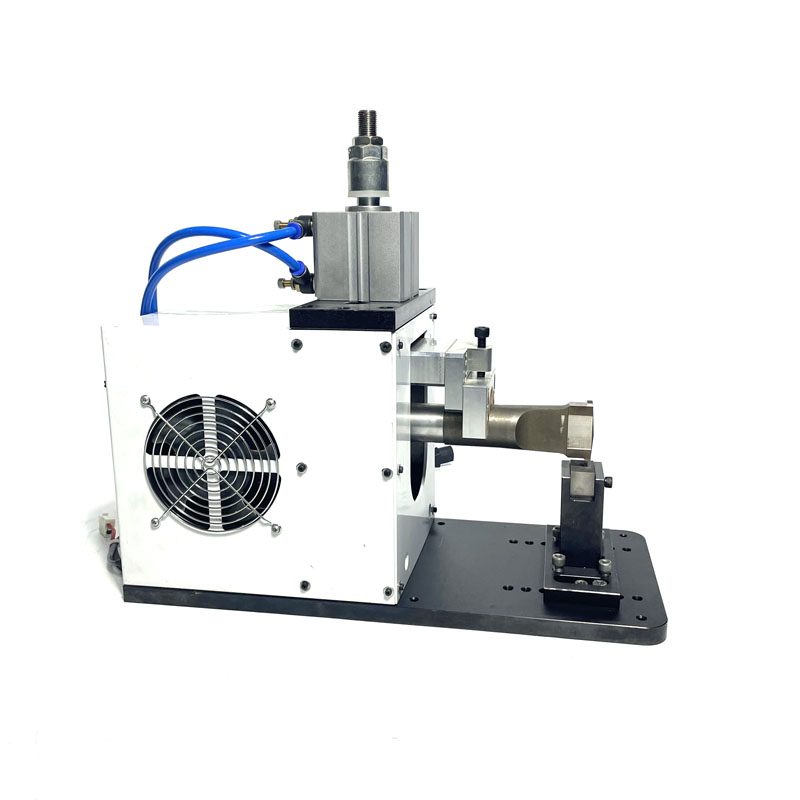

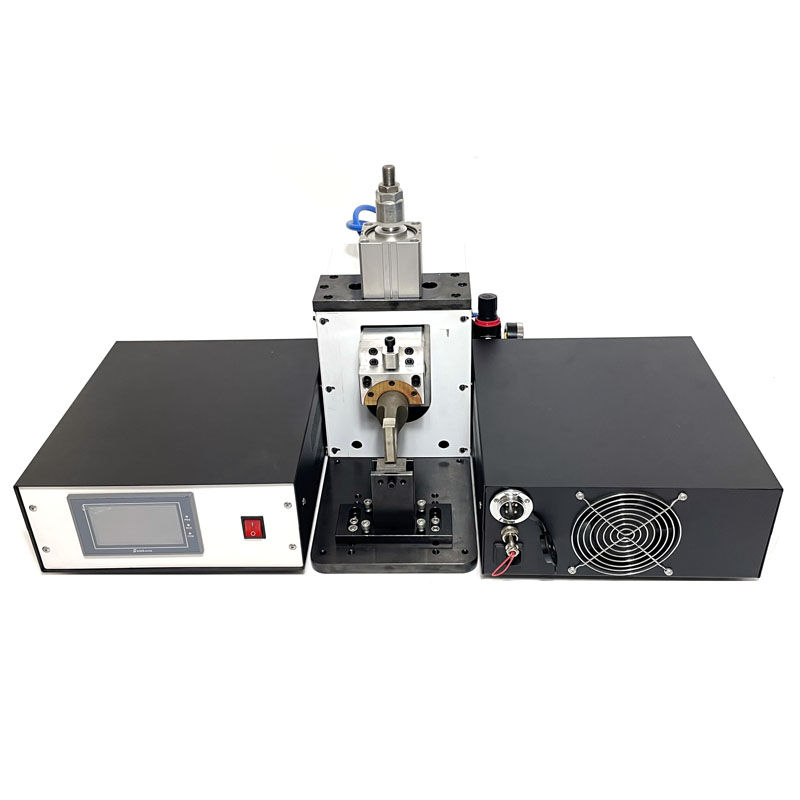

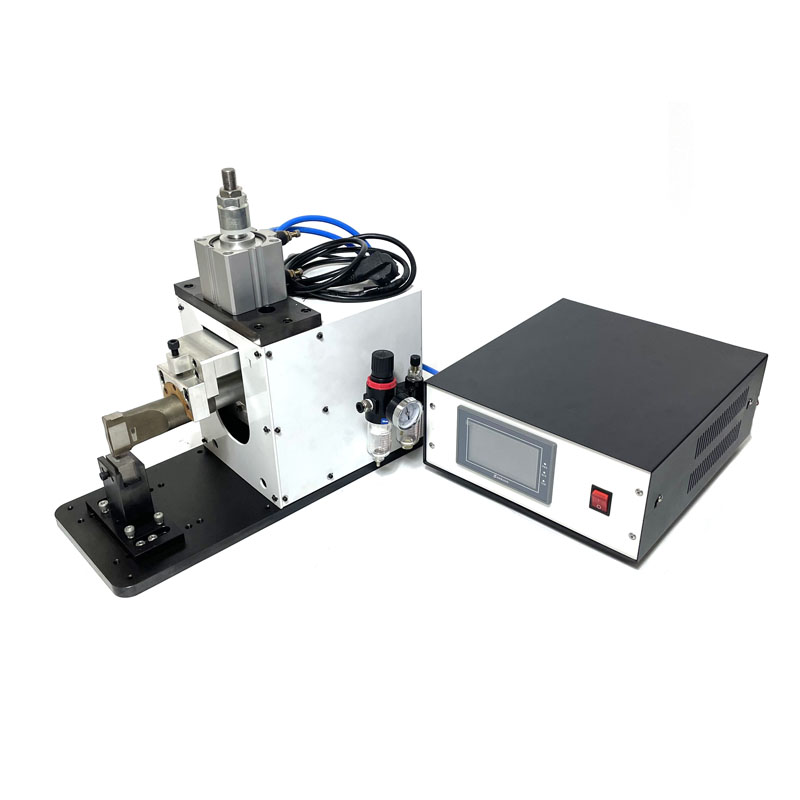

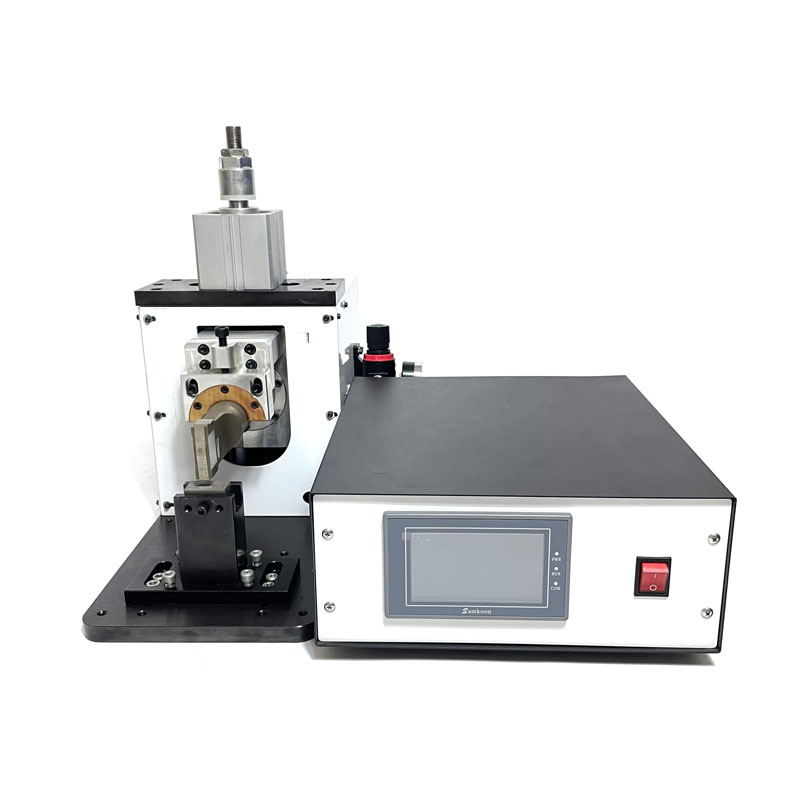

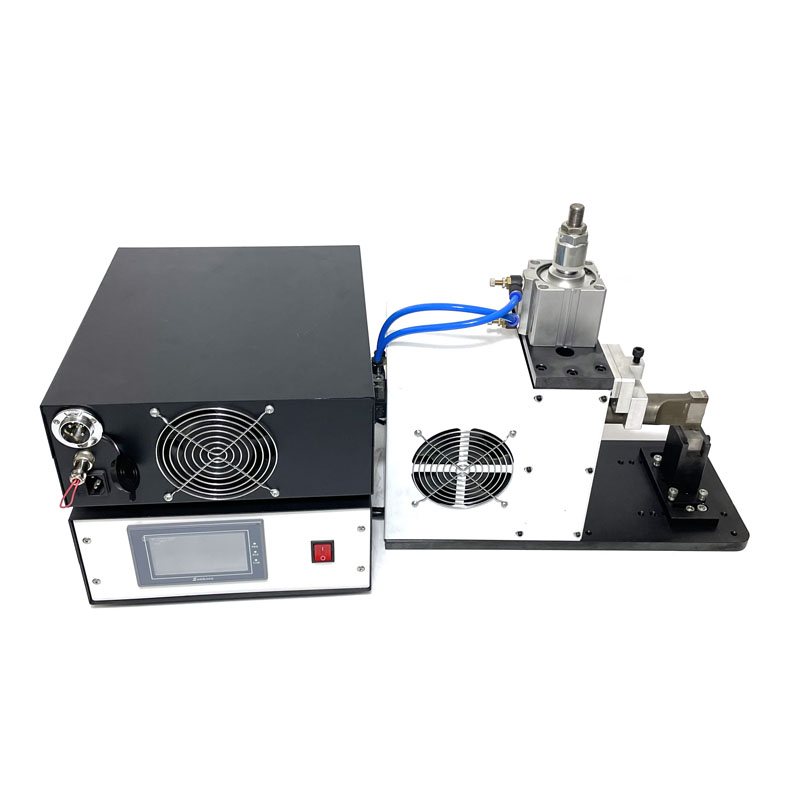

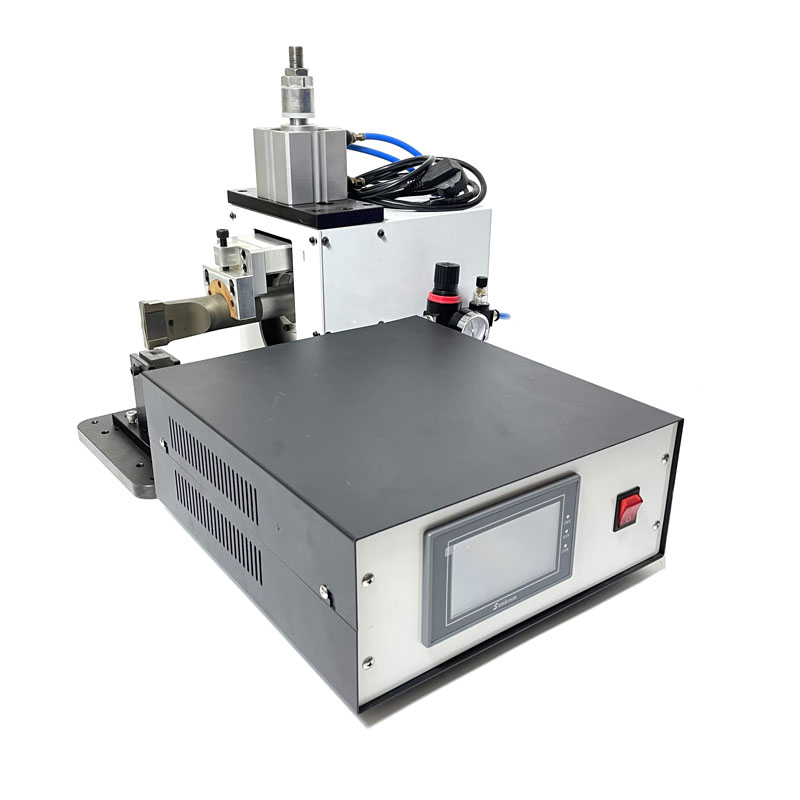

2600W Laboratory Ultrasonic Metal Spot Welder For Battery Pack Electrode Tab Welding Machine

The ultrasonic wire harness welding machine consists of two parts: a machine and an ultrasonic power generator. The machine consists of a chassis, guide pillars, transducers, pneumatic systems, PC circuits, and bottom molds.The sound component consists of two parts: a transducer and a welding head. The transducer …

2600W Laboratory Ultrasonic Metal Spot Welder For Battery Pack Electrode Tab Welding Machine

