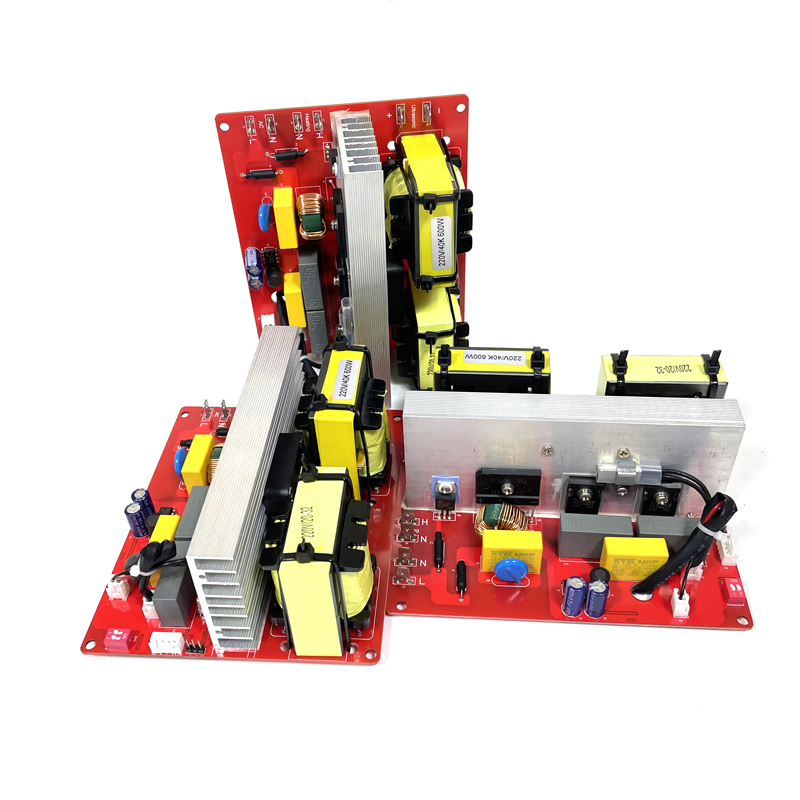

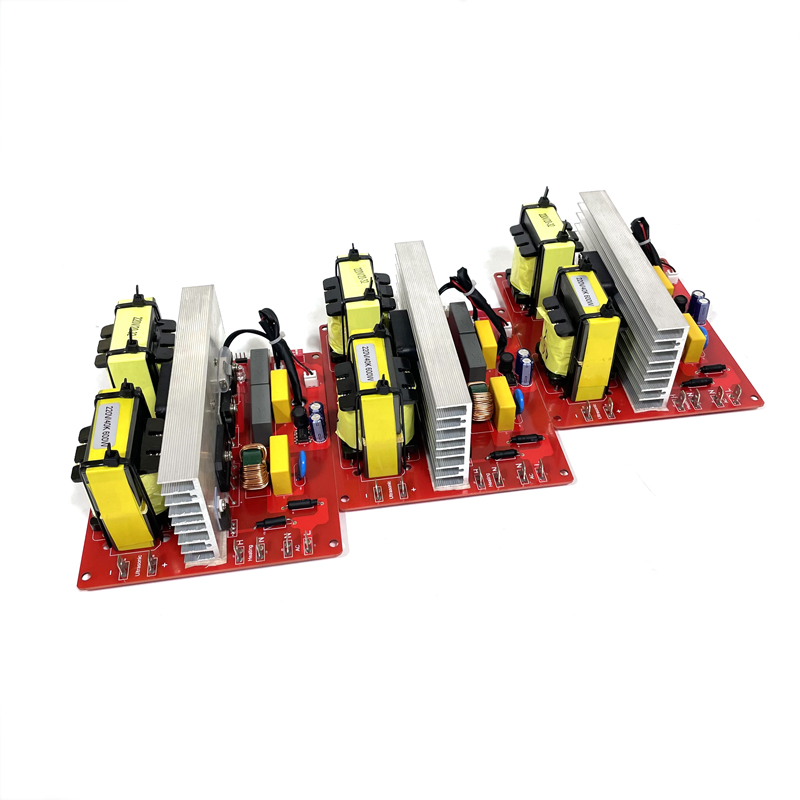

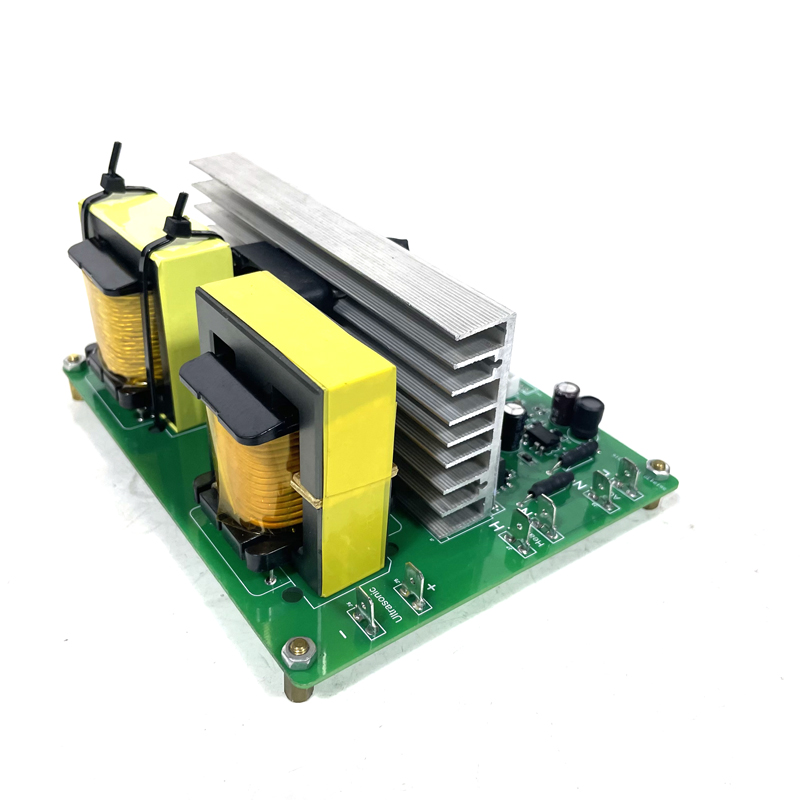

