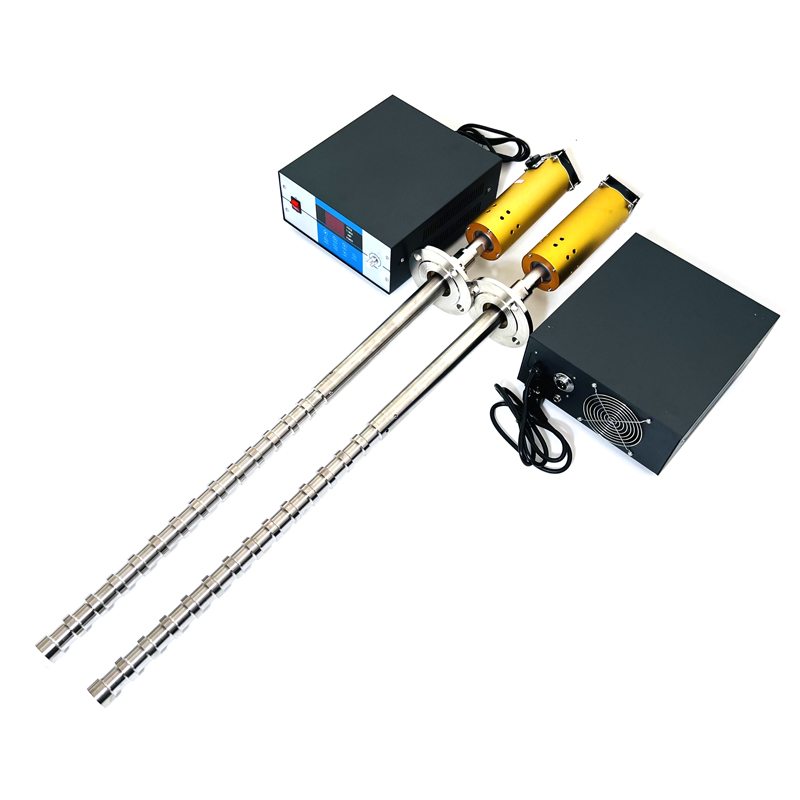

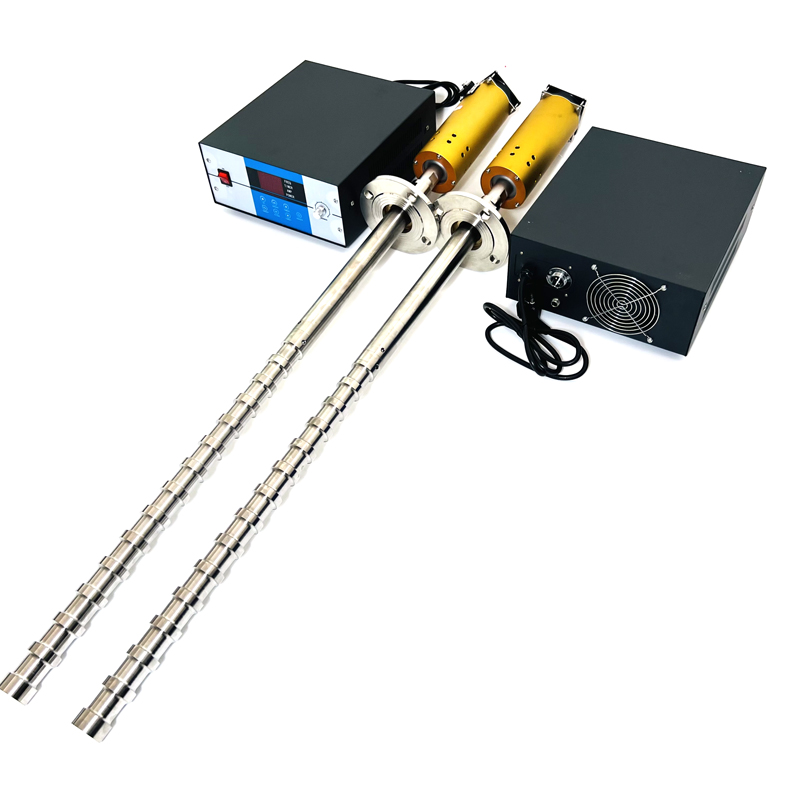

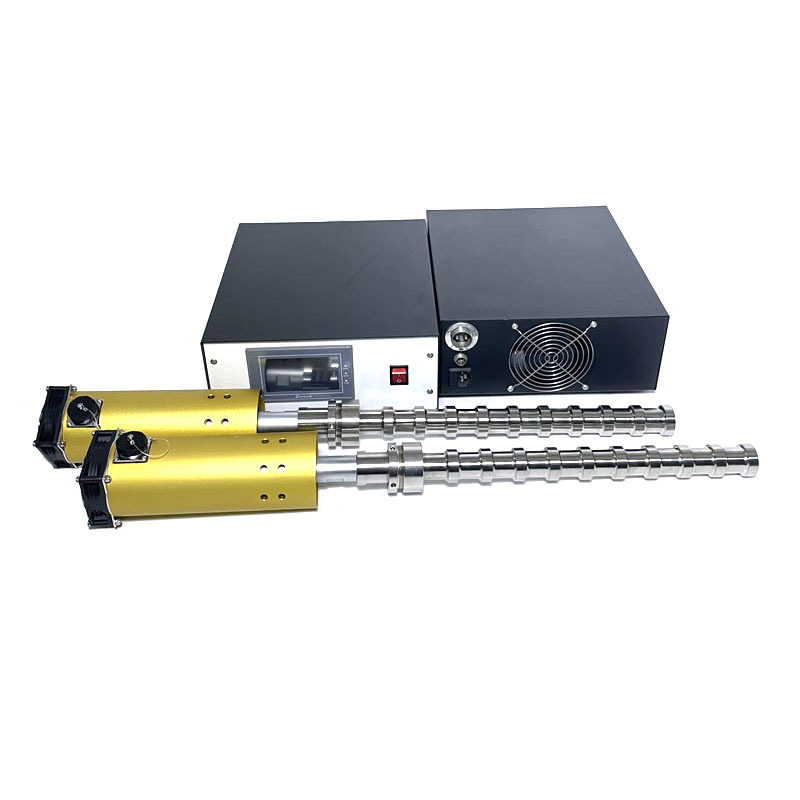

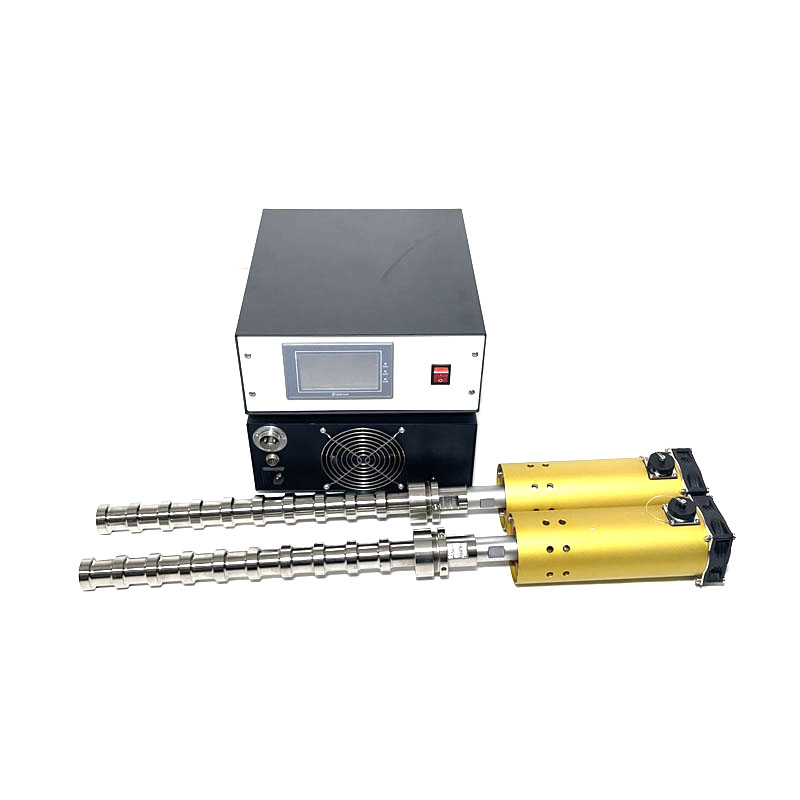

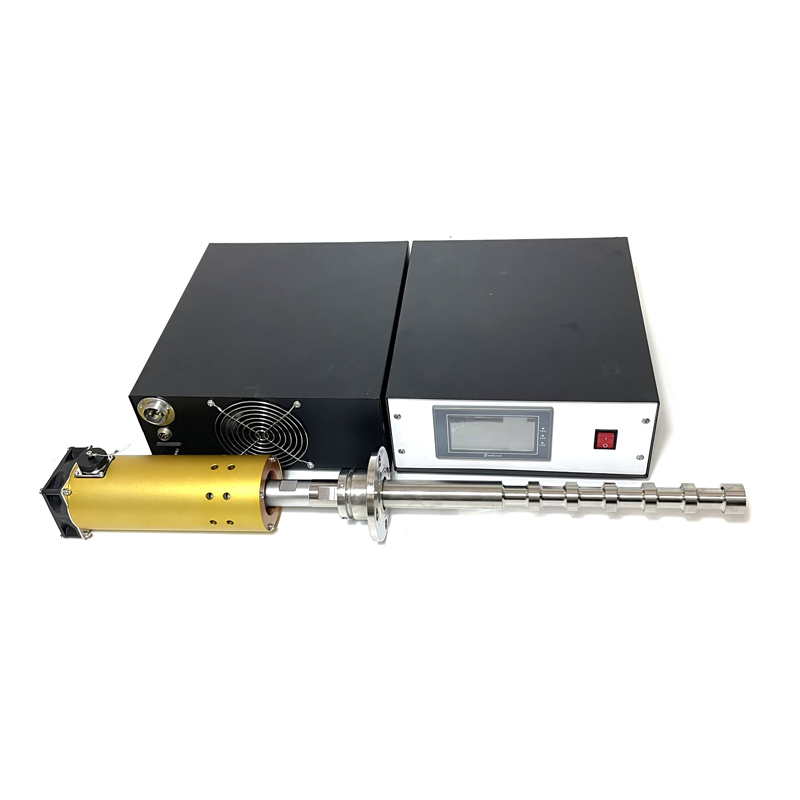

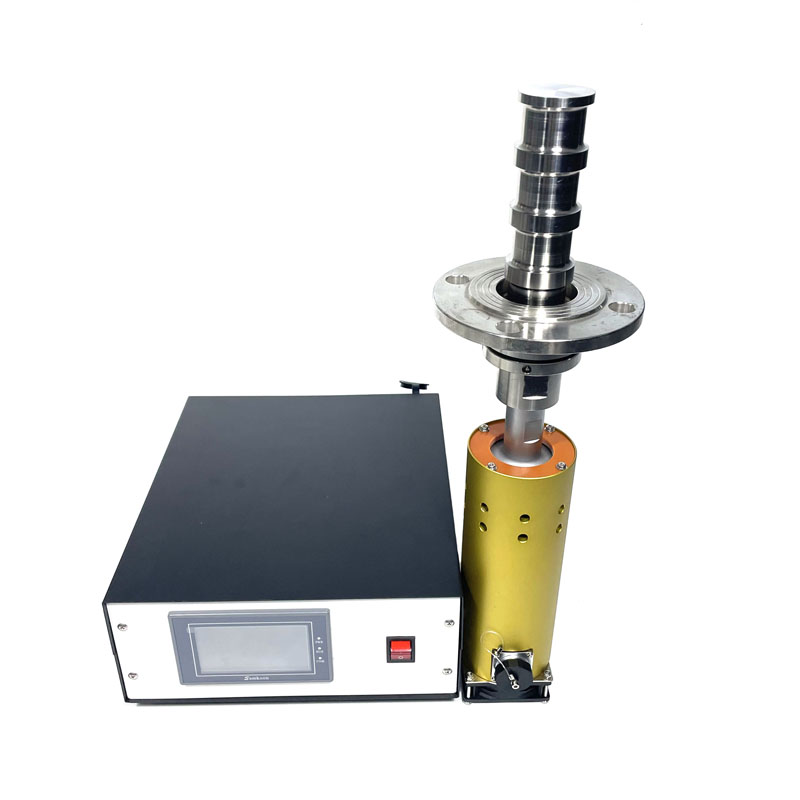

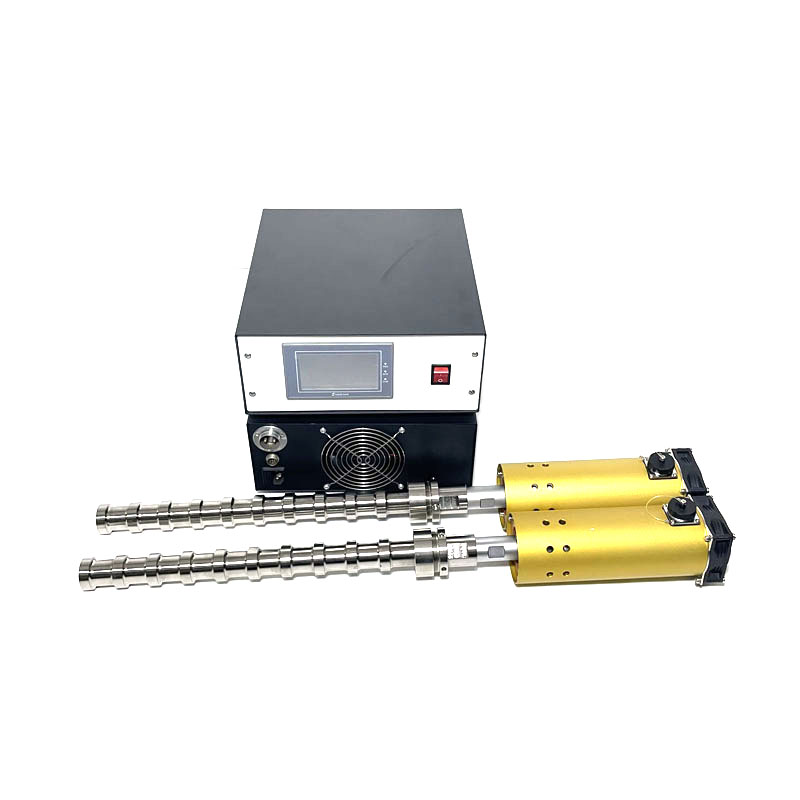

20khz 3000W Tubular Homogenizer Ultrasonic Disrupter For Nanoparticle Dispersion

Application of Ultrasonic Vibrating Rod in Cleaning Due to the unique round pipe design features, ultrasonic vibrating rods are especially suitable for cleaning various pipelines. The principle is to convert electric energy into ultrasonic energy, and transfer it to scale, water, and the inner wall of the pipeline…

20khz 3000W Tubular Homogenizer Ultrasonic Disrupter For Nanoparticle Dispersion

