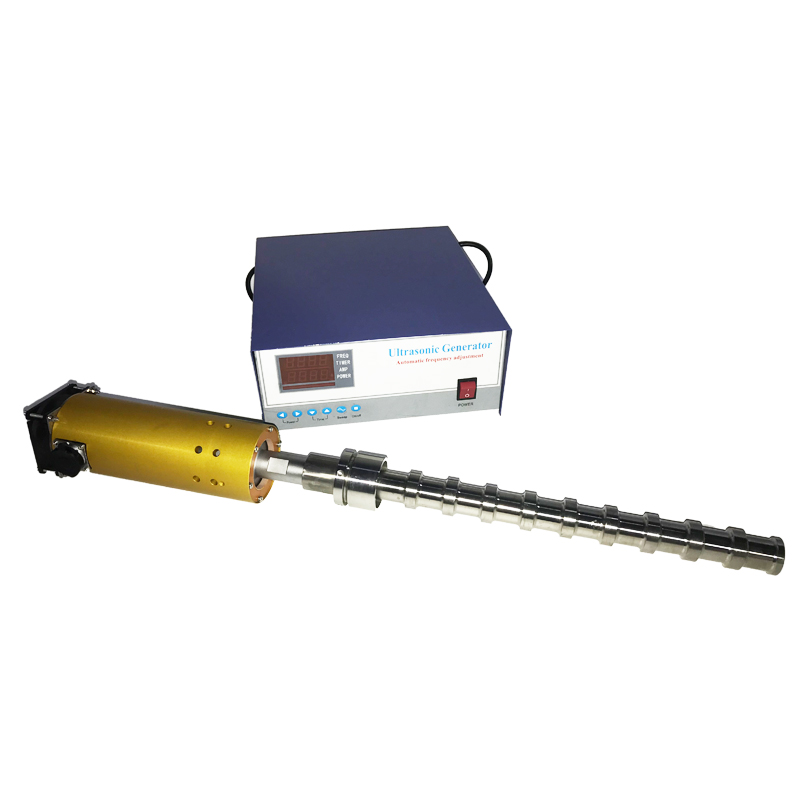

20KHZ 900W 220V Ultrasonic Emulsification Homogenizer Plant Oil Extraction For Nanoemulsion Mixing

The degradation of organic pollutants by ultrasound does not come from the direct interaction between sound waves and organic molecules, but mainly from the phenomenon of acoustic cavitation. Ultrasonic cavitation is an extremely complex physical phenomenon in liquids, which refers to a series of dynamic processes su…

20KHZ 900W 220V Ultrasonic Emulsification Homogenizer Plant Oil Extraction For Nanoemulsion Mixing

The degradation of organic pollutants by ultrasound does not come from the direct interaction between sound waves and organic molecules, but mainly from the phenomenon of acoustic cavitation. Ultrasonic cavitation is an extremely complex physical phenomenon in liquids, which refers to a series of dynamic processes such as oscillation, growth, contraction, and collapse of small bubble nuclei excited by ultrasound. Dissolved gases in water, dispersed small bubbles, or bubbles and solid particles generated by thermal disturbances may all promote cavitation. The presence of dissolved gases in the reaction system can provide cavitation nuclei to stabilize the cavitation effect. The larger the heat capacity ratio of dissolved gas is, the more obvious the sonochemistry effect is. Therefore, in sonochemistry, monoatomic gases (He, Ne, Ar) are used more than diatomic gases and air (N2, 02). When ultrasonic waves with a frequency of 20 kHz are used to degrade and dissolve aqueous solutions of h, Ar, He, and 0, the generation rate of H202 and · OH varies by about an order of magnitude due to the different dissolved gases.

The research shows that high-frequency ultrasound is helpful to improve the speed of ultrasound assisted bio plant catalytic degradation of vibrating rod, because the yield of hydroxyl radical increases with the increase of sound source frequency, but the frequency is also related to the attenuation of ultrasound. Increasing sound intensity is beneficial for oxidation reaction and increases degradation rate. When using a probe type ultrasonic generator to degrade pesticide methamidophos aqueous solution, as the sound intensity increases, the degree of cavitation increases, and the degradation rate of methamidophos increases. However, if the sound energy is too high, the cavitation bubbles will grow greatly in the negative phase of the sound wave, forming a sound shield. The available sound field energy of the system will instead decrease, and the degradation rate will also decrease.