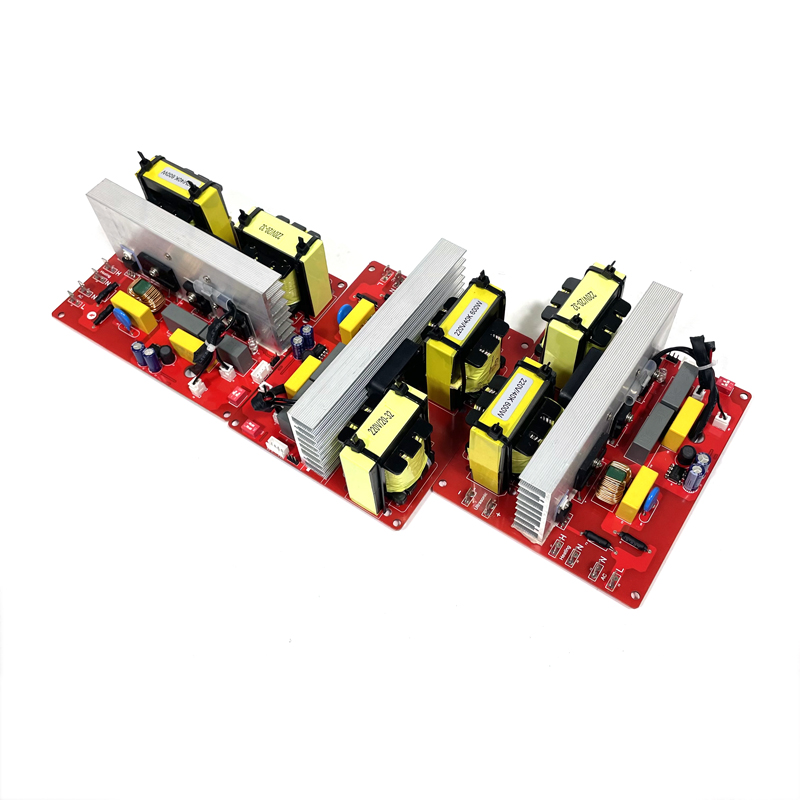

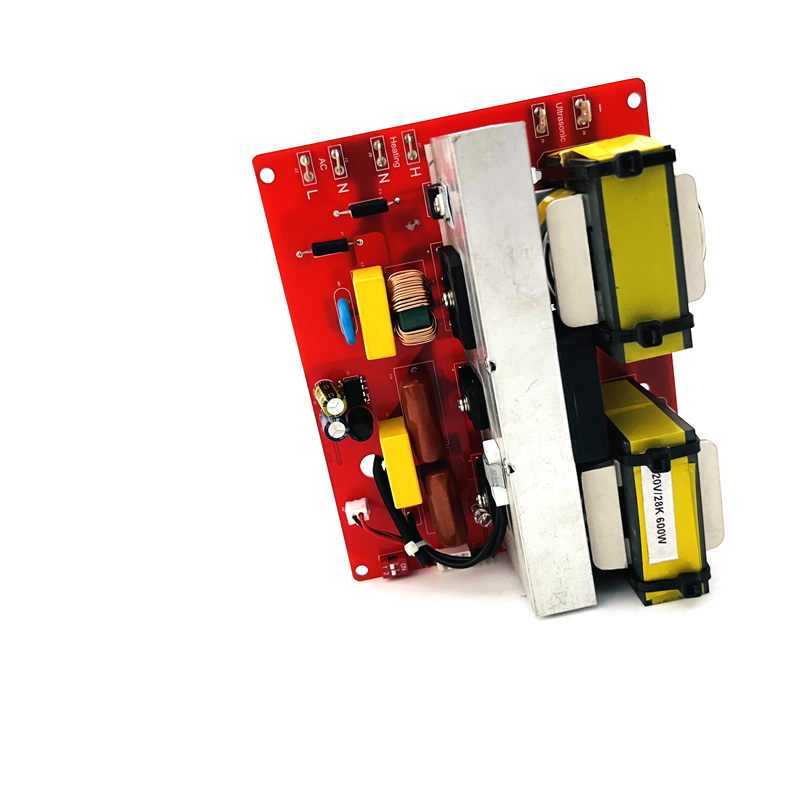

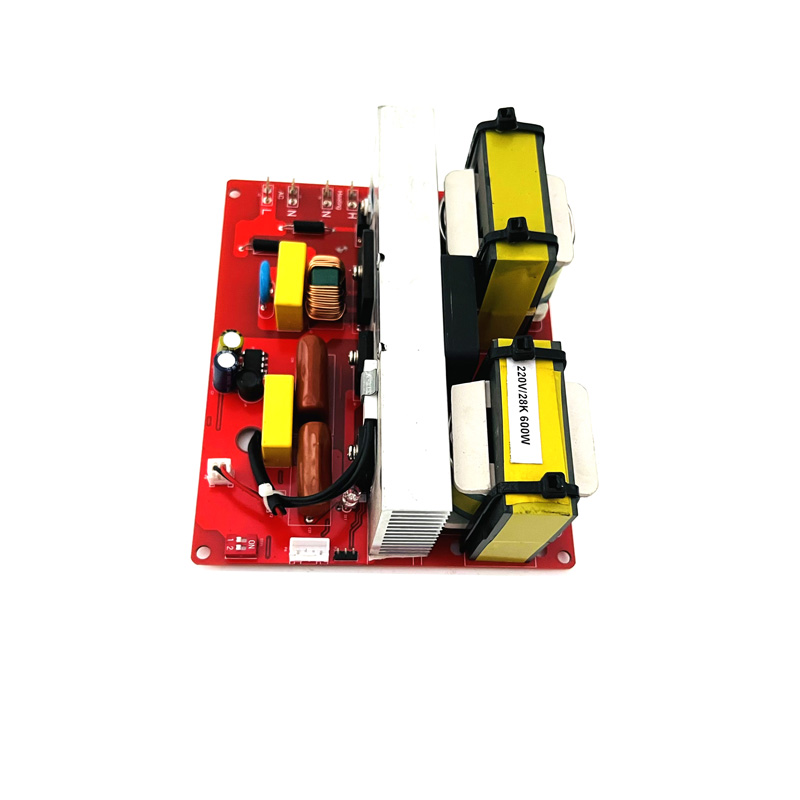

28KHZ 2000W 220V Digital Ultrasonic Generator PCB Parts Circuit Board For 200L Industrial Ultrasonic Cleaner