Application of Ultrasonic Vibrating Rod in Cleaning

Due to the unique round pipe design features, ultrasonic vibrating rods are especially suitable for cleaning various pipelines. The principle is to convert electric energy into ultrasonic energy, and transfer it to scale, water, and the inner wall of the pipeline according to its own laws, so that it can obtain a lot of energy. The shock wave generated in the transmission process of ultrasonic wave makes scale, water and pipe inner wall resonate. Due to the different vibration frequencies of scale, water and pipe inner wall, the water molecules in the pipe collide violently, generating strong impact force, impacting the scale layer on the heat exchange surface, making it brittle, peeling, falling off, crushing, and discharged together with the sewage discharge of the equipment, thus realizing the thorough cleaning of the pipe inner wall by the ultrasonic vibrating rod. In addition, the ultrasonic vibrating rod can also be used for cleaning the tank body. It can be freely placed in any position of the cleaning tank. It is very flexible and convenient to use, while the volume space occupied is very small, leaving no dead space for cleaning.

Application of ultrasonic vibrating rod in extraction of traditional chinese medicine

The effective components of traditional Chinese medicine can be extracted by ultrasonic vibrating rod. First, add the extraction solvent into the container, crush or cut the Chinese herbal medicine into granules as needed, and put it into the extraction solvent; Turn on the ultrasonic generator, install the ultrasonic vibrating rod on the top of the extraction tank, and send ultrasonic wave to the extraction solvent. The ‘cavitation effect’ and mechanical action of ultrasonic wave in the extraction solvent can effectively break the cell wall of the medicinal materials, so that the effective components are free and dissolved in the extraction solvent, and on the other hand, accelerate the molecular movement of the extraction solvent, so that the extraction solvent and the effective components in the medicinal materials can quickly contact, Dissolve and mix with each other.