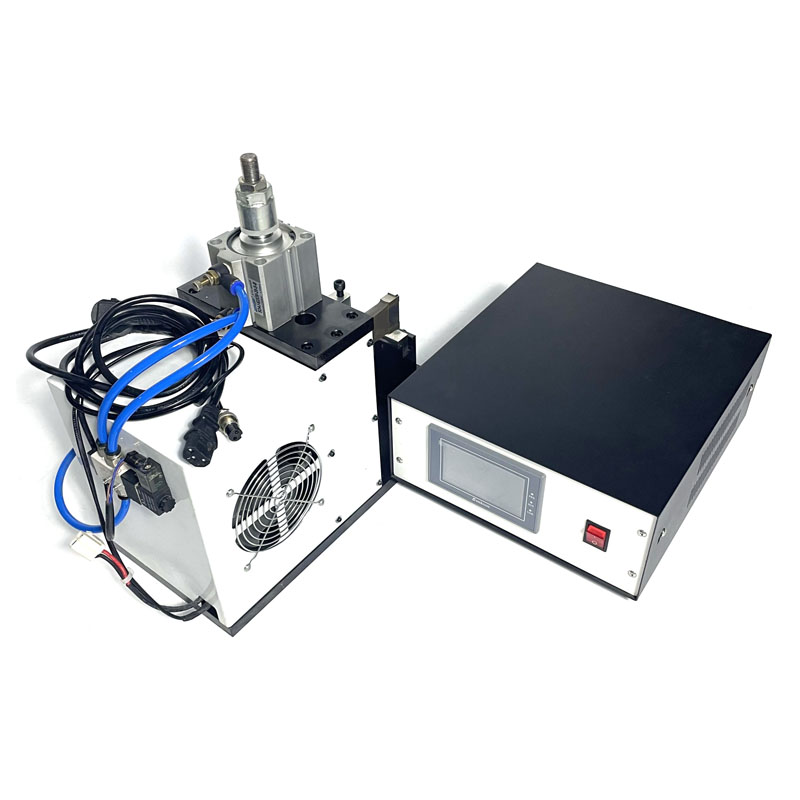

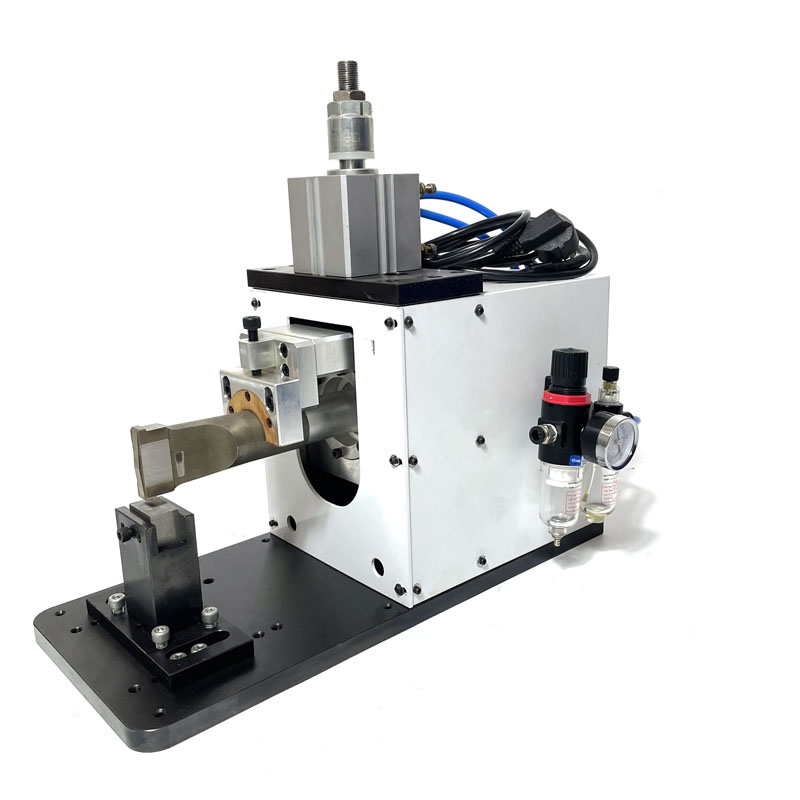

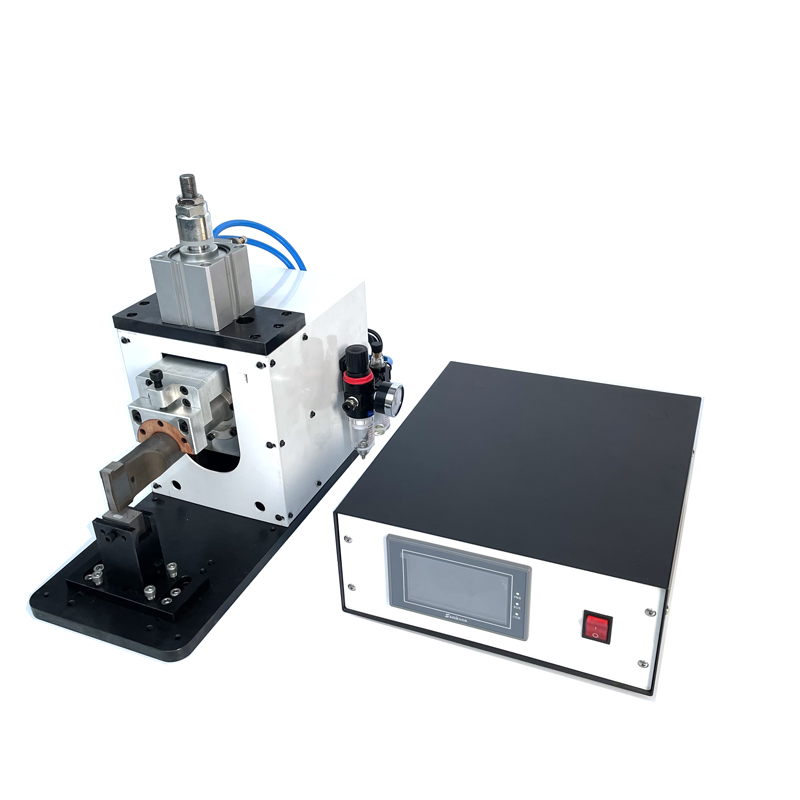