The 40khz 60W/120W ultrasonic circuit board adopts the circuit form of switching power supply, and is the energy provider in all ultrasonic application fields. Due to the influence of the working environment (such as temperature, pressure, etc.), the resonance frequency of the ultrasonic transducer will drift. In ord…

The 40khz 60W/120W ultrasonic circuit board adopts the circuit form of switching power supply, and is the energy provider in all ultrasonic application fields. Due to the influence of the working environment (such as temperature, pressure, etc.), the resonance frequency of the ultrasonic transducer will drift. In order to keep the transducer in the resonance state, the output voltage frequency of the ultrasonic power supply must always follow the resonance frequency of the ultrasonic transducer.

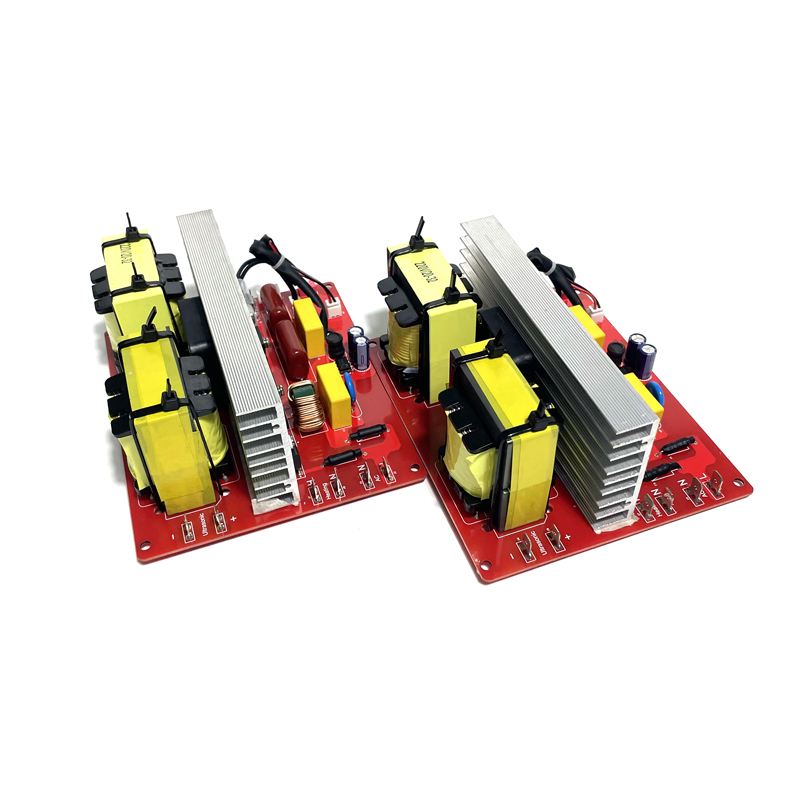

The traditional frequency tracking methods for ultrasonic power supply on 40khz 60W/120W ultrasonic circuit boards include maximum current search resonance frequency method, phase-locked loop frequency tracking method, and matching inductance adjustment method. Among them, the maximum current search resonant frequency method is to collect the maximum current of the transducer circuit by taking advantage of the characteristics of the ultrasonic transducer that has the smallest impedance and the largest output current under the resonant frequency state, and compare the frequency corresponding to the maximum current, that is, the resonant frequency of the transducer. This method requires the power supply to sweep the frequency of the transducer. The speed of frequency tracking is restricted by the sweep period, and the starting time is long.

The 40khz 60W/120W ultrasonic circuit board phase-locked loop frequency tracking method changes the alternating frequency of the output voltage by sampling the phase relationship between the output voltage and current of the power supply to achieve the resonance effect of the transducer circuit. Its tracking accuracy is higher than that of the maximum current method, which can achieve better resonance effect, but its working bandwidth is narrow. The matching inductance adjustment method is to adjust the phase difference of the output voltage and current of the power supply by adjusting the size of the matching inductance of the transducer circuit, while the output frequency of the power supply remains unchanged, in order to achieve the resonance of the transducer circuit. This method has low control accuracy and is often achieved through manual control in many situations. It is not recommended to use it in fields with high accuracy requirements and is generally used as an auxiliary control for other frequency tracking methods.

