

| PLS-HJHNQ152600 | 153 | M20×1.5 | 15 | 15 | 13000 | 2600 |

| PLS-HJHNQ152000 | 167 | M20×1.5 | 15 | 10 | 9500 | 2000 |

| PLS-HJHNQ202000 | 128 | M18×1 | 20 | 10 | 11000 | 2000 |

| PLS-HJHNQ30500 | 77 | M10×1.5 | 30 | 5 | 5500 | 500 |

| PLS-HJHNQ28200 | 92.1 | M10×1 | 28 | 20 | 3000 | 200 |

| PLS-HJHNQ28100 | 91 | M8×1 | 28 | 25 | 2200 | 100 |

| PLS-HJHNQ28250 | 94 | 1/2-20 UNF | 28 | 20 | 4000 | 250 |

| PLS-HJHNQ202000 | 128 | 1/2-20 UNF | 20 | 10 | 20000 | 2000 |

| PLS-HJHNQ201500 | 124 | 1/2-20 UNF | 20 | 10 | 16000 | 1500 |

| PLS-HJHNQ38100 | 66 | M8×1.25 | 38 | 40 | 1200 | 100 |

| PLS-HJHNQ38200 | 65 | M8×1 | 38 | 14 | 3300 | 200 |

标签:20KHZ Ultrasonic Welding Transducer With Booster Horn, Plastic Slabs Case Sealing Ultrasonic Welding Machine

Send Inquiry

20KHZ 2000W PZT8 High Power Ultrasonic Welding Transducer Booster Horn Vibrator Sensor For Non Woven Ultrasonic Spot Welder

20KHZ 2000W PZT8 High Power Ultrasonic Welding Transducer Booster Horn Vibrator Sensor For Non Woven Ultrasonic Spot Welder Ultrasonic Welding Transducer With Booster And Horn For Automatic Ultrasonic Welding Machine

Ultrasonic Welding Transducer With Booster And Horn For Automatic Ultrasonic Welding Machine Piezoelectric Ultrasonic Welding Transducer With Booster Horn For Sponge Cloth Ultrasonic Plastic Welding Machine

Piezoelectric Ultrasonic Welding Transducer With Booster Horn For Sponge Cloth Ultrasonic Plastic Welding Machine 2600W 15KHZ/20KHZ Ultrasonic Waves Welder Converter Horn For Plastic Ultrasonic Welding Machine

2600W 15KHZ/20KHZ Ultrasonic Waves Welder Converter Horn For Plastic Ultrasonic Welding Machine 3000W 15KHZ Ultrasonic Welding Transducer With Booster Horn For Pet Pc Pe Ultrasonic Plastic Welding Machine

3000W 15KHZ Ultrasonic Welding Transducer With Booster Horn For Pet Pc Pe Ultrasonic Plastic Welding Machine High Power Ultrasonic Welding Transducer Booster Horn For Ultrasonic Plastic Welding Machine

High Power Ultrasonic Welding Transducer Booster Horn For Ultrasonic Plastic Welding Machine Ultrasonic Metal Welding Transducer With Booster Horn For Smart Card Ultrasonic Metal Welding Machine

Ultrasonic Metal Welding Transducer With Booster Horn For Smart Card Ultrasonic Metal Welding Machine Industrial Ultrasonic Welding Transducer With Booster Horn For Cards Psa Grading Card Ultrasonic Plastic Welding Machine

Industrial Ultrasonic Welding Transducer With Booster Horn For Cards Psa Grading Card Ultrasonic Plastic Welding Machine 2000W 15KHZ/20KHZ Small Ultrasonic Welder Converter Horn For Ultrasonic Welder Machine

2000W 15KHZ/20KHZ Small Ultrasonic Welder Converter Horn For Ultrasonic Welder Machine 1800W 15KHZ 20KHZ Ultrasonic Welding Transducer With Booster Horn For Plastic Lamp Packaging Carton Ultrasonic Welding Machine

1800W 15KHZ 20KHZ Ultrasonic Welding Transducer With Booster Horn For Plastic Lamp Packaging Carton Ultrasonic Welding Machine Piezoelectric Ultrasonic Welding Transducer With Booster Horn For Sponge Cloth Ultrasonic Plastic Welding Machine

Piezoelectric Ultrasonic Welding Transducer With Booster Horn For Sponge Cloth Ultrasonic Plastic Welding Machine 4000W 15KHZ Industrial Ultrasonic Welding Transducer Booster Horn Converter Transducer For Ultrasonic Seamless Sealing Welding Machine

4000W 15KHZ Industrial Ultrasonic Welding Transducer Booster Horn Converter Transducer For Ultrasonic Seamless Sealing Welding Machine