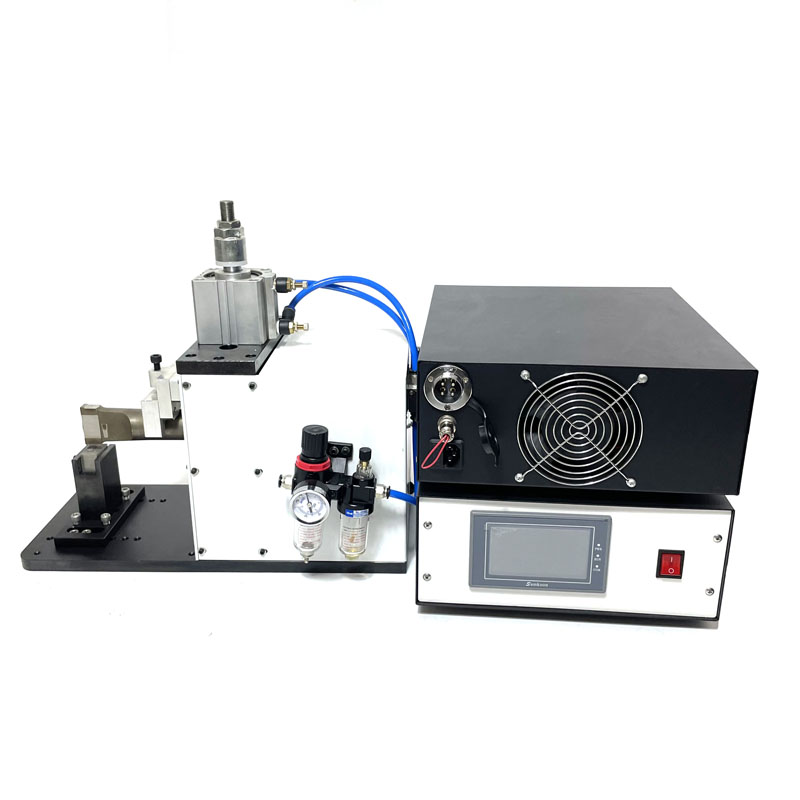

The ultrasonic wire harness welding machine consists of two parts: a machine and an ultrasonic power generator.