The optimal temperature for ultrasonic vibrating rod extraction of medicinal materials is 40-60 ℃, so no boiler is required to provide steam heating, which is conducive to energy conservation and environmental pollution improvement. More importantly, it can protect the active ingredients in the medicinal materials that are unstable in heat, easy to hydrolyze or oxidize. Generally, the ultrasonic vibrating rod can get the best effect when it runs for about 30 minutes. Compared with the traditional process, the extraction efficiency is greatly improved, and is not limited by the nature and molecular weight of the components of traditional Chinese medicine. It is suitable for the extraction of most kinds of traditional Chinese medicine and various components (including liquid-liquid extraction and solid-liquid extraction). Therefore, the use of ultrasonic vibrators for traditional Chinese medicine extraction has been increasingly adopted by the majority of pharmaceutical factories.

Application of Ultrasonic Vibrating Rod in Accelerating ultrasonic chemical reaction

The front end of the ultrasonic vibrating rod ultrasonic tool head is close to the outer wall of the kettle body or extends into the kettle cavity of the kettle body. The Ultrasonic Transducer can send ultrasonic waves to the chemical reactants in the kettle cavity. The treated liquid can change the activity of the reaction system due to the “cavitation” effect of ultrasonic waves, damage the solvent structure of the chemical reactants in the kettle cavity, generate instantaneous high temperature and pressure sufficient to trigger the chemical reaction, and form a local high energy center, To promote the smooth progress of chemical reaction is the main factor for catalytic chemical reaction using ultrasonic vibrating rod.

The secondary effects of ultrasonic wave, such as mechanical vibration, emulsification, diffusion, and fragmentation, are conducive to the full mixing of reactants in all directions. The ultrasonic vibrating rod uses a high-power shaped transducer, which can make the material perform violent forced movement, accelerate the transmission and diffusion of the material, and can replace the traditional mechanical mixing. Of course, it is better to use it with electric agitator in practical application to accelerate reaction.

Application of Ultrasonic Vibrating Rod in Scale Prevention

Taking the heat exchanger as an example, the ultrasonic vibrating rod is generally installed at the liquid inlet of the heat exchanger, which is controlled by flange connection and control valve, so that the ultrasonic equipment can be overhauled and maintained without stopping production. The main principle is that the ultrasonic wave transmits and generates energy due to resonance in the transmission process, and the material molecules such as scale, water and metal heat exchange surface obtain energy in the vibration process. The water in the heat exchange tube generates vibration and fierce collision while obtaining energy, which causes the unstable water molecules containing various inorganic salts to generate countless cavitation bubbles (cavitation), forming the cavitation cavity of water molecules. When these bubbles expand rapidly and close suddenly, they produce thousands of local impacts of atmospheric pressure, high-speed jets with a speed of up to 400 km/h and high energy above 5000 k. These energies destroy the combination of positive and negative ions and acid radicals, and destroy the conditions for scale formation, thus realizing scale prevention.

Application of Ultrasonic Vibrating Rod in Water Treatment

The ultrasonic vibrating rod shaped ultrasonic probe concentrates the energy, and can obtain strong sound intensity on the ultrasonic radiation end face. Due to the energy gathering effect of the horn, the sound energy density is greatly improved; The reactor can be accurately designed according to the sound energy density; The transmitter end face of the probe is generally designed to be detachable, so that the probe with appropriate end face size can be selected at any time according to the required sound intensity. At the same time, when the probe is seriously corroded by cavitation, only the end needs to be replaced, rather than the expensive whole vibrator. The ultrasonic vibrating rod can be used to treat various organic wastewater that is difficult to degrade, and has been used in the research of wastewater treatment containing monocyclic aromatic compounds, polycyclic aromatic hydrocarbons, phenols, chlorinated hydrocarbons, chlorinated hydrocarbons, organic acids, dyes, alcohols, ketones, etc., and has achieved good results. In the actual industrial wastewater, the equipment has been used to treat papermaking wastewater, printing and dyeing wastewater, tanning wastewater, coking wastewater, pharmaceutical wastewater, garbage leachate, etc., and achieved good results.