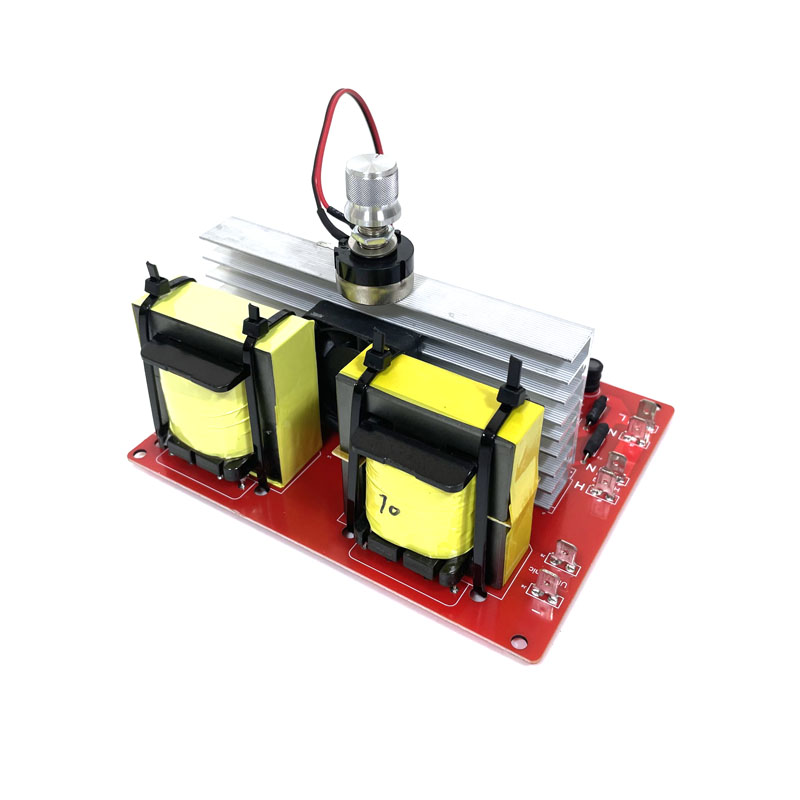

| Type | Power(W) | Frequency (KHz) |

| PU-PCB200W | 200 | 20khz,25khz,28khz,33khz,40khz Frequency is adjustable 50khz,54khz,60khz,68khz,80khz,90khz 100khz,120khz,135khz,165khz,200khz |

| PU-PCB300W | 300 | 20khz,25khz,28khz,33khz,40khz Frequency is adjustable 50khz,54khz,60khz,68khz,80khz,90khz 100khz,120khz,135khz |