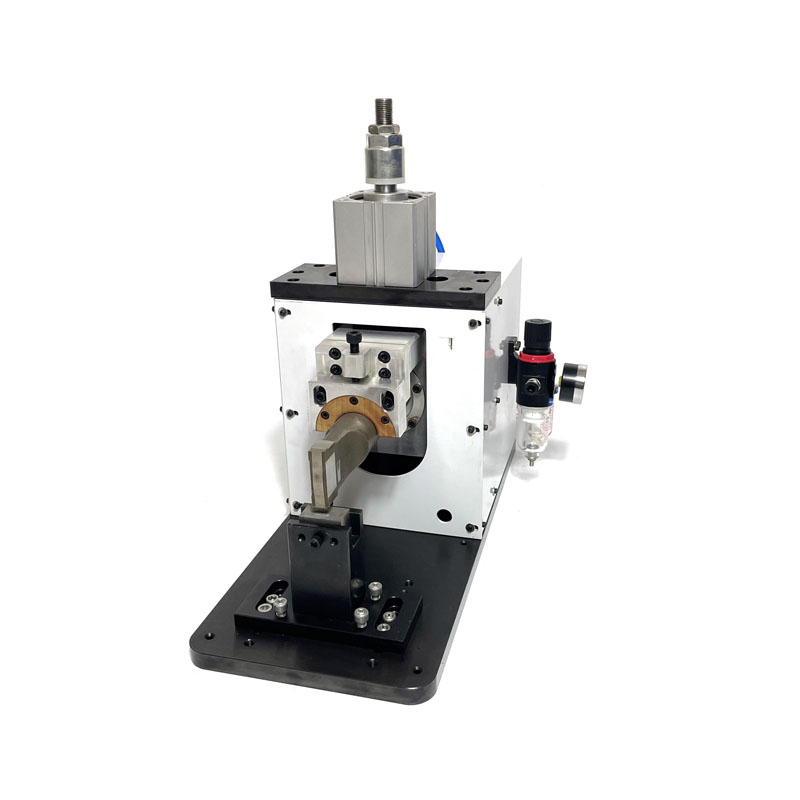

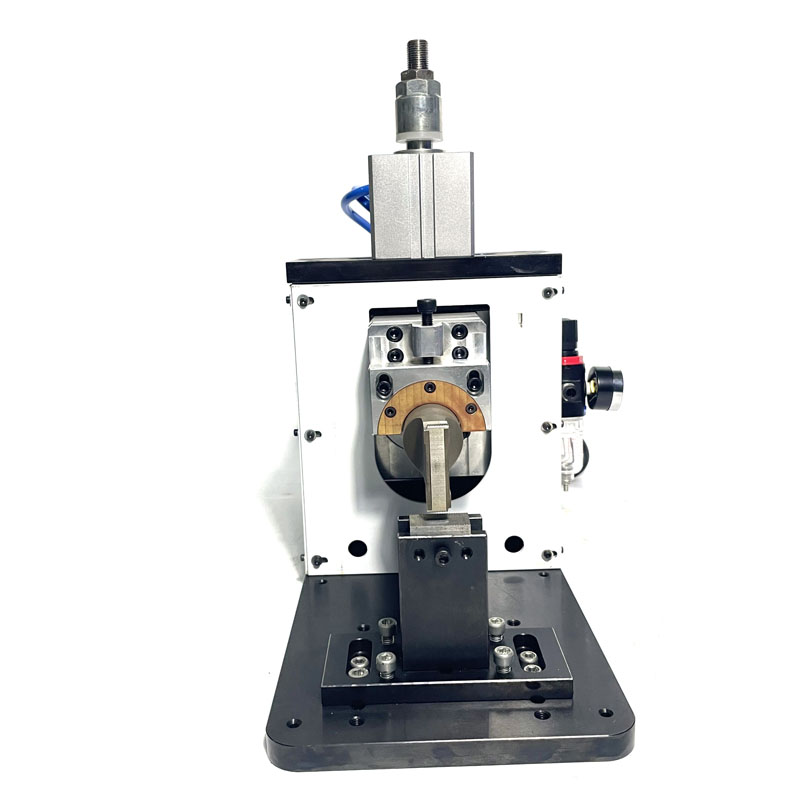

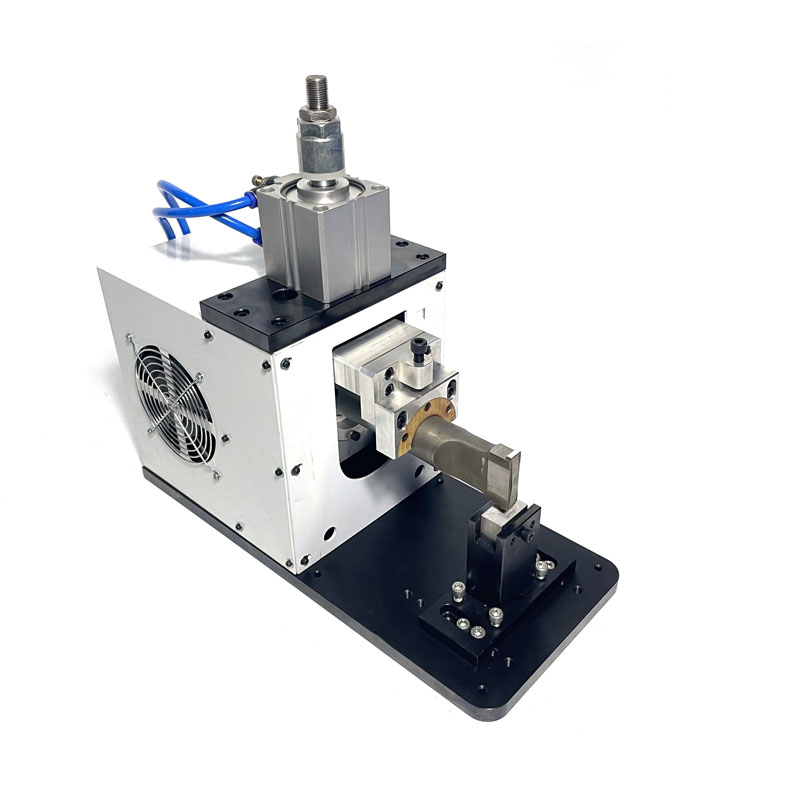

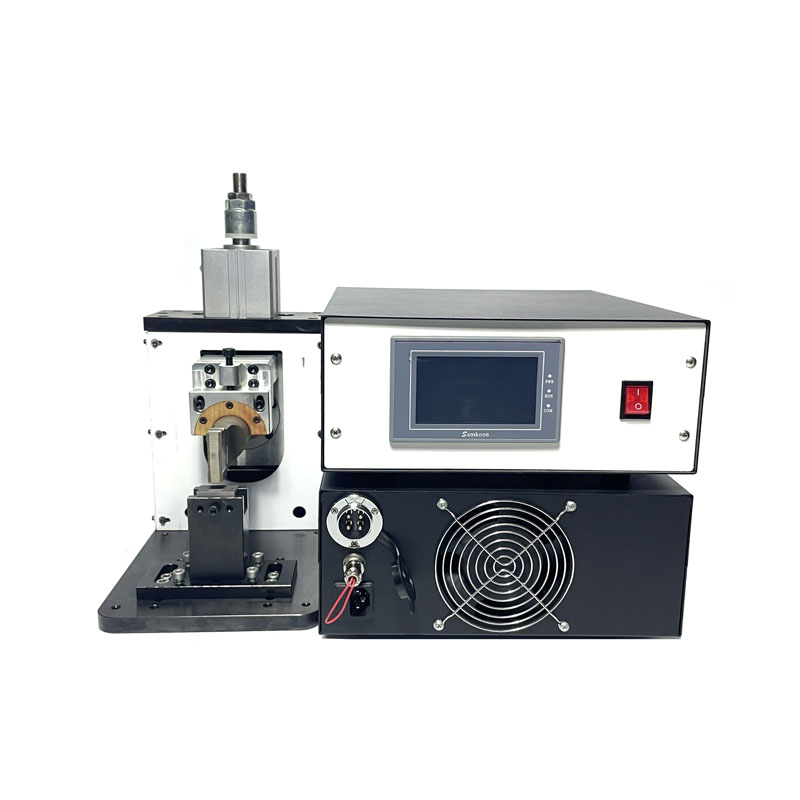

- The machine consists of a chassis, guide pillars, transducers, pneumatic systems, PC circuits, and bottom molds.

- The sound component consists of two parts: a transducer and a welding head. The transducer uses a piezoelectric vibrator, which converts electrical energy into mechanical vibration. A transformer, similar to a transformer in a circuit, plays a role in mechanical damping transformation and amplitude amplification. The welding head is designed according to the welding requirements and the shape of the weldment, and it also plays a secondary impedance transformation and amplitude amplification role. From the perspective of structure and shape, the welding head is not complex, but it requires good design, good materials, and excellent processing technology. Welding heads with complex shapes and large sizes are difficult to design and are generally designed by the manufacturing plant.

- The Pressure system Pressure system is powered by compressed air and drives the cylinder piston to drive the welding head up and down through the switching circuit of the solenoid valve. Use a pressure regulating valve to control the pressure, and use a one-way throttle valve to control the lifting speed.