In order to improve the efficiency of ultrasound assisted biological plant catalytic degradation of vibrating rods, in recent years, researchers have not only explored the degradation mechanism and performance of ultrasound, but also conducted extensive research on ultrasound reactors. Some improved reactors have also been continuously introduced.

| Tubular EquipmentType | Tubular TransducerType | Frequency(KHz) | UltrasoundOutput(W) | Total Length(mm) | Diameter(mm) | Static Capacity(pF±10%) |

| PU-UE1 | US-61 | 15-28 | 1000 | 500 | Φ50-55 | 68000 |

| PU-UE5 | US-25 | 15-28 | 1500 | 850 | Φ50-55 | 68000 |

| PU-UE6 | US-16 | 15-28 | 2000 | 1100 | Φ50-55 | 132000 |

20KHZ 900W 220V Ultrasonic Emulsification Homogenizer Plant Oil Extraction For Nanoemulsion Mixing

标签:20KHZ 900W 220V Ultrasonic Emulsification Homogenizer Plant Oil Extraction, Ultrasonic Emulsification Homogenizer Plant Oil Extraction, Ultrasonic Emulsification Homogenizer Plant Oil Extraction For Nanoemulsion Mixing

Send Inquiry

20khz 900w Tuber Extraction Ultrasonic Reactor Ultrasonic Extraction Green Tea

20khz 900w Tuber Extraction Ultrasonic Reactor Ultrasonic Extraction Green Tea Ultrasonic Disruption And Extraction Ultrasonic Processor Homogenizer Mixer Extraction Sonicator Dispersion

Ultrasonic Disruption And Extraction Ultrasonic Processor Homogenizer Mixer Extraction Sonicator Dispersion 1200W 20KHZ Industrial Ultrasonic Emulsifier Biodiesel Processor Reactor With Signal Generator

1200W 20KHZ Industrial Ultrasonic Emulsifier Biodiesel Processor Reactor With Signal Generator 20KHZ 900W 220V Ultrasonic Emulsification Homogenizer Plant Oil Extraction For Nanoemulsion Mixing

20KHZ 900W 220V Ultrasonic Emulsification Homogenizer Plant Oil Extraction For Nanoemulsion Mixing Lab Ultrasonic Probe Homogenizer Sonicator Ultrasonic Biodiesel Reactor And Generator Control Box

Lab Ultrasonic Probe Homogenizer Sonicator Ultrasonic Biodiesel Reactor And Generator Control Box Ultrasonic Liquid Sonochemistry Processor For Emulsifier Extraction Disruption With Wave Generator

Ultrasonic Liquid Sonochemistry Processor For Emulsifier Extraction Disruption With Wave Generator Ultrasonic Homogenizer Reactor For Cosmetics Cream Continuous Flow Industrial Ultrasonic Homogenizer

Ultrasonic Homogenizer Reactor For Cosmetics Cream Continuous Flow Industrial Ultrasonic Homogenizer 20khz Ultrasound Ultrasonic Biodiesel Reactor 50L Ultrasonic Homogenizer Reactor For Cosmetics Cream

20khz Ultrasound Ultrasonic Biodiesel Reactor 50L Ultrasonic Homogenizer Reactor For Cosmetics Cream 2000W 20KHZ Ultrasonic Cavitation Reactor Ultrasonic Sonochemistry Biodiesel

2000W 20KHZ Ultrasonic Cavitation Reactor Ultrasonic Sonochemistry Biodiesel Industry Ultrasonic Sonochemistry Reactor Emulsify Homogenizer Mixing Machine With Ultrasonic Generator

Industry Ultrasonic Sonochemistry Reactor Emulsify Homogenizer Mixing Machine With Ultrasonic Generator 20KHZ 2000W 220V Ultrasonic Sonochemistry Reactor Disperser Emulsifying Homogenizer For Hemp Oil Extraction

20KHZ 2000W 220V Ultrasonic Sonochemistry Reactor Disperser Emulsifying Homogenizer For Hemp Oil Extraction 300W 20KHZ Ultrasonic Cavitation Reactor Ultrasonic Sonochemistry Biodiesel And Sound Generator

300W 20KHZ Ultrasonic Cavitation Reactor Ultrasonic Sonochemistry Biodiesel And Sound Generator