In addition, in some landscape lakes and rivers, ultrasonic vibrators can also be used to kill and suppress algae. The mechanical effect, cavitation effect, thermal effect, acoustic flow effect and other characteristics of ultrasonic wave make algae cells rupture and chemical bond rupture in material molecules act on the outer wall of algae and make them rupture and die, so as to achieve the role of algae vacuole lifting and breaking, cell death or growth inhibition, causing a series of biological effects. Cavitation makes the microbubbles in the liquid rapidly expand and then suddenly close, Shock wave and jet are generated to eliminate algae and balance water environment ecology. Low intensity ultrasound destroys the structure and function of the phycobilisome, interferes with the synthesis of chlorophyll, and thus inhibits the growth of algae.

| Tubular EquipmentType | Tubular TransducerType | Frequency(KHz) | UltrasoundOutput(W) | Total Length(mm) | Diameter(mm) | Static Capacity(pF±10%) |

| PU-UE1 | US-61 | 15-28 | 1000 | 500 | Φ50-55 | 68000 |

| PU-UE5 | US-25 | 15-28 | 1500 | 850 | Φ50-55 | 68000 |

| PU-UE6 | US-16 | 15-28 | 2000 | 1100 | Φ50-55 | 132000 |

20khz 3000W Tubular Homogenizer Ultrasonic Disrupter For Nanoparticle Dispersion

标签:ultrasonic chemical reaction, ultrasonic tool head, Ultrasonic Transducer, ultrasonic vibrating rod

Send Inquiry

Ultrasonic Emulsifier Processor Reactor Sonochemistry Reactor Chemical Homogenizing Emulsified

Ultrasonic Emulsifier Processor Reactor Sonochemistry Reactor Chemical Homogenizing Emulsified 300W 20KHZ Ultrasonic Cavitation Reactor Ultrasonic Sonochemistry Biodiesel And Sound Generator

300W 20KHZ Ultrasonic Cavitation Reactor Ultrasonic Sonochemistry Biodiesel And Sound Generator Ultrasonic Ultrasound High-Power Customization Ultrasonic Agitator Homogenizer Machine

Ultrasonic Ultrasound High-Power Customization Ultrasonic Agitator Homogenizer Machine 1000W-2000W Ultrasonic Reactor Ultrasonic Biodiesel Reactor Ultrasonic Probe Sonicator

1000W-2000W Ultrasonic Reactor Ultrasonic Biodiesel Reactor Ultrasonic Probe Sonicator 20KHZ 3000W Industrial Ultrasonic Sonochemistry System Ultrasonic Disperser Machine

20KHZ 3000W Industrial Ultrasonic Sonochemistry System Ultrasonic Disperser Machine Industrial 3000W Animal Fat Oil Emulsify Ultrasonic Biodiesel Processor Homogenizer Machine For Nanoemulsion

Industrial 3000W Animal Fat Oil Emulsify Ultrasonic Biodiesel Processor Homogenizer Machine For Nanoemulsion 20KHZ 1000W Ultrasonic Tissue Extraction Machine Extractor Homogenizer Reactor

20KHZ 1000W Ultrasonic Tissue Extraction Machine Extractor Homogenizer Reactor Enhancing Biodiesel Production From Soybean Oil Using Titanium Ultrasonic Tubular Transducer

Enhancing Biodiesel Production From Soybean Oil Using Titanium Ultrasonic Tubular Transducer 1000W 20KHZ Ultrasonic Cavitation Reactor Biodiesel Production And Power Supply Generator

1000W 20KHZ Ultrasonic Cavitation Reactor Biodiesel Production And Power Supply Generator 2400W Ultrasonic Emulsifier Mixer Homogenizer For Batch Extraction/Homogenisation

2400W Ultrasonic Emulsifier Mixer Homogenizer For Batch Extraction/Homogenisation Ultrasonic Sonochemistry System With 600-3000w Generator Biodiesel Reactor

Ultrasonic Sonochemistry System With 600-3000w Generator Biodiesel Reactor 20KHZ 900W 220V Ultrasonic Emulsification Homogenizer Plant Oil Extraction For Nanoemulsion Mixing

20KHZ 900W 220V Ultrasonic Emulsification Homogenizer Plant Oil Extraction For Nanoemulsion Mixing