- Control circuit

The control circuit executes program control over the welding process. The function keys on the panel can set the welding time and delay time according to different welding objects. Then, press the foot switch, and the welding machine will automatically complete a welding process.

- Ultrasonic power generator The ultrasonic power generator provides electrical power to the sound component. Due to significant changes in the resonant frequency and impedance of the acoustic components during the welding process, the ultrasonic power sounder must have the ability to automatically track the frequency and adjust the output power automatically by the load. The NC-3000 ultrasonic metal spot welding machine adopts external excitation oscillation; Automatic frequency tracking using phase method; Constant vibration speed control.

| Type | Power(W) | Frequency (KHz) |

| PU-MSW2000W | 2000W | 20KHZ |

| PU-MSW2600W | 2600W | 20KHZ |

| PU-MSW3200W | 3200W | 20KHZ |

| PU-MSW4000W | 4000W | 20KHZ |

| PU-MSW800W | 800W | 40khz |

2600W Laboratory Ultrasonic Metal Spot Welder For Battery Pack Electrode Tab Welding Machine

标签:2600W Laboratory Ultrasonic Metal Spot Welder, Ultrasonic Metal Spot Welder For Battery Pack Electrode Tab Welding Machine

Send Inquiry

20khz Ultrasonic Spot Metal Welding Ultrasonic Welding Machine For Aluminum And Copper Foils Wires Welding

20khz Ultrasonic Spot Metal Welding Ultrasonic Welding Machine For Aluminum And Copper Foils Wires Welding Pouch Cell Tab Ultrasonic Metal Spot Welder Welding Machine Ultrasonic Spot Welding Machine For Cathode Electrode

Pouch Cell Tab Ultrasonic Metal Spot Welder Welding Machine Ultrasonic Spot Welding Machine For Cathode Electrode Au Fe Ni Ag Tab Ultrasonic Metal Spot Welder Welding Machine for Pouch Cell Preparation

Au Fe Ni Ag Tab Ultrasonic Metal Spot Welder Welding Machine for Pouch Cell Preparation Digital Ultrasonic Metal Tube Welding Machine For Cutting And Sealer Copper Tube Ultrasonic Spot Welder

Digital Ultrasonic Metal Tube Welding Machine For Cutting And Sealer Copper Tube Ultrasonic Spot Welder Ultrasonic Lithium Battery Spot Welding Machine for Aluminum Foil Copper Foil Welding of Li-ion Battery Spot Welding System

Ultrasonic Lithium Battery Spot Welding Machine for Aluminum Foil Copper Foil Welding of Li-ion Battery Spot Welding System 28khz 20khz Ultrasonic Metal Welding Machine For Aluminum Wire Copper Wire Spot Bonding Machines

28khz 20khz Ultrasonic Metal Welding Machine For Aluminum Wire Copper Wire Spot Bonding Machines Copper Wire Harness Assembly Ultrasonic Welding Machine For Metal cable Line Soldering

Copper Wire Harness Assembly Ultrasonic Welding Machine For Metal cable Line Soldering Copper Sheet Ultrasonic Welding Machine Ultrasonic Terminal Welding Machine Ultrasonic Wire Harness Weld Machine

Copper Sheet Ultrasonic Welding Machine Ultrasonic Terminal Welding Machine Ultrasonic Wire Harness Weld Machine 6000W Desktop Ultrasonic Electrical Wire Splicing and Joint Spot Welding Machine And Signal Generator

6000W Desktop Ultrasonic Electrical Wire Splicing and Joint Spot Welding Machine And Signal Generator 4000W 20KHZ Ultrasonic Spot Welding Machine For Aluminum Nickel Copper And Stainless Steel Sheet Metal

4000W 20KHZ Ultrasonic Spot Welding Machine For Aluminum Nickel Copper And Stainless Steel Sheet Metal Ultrasonic Metal Welding Machine 20khz 5000W Ultrasonic Metal Spot Welding Machine For Battery Al Tab weld Cap

Ultrasonic Metal Welding Machine 20khz 5000W Ultrasonic Metal Spot Welding Machine For Battery Al Tab weld Cap 4000W High Power Ultrasonic Metal Welding Machine Of Copper Wire Soldering Metal Wire Splicing

4000W High Power Ultrasonic Metal Welding Machine Of Copper Wire Soldering Metal Wire Splicing