| PU-PCB400W | 400 | 20khz,25khz,28khz,33khz,40khz Frequency is adjustable |

| PU-PCB500W | 500 | 20khz,25khz,28khz,33khz,40khz Frequency is adjustable |

| PU-PCB600W | 600 | 20khz,25khz,28khz,33khz,40khz Frequency is adjustable |

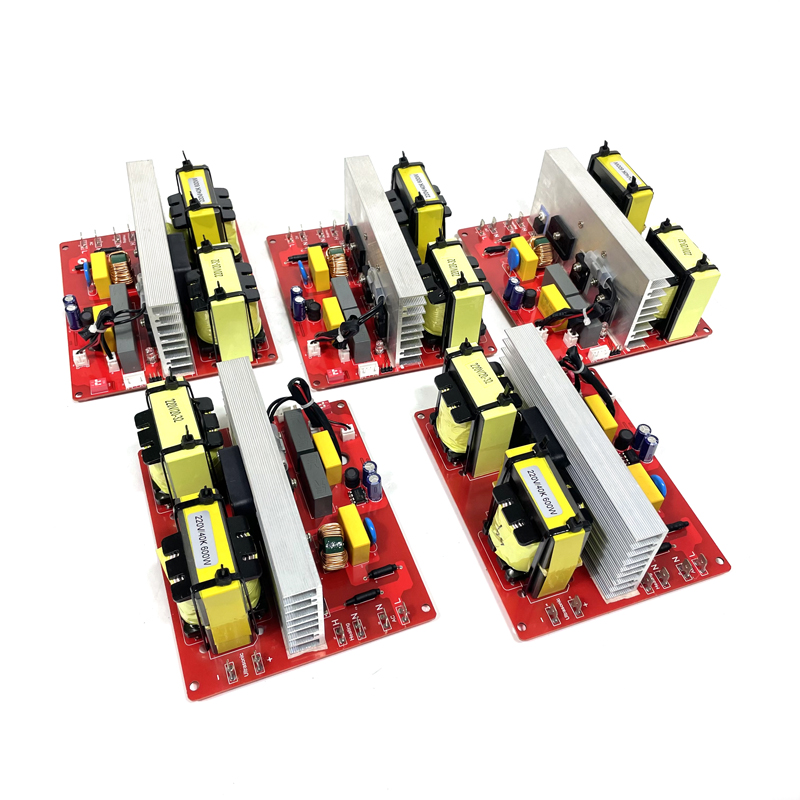

标签:200L Industrial Ultrasonic Cleaner, 28KHZ 2000W 220V Digital Ultrasonic Generator PCB Parts Circuit Board, Ultrasonic Generator PCB Parts Circuit Board

Send Inquiry

25KHZ 300W Ultrasonic Generator Kit for PCB Driver Circuit Board For Cleaning System

25KHZ 300W Ultrasonic Generator Kit for PCB Driver Circuit Board For Cleaning System 1500W-2500W Ultrasonic PCB Generator Circuit Control Board Driving Ultrasonic Cleaner Transducer

1500W-2500W Ultrasonic PCB Generator Circuit Control Board Driving Ultrasonic Cleaner Transducer 500W Ultrasonic Sound Generator Control Board 300W Power And Timer Adjustable Ultrasonic PCB Circuit Generator

500W Ultrasonic Sound Generator Control Board 300W Power And Timer Adjustable Ultrasonic PCB Circuit Generator Ultrasonic PCB Circuit Motherboard 40KHZ 300W Ultrasonic Generator Kit Circuit PCB Board Piezo Transducer Driver Circuit

Ultrasonic PCB Circuit Motherboard 40KHZ 300W Ultrasonic Generator Kit Circuit PCB Board Piezo Transducer Driver Circuit 17khz-40khz AdjuStable Frequency Digital Ultrasonic PCB Generator For Ultrasonic Cleaning Tank

17khz-40khz AdjuStable Frequency Digital Ultrasonic PCB Generator For Ultrasonic Cleaning Tank 600W Ultrasonic Sound Generator Power Circuit Board China Discount Ultrasonic PCB Generator Suppliers Factory

600W Ultrasonic Sound Generator Power Circuit Board China Discount Ultrasonic PCB Generator Suppliers Factory 40Khz 1200W Digital Display Ultrasonic Circuit Board Pcb Drive Boards For Ultrasonic Cleaner Parts Generato

40Khz 1200W Digital Display Ultrasonic Circuit Board Pcb Drive Boards For Ultrasonic Cleaner Parts Generato 240W Single Frequency Ultrasonic PCB Generator And Vibration Cleaning Transducer For Digital Ultrasonic Cleaner

240W Single Frequency Ultrasonic PCB Generator And Vibration Cleaning Transducer For Digital Ultrasonic Cleaner 600W 40KHZ Ultrasonic Generator PCB Board Driver Circuit Ultrasonic Cleaner PCB Driver Boards Circuit Board Kit

600W 40KHZ Ultrasonic Generator PCB Board Driver Circuit Ultrasonic Cleaner PCB Driver Boards Circuit Board Kit 400W 25KHZ-40KHZ Ultrasonic Control Board PCB Generator Circuit For Control Time And Temperature Ultrasonic Cleaner

400W 25KHZ-40KHZ Ultrasonic Control Board PCB Generator Circuit For Control Time And Temperature Ultrasonic Cleaner Ultrasonic Pcb Control Board 28kHz 40kHz Piezoceramic Ultrasonic Transducer Driver Board For Ultrasonic Cleaner

Ultrasonic Pcb Control Board 28kHz 40kHz Piezoceramic Ultrasonic Transducer Driver Board For Ultrasonic Cleaner Ultrasonic Power Supply High Accuracy Circuit Board PCB Ultrasonic Generator PCB Transducer Driving Power Supply

Ultrasonic Power Supply High Accuracy Circuit Board PCB Ultrasonic Generator PCB Transducer Driving Power Supply